by Gary Mintchell | Dec 1, 2015 | Marketing, News, Productivity

My new boss was chatting with me in his office. He turned to a shelf with notebooks and pulled one off the shelf. Opening it to a tab, he removed a section and told me to copy it and start my own notebook.

The contents were articles clipped and copied from trade press, B2B, magazines. He had given me a new position as program manager in product development. These were articles on project management and program management. This was my introduction to the trade press.

I subscribed and read a variety of publications over the course of the next 20 years collecting useful articles. Some of the magazines were quick reads. Articles were by people whose titles were “marketing manager” with the contents reflecting that point of view. Some were written by engineers or other practitioners with useful information.

When I became a trade press editor at Control Engineering in 1998, the media landscape was unchanged. It consisted of magazines delivered by the US Postal Service on a more or less regular basis.

Wow, but do we have so many ways of getting information these days. There remains the inevitable tension within the trade press of writing what advertisers want to see in print versus focusing on useful information for readers. Information availability moved rapidly from print to Web to email to Twitter to LInkedIn and Facebook.

Advantages and deficiencies

Web–I always had trouble “bookmarking” Websites to return to and read. Or to develop a regular system to go to my Websites to read what was new. It was usually impossible to see what was new, anyway. On the other hand, the Web is a great place to store large amounts of information whether for media companies or for technology suppliers. What I have always desired is a push notification telling me not only that something changed, but also directing me to what changed.

Pop-up ads and enticements, pop-overs, cluttered pages, proliferation of ads all serve to destroy my motivation to go to media Websites to read articles. The race to create as much ad revenue as possible has reached the point for me that I hate to visit to try to read an article.

You also have to beware the “listicle” article. Many devices are designed to get you to click–top 10, view three ways, here are 6 things you didn’t know about. Sometimes they even make you click each one individually. Know why? The publisher needs to improve page views and therefore ad impressions. I have mostly quit getting suckered in.

What I will do is go to an “advertiser” site for a good technical or business white paper or other such information. Today you are more likely to get the kind of information there that I used to copy into my notebook. Oh, and today, my notebook is Evernote.

Twitter–Initially a great conversation tool, now there is so much noise that I seldom look at the stream. The tools I used to sort through the flood often were killed by Twitter. This killed much of my enthusiasm. I still Tweet. Some people actually find them.

Email–Believe it or not, emails remain the best way of notifying people with reasons to visit a Website or otherwise send information. Maybe someday there will be a ubiquitous chat app (Messenger or Snapchat or Slack?) that would take the place of email–but wouldn’t it just be another form of email? In the meantime, it’s not email but the misuse of email that is annoying.

General media–I’m seeing many more articles in Forbes, The New York Times, Wall Street Journal and other such general media publications that once would be seen only in trade press. Coverage of the Internet of Things, for instance, may be stronger there, as well as coverage of safety and security.

The Future

For the curious, check out the recent Notifications Summit put on by a couple of technology luminaries John Borthwick of Betaworks and Steve Gillmor who is a long-time reporter and analyst of technology. Many hours of video were recorded. They were great presentations and conversations about the developing technologies and uses of notifications.

Start with John Borthwick.

Or go to TechCrunch and search for Steve Gillmor.

by Gary Mintchell | Nov 27, 2015 | News, Productivity

I only visit Websites when I am doing research. I never browse Websites searching for new information. Most information flows to me through a carefully curated RSS feed into Feedly. Otherwise, notifications key me into new information that may be important guiding me to a Website for a deeper dive.

Steve Gillmor (The Gillmor Gang) has been a notifications advocate (after his brash “Microsoft is dead” and “RSS is dead” mantras got old). Early on he berated Twitter for dropping tracking and then for its inability to provide a strategy for sorting through the firehose of tweets to cull out only what’s important.

Last month, he and John Borthwick of Betaworks teamed for a Notifications Summit last month. Videos of the presentations can be found at TechCrunch or on iTunes (searching for Gillmor Gang), or here at Betaworks.

Take a dive into these technologies especially if you are a software developer. The information also educates users into what is possible and into perhaps new ways of finding the important signal amongst all the noise.

Borthwick’s introduction can be found on Medium. (Note: I’m also beginning to post on Medium. Seems to be an interesting new media idea.)

Borthwick wrote, “A few months ago Steve Gillmor and I discussed bringing together key people we knew who were building, designing and innovating around mobile notifications for a half day meeting. The meeting or summit — as we ended up calling it — took place on October 1st. We had about 50 people in attendance here at betaworks, it ran half the day. ”

Conference organizers take note. A very important and substantive gathering was held in a half-day. Note the quick-paced panels that were at once informal and punctual.

Anyway, back to Borthwick, the conference led with an important observation, “Right now we are witnessing another round of unbundling as the notification screen becomes the primary interface for mobile computing.”

Then he added, “Adam Bosworth kicked off the day with a discussion of how the notification stream represents complete re-construction of internet and HTTP from pull to push. This shift was predicted for a while but now it’s driving our primary mobile compute experience.”

There is a sense we can say that we’ve had notifications for years in automation and control. They are called “alarms.” Let us begin to think more creatively about the value of notifications in our work. It’s the future–and it’s here.

by Gary Mintchell | Nov 6, 2015 | Asset Performance Management, Automation, Manufacturing IT, Operations Management, Technology

I have written before about how Zebra Technologies Corporation has grown into an IoT supplier through some strategic acquisitions. An integral part of the overall IoT ecosystem is asset intelligence application.

The company has introduced its next-generation ET50 and ET55 tablet computers, which combine the consumer styling with the enterprise-class features necessary to increase workforce productivity. With a choice of the Microsoft Windows 8.1 or Android 5.1 (Lollipop) operating system (OS) and two different display sizes, businesses can choose the modern enterprise-grade tablet that best meets their application needs and technology strategy. This brings enterprise asset intelligence to the mobile worker.

KEY FACTS

- Operating Flexibility to Empower Business Applications: The ET50/55 is the first Zebra tablet computer available with the Microsoft Windows 8.1 OS and is Windows 10-ready. Windows gives access to legacy ERP systems and commonality to desktop solutions. The Android version of the ET50/55 tablet computer comes standard with Zebra’s Mobility Extensions (Mx) providing enterprise-class security; device management and data capture capabilities. The Android tablets are also equipped with Zebra’s AppGallery – an Android enterprise app store providing ready-to-use apps.

- A Business Tool with an Enterprise-Class Accessory Ecosystem: Tablets need the right accessories to make them enterprise-grade productivity tools. New vehicle mount cradles are ideal for service technicians; delivery drivers and salespeople on the road while a forklift mount can handle most warehouse environments. Advanced scanning capabilities are available that can accurately and rapidly capture photos, NFC tags, bar codes in virtually any condition and on practically any surface. Hot-swappable batteries augment the built-in battery and deliver 24 x 7 power to field service, transportation and logistics, retail, warehouse, manufacturing and government employees.

- Features Designed for Enterprise Mobile Workforces: The ET50 features Wi-Fi connectivity while the ET55 adds 4G LTE cellular connectivity, and both models offer an advanced capacitive touch display that enables gloved or ungloved usage and the ability to use a stylus or a finger for annotating and capturing signatures. All configurations are designed to MIL-STD specification for drops to concrete and have IP65 sealing.

- Enterprise-Class Services: Zebra OneCare Essential Services provide device diagnostics and coverage for normal wear and tear as well as accidental damage to internal and external components, significantly reducing unforeseen repair expenses.

by Gary Mintchell | Aug 10, 2015 | Automation, Internet of Things, Interoperability, News, Technology

During NI Week last week in Austin, Texas, IBM representatives discussed some news with me about a new engineering software tool the company has released – called Product Line Engineering (PLE) — designed to help manufacturers deal with the complexity of building smart, connected devices. Users of Internet of Things (IoT) products worldwide have geographic-specific needs, leading to slight variations in design across different markets. The IBM software is designed to help engineers manage the cost and effort of customizing product designs.

You may think, as I did, about IBM as an enterprise software company specializing in large, complex databases along with the Watson analytic engine. IBM is also home to Rational Software—an engineering tool used by many developers in the embedded software space. I had forgotten about the many engineering tools existing under the IBM umbrella.

They described the reason for the new release. Manufacturers traditionally manage customization needs by grouping similar designs into product lines. Products within a specific line may have up to 85% of their design in common, with the rest being variable, depending on market requirements and consumer demand and expectation. For example, a car might have a common body and suspension system, while consumers have the option of choosing interior, engine and transmission.

Product Line Engineering from IBM helps engineers specify what’s common and what’s variable within a product line, reducing data duplication and the potential for design errors. The technology supports critical engineering tasks including software development, model-based design, systems engineering, and test and quality management—helping them design complex IoT products faster, and with fewer defects. Additional highlights include:

- Helps manufacturers manage market-specific requirements: Delivered as a web-based product or managed service, the IBM software can help manufacturers become more competitive across worldwide markets by helping them manage versions of requirements across multiple domains including mechanical, electronics and software;

- Leverages the Open Services for Lifecycle Collaboration (OSLC) specification: this helps define configuration management capabilities that span tools and disciplines, including requirements management, systems engineering, modeling, and test and quality.

Organizations including Bosch, Datamato Technologies and Project CRYSTAL are leveraging new IBM PLE capabilities to transform business processes. Project CRYSTAL aims to specify product configurations that include data from multiple engineering disciplines, eliminating the need to search multiple places for the right data, and reducing the risk associated with developing complex products.

Dr. Christian El Salloum, AVL List GmbH Graz Austria, the global project coordinator for the ARTEMIS CRYSTAL project, said, “Project CRYSTAL aims to drive tool interoperability widely across four industry segments for advanced systems engineering. Version handling, configuration management and product line engineering are all extremely important capabilities for development of smart, connected products. Working with IBM and others, we are investigating the OSLC Configuration Management draft specification for addressing interoperability needs associated with mission-critical design across multi-disciplinary teams and partners.”

Rob Ekkel, manager at Philips Healthcare R&D and project leader in the EU Crystal project, noted, “Together with IBM and other partners, we are looking in the Crystal project for innovation of our high tech, safety critical medical systems. Given the pace of the market and the technology, we have to manage multiple concurrent versions and configurations of our engineering work products, not just software, but also specifications, and e.g. simulation, test and field data. Interoperability of software and systems engineering tools is essential for us, and we consider IBM as a valuable partner when it comes to OSLC based integrations of engineering tools. We are interested to explore in Crystal the Product Engineering capabilities that IBM is working on, and to extend our current Crystal experiments with e.g. Safety Risk Management with OSLC based product engineering.”

Nico Maldener, Senior Project Manager, Bosch, added, “Tool-based product line engineering helps Bosch to faster tailor its products to meet the needs of world-wide markets.”

Sachin Londhe, Managing Director, Datamato Technologies, said, “To meet its objective of delivering high-quality products and services, Datamato depends on leading tools. We expect that product line engineering and software development capabilities from IBM will help us provide our clients with a competitive advantage.”

by Gary Mintchell | Jul 14, 2015 | Automation, Industrial Computers, News, Security, Technology

Potentially viable start-ups are rare in the industrial automation space. Recently Russ Fadel, Rick Bullotta, and John Richardson did it with ThinkWorx an Internet of Things oriented software they sold to PTC. That was their second effort having previously sold Lighthammer to SAP.

Potentially viable start-ups are rare in the industrial automation space. Recently Russ Fadel, Rick Bullotta, and John Richardson did it with ThinkWorx an Internet of Things oriented software they sold to PTC. That was their second effort having previously sold Lighthammer to SAP.

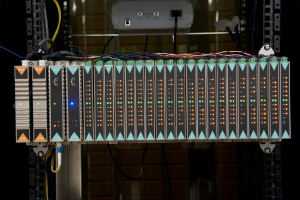

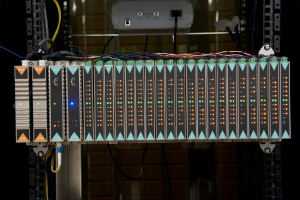

Now we have Albert Rooyakkers, CTO and inventor, and Bob Honor, president and former VP at Rockwell Automation and GE Intelligent Platforms, releasing a new industrial control system and company—Bedrock Automation. This company was introduced to Manufacturing Connection readers last December.

This is a tough area for an entrant. I’ve watched the rise and fall of PC-based control from back in the late 90s. Rockwell Automation and Siemens are so entrenched in the market. The next tier is solid with AutomationDirect, B+R Automation, Beckhoff Automation, Mitsubishi, and Schneider Electric.

When you develop a product for a crowded market, you basically have to execute one of two strategies. Either you think that the products have reached commodity status and that you can make them better, faster, cheaper (at least the last two). Or, you totally disrupt the industry by bringing out something that does what others do better—and adds some significant new features and benefits.

Disruptive?

Bedrock Automation executives believe they have accomplished the latter. The design begins with built-in cyber security. Its patented architecture features a pin-less, electromagnetic backplane. It addresses “virtually all control applications with fewer than a dozen part numbers, reducing cyber attack vectors, cutting lifecycle costs, and simplifying engineering, commissioning and maintenance.”

“Starting from a blank sheet of paper while inventing and deploying advanced semiconductor, mechanical design, cyber computing and communication technologies has resulted in a completely new automation platform. The future is now,” said Bedrock Automation CTO and Engineering VP, Albert Rooyakkers.

Commitment to simple, elegant design is a core tenet of the system. Bedrock delivers I/O, power and communications across the pin-less electromagnetic backplane with a parallel architecture that supports ultra fast scan times regardless of I/O count. The removal of I/O pins improves reliability and increases cyber security while forming a galvanic isolation barrier for every I/O channel. This innovative backplane also allows installation of I/O modules in any orientation and location for “unprecedented” flexibility in I/O and cable management.

Secure I/O modules use layers of advanced technology to deliver software-defined I/O for universal analog, discrete, Ethernet and Fieldbus signal types. A secure power module is functionally and physically coupled to the backplane to deliver single and dual redundant cyber secure power for the control system. A secure universal controller can run virtually every application independent of size or control task: discrete, batch, continuous, or multivariable control from one device that supports as few as ten, to as many as thousands of I/O points. No longer are separate programmable logic controllers (PLC) and distributed control systems (DCS) required.

“As cyber threats to all industries grow, traditional control system vendors respond by adding cost and complexity to their legacy technology. With deep roots in both automation and semiconductors, and unburdened by legacy, Bedrock Automation has created not only the most cyber secure system available today but we have also established new benchmarks for performance, scalability and affordability,” said Bedrock Automation President, Bob Honor.

Layers of protection

Replacing pins with an electromagnetic backplane is one of many layers of cyber security protection that Bedrock Automation has implemented. Additional cyber security layers include:

- A real time operating system with the highest safety (SIL 4) and security (EAL6+) rating of any RTOS available today

- Cyber secure microcontrollers with encrypted keys and TRNG embedded in all system modules including the controller, power supply and I/O

- All modules encased in anti-tamper metal that is impenetrable without metal cutting tools

- Authentication extending throughout the supply chain, including third party software and applications

Adding so many layers of protection to a conventional DCS, SCADA RTU, PAC or PLC would add cost and complexity and degrade performance. With Bedrock, they were built in from the start.

“Brown Engineers is excited to join the Bedrock revolution. Clients in our focus markets of electric, water, and sewer utilities, are increasingly concerned about cyber security and are confident that installing Bedrock will give them peace of mind to tell their ratepayers and their board members that they are taking every precaution to protect their processes. Brown Engineers demonstrates its continued commitment to keeping clients on the forefront of technical innovation,” said Dee Brown of Brown Engineers, an industrial systems integration firm based in Little Rock, Arkansas.

Open, flexible engineering

Bedrock delivers an Integrated Development Environment (IDE) based on an open IEC 61131 software toolset that supports embedded OPC UA. The IDE enables users to develop, operate and authenticate control for a vast array of PLC, SCADA and DCS applications. Fewer components means fewer panel layouts and wiring diagrams to contend with. Software configurable I/O can be changed in the field with the click of a mouse. Ninety percent fewer I/O module types means fewer spare parts to keep and manage. Such innovations contribute to reducing overall engineering design costs by up to 33 percent.

“Bedrock is the first unique platform to enter the control market in the last 15 years. It diverges radically from the typical platforms and is superior in terms of processing power, redundancy, scalability, security and cost efficiency. We plan to use it as a point of differentiation for our business,” said Chris McLaughlin of Vertech, a Phoenix-based industrial systems integrator.

Pricing and availability

The Bedrock control system is available now in baseline configuration starting at $20,000 MSRP. A growing network of world-class system integrators and automation solution providers is available to provide local sales and support.

For more information about the Bedrock revolution, download the first white paper in the series: Revolution – Chapter One: The Backplane.