by Gary Mintchell | Jul 23, 2018 | Automation, Operator Interface, Productivity

As manufacturing shifts towards smart factories, with interconnected production systems and automation, engineers at the University of Nottingham are leading a £1.9m project to develop a predictive toolkit to optimise productivity and communication between human workers and robots.

This research fits in with much other reporting I’ve done including the work of Dell Technologies on “human-machine partnerships.”

DigiTOP is one of seven national projects to create novel digital tools, techniques and processes to support the translation of digital capabilities into the manufacturing sector, funded by the Engineering and Physical Sciences Research Council (EPSRC).

It comes following the industry-led Made Smarter review, chaired by Siemens Chief Executive Juergen Maier, which stated that industrial digitalisation could be worth as much as £455bn to UK manufacturing over the next decade.

DigiTOP officially started on 1st July with the first month dedicated to project set up activities culminating in our internal kick off meeting at the end of the month, after which we should have a more outward focus. The project will take 39 months and complete on 30 September 2021. The twitter account @DigiTOP_Project will be regularly updated, and they are in the process of setting up a website to aid dissemination of progress.

A digital toolkit for the optimisation of operators and technology in manufacturing partnerships, DigiTOP will be led by Professor Sarah Sharples at the University of Nottingham in collaboration with Loughborough University, Cranfield University, University of the West of England, BAE Systems, Babcock International, Synertial Labs Ltd, Artinis Medical Systems B.V., High Value Manufacturing (HVM) Catapult and Jaguar Land Rover Ltd.

The toolkit will focus on using human factor theories and data to digitally capture and predict the impact of digital manufacturing on future working practices. Demonstrators will be used to test the implementation of sensing technologies that will capture and evaluate performance change and build predictive models of system performance.

The project will also provide an understanding of the ethical, organisational and social impact of the introduction of digital manufacturing tools and digital sensor-based tools to evaluate work performance in the future workplace.

DigiTOP’s findings will help companies that are planning to implement digital manufacturing technologies to understand how it will alter working practices, and how to optimise workplace designs to take these changes into account.

The tools developed within DigiTOP will help industry to design future work which might take place with a human and robot working in collaboration to complete a task or help with understanding how to design a data visualisation which shows how current parts of the factory are performing, and where maintenance or systems change might be needed in the short or long-term future.

Professor Sharples said: “The manufacturing industry, with the drive towards ‘Industrie 4.0’, is experiencing a significant shift towards digital manufacturing. This increased digitisation and interconnectivity of manufacturing processes is inevitably going to bring substantial change to worker roles and manual tasks by introducing new digital manufacturing technologies to shop floor processes.

“It may not be enough to simply assume that workers will adopt new roles bestowed upon them; to ensure successful worker acceptance and operational performance of a new system it is important to incorporate user requirements into digital manufacturing technologies design.

“New approaches to capture and predict the impact of the changes that these new types of technologies, such as robotics, rapidly evolvable workspaces, and data-driven systems are required,” adds Professor Sharples, who is Associate Pro-Vice Chancellor for Research and Knowledge Exchange for Engineering at Nottingham.

“These approaches consist of embedded sensor technologies for capture of workplace performance, machine learning and data analytics to synthesise and analyse these data, and new methods of visualisation to support decisions made, potentially in real-time, as to how digital manufacturing workplaces should function.”

The EPSRC investment arose out of work conducted by the Connected Everything Network Plus, which was established to create a multidisciplinary community focussed on industrial systems in the digital age.

EPSRC’s Executive Chair, Professor Philip Nelson, said: “The adoption of advanced ICT techniques in manufacturing provides an enormous opportunity to improve growth and productivity within the UK.

“The effective implementation of these new technologies requires a multidisciplinary approach and these projects will see academic researchers working with a large number of industrial partners to fully harness their potential, which could generate impact across many sectors.”

by Gary Mintchell | Feb 1, 2017 | Automation, Manufacturing IT, Operations Management, Operator Interface

One of my customers back in the 90s established an OEE office and placed an OEE engineer in each plant. OEE, of course is the popular abbreviation for Overall Equipment Effectiveness—a sum of ratios that places a numerical value on “true” productivity. I’ve always harbored some reservations about OEE, especially as a comparative metric, because of the inherent variability of inputs. Automated data collection and modern data base analytics are a solution.

One of my customers back in the 90s established an OEE office and placed an OEE engineer in each plant. OEE, of course is the popular abbreviation for Overall Equipment Effectiveness—a sum of ratios that places a numerical value on “true” productivity. I’ve always harbored some reservations about OEE, especially as a comparative metric, because of the inherent variability of inputs. Automated data collection and modern data base analytics are a solution.

A press release and email conversation with Parsec came my way this week. It sets the stage by pointing to the pressure to increase quality and quantity, while reducing costs, leading manufacturers to seek a deeper understanding of trends and patterns and new ways to drive efficiency. The very nature of OEE is to identify the percentage of manufacturing time that is truly productive. It is the key metric for measuring the performance of an operation, but many companies measure it incorrectly, or don’t measure it at all.

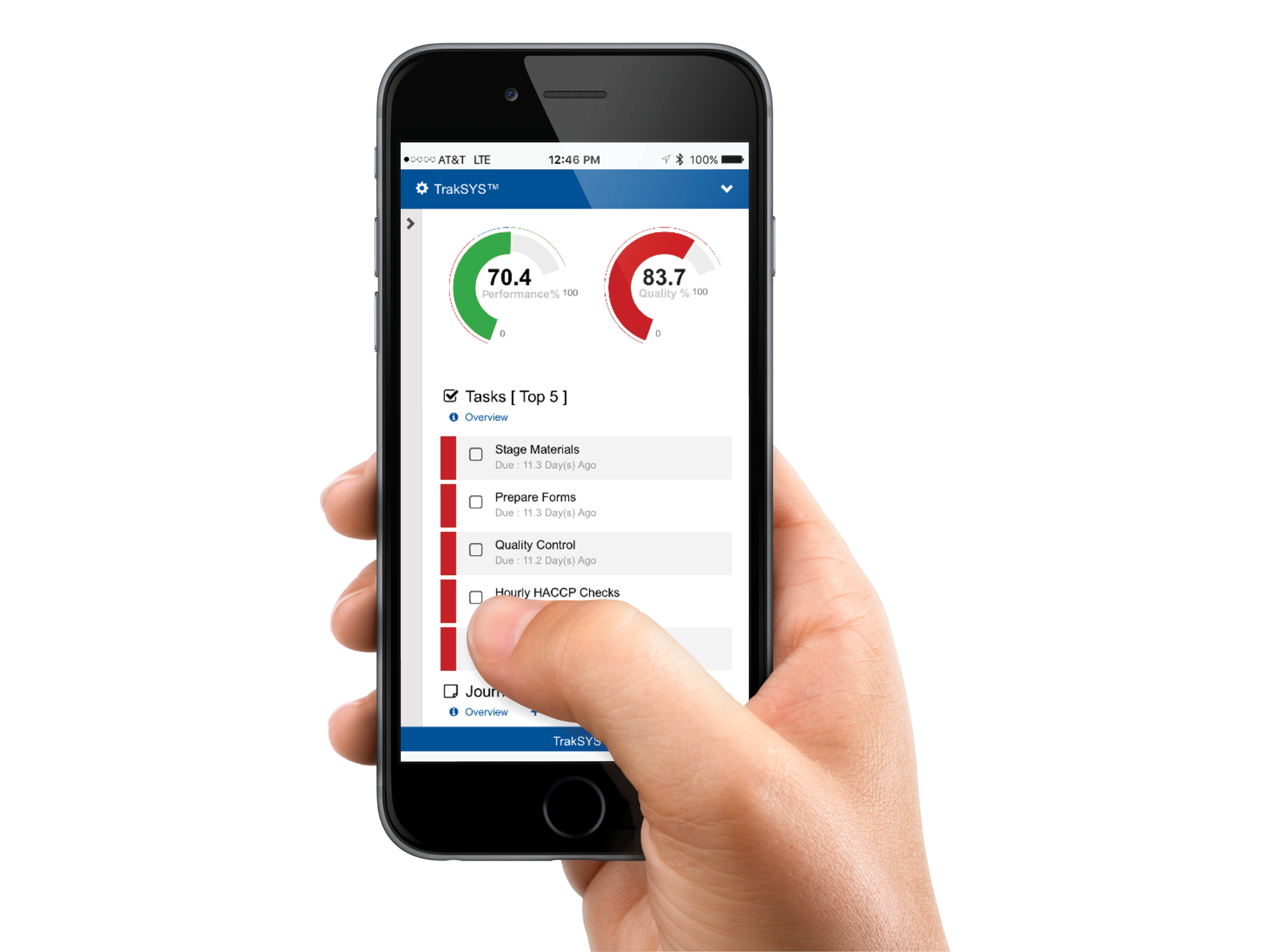

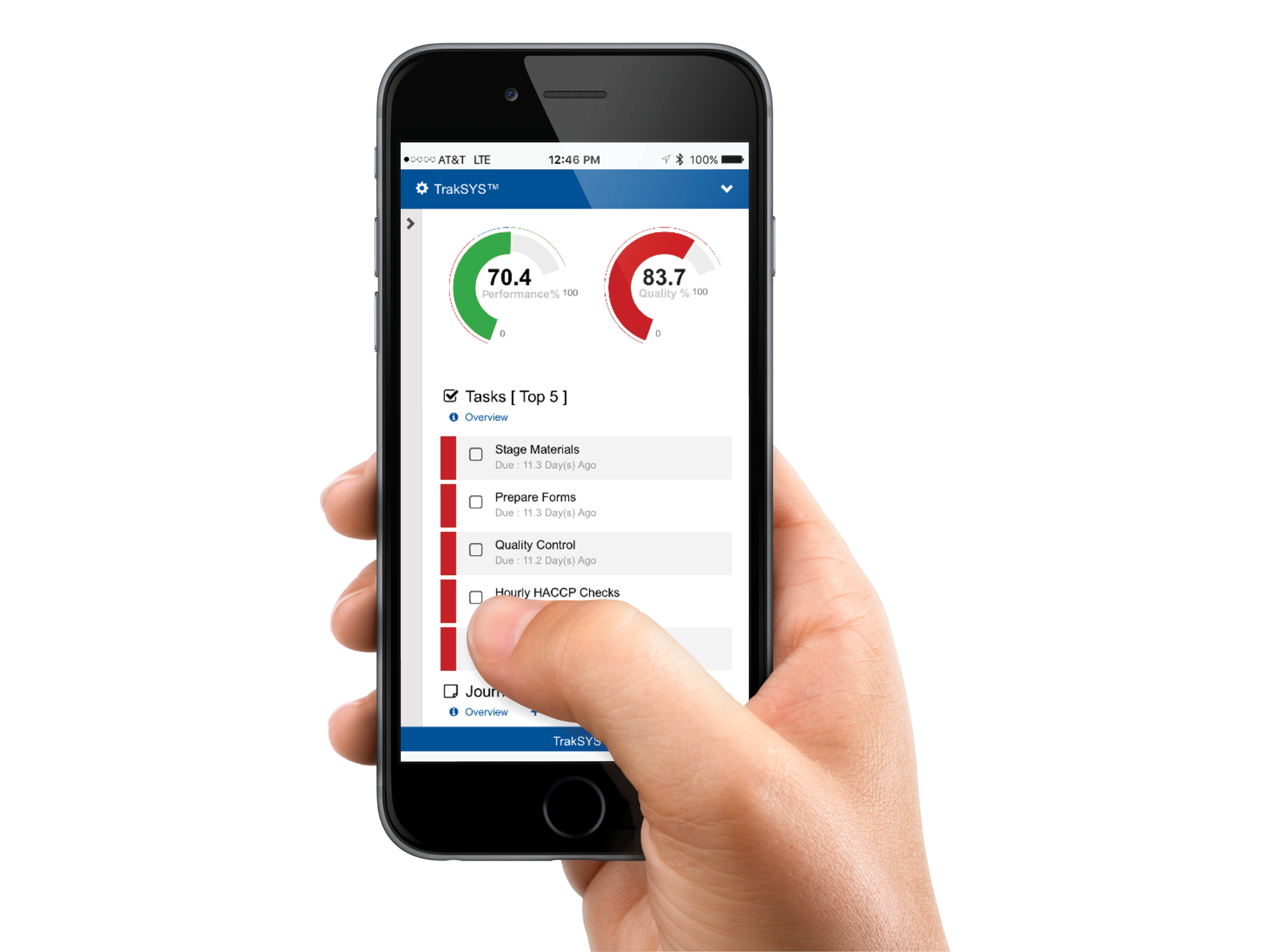

In the latest example of its efforts to help manufacturers maximize performance while reducing costs and complexity, Parsec launched its real-time Overall Equipment Effectiveness (OEE) Performance Management solution.

Most OEE measurement systems capture data from a single source and offer reports that may be visually appealing but actually contain very little substance. Other OEE systems capture lots of data but fail to give operators the necessary tools to act on that data. The TrakSYS OEE Performance Management solution collects and aggregates data from multiple sources, leveraging existing assets, resources and infrastructure, and provides insight into areas of the operation that need improvement with the tools to take action.

“We are challenging manufacturers to go beyond OEE measurement and to begin thinking about performance management,” said Gregory Newman, Parsec vice president of marketing. “Our TrakSYS OEE Performance Management solution pinpoints the root causes of poor performance and closes the loop by providing actionable intelligence and the tools necessary to fix the bottlenecks and improve productivity.”

The Power to Perform

When designing the TrakSYS OEE Performance Management solution, Parsec took into account three key criteria for measuring OEE: Availability, Performance and Quality. Availability, or downtime loss, encompasses changeovers, sanitation/cleaning, breakdowns, startup/shutdown, facility problems, etc. Performance, or speed loss, includes running a production system at a speed lower than the theoretical run rate, and short stop failures such as jams and overloads. Quality, or defect loss, is defined as production and startup rejects, process defects, reduction in yield, and products that need to be reworked to conform to quality standards. As part of the solution, Parsec created a variety of standard dashboards and reports as well as the ability to customize reports through powerful web-based configuration tools.

When designing the TrakSYS OEE Performance Management solution, Parsec took into account three key criteria for measuring OEE: Availability, Performance and Quality. Availability, or downtime loss, encompasses changeovers, sanitation/cleaning, breakdowns, startup/shutdown, facility problems, etc. Performance, or speed loss, includes running a production system at a speed lower than the theoretical run rate, and short stop failures such as jams and overloads. Quality, or defect loss, is defined as production and startup rejects, process defects, reduction in yield, and products that need to be reworked to conform to quality standards. As part of the solution, Parsec created a variety of standard dashboards and reports as well as the ability to customize reports through powerful web-based configuration tools.

“Our goal is to empower manufacturers to unlock unseen potential with their existing infrastructure,” added Newman. “Even small tweaks can save a plant millions of dollars each year.”

TrakSYS is an integrated platform that contains all of the functionality of a full manufacturing execution system (MES) in one package. The modular nature of TrakSYS brings flexibility to deploy only the functions that are required, without a major software upgrade. TrakSYS business solutions include OEE, SPC, e-records, maintenance, traceability, workflow, batch processing, sustainability, labor, and more.

www.parsec-corp.com

by Gary Mintchell | Sep 9, 2016 | Automation, Operations Management, Operator Interface, Process Control

Plant operators have been isolated in remote control rooms for decades. They tend to lose intimate knowledge of their processes as they monitor computer screens in these isolated rooms. The sounds and smells are gone. Everything is theoretical.

This system has worked. But, is it the best, most efficient, most effective use of human intelligence?

Not likely. Technologies and work processes are joining to allow plant managers to change all this.

Tim Sowell, VP and Fellow at Schneider Electric, recently shared some more of his prescient thoughts on this issue–spurred as usual by conversations with customers.

He asks, “What is the reason why users have been locked to the desk/ control room, why has this transition not happened successfully before? It is simple, the requirement to be monitoring the plant. A traditional control room is the central place alarms, notifications were traditionally piped.”

Diving into what it takes to change, Sowell goes on to say, “The user needs to empowered with situational plant awareness, freed from monitoring, shifting to the experience of exception based notification. As the user roams the plant, the user is still responsible, and aware, and able to make decisions across the plant he is responsible for even if he not in view of that a particular piece of equipment. Driving the requirement for the mobile device the user carries to allow notification, drill thru access to information and ability to collaborate so the dependency to sit in the control room has lifted.”

Two streams join to form a river. Sowell continues, “The second key part of the transformation/ enablement of an edge worker is that their work, tasks and associated materials can transfer with them. As the world moves to planned work, a user may start work task on a PC in the control room, but now move out to execute close action. As the user goes through the different steps, the associated material and actions are at his finders tips. The operational work can be generated , assigned and re directed from all terminal.s and devices.”

The first generation of this thinking formed around the rapid development of mobile devices. Before plant managers and engineers could come to grips with one technology, the next popped up. Instead of careful and prolonged development by industrial technology providers, these devices came directly from consumers. Operators and maintenance techs and engineers brought them from home. Smart phones–the power of a computer tucked into their pockets.

Sowell acknowledges it takes more than a handheld computer. “It requires the transformation to task based integrated operational environment where the ‘edge worker’ is free to move.”

The information must free them to navigate with freedom, no matter the format, no matter where they start an activity, and have access to everything.

by Gary Mintchell | Jul 28, 2016 | Manufacturing IT, Operations Management, Software

A manufacturing software supplier must go beyond where they are to keep pace with today’s needs. GE Digital just announced such an extension–to offer decision support capabilities. The new GE HMI/SCADA software offers “comprehensive and best-in-class monitoring and visualization capabilities,” as well as work process management, analytics, and mobility. Based on ISA high performance design principles, this solution enables companies to troubleshoot faster, reduce waste and increase productivity.

“Most SCADA systems are still configured as HMIs – simply a display to indicate status,” said Matthew Wells, General Manager Automation Software for GE Digital. “In developing this new generation solution, we have combined industry standards, GE research and Industrial Internet technologies to exceed traditional HMI/SCADA, increasing operational efficiency and delivering on business outcomes.”

Context-driven navigation and situational awareness

The new GE software features a context-rich HMI that changes as the user moves through the system. Navigation is derived from a structured asset model. Using the model, the software always can provide operators with the most relevant information – in context – and minimize time to response. Additionally, the structured asset model mapped to the SCADA database significantly speeds configuration. Modern technologies such as HTML5 and Web HMI allow for centralized development and deployment, as well as accessibility anywhere in multiple form factors.

“With high performance HMI/SCADA, operators are able to quickly determine an abnormal situation and get to the root causes of many issues,” said Sergio Chavez, Automation Engineer with Los Angeles Dept. of Water and Power. “We help operators visualize a process and make alarms very visible. We’re shaving the time it takes for operators to act on a situation.”

To help engineers create the right user experience, GE also provides predefined smart objects and templates designed using efficient HMI concepts. Standard layouts and cards – such as trends, alarms, alarm summaries, and KPIs – are available out of the box, speeding configuration and improving user situational awareness.

Task management and mobility

Additionally, GE’s fourth generation HMI/SCADA portfolio has task management capabilities, triggering the right actions, at the right time, by the right person, in the right place based on alarms or other events. GE’s new Workflow 2.5 and Mobile 2.0 solutions extend the capabilities of Decision Support HMI/SCADA further, helping companies achieve their critical business outcomes with integrated workflows and intelligent alarming, available anytime and anywhere.

“Operator effectiveness allows operators the opportunity to grow professionally,” according to Bill Fritz, Director of Public Works, Waterford Township, Michigan. “They can reinvent themselves and gain new value-added skills. They can take on new roles.”

GE’s Wells explained, “Use technology to improve the operator experience and manage operations for greater efficiency. With just a quick look, operators today should be able to recognize which information requires their attention and what it indicates – which speeds response and drives to business outcomes.”

by Gary Mintchell | Oct 16, 2015 | Asset Performance Management, Automation, News, Operations Management, Process Control, Security, Technology, Wireless

This is another long post—and it is a summary—running through many of the new products introduced to the press and analysts durning Emerson Exchange 2015. If any of these whet your appetite, visit the Emerson Process Website for more information.

Another place to catch up on happenings at the conference is Jim Cahill’s Emerson Process Experts blog. He also has been introducing readers to highlighted sessions.

Machinery protection

CSI 6500 ATG protection system, a stand-alone machinery protection solution that allows users to cost-effectively introduce prediction monitoring of critical assets from the same system. Predictive intelligence is a key component to increasing availability and improving the reliability of plant assets.

These multi-functional cards can be easily reconfigured for a wide range of measurements, including the impacting or peak-to-peak data used in Emerson’s unique PeakVue technology. In addition to monitoring the start-up and coastdown of critical turbo machinery for safe operation, users will be able to utilize PeakVue technology to identify the earliest indications of developing faults in gearboxes and bearings.

With the CSI 6500 ATG, it is no longer necessary to return to the control room or open cabinets in the field to view or analyze data. The CSI 6500 ATG can be networked over wired or wireless Ethernet to deliver asset health information to authorized users through a PC or phone application.

To facilitate easy system integration with third party systems, CSI 6500 ATG is the first protection system to include a secure embedded OPC UA server.

Gas ultrasonic flow meter

A new Daniel gas ultrasonic flow meter platform elevates its well-proven British Gas design by providing two meters and transmitters in a single body to help natural gas operators and pipelines improve reliability and efficiency. Designed to maximize capital budgets by permitting two completely independent measurements with the installation of just a single flowmeter, the new 3415 (four-path + one-path) and 3416 (four-path + two-path) gas ultrasonic flow meters combine a four-path fiscal meter with an additional check meter, while the new 3417 (four-path + four-path) meter provides two fiscal meters for full redundancy and equal accuracy within one meter body. This two-in-one redundant design delivers continuous on-line verification of custody transfer measurement integrity, device health and process conditions, and improves fiscal metering confidence while ensuring regulatory compliance.

Both Daniel 3415 and 3416 gas ultrasonic meters measure flow using four horizontal chordal paths in addition to a reflective path dedicated to verification of the primary measurement, enabling improved metering insight, more informed decision making and simplified flow meter verification. For enhanced immunity to pipe wall contamination, the 3416 meter is equipped with an additional vertical reflective path to detect liquid or very thin layers of contamination at the bottom of the meter that otherwise remain completely hidden in a direct-path meter design. This allows reliable monitoring of process changes before they affect measurement, thus reducing calibration frequency and enabling maintenance to be condition-based instead of calendar-based.

Electric actuator control

DCMlink Software, a unified electric actuator control, monitoring and diagnostics platform, will allow, for the first time, Emerson customers to diagnose, configure, and monitor all electric actuators from a central location independent of protocol, actuator or host system. The software extends the useful life of field assets by providing actuator data gathering, condition monitoring, events log and prioritization of actuator alarms in a unified and consistent user interface. Actuator configuration includes custom characterization, as well as the ability to import and export historical configuration profiles.

Whether it is viewing value torque profile, live trending data or actionable alarms straight from the actuator, plant operators will be able to access detailed monitoring and diagnostics data, allowing them to take action before a fault occurs. DCMlink offers advanced control and diagnostics, including torque profile curves, initiating partial stroke test or emergency shut down and alarms in NE-107 format. Current communications support included Modbus, TCP-IP, and Bluetooth.

DeltaV v13

Version 13 (v13) of the DeltaV distributed control system (DCS) new features focus on integration, advanced alarm management, and security with an overarching design that improves ease of use and minimizes the need for specialized expertise.

DeltaV v13 delivers technologies to bring sources together for easy operator access and use. These technologies include an Ethernet I/O card (EIOC) for integrating Ethernet-based subsystems and devices, including a direct interface with smart motor control centers and substations. It improves the factory acceptance testing (FAT) experience by providing enhanced safety instrumented system simulation capabilities and easy-to-use virtualization environment.

The new DeltaV Alarm Mosaic has an intuitive alarm display that enables operators to more quickly identify, analyze, and respond correctly to the root cause of an abnormal process condition. The new release also provides trend display optimizations for better visibility of process changes.

SCADA

OpenEnterprise v3.2 release adds a native interface to the AMS Device Manager asset management software, enabling users to remotely manage and maintain HART and WirelessHART devices in wide-area SCADA networks.

OpenEnterprise v3.2 together with AMS Device Manager allows asset owners to extend the reach of their predictive maintenance capability out to their remote assets, providing a powerful and proactive method of diagnosing potential device problems remotely. This results in reduced trips to the field and helps to avoid unplanned process shutdowns, improving safety, reliability, and profitability.

The native interface of OpenEnterprise v3.2 to AMS Device Manager enables the collection of wired and wireless HART digital device data over low bandwidth wide-area SCADA networks from Emerson ROC, FloBoss, and ControlWave RTUs without adding the additional complexity and expense of external HART multiplexers. Support for AMS Device Manager SNAP-ON applications, OpenEnterprise SCADA server redundancy, multiple deployment options, and data collection for up to 10,000 HART devices ensures flexibility and scalability for a wide range of remote oil and gas applications.

Machinery health in PowerGen

Emerson now offers its power generation and water/wastewater industry customers native machinery health monitoring and protection capability within the Ovation distributed control system.

Ovation Machinery Health Monitor leverages the Ovation platform through a high-performance I/O module dedicated to machinery health functions. Simply install by inserting the module into a spare I/O slot.

With the Ovation Machinery Health Monitor, operators receive alerts from a single set of common plant HMIs and no longer need to manually check machinery functions through a separate system.

The Ovation Machinery Health Monitor also reduces the risk of cyber attack by eliminating links to standalone systems and isolating process information – all of which can help facilities meet NERC CIP and other security regulations.

Silica sensing

Costly damage to turbine blades caused by silica deposition can occur due to a poorly monitored steam purity program. The new Rosemount 2056 Silica Analyzer provides continuous accurate measurements of silica in process streams with a range of 0.5 ppb to 5000 ppb. The 2056’s usability features make it one of the easiest -to-use and high performing analyzers.

Harsh duty pressure sensing

Rosemount 3051S Thermal Range Expander with new UltraTherm 805 oil fill fluid enables pressure measurements by direct-mounting a diaphragm seal system to processes that reach up to 410°C (770°F) without requiring the challenging impulse piping or heat tracing used in traditional connection technology. In applications where ambient temperatures drop below ideal operating conditions, system response time becomes slow, resulting in delayed process pressure readings. Traditionally, this problem is solved by using heat tracing which is costly, maintenance intensive, and difficult to install. By using the new thermal range expander dual fill fluid seal, the Rosemount 3051S can reliably measure pressure at extremely high process and low ambient temperatures.

The Rosemount 3051S Electronic Remote Sensors (ERS) System now has safety certification. The ERS System calculates differential pressure through a digital architecture — and is now suitable for SIL 2 and 3 applications.

Rosemount 3051S High Static Differential Pressure Transmitter provides reliable flow measurement in high pressure applications with capabilities up to 15,000 psi (1034 bar). The transmitter’s SuperModule platform and coplanar design reduce potential leak points by 50 percent compared to traditional designs, ensuring the highest differential pressure measurement accuracy, field reliability and safety.

Corrosion monitoring

The Roxar Corrosion Monitoring system, consisting of wireless-based probes, will provide refineries with flexible, responsive, integrated and highly accurate corrosion monitoring.

Combined with the Emerson’s non-intrusive Field Signature Method (FSM) technology, a non-intrusive system for monitoring internal corrosion at the pipewall, refinery operators will be able to access more comprehensive corrosion information and corrosion rates, leading to improved operator insight and control over assets.

The system will also help identify and track opportunity/high TAN crudes and their corrosive elements. Such crudes are less expensive but more corrosive than others with the new system enabling the maximum amount of such crudes to be blended into the mix without increasing corrosion risk.

Wireless pressure gauge

Emerson Process Management has introduced the industry’s first WirelessHART pressure gauge. The Rosemount Wireless Pressure Gauge enables remote collection of field data.

The Wireless Pressure Gauge eliminates mechanical gauge common weak points by removing the components that inhibit the device from reporting/displaying pressure and providing up to a 10-year life, which reduces maintenance cost and time. The large 4.5-inch gauge face provides easy field visibility.

One of my customers back in the 90s established an OEE office and placed an OEE engineer in each plant. OEE, of course is the popular abbreviation for Overall Equipment Effectiveness—a sum of ratios that places a numerical value on “true” productivity. I’ve always harbored some reservations about OEE, especially as a comparative metric, because of the inherent variability of inputs. Automated data collection and modern data base analytics are a solution.

One of my customers back in the 90s established an OEE office and placed an OEE engineer in each plant. OEE, of course is the popular abbreviation for Overall Equipment Effectiveness—a sum of ratios that places a numerical value on “true” productivity. I’ve always harbored some reservations about OEE, especially as a comparative metric, because of the inherent variability of inputs. Automated data collection and modern data base analytics are a solution.

When designing the TrakSYS OEE Performance Management solution, Parsec took into account three key criteria for measuring OEE: Availability, Performance and Quality. Availability, or downtime loss, encompasses changeovers, sanitation/cleaning, breakdowns, startup/shutdown, facility problems, etc. Performance, or speed loss, includes running a production system at a speed lower than the theoretical run rate, and short stop failures such as jams and overloads. Quality, or defect loss, is defined as production and startup rejects, process defects, reduction in yield, and products that need to be reworked to conform to quality standards. As part of the solution, Parsec created a variety of standard dashboards and reports as well as the ability to customize reports through powerful web-based configuration tools.

When designing the TrakSYS OEE Performance Management solution, Parsec took into account three key criteria for measuring OEE: Availability, Performance and Quality. Availability, or downtime loss, encompasses changeovers, sanitation/cleaning, breakdowns, startup/shutdown, facility problems, etc. Performance, or speed loss, includes running a production system at a speed lower than the theoretical run rate, and short stop failures such as jams and overloads. Quality, or defect loss, is defined as production and startup rejects, process defects, reduction in yield, and products that need to be reworked to conform to quality standards. As part of the solution, Parsec created a variety of standard dashboards and reports as well as the ability to customize reports through powerful web-based configuration tools.