by Gary Mintchell | Nov 29, 2016 | Internet of Things, News, Operations Management, Organizations, Standards

IIoT Business Model

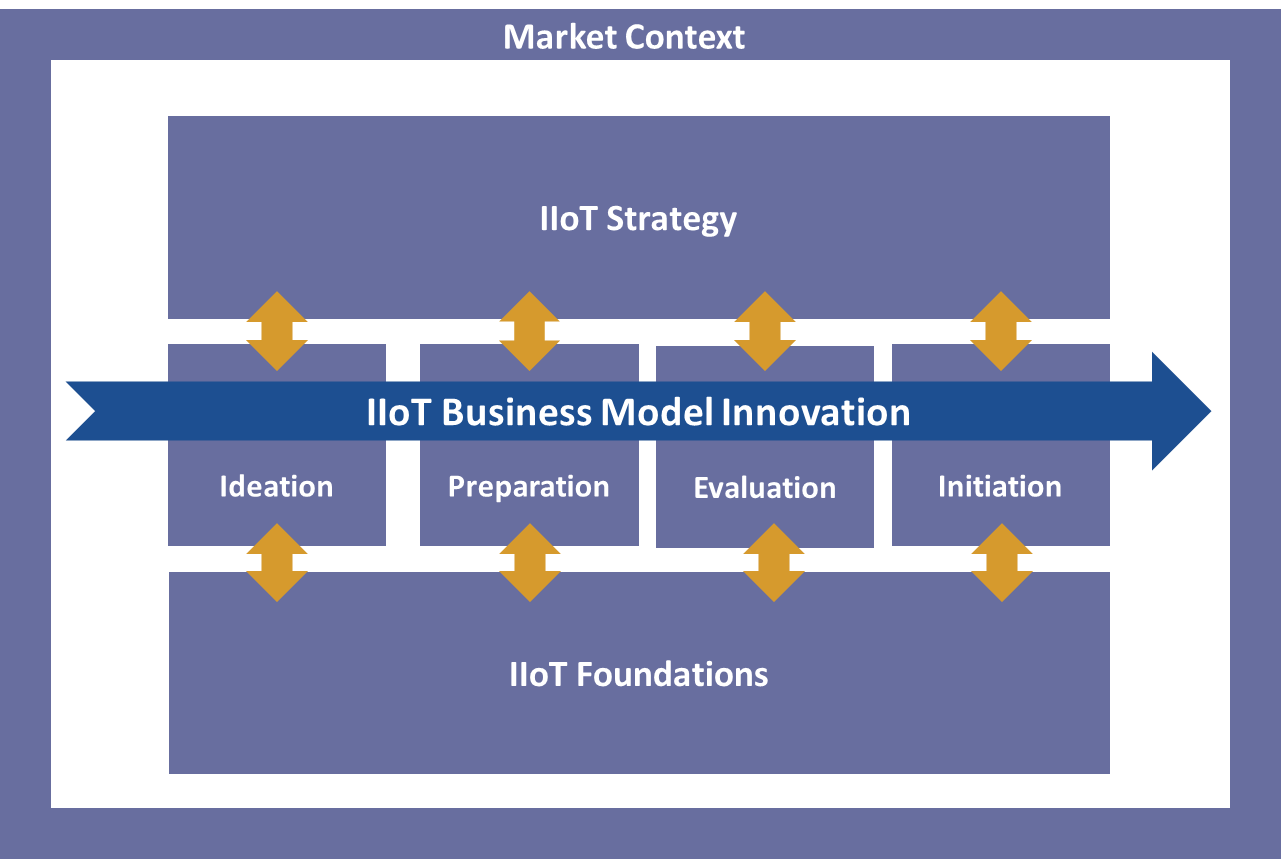

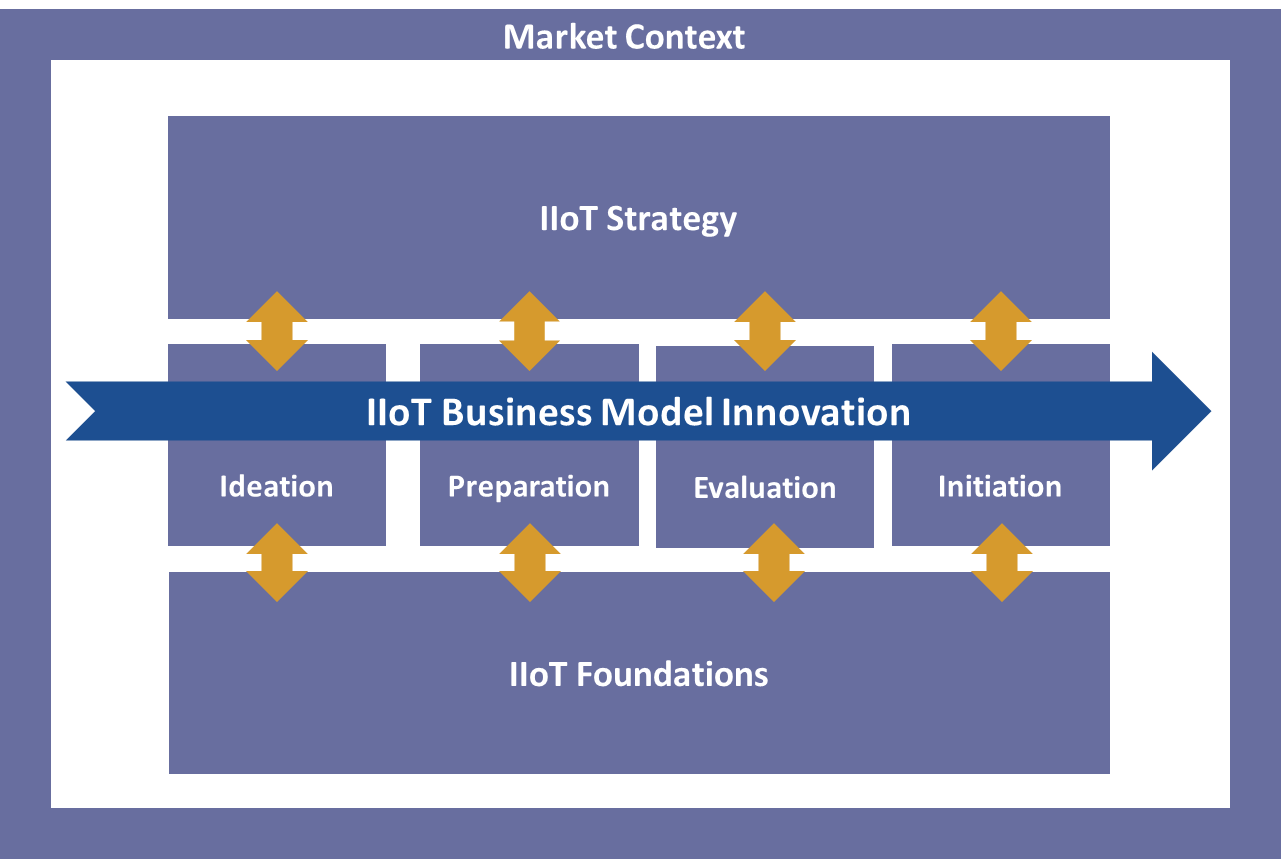

In another advancement for the Industrial Internet of Things, The Industrial Internet Consortium (IIC), the global, member-supported organization that promotes the accelerated growth of the Industrial Internet of Things (IIoT), announced the publication of the Business Strategy and Innovation Framework (BSIF). The BSIF helps enterprises to identify and analyze issues that must be addressed to capitalize on the opportunities emerging within the IIoT.

“Everybody knows that the Industrial Internet of Things will completely transform the way that business works. What’s not clear is exactly how to deploy these new IIoT concepts to best effect,” said Jim Morrish, Chair of the Business Strategy Task Group, and Founder and Chief Research Officer, Machina Research. “What the IIC’s Business Strategy and Innovation Framework provides is a toolkit for identifying, prioritizing and initiating the deployment of those crucial IIoT initiatives. It’s a significant step forward for the IIoT industry in terms of working to capitalize on the huge opportunities presented by this new technology wave.”

The BSIF serves as a reference document for chief executives in enterprises planning to engage in IIoT concepts. A single-source compendium of the issues and challenges enterprises should consider before they deploy IIoT initiatives, the BSIF details frameworks and concepts to help enterprises increase value for users, customers and partners while at the same time helping to reduce market and technical uncertainties.

The BSIF outlines a comprehensive set of best practices for companies engaging in IIoT, but companies are free to adopt a lighter touch or use an existing internal project model, especially within smaller companies. Alternatively, a range of project support processes may already be in place and the approach documented in the BSIF may be used to enhance existing infrastructures to address new IIoT opportunities (particularly for larger companies).

“The IIC’s Business Strategy and Innovation Framework is an important industry milestone,” said Jim Nolan, EVP, IoT Solutions, InterDigital. “It offers timely, strategic guidance to the many organizations that are beginning to implement IIoT solutions.”

The BSIF is the most in-depth Industrial IoT-focused business strategy framework comprising expert vision, experience and business strategy best practices from IIC members, including Bosch Software Innovations, InterDigital, Hewlett Packard Enterprise, and Machina Research. The BSIF is available free of charge. For more information about the BSIF, click here.

The Business Strategy and Innovation Framework provides a high-level identification and analysis of issues that any enterprise will need to address to capitalize on the opportunities emerging from this current revolution that is the IIoT. This comprehensive document is a product of the Business Strategy Task Group, a strategy-focused task group within the Industrial Internet Consortium’s Business Strategy and Solution Lifecycle Working Group.

The Business Strategy and Innovation Framework describes the requirements to succeed in IIoT:

- An IIoT strategy and goals

- A structured framework to target and select the right IIoT opportunities

- A system in place to identify, assess and initiate IIoT opportunities

IIoT requires enterprises to rethink their current business models. This is necessary regardless of whether they actually adopt IIoT solutions internally: Industry is moving toward IIoT adoption, and enterprises that keep pace with this trend will undoubtedly have a strong competitive advantage.

Contributors to the Business Strategy and Innovation Framework dedicated their valuable time and expertise in authoring, editing and other ways. In particular, we would like to thank the following contributing members and their organizations:

- Veronika Brandt – Bosch Software Innovations

- Ken Figueredo – InterDigital, Inc.

- Steve Haldeman – Hewlett Packard Enterprise

- Jim Morrish – Machina Research, Chair of the Industrial Internet Consortium Business Strategy Task Group

by Gary Mintchell | Nov 18, 2016 | Automation, Networking, Standards

News regarding Time Sensitive Networking continues to flow. The University of New Hampshire InterOperability Laboratory (UNH-IOL), an independent provider of broad-based testing and standards conformance services for the networking industry, announced the launch of three industry-specific time sensitive networking (TSN) consortiums – Automotive Networking, Industrial Networking, and ProAV Networking – designed to provide deterministic performance within standard Ethernet for real-time, mission critical applications. By providing high quality test plans, tools, and test beds for TSN, UNH-IOL allows businesses to improve products and accelerate market readiness.

“Standards-based precise time, guaranteed bandwidth, and guaranteed worst-case latency in a converged Ethernet network is a game-changer to many industries,” said Bob Noseworthy, Chief Engineer, UNH-IOL. “Through UNH-IOL’s industry-specific TSN consortiums, companies can be at the forefront and drive the technology forward by validating their solutions with a full suite of testing services, which will allow applications such as self-driving cars and the Industrial Internet of Things (IIoT) to take off.”

Originally established as a “best effort” network, Ethernet needs additional specific features to deploy mission critical applications. TSN standards enable deterministic real-time communication over Ethernet, allowing solutions to be built to provide extremely precise, predictable timing across the network. By adding features to Ethernet such as time synchronization, ingress policing, seamless redundancy, frame preemption, scheduled traffic, and stream reservation, TSN ensures mission-critical, time sensitive data is not held up on the network, promoting an interoperable ecosystem spanning across many industries. As TSN standards mature, UNH-IOL consortium members are able to support rapid development of conformance and interoperability solutions for emerging standards, validating their silicon and early products by gaining access to test solutions as well as multi-vendor test beds.

A major driving force behind the development of TSN standards is the emerging Automotive Ethernet market. The future connected, autonomous vehicle requires the time sensitivity and predictability in networking that TSN provides to support Advanced Driver Assistance System (ADAS) requirements, infotainment expectations from consumers, and other elements of vehicle electronics. Supporting automotive original equipment manufacturers (OEMs) and manufacturers supplying OEMs enabled with deterministic Ethernet solutions, the TSN Automotive Networking Consortium provides a setting for collaboration and participation in shaping the emerging standards through neutral, third party conformance and interoperability testing.

TSN’s importance is also emerging in industrial automation due to the rise in interest around the IIoT, specifically the mission-critical, time sensitive data that must be transferred and shared within strict bounds of latency and reliability. TSN enhancements for Industrial Ethernet provide standards-based determinism and reliability needed for these applications. The TSN Industrial Networking Consortium brings together stakeholders to realize the benefits of TSN – bandwidth, security, interoperability, and latency and synchronization for IIoT, robotics, assembly plants, and machines, as well as shape the standards and protocols for TSN in the industrial market.

Recent enhancements and certifications in the audio/video market have created a wider choice of compatible products and open technology that brings high-quality AV networking within the reach of any size Professional AV system. TSN enhancements provide the important timing audio and video systems need. The Pro AV Networking TSN Consortium is a testing ground for the promises of seamless redundancy, low-latency, and synchronization in the professional audio/video market.

UNH-IOL provides the test facility for stakeholders across multiple industries – automotive, industrial, and Pro AV – to drive the emerging, maturing TSN standards. To learn more about joining the new consortiums, please visit: Automotive Networking TSN Consortium, Industrial Networking TSN Consortium, Pro AV Networking TSN Consortium.

by Gary Mintchell | Nov 17, 2016 | Automation, Education, News, Workforce

Rockwell Automation has long supported FIRST — For Inspiration and Recognition of Science and Technology — among other things supplying floor space during Automation Fair so that students can show off robotic projects. Now Rockwell Automation has announced a $12M, four-year commitment to inspire young people’s interest and participation in science and technology.

Rockwell Automation has long supported FIRST — For Inspiration and Recognition of Science and Technology — among other things supplying floor space during Automation Fair so that students can show off robotic projects. Now Rockwell Automation has announced a $12M, four-year commitment to inspire young people’s interest and participation in science and technology.

Over the past 10 years, Rockwell Automation has provided more than $15M of broad-based support to address the critical need to fill science, technology, education and math (STEM) jobs that drive innovation. Many of these jobs go unfilled because of both the lack of awareness of the kinds of high-tech jobs available, and the lack of skills to qualify for today’s needs.

“Through our technology and people, we are helping to inspire the next generation of innovators to fill the talent pipeline for our customers and for our company,” said Blake Moret, President and CEO, Rockwell Automation. “Our strategic partnership with FIRST helps us increase our reach and visibility to STEM students around the world.”

In addition to being a global sponsor of the FIRST LEGO League program and sole sponsor of the FIRST Robotics Competition (FRC) Rockwell Automation Innovation in Control Award, nearly 200 Rockwell Automation employees around the world donate their time for the FIRST programs, and more than 300 employees volunteer for the organization in other capacities. The company also donates products integral to FIRST program games and scoring. These product donations are specifically used for the FIRST Robotics Competition playing fields and scoring systems, and they are included within the parts kits teams use to build their robots.

“This generous, multiyear commitment from Rockwell Automation will allow us to focus on the strategic aspects of our partnership while continuing to help scale our programs and expose students to a broader range of industry-leading products and applications,” said Donald E. Bossi, President, FIRST. “The company has a long, rich history of supporting FIRST.”

Rockwell Automation is recognized as a FIRST Strategic Partner, which signifies the highest levels of sponsorship available at FIRST. It is also a FIRST Robotics Competition Crown Supplier.

Accomplished inventor Dean Kamen founded FIRST (For Inspiration and Recognition of Science and Technology) in 1989 to inspire an appreciation of science and technology in young people. Based in Manchester, N.H., FIRST designs accessible, innovative programs to build self-confidence, knowledge, and life skills while motivating young people to pursue opportunities in science, technology, and engineering. With support from over 200 of the Fortune 500 companies and more than $30 million in college scholarships, the not-for-profit organization hosts the FIRST Robotics Competition for students in Grades 9-12; FIRST Tech Challenge for Grades 7-12; FIRST LEGO League for Grades 4-8; and FIRST LEGO League Jr. for Grades K-4. Gracious Professionalism is a way of doing things that encourages high-quality work, emphasizes the value of others, and respects individuals and the community.

by Gary Mintchell | Nov 15, 2016 | Automation, Security

Cyber protection takes on a number of forms. Most everything involves “defense in depth” strategies. I just talked with an Israeli company started by former security agents who has found a different vulnerability and counteracts it. This is the first of three press releases I’ve been sitting on for release today. I guess Nov. 15 is a magic day in the PR world.

Cyber protection takes on a number of forms. Most everything involves “defense in depth” strategies. I just talked with an Israeli company started by former security agents who has found a different vulnerability and counteracts it. This is the first of three press releases I’ve been sitting on for release today. I guess Nov. 15 is a magic day in the PR world.

APERIO Systems emerged from stealth mode, launching the industry’s first technology that detects artificial manipulations of industrial process data, enabling operators to take real-time corrective action without service disruption to industrial control systems (ICS). From the rate of gas flow at a petroleum refinery, to the temperature and spin rates of turbines in a power plant, or the chlorine level of water supply networks, APERIO Systems’ proprietary Data Forgery Protection (DFP) technology delivers the last line of defense in protecting critical SCADA systems against insider and external threats.

APERIO Systems, already deployed at several sites across EMEA, secured seed funding from a consortium of private investors, including prominent cybersecurity veterans Doron Bergerbest-Eilon, Liran Tancman, and Shlomi Boutnaru. Bergerbest-Eilon is renowned for his role in establishing the agency charged with protecting all critical infrastructure in the State of Israel and is the former director of the security and protection division of the Israel Security Agency (ISA). He is currently the founder, president and CEO of ASERO Worldwide, a security consulting firm. Tancman and Boutnaru, who played key roles in building Israel’s cybersecurity capabilities, founded predictive cybersecurity startup CyActive, which was acquired by PayPal in 2015.

“Current solutions focus on keeping hackers outside critical systems, but attacks like the one that took down the power grid in Ukraine clearly show that sophisticated attackers will eventually penetrate these systems,” said Bergerbest-Eilon. “Once attackers breach a system, they must blind the operators and protection mechanisms by falsifying data in order to inflict severe and long-lasting damage. This entirely new category of Data Forgery Protection (DFP) is the key to keeping our critical infrastructure safe from attacks.”

Industrial control systems (ICS) are generally outdated from a cybersecurity perspective, vulnerable and difficult to patch because mission critical systems cannot be taken offline. While the threat to ICS is growing, critical systems security products on the market today are intrusive, hard to maintain, costly to integrate, and often produce vague and unactionable alerts, which cannot be acted upon by critical utility control rooms.

“Think of APERIO Systems as a polygraph for process data — it detects when your system is lying to you,” said Yevgeni Nogin, CEO of APERIO Systems. “With the unrelenting tenacity of cybercriminals, critical infrastructure breaches are inevitable. By guaranteeing the authenticity and integrity of operational data, APERIO Systems ensures that operators always know what’s really going on, enabling them to react quickly to a breach and take corrective action — making the critical systems resilient to the most dangerous of attacks.”

APERIO Systems’ advanced proprietary algorithms search for the data’s unique fingerprints and validate its authenticity. Any mismatches generate an alert and APERIO Systems pinpoints the attacked equipment and forged process data. Using a sophisticated combination of physics and state-of-the-art machine learning techniques, APERIO Systems reconstructs the real values of the forged operational data and reverts it to its original state in real time — establishing unprecedented operational resilience.

How APERIO Systems Protects

Both internal and external attackers can penetrate the most critical infrastructures, causing severe and long lasting damage. In order to do so, they must hide their malicious activity and deceive plant operators by forging the reported values of critical devices — remaining undetected and preventing timely corrective action. APERIO Systems’ Data Forgery Protection technology immediately exposes forged system readings to safeguard critical control systems and allow quick and effective remediation.

- APERIO Systems provides:

Data Forgery Protection (DFP): Validates integrity and authenticity of reported signals to provide operators with true state awareness, enabling them to take corrective action in real time.

- Process Continuity: Enables trust in the most critical data and provides resilience when attacked.

- Operational Alerts: Fast, actionable, specific and accurate alerts integrate cybersecurity into operational emergency procedures, allowing operators to mitigate permanent damage.

- Accurate and Relevant: Alerts operators only when the reported process state does not reflect the plant’s real situation — providing an extremely low false alert rate.

- Minimized Risk: Passive and non-intrusive system minimizes operational risks, as well as installation and maintenance costs.

- Counters Insider Threats: Protects the plant’s process continuity from both external and internal actors.

APERIO Systems is led by a veteran executive team with roots in the elite units of the Israel Defense Forces (IDF), as well as top cybersecurity and industrial companies:

- Yevgeni Nogin, CEO — a graduate of the elite “Talpiot” IDF military academy served over nine years in elite intelligence and R&D units of the IDF, and brings expertise in SCADA systems security.

- Michael Shalyt, VP Product — a graduate of the “Psagot” IDF academic program and served as leading researcher and team leader in the elite 8200 unit. Prior to joining APERIO Systems, he led the malware research team at Check Point.

- Itay Baruchi, Head of Algorithms — served as director of Industrial MRI, where he worked closely with several of the biggest oil and gas drilling companies. Before that, he founded and served as CTO of Pythagoras Solar.

- Charles Tresser, Chief Scientific Officer — a world renowned expert in dynamical systems. Tresser is one of the world’s leading experts in chaos theory and formerly Director of Research at IBM and France’s National Center for Scientific Research (CNRS).

by Gary Mintchell | Nov 8, 2016 | Asset Performance Management, Internet of Things, Operations Management

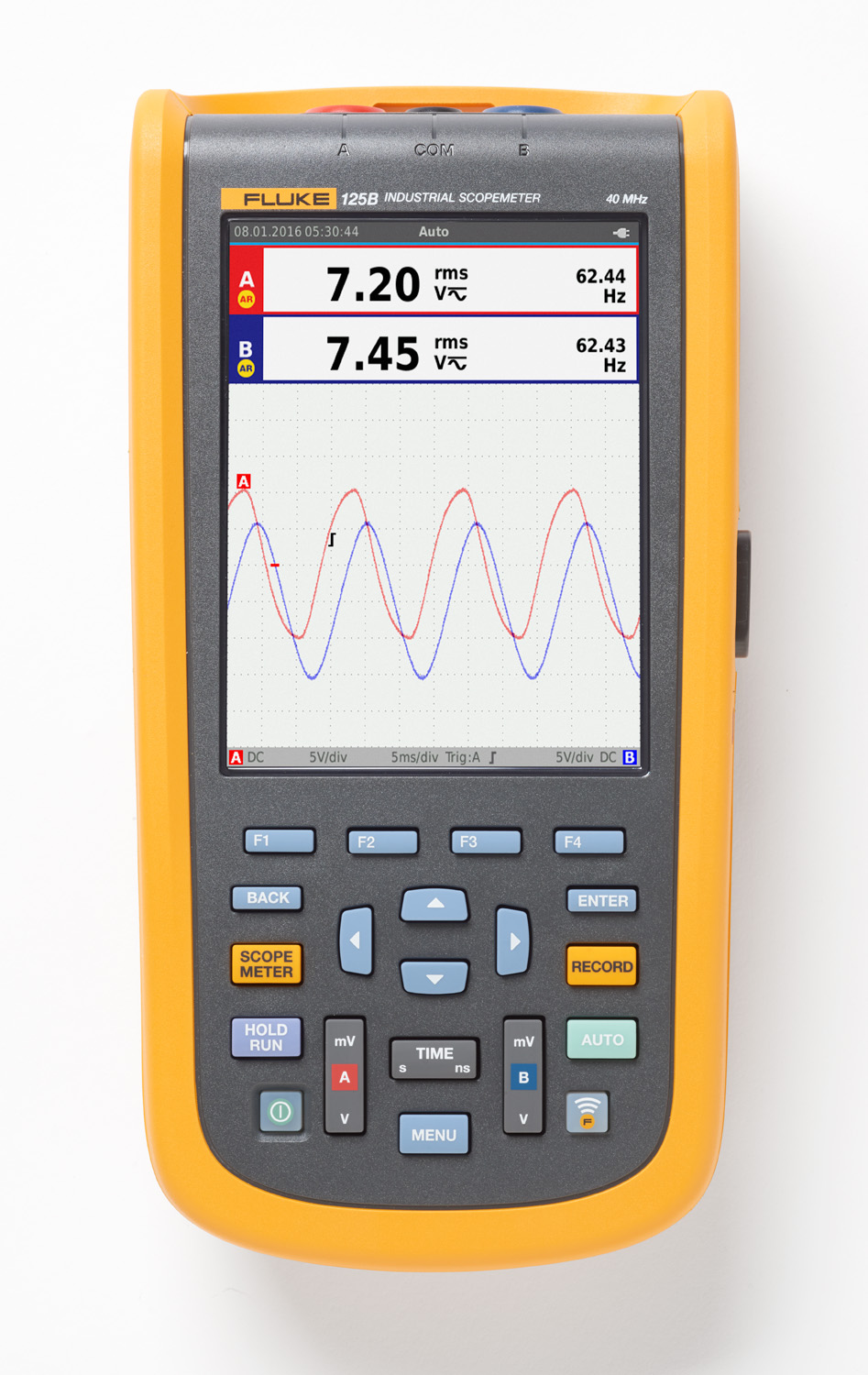

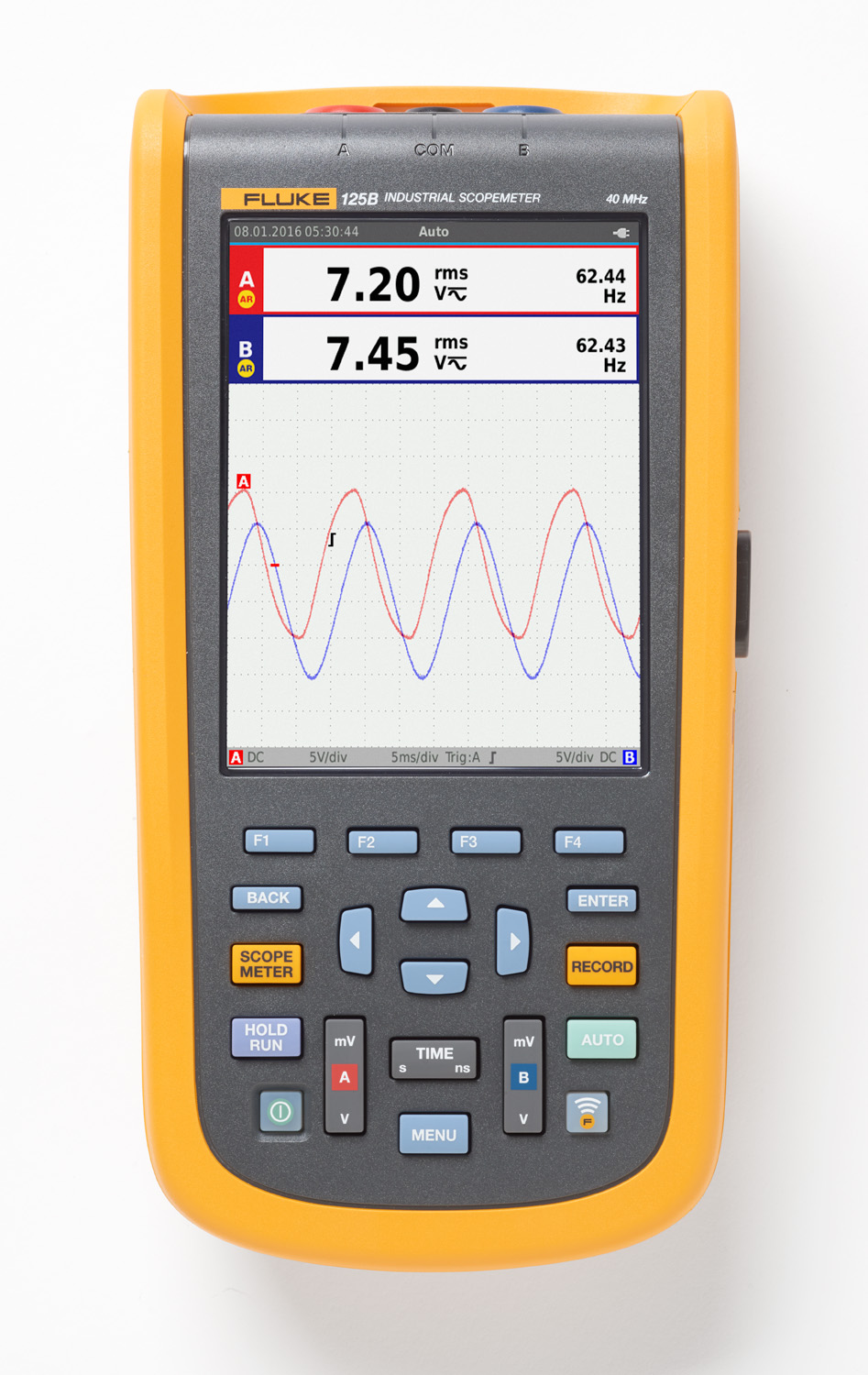

Fluke has drunk the Internet of Things kool-aid. It has taken a portfolio of measurement products and technology and connected them. I’ve followed it for a few years. It has recently announced an expansion of its cloud-based monitoring platform.

Fluke Connect reliability platform now offers cloud-based condition monitoring.

Monitoring plant equipment is crucial to avoiding costly downtime, but it is often too expensive, impractical, or complicated to capture performance data from all critical assets. The latest addition to the Fluke Connect reliability platform, Fluke Condition Monitoring, solves these problems with a new system of rugged voltage, current, temperature, and power sensors that can be moved from asset to asset or left in place for continuous monitoring. With Fluke Condition Monitoring, maintenance teams get a practical, scalable system that delivers the continuous data and alarms they need to prevent equipment downtime without costly equipment retrofits or specialized training.

“Adding Condition Monitoring to Fluke Connect revolutionizes maintenance workflows,” said Paul de la Port, President, Industrial Group, Fluke Corporation. “One system now manages the entire process — from equipment inspection and monitoring to setting alarm thresholds and assigning repairs. Certain types of plant equipment have fallen outside monitoring until now; the ROI just wasn’t there to retrofit with permanent sensors. The Fluke Condition Monitoring setup is so flexible and easy to install that technicians can put it wherever they need additional eyes on their equipment. And the new sensors funnel data into the same Fluke Connect reliability platform as all of our other connected test tools. With this system, technicians collect more data and engineers analyze more data in less time, with less work.”

Fluke Condition Monitoring consists of wireless sensors and a gateway that receives signals from the sensors from up to 30 feet away and works seamlessly with trusted, award-winning Fluke technologies, such as iFlex current probes, current clamps, temperature sensors and three-phase power monitoring.

Maintenance technicians can set the system up and begin monitoring in a matter of minutes, with the sensors transmitting measurements to the cloud as frequently as one measurement per second. Equipment data and alarm notifications are viewed through the Fluke Connect platform on a smartphone or web browser.

With this addition, the Fluke Connect reliability platform now compiles measurements from both the Fluke Condition Monitoring sensors and Fluke Connect wireless tools along with a history of work orders to create a comprehensive view of equipment health. The wireless, cloud-based solution overcomes legacy system silos and IT conflicts, works on any equipment type and helps teams stay effective while monitoring issues in different locations.

“The 3500 FC Series sensors operating with Fluke’s already well-established IIoT platform, Connect, create a strong value proposition for manufacturers, which seek to benefit from IIoT insights without a rip-and-replace greenfield buy,” said Christian Renaud, Research Director of 451 Research’s Internet of Things practice. “Products that are quick and easy to install and provide simple-to-determine ROI metrics should appeal to manufacturers.” 451 Research is focused on the business of enterprise IT innovation within emerging technology segments and provides timely insight to end user, service provider, vendor and investor organizations worldwide.

Rockwell Automation

Rockwell Automation

Cyber protection takes on a number of forms. Most everything involves “defense in depth” strategies. I just talked with an Israeli company started by former security agents who has found a different vulnerability and counteracts it. This is the first of three press releases I’ve been sitting on for release today. I guess Nov. 15 is a magic day in the PR world.

Cyber protection takes on a number of forms. Most everything involves “defense in depth” strategies. I just talked with an Israeli company started by former security agents who has found a different vulnerability and counteracts it. This is the first of three press releases I’ve been sitting on for release today. I guess Nov. 15 is a magic day in the PR world.