by Gary Mintchell | Apr 12, 2017 | Internet of Things, Operations Management

I received report recently from Altizon (www.altizon.com). It is an interesting look at some Industrial Internet of Things implementations.

The distribution of projects was (out of 62 companies reporting):

• Condition based maintenance 30

• Productivity improvement 62

• Quality Improvement 10

• Energy optimization 35

• Warehouse management 5

• Predictive maintenance 12

• EHS 1

They then looked at overall benefits that their customers derived so far from Industrial Internet of Things projects. The results were distributed with average and spread noted:

• Average Improvement in Topline 5% (3%-8%)

• Average Improvement in Productivity 13% (7% – 50%)

• Savings in Energy Expenses 5% (1%-8%)

• Savings in Indirect Cost 15% (1%-20%)

• Savings in Tooling and Spares Cost 3% (0.5%-6%)

These are interesting numbers. All the companies were implementing productivity improvement projects. Two-thirds also were upgrading maintenance strategies. This showed in an average of 13% improvement in productivity with at least one actually showing a 50% improvement (maybe we don’t want to benchmark the “before”).

I don’t know what they included in indirect costs. But I’m intrigued by the improvement in top line of 5%. This must be from better communication from customer to manufacturing. Certainly that’s an IioT program worth going for.

Altizon works in a number of industries. They looked at trends among their customers in the various industries. Following are highlights.

Trends

Automotive—Move towards a connected Supply chain: Visibility into a supplier’s manufacturing process, in-transit visibility, and management of inventory.

Industrial Products—End-to-end process traceability and Genealogy: if a product fails, it can be traced back to the conditions under which the product was built and the components that constitute the product, right down to the vendor.

Steel Industry—Genealogy and Process traceability-from mining to distribution; environmental management and adoption of ISO 50001.

Tire Industry—Reconciliation of real-time production booking with planned data in ERP systems; environmental management and adoption of ISO 50001.

Food and Consumer Goods—Genealogy and process traceability; performance benchmarking within and across plants.

Chemical Industry—Predicting quality and process yield based on detailed analysis of raw material used; IoT enabled system’s safety.

If you are planning an Internet of Things program and researching potential projects and benefits, these findings would be valuable toward the success of your proposal.

by Gary Mintchell | Apr 10, 2017 | Automation, Security

Cyber Security is always the “elephant in the room” at Industrial Internet of Things (IIoT) and Industrial Control Systems (ICS) conferences.

The latest edition of the ARC Industry Forum in Orlando featured many cyber security firms. Most were monitoring network traffic for anomalies. Some look at other aspects of the system. More firms are pivoting from other emphases into a cyber security firm.

Here are two news items attacking cyber security from totally different angles. One from the enterprise; the other from the lowest level user.

Manage Cyber Security Risks

Deloitte, the enterprise consulting company, announced plans to expand its cyber risk platform for end-to-end industrial control systems (ICS) and operational technologies (OT) security with next generation technology enabled by Dragos, a cybersecurity company focusing on securing ICS and OT networks.

The tactic Deloitte is taking is to monitor emerging cyber threats. Deloitte Risk and Financial Advisory Cyber Risk Services’ end-to-end ICS offering, enabled by Dragos technology, uses a combination of innovative cyber security products and services. This combination brings hunting and reconnaissance capabilities that now allow organizations to look beyond internal data to threat documentation found in external databases. Beyond securing ICS and OT systems, this combination of cyber risk services and technologies can provide a more complete picture of an organization’s ICS and OT threat landscape through active monitoring that can better inform scenario planning and response.

“Assessing the cyber risks of our clients’ ICS and OT, we see that many organizations are often unprepared for the magnitude of the impact to operational technology and industrial control systems environments” said Ed Powers, principal, Deloitte & Touche LLP, and U.S. leader for Deloitte Risk and Financial Advisory Cyber Risk Services. “A decision to include OT and ICS as a part of a broader cyber risk management program can improve a company’s understanding of the potential damage resulting from a cyberattack and can bolster the efficacy of its cyber risk mitigation strategy.”

The Dragos Platform, Threat Operations Center, and intelligence team form an ecosystem of technology, people, and intelligence to safeguard industrial networks. The Dragos Platform is designed for industrial networks and provides visibility into the environment, detection of threats through behavioral analytics, and the automation of workflows including incident response data collection and analysis.

“There have been pockets of excellence around the community in industrial security leading practices. But the world is facing a more connected infrastructure and a more aggressive threat than we’ve seen in years past,” said Robert M. Lee, chief executive officer, Dragos. “Now is an important time to get the solution correct and that’s what the Dragos and Deloitte cooperation represents.”

Protecting From USB Device Hacks

We all know about Stuxnet and how it was spread using malware in USB sticks. Well, here is an interesting tactic and new product from Honeywell.

Honeywell Process Solutions (HPS) announced Secure Media Exchange (SMX) to protect facilities against current and emerging USB-borne threats, without the need for complex procedures or restrictions that impact operations or industrial personnel.

Honeywell Process Solutions (HPS) announced Secure Media Exchange (SMX) to protect facilities against current and emerging USB-borne threats, without the need for complex procedures or restrictions that impact operations or industrial personnel.

Malware spread through USB devices – used by employees and contractors to patch, update and exchange data with onsite control and computer systems – is a key risk for industrial control systems. It was the second leading threat to these systems in 2016, according to BSI publications, and uncontrolled USBs have taken power plants offline, downed turbine control workstations, and caused raw sewage floods, among other industrial accidents.

“Industrial operators often have hundreds or thousands of employees and dozens of contractors on site every day,” said Eric Knapp, Cyber Security chief engineer, HPS. “Many, if not most, of those rely on USB-removable media to get their jobs done. Plants need solutions that let people work efficiently, but also don’t compromise cyber security and, with it, industrial safety.”

Currently, many plants either ban USBs, which is difficult to enforce and significantly reduces productivity, or rely on traditional IT malware scanning solutions, which are difficult to maintain in an industrial control facility and provide limited protection. These solutions fail to protect process control networks against the latest threats, and offer no means to address targeted or zero-day attacks.

Currently, many plants either ban USBs, which is difficult to enforce and significantly reduces productivity, or rely on traditional IT malware scanning solutions, which are difficult to maintain in an industrial control facility and provide limited protection. These solutions fail to protect process control networks against the latest threats, and offer no means to address targeted or zero-day attacks.

“SMX is a great example of Honeywell’s major investments in new industrial cyber security technologies, products, services, and research which further strengthen our ability to secure and protect industrial assets, operations and people,” said Jeff Zindel, vice president and general manager, Honeywell Industrial Cyber Security. “With the continued increase in cyber threats around the world, Honeywell’s industrial cyber security expertise and innovation are needed more than ever for smart industry, IIoT and critical infrastructure protection.”

Honeywell’s SMX was developed by the company’s cyber security experts based on field experience across global industrial sites and feedback from Honeywell User Group customers. Honeywell has one of the largest industrial cyber security research capabilities in the process industry, including an advanced cyber security lab near Atlanta. Honeywell also partners with cyber security leaders, including Microsoft, Intel Security and Palo Alto Networks, among others, to develop new, highly-effective industrial threat detection techniques.

Contractors “check-in” their USB drive by plugging it into an SMX Intelligence Gateway. The ruggedized industrial device analyzes files using a variety of techniques included with Honeywell’s Advanced Threat Intelligence Exchange (ATIX), a secure, hybrid-cloud threat analysis service.

SMX Client Software installed on plant Windows devices provides another layer of protection, controlling which USB devices are allowed to connect, preventing unverified USB removable media drives from being mounted, and stopping unverified files from being accessed. SMX also logs USB device connectivity and file access, providing a valuable audit capability.

“For most plants, the proliferation of removable media and USB devices is unavoidable, but the security risks they bring don’t have to be,” said Knapp. “We know our customers have limited resources to maintain another system, so Honeywell manages SMX for them. SMX never connects to our customers’ process control networks. From a system administration perspective, it’s like it’s not even there.”

Managed and maintained directly by Honeywell, SMX provides the easy and secure solution to USB security in industrial plants. It helps prevent the spread of malware through removable media; stops unverified files being read by Windows hosts; and, through the private ATIX connection, provides continually updated threat information and advanced analytics to help detect advanced, targeted, and zero-day malware.

by Gary Mintchell | Mar 23, 2017 | Data Management, Internet of Things, Operations Management

Digital Transformation and Internet of Things were prominent at this week’s user conference. I could be in San Francisco at the OSIsoft user conference. But, no, I’m in Detroit at a different one. However, we have two news items from the conference.

The first one is Marketplace, an online collection of software and hardware solutions for accelerating digital transformation for the industrial world. It links utilities, energy companies, manufacturers, food and beverage producers, and other industrial customers with the 300+ hardware, software, and integration partners in the OSIsoft Partner EcoSphere as well as the 2600 third-party developers in the PI Developers Club.

On Marketplace, customers can discover and compare leading solutions for the Internet of Things, predictive analytics and machine learning, reducing asset downtime, data visualization and cloud-based analytics. Customers can also engage specialists for remote asset and process monitoring, condition-based maintenance, and performance benchmarking.

“Industrial transformation is one of the largest, and most challenging, economic opportunities of our time. Marketplace will help our customers extend the value of their existing investments while laying the groundwork for new digital services,” said Martin Otterson, Senior Vice President of Customer Success at OSIsoft. “With Marketplace, customers will be able to connect with companies and service providers with deep experience in their fields and accelerate their journey for digital transformation.”

OSIsoft Marketplace participants and solutions include:

- National Instruments (NI) provides LabVIEW system design software and NI InsightCM Enterprise software for condition monitoring, which can bidirectionally communicate with the PI System

- Rockwell Automation, which integrates the PI System into its FactoryTalk platform, making it easy to aggregate plant automation data across the enterprise for real-time insights

- Power Factors, providing high-quality, independent performance data for renewable energy, which allows owners and operators to standardize across their diverse portfolios and drive improvements in the physical and financial performance of their assets.

- Element Analytics, an advanced industrial analytics software company that rapidly builds Asset Frameworks through software and empowers organizations to achieve new levels of operational performance, by rapidly turning data into actionable reliability, productivity, and sustainability insights.

- eVision Industry Software creates best-in-class Control of Work software. Innovative solutions that improve the way oil, gas, chemical and other hazardous industries operate on a global and local scale. eVision’s integration with the PI System provides users with real-time situational awareness, from permit draft to control room.

The OSIsoft partner EcoSphere helps customers maximize the value of their PI System infrastructure. Over 300 companies are official members of the OSIsoft Partner Ecosphere. In addition to the Marketplace, the Partner EcoSphere provides accreditation and specialization programs to recognize individuals from partner companies who have completed comprehensive technical training requirements. Globally, 250 people from more than 40 partner companies are accredited PI System specialists.

Industrial Internet of Things

The second announcement concerns collaboration with partners such as Advantech/B+B SmartWorx, ADLink, Arrow and RtTech to encourage the development of new products and offerings that will deploy PI-based gateways, for example, to link facilities data to production data or enable pipeline companies to harvest data in remote locations.

“Our customers face a digital dilemma. They want to invest in new IIoT technology and begin to capture and analyze new sources of data. At the same time, they worry about incompatibilities or integration challenges that can outweigh the benefits,” said Otterson. “Through these partnerships we can eliminate these problems by ensuring that these new sources of data can be added to existing data infrastructures easily. Ultimately we want to make it easier for any authorized person to get insight into any device or process at any time.”

OSIsoft has prepared a software portfolio for edge gateway hardware providers and others that contain the necessary PI System technology to accelerate connectivity with remote and mobile assets, IIoT sensors and the PI System. With this combination of OSIsoft software and partner hardware technology, OSIsoft enables a host of partners including equipment suppliers, application providers and system integrators to quickly and easily create solutions at the edge. This will allow customers to run the PI System closer to remote assets – transformers, gas compressor stations, distributed gas, electric and water meters, industrial vehicles, wind turbines – where the data can be stored, viewed, and analyzed, enabling robust data collection, faster decision making, and optimized network bandwidth utilization.

IIoT in Action

In addition, where existing control and monitoring systems cannot accommodate new sensors, or are too costly to upgrade, new streams of IIoT sensor-based data can be added in parallel to existing process data and viewed in a common interface.

As an early advocate of using the PI System for IIoT, RtTech is blazing the trail on what’s possible when combining these technologies. RtTech, for instance, is working with tissue manufacturers to instrument and monitor remote ‘log saws’ that cut lengthy tubes of paper into rolls of toilet paper or other consumables. Because of their isolation and age, the only option for monitoring their health was to rely on manual inspections with pencils and clipboards, or complex retrofits that are often cost prohibitive.

Using new edge gateway technology with integrated PI system technology, RtTech’s energy and reliability apps can now help with efficiency and energy savings on remote equipment. As a result, customers now have operational insight into isolated equipment and can take corrective actions in real time.

“We’ve seen manufacturers reduce power consumption by 7%, increase asset availability by as much as 10% and improve event capture rates to 99% accuracy,” said Keith Flynn, President of RtTech. “By working with OSIsoft and using IIoT technology, we are pushing these same outcomes to remote operations and assets regardless of their location. We want our customers to have the same insight and intelligence on all their equipment, local or remote.”

by Gary Mintchell | Mar 14, 2017 | Data Management, Internet of Things, Operations Management, Software

Connecting your plant devices through the Industrial Internet of Things (IIoT) generates lots of data; but, without powerful analytics and visualization, it’s all meaningless.

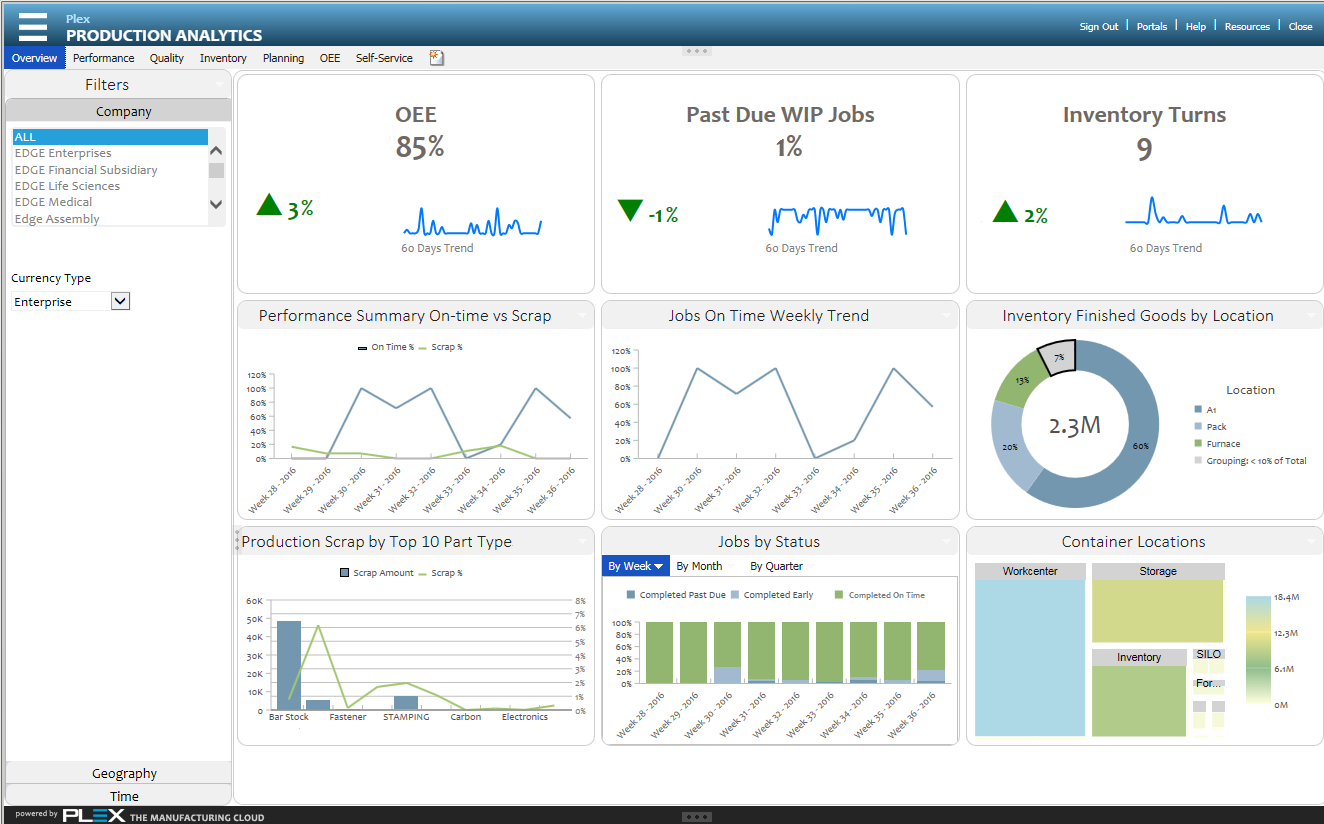

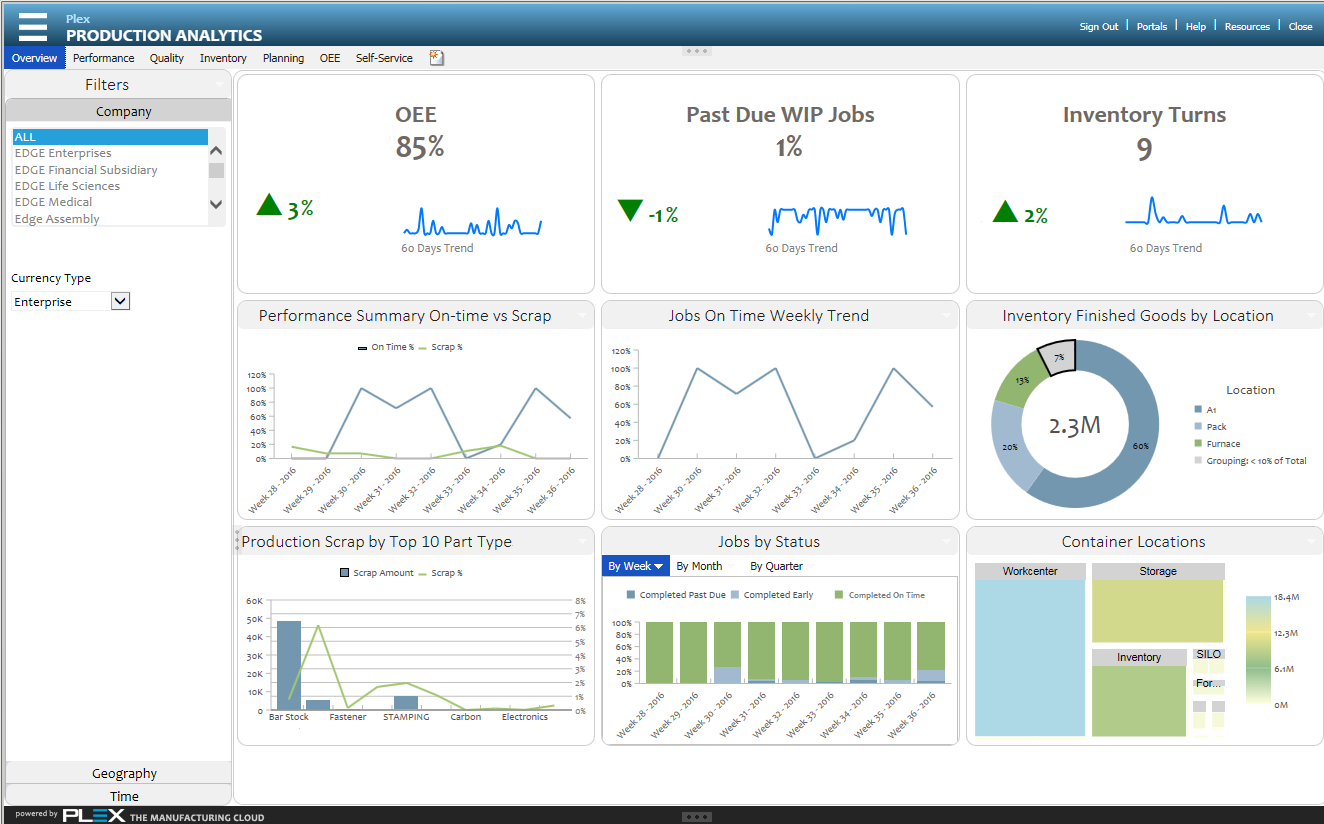

Therefore, Plex today announced a new analytics product.

The IntelliPlex Production Analytic Application, available now, taps IIoT data to provide manufacturing leaders with enterprise-wide insight into the performance of production operations, including processes and equipment on the shop floor.

The IntelliPlex Production Analytic Application, available now, taps IIoT data to provide manufacturing leaders with enterprise-wide insight into the performance of production operations, including processes and equipment on the shop floor.

This application adds to Plex’s IntelliPlex Analytic Application Suite, which includes applications for sales, order management, finance and procurement. This suite, with the addition of production analytics, delivers to manufacturers the industry’s most comprehensive cloud analytics, uniquely providing visibility all the way down to the shop floor.

The Plex Manufacturing Cloud is a comprehensive platform for manufacturing enterprises, connecting suppliers, customers, people, equipment, materials and finances across multiple facilities to form the technology backbone of an organization. Plex uses real-time IIoT connections as a core mechanism for managing manufacturing operations and enterprise resource planning.

That comprehensive view means Plex not only streamlines and automates operations, but also enables unprecedented access to companywide information including IIoT data. The IntelliPlex suite of analytic applications turns that data into configurable, role-based, decision support dashboards – with deep drill-down and drill-across capabilities. Plex first introduced the IntelliPlex Analytic Application Suite in 2016 with turnkey analytics for sales, order management, procurement and finance professionals.

- The IntelliPlex Production Analytic Application provides insight into key performance measures such as overall equipment effectiveness (OEE), scrap rates, first pass yield, inventory turns, on-time jobs and machine availability.

- IntelliPlex is configurable, so users can create custom performance dashboards and combine metrics to form their own analysis based on the wealth of data stored in the Plex Manufacturing Cloud.

- IntelliPlex analytics are also drillable, enabling users to instantly go from top-line performance analysis directly into data and details across plants, time and geographies.

- IntelliPlex applications are easy to activate as part of the Plex Manufacturing Cloud, and can be quickly extended and configured to match an organization’s evolving needs over time.

- The Production Analytic Application is available now.

Plex is planning to deliver additional analytic applications, including supply chain and human capital management. All applications are accessible to customers without the need for a lengthy implementation process.

“At Plex, we know that the best manufacturing organizations are built on the shop floor and that operational excellence is the foundation of product quality, company growth, and profitability,” said Karl Ederle, group vice president of products for Plex. “The IntelliPlex Production Analytic Application is unique because it provides an enterprise-wide view of manufacturing performance, combined with the ability to tap into the IIoT signals from equipment on a specific production line. Plex now offers customers analysis of their organization that truly spans from shop floor equipment to the financial bottom line.”

“This is not an IT tool, it’s an empowerment tool,” said Janice D’Amico, Plex specialist lead, Hatch Stamping. “The IntelliPlex Production Analytic Application has given Hatch access to accurate, near real-time data cross-enterprise that is user-friendly – easy to create, understand and share. We see this application being used at all levels of the organization to make better business decisions. The opportunities are endless.”

“In many manufacturing organizations, there is a communication breakdown between the front office and the shop floor,” said Alexi Antonio, Plex Analytics product lead. “Because the three OEE production metrics—performance, quality, and availability—are not expressed in monetary units, daily efforts to improve processes using OEE alone do not always translate into bottom-line savings. Plex puts OEE and financial metrics into a single dashboard, for the first time giving manufacturing leaders the ability to see and manage complete business performance.”

by Gary Mintchell | Mar 8, 2017 | Automation, Internet of Things, Manufacturing IT, Operations Management, Technology

You’re a technology provider and wish to expand your presence in the Internet of Things (IoT) space? Build partnerships. I’ve written about several over the past year. There will be more. This is the age of partnership. Right now companies have figured out that they cannot be all things to all people.

Here is an interesting one. Opto 22 is not a large company, but because of that it is always pushing the envelope of OT and IT applications. On the other hand, we have IBM, a huge company, and its vaunted Watson super computer technology. A little like peanut butter and chocolate, looks like a winning combination.

Industrial automation manufacturer and Internet of Things application toolset provider Opto 22 announced it has been accepted into the IBM® Watson IoT™ Partner Ecosystem. This partnership provides developers with a full stack toolset for building applications that connect real-world signals and data from industrial “things” to the digital world of information technology, mobile, and cloud computing.

Industrial automation manufacturer and Internet of Things application toolset provider Opto 22 announced it has been accepted into the IBM® Watson IoT™ Partner Ecosystem. This partnership provides developers with a full stack toolset for building applications that connect real-world signals and data from industrial “things” to the digital world of information technology, mobile, and cloud computing.

Tapping A $6 Trillion Opportunity

A Business Insider report forecasts there will be $4.8 trillion in aggregate IoT investment between 2016 and 2021. Billions of sensors, machines, and devices already exist in industrial infrastructure but are currently unable to connect to the Internet of things and cloud-based applications, like the IBM Watson IoT Platform.

This legacy equipment holds valuable untapped data that is needed to improve business processes and decisions in almost every enterprise and every industry. The partnership between IBM and Opto 22 enables developers to rapidly design, prototype, and deploy applications to connect existing industrial assets to the IBM Watson IoT platform and share their data, capabilities, and resources with other connected systems and assets, to build the Industrial Internet of Things (IIoT).

Building IIoT applications has historically been complex, requiring multiple layers of expensive middleware and significant developer manpower. IIoT applications built from the ground up can take months or even years, and require expertise in both the operations technology (OT) domain, where industrial assets live, and the information technology (IT) domain, where digital and cloud computing assets exist. These long development cycles increase cost, slow time to market, and increase risk of IIoT project failure for customers. Together these problems delay and reduce the return on investment for implementing IIoT applications.

Streamlining and Simplifying IIoT Application Development

Through this partnership, developers and systems integrators have a concise toolset for connecting the OT and IT domains. Combining open technologies like RESTful APIs and Node-RED with powerful and proven computing platforms like the IBM Watson IoT platform decreases development time, eliminates the need for expensive middleware, reduces risk for customers, and gets solutions to market faster.

According to Evans Data Corporation, 79% of Internet of Things app developers spend at least 25% of their time on developing analytics tools. The Watson IoT Platform reduces the need to focus on developing analytics systems and provides everything needed to harness the full potential of the Internet of Things. Rather than reinventing the wheel, developers can tap into the already built toolset provided by the IBM Watson IoT Platform.

Developers can connect, set up, and manage edge processing devices like programmable automation controllers from Opto 22 and apply real-time analytics, cognitive services, and blockchain technology to the data generated by these devices. Cognitive APIs deliver natural-language processing, machine-learning capabilities, text analytics, and image analytics to help developers realize the potential of the cognitive era with the IBM Watson IoT Platform.

“The industrial automation and control industry is in transition right now,” says Benson Hougland, Vice President of Marketing and Product Strategy. “A product development strategy based on proprietary and closed technologies is outdated. The future of industrial automation and process control lies in the rising API and data economies made possible through open standards-based technologies. Our objective in partnering with IBM is to enable IIoT developers to build their applications faster using well-known and proven Internet tools and technology like Node-RED, RESTful APIs, and the IBM Watson IoT Platform.”

Getting Started With Opto 22 and IBM Watson IoT

Opto 22 has provided a recipe for developers to get started in connecting industrial systems to the Watson IoT Platform, as well as a video walking developers through the steps. Developers can access a trial version of the Watson IoT Platform on the IBM website.

Honeywell Process Solutions (HPS) announced

Honeywell Process Solutions (HPS) announced  Currently, many plants either ban USBs, which is difficult to enforce and significantly reduces productivity, or rely on traditional IT malware scanning solutions, which are difficult to maintain in an industrial control facility and provide limited protection. These solutions fail to protect process control networks against the latest threats, and offer no means to address targeted or zero-day attacks.

Currently, many plants either ban USBs, which is difficult to enforce and significantly reduces productivity, or rely on traditional IT malware scanning solutions, which are difficult to maintain in an industrial control facility and provide limited protection. These solutions fail to protect process control networks against the latest threats, and offer no means to address targeted or zero-day attacks.

The IntelliPlex Production Analytic Application, available now, taps IIoT data to provide manufacturing leaders with enterprise-wide insight into the performance of production operations, including processes and equipment on the shop floor.

The IntelliPlex Production Analytic Application, available now, taps IIoT data to provide manufacturing leaders with enterprise-wide insight into the performance of production operations, including processes and equipment on the shop floor. Industrial automation manufacturer and Internet of Things application toolset provider Opto 22 announced it has been accepted into the IBM® Watson IoT™ Partner Ecosystem. This partnership provides developers with a full stack toolset for building applications that connect real-world signals and data from industrial “things” to the digital world of information technology, mobile, and cloud computing.

Industrial automation manufacturer and Internet of Things application toolset provider Opto 22 announced it has been accepted into the IBM® Watson IoT™ Partner Ecosystem. This partnership provides developers with a full stack toolset for building applications that connect real-world signals and data from industrial “things” to the digital world of information technology, mobile, and cloud computing.