by Gary Mintchell | Jan 12, 2016 | Automation, Internet of Things, Networking, News, Operations Management

Business around the Industrial Internet of Things must be maturing. I just received news of another acquisition. In the case, the acquired company has also been changing itself in response to changing landscape of industrial networking. The Advantech CEO called this a merger, but I think that’s a bit disingenuous. When a $1.2 billion company and a $0.1 billion company come together, well, you can see the picture.

Business around the Industrial Internet of Things must be maturing. I just received news of another acquisition. In the case, the acquired company has also been changing itself in response to changing landscape of industrial networking. The Advantech CEO called this a merger, but I think that’s a bit disingenuous. When a $1.2 billion company and a $0.1 billion company come together, well, you can see the picture.

Taiwanese industrial computing manufacturer Advantech announced the completion of its acquisition of privately-held industrial intelligent networking specialist B+B SmartWorx for the US$99.85 million agreement announced November 16.

Ottawa, IL-based B+B will continue to be led by its current management team, operating as Advantech B+B SmartWorx, and will lead Advantech’s new Intelligent Networking Business Sector in developing smart networking products as part of the company’s Global Industrial IoT Business Group.

The two companies’ complementary product lines brought them together often over the last decade to collaborate on industrial connectivity projects, so the combination of the two companies felt natural. The merger creates a $1.3 billion company with approximately 7,600 employees worldwide.

“B+B has undergone a transformation over recent years, acquiring several companies itself and developing technologies that bring ‘intelligence to the network edge’ to address evolving needs in the Industrial IoT (IIoT) market,” said B+B CEO Jerry O’Gorman. “We are pleased to join forces with Advantech, a global leader who shares our strategic view of the future.”

With B+B SmartWorx now a part of its portfolio, Advantech said it aims to accelerate its growth in industrial network connectivity-related products. The company will leverage B+B’s established branding, product lines, engineering teams and sales channels in the U.S., Europe and the Middle East, and it will also begin selling B+B’s device connectivity products, cellular routers, gateways and the Wzzard wireless sensing platform into Asia. Products will retain B+B branding, bolstered by Advantech’s name recognition, and sold as “B+B SmartWorx powered by Advantech.”

Advantech chairman KC Liu explained that Advantech views this acquisition more as a merger, seeing value in all of B+B’s networking products from wired networking and fiber infrastructure to wireless connectivity. “B+B has in particular struck a nerve with its Wzzard wireless sensing system which satisfies enterprise IT’s desire to receive data from the field, and overcomes field OT’s (operational technology) fear of disruption, by creating ‘overlay networks’ that leave existing programming, processes and people in place,” said Liu.

B+B’s Wzzard together with its routers and gateways complement Advantech’s own WISE wireless sensing platform, and company engineers will be developing solutions leveraging the strength of both platforms.

by Gary Mintchell | Dec 11, 2015 | Automation, Internet of Things, Networking, Operations Management, Software, Technology

National Instruments is a company started by technologists and continues to this day as a company full of technologists–many studying industrial networking and engineering software. They really watch new technologies and watch for trends. The past couple of years the company has been issuing a “Trend Watch” document.

Two items in the 2016 Trend Watch piqued my interest, so I was able to talk with Jeffrey Phillips, Section Manager, Software Platform Marketing, and Nick Butler, Sr. Group Manager, Embedded Systems Product Marketing, to flesh out the two trends and what they mean in the area I cover–Consumerization of Software and Standardization of Networks for Internet of Things.

Consumerization of Software

The idea behind the “consumerization of software” trend is an expansion of things we’ve seen building for years–new engineers are coming into the marketplace with far different experiences interacting with technology than us old guys. I still like text. I started out with BASIC, C, scripts, Java–text things. Ladder Diagram is a visual “language” and I found it arcane and difficult to work with.

The idea behind the “consumerization of software” trend is an expansion of things we’ve seen building for years–new engineers are coming into the marketplace with far different experiences interacting with technology than us old guys. I still like text. I started out with BASIC, C, scripts, Java–text things. Ladder Diagram is a visual “language” and I found it arcane and difficult to work with.

Think about toda y’s engineers. We pretty much learned one language at a time and specialized. Today, graduates move fluidly among several language. But their experience is with touch and graphic interfaces.

y’s engineers. We pretty much learned one language at a time and specialized. Today, graduates move fluidly among several language. But their experience is with touch and graphic interfaces.

So?

NI Software Trend Description

Engineering software users of the past typically graduated from a university with an understanding of one programming language. Some were even experienced users who demanded exposure to the darkest corners of programming, with custom memory calls, from-scratch multithreading commands, and hand-optimized performance demands. Software was hard and unapproachable to those who dared to enter without proper training and previous exposure.

And just like that, things started to change. First, graduating engineers were required to have a broad skillset of programming languages to tackle the challenges handed to them in the workplace. Like a trained warrior switching from sword to axe to bow, today’s engineer can jump in and out of Python, C#, HTML, JavaScript, LabVIEW, and Swift. This puts an unprecedented demand on approachability and removes the expectation of expertise. Today’s engineer expects to use multiple tools for any given application.

Secondly, the cost of accessing and acquiring data has rapidly decreased while the need for data has risen. And as technology has become more connected, the cost of processors has declined. According to DataBeans, the price of a processor decreased over 30 percent between 2011 and 2015. This has accelerated the need for highly approachable software by introducing more “nontraditional” programmers to the worlds of robotics, home automation, and even general data acquisition and analysis. Likewise, cultural trends like the Maker Movement and the emergence of consumer product start-ups being acquired for unreal amounts of money further illustrate this shift.

An Inevitable Convergence

For engineers, who are defined by the pride of conquering complex challenges, this confluence of usability and technical sophistication couldn’t come at a better time. No longer tethered and bogged down by the intricate details of multiple languages, tools, and approaches (like writing an actor framework), they can now refocus on engineering’s most grand and impactful challenges (like 5G research and the IoT). In this new tightly integrated future, engineers can find better, faster ways from point A to point B instead of spending their time making better maps.

Likewise, this convergence means that engineers can embrace a future in which they aren’t sole proprietors of innovation. With software that is (gasp) easy to use, the rest of the world is catching up. And by acknowledging the prevalence of simplicity and beauty in software of all stripes, more and more smart people will play meaningful roles in major problem solving.

Standardized industrial networking for IoT

The Industrial Internet of Things (IIoT) promises a world of smarter, hyper-connected devices and infrastructure where electrical grids, manufacturing machines, and transportation systems are outfitted with embedded sensing, processing, control, and analysis capabilities.

The Industrial Internet of Things (IIoT) promises a world of smarter, hyper-connected devices and infrastructure where electrical grids, manufacturing machines, and transportation systems are outfitted with embedded sensing, processing, control, and analysis capabilities.

NI technologists are evaluating (and working on the standard) a new standard for Ethernet networking. Time-Sensitive Networking (TSN) will evolve Ethernet to provide reliable, remote, and secure access to smart edge devices. One key aspect is the development of edge devices that can combine local control and information filtering such that only important data are transmitted rather than the flood of all data.

From the Trend Watch paper an explanation of TSN:

TSN: The Time is Now

Industrial suppliers, IT vendors, and silicon providers are collaborating within IEEE 802 and the recently formed AVnu Alliance to update standard Ethernet protocols and provide bounded, low-latency data transfer for time-critical data in IIoT applications.

The AVnu Alliance, working with companies such as Broadcom, Cisco, Intel, and NI, will drive the creation of an interoperable ecosystem through certification, similar to how the Wi-Fi Alliance certifies products and devices to be compatible with the IEEE 802.11 standard. The new TSN standard will provide numerous benefits, including the following:

Bandwidth—Large data sets from advanced sensing applications such as machine vision, 3D scanning, and power analysis can put a strain on network bandwidth. Proprietary Ethernet derivatives commonly used for industrial control today are limited to 100 Mb of bandwidth and half-duplex communication. TSN will embrace standard Ethernet rates and support full-duplex communication.

Security—TSN protects critical control traffic and incorporates top-tier IT security provisions, while segmentation, performance protection, and temporal composability can add multiple levels of defense to the security framework.

Interoperability—By using standard Ethernet components, TSN can integrate with existing brownfield applications and standard IT traffic to improve ease of use. TSN inherits many features of existing Ethernet, such as HTTP interfaces and web services, which enable the remote diagnostics, visualization, and repair features common in IIoT systems. As an added benefit, leveraging standard Ethernet chipsets drives component cost down by virtue of high-volume, commercial silicon.

Latency and Synchronization—TSN prioritizes the low-latency communication required for fast system response and closed-loop control applications. It can achieve deterministic transfer times on the order of tens of microseconds and time synchronization between nodes down to tens of nanoseconds. To ensure reliable delivery of this time-critical traffic, TSN provides automated configurations for high-reliability data paths, where packets are duplicated and merged to provide lossless path redundancy.

by Gary Mintchell | Dec 5, 2015 | Automation, Internet of Things, Networking, Operations Management, Standards

Katherine Voss, president and executive director of ODVA

ODVA announced several enhancements to its EtherNet/IP and CIP specifications during the SPS IPC Drives Trade Fair in Nuremberg. The first relates to cybersecurity. The second involves time-sensitive networking.

ODVA announced that it has achieved a milestone with the pending publication of a new volume in its specifications specifically dedicated to cybersecurity. This body of work will be released under the name of CIP Security and will join the family of distinctive CIP services which includes CIP Safety, CIP Energy, CIP Sync, and CIP Motion. CIP Security will be initially applicable to EtherNet/IP.

Because EtherNet/IP relies on commercial-off-the-shelf (COTS) technologies for Ethernet and the Internet, users have been able to deploy traditional defense-in-depth techniques in EtherNet/IP systems for some time, explained by ODVA as early as 2011 in its publication “Securing EtherNet/IP Networks.” CIP Security will help users take additional steps to protect their industrial control systems with industry-proven techniques for securing transport of messages between EtherNet/IP devices and systems and thus reduce their exposure to cybersecurity threats.

The initial release of CIP Security includes mechanisms to address spoofing of identity, tampering with data and disclosing of information. Mechanisms supported in the initial release of CIP Security include device authorization, integrity of message transport and confidentiality of messages. To support these mechanisms, ODVA has adapted encryption standards from the Internet Engineering Task Force (IETF) for encryption based on Transport Layer Security (TLS), Data Transport Layer Security (DTLS) and authentication based on the X.509v3 standard for certificate handling. Details of ODVA’s initial implementation of CIP Security and outlook for the future were presented in a technical paper at ODVA’s 2015 Industry Conference and 17th Annual Meeting of Members.

“The publication of the volume dedicated to cybersecurity in The EtherNet/IP Specification is the next step in providing users with methods to help them manage threats and vulnerabilities in EtherNet/IP systems,” said Katherine Voss, ODVA president and executive director. “Following this publication will be the realization of the mechanisms provided by CIP Security in ODVA CONFORMANT EtherNet/IP products.”

ODVA’s focus on cybersecurity is not only a function of increased emphasis on cybersecurity for industrial control systems but also because of the widespread adoption of EtherNet/IP in broad range of applications from manufacturing to critical infrastructure. As a result of the breadth of applications, the next edition of The EtherNet/IP Specification will expand support for IEC 62439-3 “Industrial communication networks – high availability automation networks – part 3” to include High Availability Seamless Redundancy (HSR) in addition to Parallel Redundancy Protocol (PRP). HSR is commonly used in electrical substation automation as specified in IEC-61850. Other high reliability techniques supported in The EtherNet/IP Specification include Rapid Spanning Tree (RSTP) and Device Level Ring (DLR).

Other ODVA Industrial Networking News

One area of focus will be the adaptation of certain emerging standards for Time-Sensitive Networking (TSN) to EtherNet/IP. In particular, ODVA will create enhancements to The EtherNet/IP Specification for frame preemption and stream reservation based on the standards being defined in the IEEE-802.1 projects. ODVA’s adaptation of TSN technologies is a straightforward evolution of the EtherNet/IP technology, which relies on commercial-off-the-shelf (COTS) technologies for Ethernet and the Internet to solve demanding applications in industrial automation. Users of EtherNet/IP will be able to realize performance improvements in systems using EtherNet/IP by as much as two orders of magnitude by combining TSN with existing standards already included in The EtherNet/IP Specification, such as Quality of Service, Gigabit Ethernet and CIP Sync — ODVA’s adaptation of IEEE-1588.

To complement the adoption of EtherNet/IP in a diverse range of industries and applications, ODVA is expanding CIP to include data models to facilitate the exchange of application information within EtherNet/IP systems and between EtherNet/IP systems and supervisory systems which may or may not use EtherNet/IP. One application area where specification enhancements are underway is the adaptation of the recommendations in NAMUR NE-107 “Self-monitoring and Diagnosis of Field Devices“ to the data format and access methods needed to retrieve such process data from EtherNet/IP field devices. Another application area where enhancements to the ODVA specifications are expected in 2016 is the inclusion of a machine data model and services for machine-to-supervisory communications. By instantiating standards for application data models for process field devices and machinery, EtherNet/IP will provide yet another way for users to decrease their reliance on proprietary implementations by using vendor-independent standards designed for multi-vendor interoperablity.

ODVA is now expanding The EtherNet/IP Specification to include standards for the integration of data between EtherNet/IP and HART and IO-Link. Joining the already-published integration of data between EtherNet/IP and Modbus-TCP, these standards will allow users to accelerate their progress towards a converged network architecture.

“Because EtherNet/IP is based on commercial-off-the-shelf technologies and uses widely accepted standards from the Ethernet and Internet, EtherNet/IP is now a major industry catalyst for the realization of the Industrial Internet of Things,” said Katherine Voss, ODVA president and executive director. “The enhancements to EtherNet/IP that are underway for 2016 are at the forefront of innovations that are driving the future of industrial automation toward the fourth industrial revolution.”

by Gary Mintchell | Jun 29, 2015 | Automation, Internet of Things, Networking, News, Operations Management, Technology

The Internet of Things (IoT) is nothing if not about connectivity. Connecting edge devices to control and information platforms is nothing new to industrial systems, but technology advances attempt to make things easier and faster to deploy.

The Internet of Things (IoT) is nothing if not about connectivity. Connecting edge devices to control and information platforms is nothing new to industrial systems, but technology advances attempt to make things easier and faster to deploy.

Cisco’s connectivity products and technologies have long been at the core of enterprise networks. Cisco has also partnered with automation companies such as Rockwell Automation, Emerson Process Management, and Honeywell Process Solutions.

Cisco just announced its latest extensions to the technology. The new Cisco IoT System addresses the complexity of digitization “with an infrastructure that can manage a growing mix of endpoints, platforms and the data deluge.”

Within the new Cisco IoT System framework, Cisco introduced more than 15 new IoT products across six pillars to address the complexities of digitization and help organizations deploy, accelerate and innovate with IoT. Together, the framework supports the infrastructure growth requirements that organizations are facing with IoT by helping raise operational efficiency, create new services, and improve quality and security.

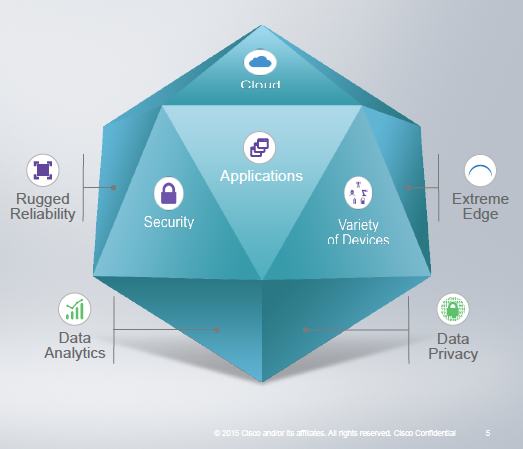

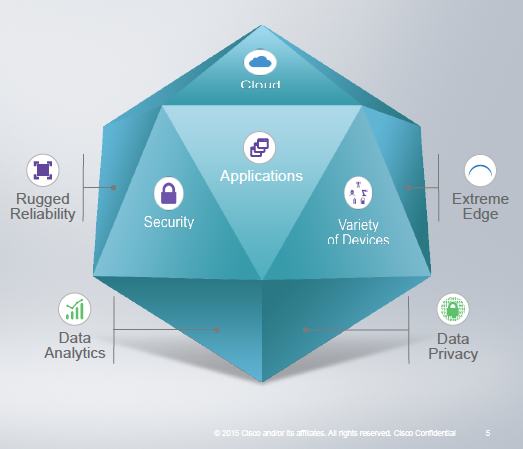

Six‐Pillar Approach for Cisco IoT System

The Cisco IoT System integrates six pillars that must come together for a successful IoT solution and deployment:

- Network Connectivity: Includes purpose-‐built routing, switching, and wireless products available in ruggedized and non‐ruggedized form factors.

- Fog Computing: Extends cloud connectivity closer to the edge to produce immediate insights and efficiently analyze and manage d Cisco predicts that 40% of IoT ‐created data will be processed in the fog by 2018. Over 25 of Cisco’s network products are enabled with Cisco’s fog computing or edge data processing platform, IOx.

- Security: Connects cyber and physical security for visibility into both physical and digital assets, to increase protection and expand operational benefit Cisco’s IP surveillance portfolio and network products with TrustSec security and cloud/cyber security products allow users to monitor, detect and respond to combined IT and Operational Technology (OT) attacks. Organizations in industries such as manufacturing and energy are increasingly working to integrate proprietary process control systems with the IP network infrastructure, which requires a multi‐layer security approach to maintain logical separation of business functions.

- Data Analytics: The Cisco IoT System provides an optimized infrastructure to implement analytics and harness actionable data for both the Cisco Connected Analytics Portfolio and third party analytics

- Management and Automation: The IoT System provides enhanced security, control and support for multiple siloed functions to deliver an easy-‐to-‐use system for managing an increasing volume of endpoints and applications, that field operators need an easy-‐to-‐use management system

- Application Enablement Platform: Offers a set of APIs for industries and cities, ecosystem partners and third-‐party vendors to design, develop and deploy their own applications on the foundation of IoT System capabilities.

Over 15 new IoT products across the six pillars of the IoT System:

Network Connectivity Highlights:

IE5000: Purpose-‐built IE switch that brings connectivity to factory-‐level manufacturing and cities.

IW3702: Wireless access point for connected mass transit systems and city Wi-‐Fi. IR 809, IR 829 series: Introducing 7 new industrial routers with Wi-‐Fi and 4G/LTE connectivity, ideal for transportation or IoT application deployments.

4G/LTE module for CGR 1000 for utilities, Mobile IP Gateway (MIG-‐2450) for connected rail solutions, and 5921 Embedded Services Routers for defense extend reach of industrial networking into remote environments.

Physical and Cyber Security

360° 5MP & 720p IP cameras: These high-‐quality cameras cater to versatile environments and can host 3rd party software applications. Features include 360° view for situational awareness and audio and digital sensors.

Physical Security Analytics: Camera applications include audio detection, sensor aggregation, audio message triggers, metadata generation, local video player and video summarization.

Data Analytics

Fog Data Services: Allow operators to create policies that monitor and take actions on data flowing through the IoT environment (data-‐in-‐motion). It resides on the IOx platform so users can integrate custom policies with applications.

Management and Automation

IoT Field Network Director: This management software allows operators to monitor and customize IoT network infrastructure for industrial scale.

Fog Director: Allows central management of multiple applications running at the edge. This management platform gives administrators control of application settings and lifecycle, for easier access and visibility into large-‐scale IoT deployments.

Partners support Cisco IoT System and IOx for fog computing

Cisco IoT System enables industry verticals such as manufacturing, oil & gas, utilities, transportation, public safety and smart cities to deploy and accelerate IoT solutions and realize business benefits with targeted solutions. Key industry leaders have already ported their software applications to run on the Cisco Fog Computing system, including GE (Predix), Itron (Riva), OSISoft (PI), smartFOA in Japan, Bitstew, Davra, SK Solutions, Toshiba and more.

Cisco also announced the addition of Covacsis, which is taking advantage of Cisco IOx to provide predictive analytics to manufacturing industries. Cisco also provides comprehensive consulting and professional services for IoT. Our leading networking expertise combined with our technology partners’ expertise helps accelerate transformation and ensures IT and operational technology alignment.

Sujeet Chand, senior vice president and CTO, Rockwell Automation, noted, “Together with Cisco, we are helping customers derive value from the Internet of Things, by simplifying connectivity of assets on the plant floor with the rest of the enterprise and with remote experts. By focusing on the key values of the Cisco approach to IoT, our mutual customers can benefit from improved decision making that can lead to streamlined business and manufacturing processes, reduced network complexities and improved security. Rockwell Automation and Cisco take a collaborative approach to bring OT and IT together to deliver performance-‐critical information to drive business outcomes across The Connected Enterprise.”

Sujeet Chand, senior vice president and CTO, Rockwell Automation, noted, “Together with Cisco, we are helping customers derive value from the Internet of Things, by simplifying connectivity of assets on the plant floor with the rest of the enterprise and with remote experts. By focusing on the key values of the Cisco approach to IoT, our mutual customers can benefit from improved decision making that can lead to streamlined business and manufacturing processes, reduced network complexities and improved security. Rockwell Automation and Cisco take a collaborative approach to bring OT and IT together to deliver performance-‐critical information to drive business outcomes across The Connected Enterprise.”

by Gary Mintchell | Jun 18, 2015 | Automation, Internet of Things, Networking, News, Operations Management, Security

The Cisco and Rockwell Automation partnership continues its step-by-step extension strengthening Rockwell’s “Connected Enterprise” strategy. This strategy builds on the foundation of EtherNet/IP and CIP (common industrial protocol). Now that all the magazines and newspapers and bloggers are writing about the Internet of Things and the Industrial Internet of Things, supplier communications managers cannot keep themselves from applying IoT to everything their companies do.

The two companies have issued two press releases recently. One concerns enhanced training couched in the strategy of bringing IT and OT together (the once and future kingdom). The other relates to extensions and additions to the partners’ reference architecture.

First, let’s see how many buzz words a marketing manager can fit into one sentence:

“The expansion of the Industrial Internet of Things (IoT) and convergence of operations technology (OT) and information technology (IT) systems into The Connected Enterprise raises questions of who within industrial organizations should design and oversee unified network infrastructures. Rockwell Automation, in collaboration with its Strategic Alliance partner Cisco, is helping address this workforce challenge with the new training and certification offerings.”

Last year, the companies jointly rolled out the Managing Industrial Networks with Cisco Networking Technologies (IMINS) training course and Cisco Industrial Networking Specialist certification. This first-of-its-kind course provided foundational skills needed to manage and administer networked, industrial control systems.

This year, Rockwell Automation and Cisco are unveiling the five-day, hands-on Managing Industrial Networks for Manufacturing with Cisco Technologies (IMINS2) course and CCNA Industrial certification exam. The course offers deeper analysis of EtherNet/IP architectures with industrial protocols, wireless and security technologies implementation, and advanced troubleshooting. The CCNA Industrial certification ensures that OT and IT professionals have the skillset needed to design, manage and operate converged industrial networks.

Pathways to Certification

Students who successfully complete the Industrial Networking Specialist and CCNA Industrial certification exams will earn CCNA Industrial certification. Alternatively, IT and OT professionals that already have their CCNA Routing & Switching or Cisco Certified Entry Networking Technician (CCENT) certification can enroll directly in IMINS2 and take the CCNA Industrial certification exam to receive CCNA Industrial certification. Once completed, the certification is valid for three years.

Participants in the IMINS and IMINS2 courses will receive exam vouchers for the Industrial Networking Specialist and CCNA Industrial certification exams, respectively, as part of course tuition. This offer is only available through courses offered and delivered by Rockwell Automation. The CCNA Industrial certification exam can be taken at one of any Pearson VUE testing centers located in more than 165 countries.

IMINS courses are offered on an ongoing basis. The enrollment schedule for IMINS2 will be posted in June, with classes beginning in July. As the leader in OT/IT skills development, Rockwell Automation will continue to invest in The Connected Enterprise and IoT training curriculum to address emerging skills requirements.

Converged Plantwide Ethernet Architectures (CPwE)

As industrial markets evolve to unlock the promise of the Internet of Things (IoT), Rockwell Automation and Cisco are announcing new additions to their Converged Plantwide Ethernet (CPwE) architectures to help operations technology (OT) and information technology (IT) professionals address constantly changing security practices. The latest CPwE security expansions, featuring technology from both companies, include design guidance and validated architectures to help build a more secure network across the plant and enterprise.

The Industrial IoT is elevating the need for highly flexible, secure connectivity between things, machines, work flows, databases and people, enabling new models of policy-based plant-floor access. Through these new connections, machine data on the plant floor can be analyzed and applied to determine optimal operation and supply-chain work flows for improved efficiencies and cost savings. A securely connected environment also enables organizations to mitigate risk with policy compliance, and protects intellectual property with secure sharing between global stakeholders.

Core to the new validated architectures is a focus on enabling OT and IT professionals to utilize security policies and procedures by forming multiple layers of defense. A defense-in-depth approach helps manufacturers by establishing processes and policies that identify and contain evolving threats in industrial automation and control systems. The new CPwE architectures leverage open industry standards, such as IEC 62443, and provide recommendations for more securely sharing data across an industrial demilitarized zone, as well as enforcing policies that control access to the plantwide wired or wireless network.

Rockwell Automation and Cisco have created resources to help manufacturers efficiently deploy security solutions. Each new guide is accompanied by a white paper summarizing the key design principles, as follows:

The Industrial Demilitarized Zone Design and Implementation Guide and white paper provide guidance to users on securely sharing data from the plant floor through the enterprise.

The Identity Services Design and Implementation Guide and white paper introduce an approach to security policy enforcement that tightly controls access by anyone inside the plant, whether they’re trying to connect via wired or wireless access.

This announcement further extends the commitment by Rockwell Automation and Cisco to be one of the most valuable resources in the industry for helping manufacturers improve business performance by bridging the gap between plant-floor industrial automation and higher-level information systems.

Business around the Industrial Internet of Things must be maturing. I just received news of another acquisition. In the case, the acquired company has also been changing itself in response to changing landscape of industrial networking. The Advantech CEO called this a merger, but I think that’s a bit disingenuous. When a $1.2 billion company and a $0.1 billion company come together, well, you can see the picture.

Business around the Industrial Internet of Things must be maturing. I just received news of another acquisition. In the case, the acquired company has also been changing itself in response to changing landscape of industrial networking. The Advantech CEO called this a merger, but I think that’s a bit disingenuous. When a $1.2 billion company and a $0.1 billion company come together, well, you can see the picture.

The idea behind the “consumerization of software” trend is an expansion of things we’ve seen building for years–new engineers are coming into the marketplace with far different experiences interacting with technology than us old guys. I still like text. I started out with BASIC, C, scripts, Java–text things. Ladder Diagram is a visual “language” and I found it arcane and difficult to work with.

The idea behind the “consumerization of software” trend is an expansion of things we’ve seen building for years–new engineers are coming into the marketplace with far different experiences interacting with technology than us old guys. I still like text. I started out with BASIC, C, scripts, Java–text things. Ladder Diagram is a visual “language” and I found it arcane and difficult to work with. y’s engineers. We pretty much learned one language at a time and specialized. Today, graduates move fluidly among several language. But their experience is with touch and graphic interfaces.

y’s engineers. We pretty much learned one language at a time and specialized. Today, graduates move fluidly among several language. But their experience is with touch and graphic interfaces.