by Gary Mintchell | Sep 7, 2016 | Internet of Things, Leadership, News

Once again, an industrial corporation striving for digitalization solutions looks to Silicon Valley. Industrial and automation companies continue to search outside the industry for talent. Often, they just don’t work out. The pace of change in industrial is so much slower and bureaucracies are so entrenched that they get frustrated and leave. This one from ABB is interesting. Will he be able to build a software division to rival GE? We’ll keep watching.

Once again, an industrial corporation striving for digitalization solutions looks to Silicon Valley. Industrial and automation companies continue to search outside the industry for talent. Often, they just don’t work out. The pace of change in industrial is so much slower and bureaucracies are so entrenched that they get frustrated and leave. This one from ABB is interesting. Will he be able to build a software division to rival GE? We’ll keep watching.

ABB has appointed Guido Jouret as Chief Digital Officer, reporting to ABB’s CEO Ulrich Spiesshofer, effective October 1, 2016. Labeled a “pioneer of the Internet of Things” by ABB, Jouret will lead the next level of development and deployment of ABB’s digital solutions for customers globally and across all businesses.

Jouret is a citizen of both the United States and Belgium, with long experience in Silicon Valley. He served for 20 years at Cisco after obtaining a PhD in Computer Science. His most recent role at Cisco was as General Manager of the Internet of Things division, which aims to connect billions of devices to the internet across a wide range of industries.

Prior to that, he was Chief Technology Officer and General Manager of Cisco’s Emerging Technologies Group, a unit responsible for incubating new businesses. Under his leadership, the team created nine new start-ups, including those, which became Cisco’s TelePresence and Internet of Things groups. He has lived in 12 countries including France, Singapore and the United States. Additionally, he worked for Cisco as IT Director for the Europe, Middle East and Africa region and in the Internet Business Solutions Group.

Jouret left Cisco in 2014 to join Envision Energy, where he led the software products business, including a platform for the emerging energy internet. Jouret has been Chief Technical Officer at Nokia Technologies since April 2015, and recently drove a major acquisition in the digital health sector.

“Guido Jouret is a proven leader in the digital revolution, with a solid track record in creating and growing new businesses as well as in the digital transformation of mature businesses. His global digitalization experience spans across companies in utilities, industry and transport & infrastructure,” said CEO Ulrich Spiesshofer. “With his customer and innovation focus, and his extensive international technology business experience, he is the ideal person to take the software-led differentiation of our offerings to the next level and to cement ABB’s pioneering technology leadership, building on our more than 40 years’ history in embedded, control and applications software and our strong position in the Internet of Things, Services and People.”

Jouret will work from ABB’s Silicon Valley and Zurich offices.

He obtained his PhD in Computer Science from the Imperial College of Science, Technology and Medicine in the UK in 1991, and has a bachelor’s degree in Electrical Engineering from Worcester Polytechnic Institute in the US. He is married and has two children.

by Gary Mintchell | Aug 26, 2016 | Interoperability, Standards

This snippet from the conversation shows some of the urgency:

The first is that the kinds of technologies that have access controls for copyrighted works have gone from these narrow slices (consoles and DVD players) to everything (the car in your driveway). If it has an operating system or a networking stack, it has a copyrighted work in it. Software is copyrightable, and everything has software. Therefore, manufacturers can invoke the DMCA to defend anything they’ve stuck a thin scrim of DRM around, and that defense includes the ability to prevent people from making parts. All they need to do is add a little integrity check, like the ones that have been in printers for forever, that asks, “Is this part an original manufacturer’s part, or is it a third-party part?” Original manufacturer’s parts get used; third-party parts get refused. Because that check restricts access to a copyrighted work, bypassing it is potentially a felony. Car manufacturers use it to lock you into buying original parts.

This is a live issue in a lot of domains. It’s in insulin pumps, it’s in voting machines, it’s in tractors. John Deere locks up the farm data that you generate when you drive your tractor around. If you want to use that data to find out about your soil density and automate your seed broadcasting, you have to buy that data back from John Deere in a bundle with seed from big agribusiness consortia like Monsanto, who license the data from Deere. This metastatic growth is another big change. It’s become really urgent to act now because, in addition to this consumer rights dimension, your ability to add things to your device, take it for independent service, add features, and reconfigure it are all subject to approval from manufacturers.

We are all familiar with lock in. Heck, I’ve been in some product development meetings where some of these things came up. “How can we keep customers with us and away from the competition?” they ask.

Meanwhile the customer says, “I’m pretty happy with your product now. But what if you start acting like Mylan and its EpiPen? I find myself locked in, and now I am susceptible to frequent price increases. Or what if your quality begins to dip? Not to mention, what is your incentive to innovate any longer?

And so, the inevitable dance continues.

I’m not opposed to big companies with comprehensive product offerings. Sometimes there is a lot of innovation. It takes a lot of money to invest in developing some of these products. Customers appreciate this. They welcome partners. They just want to see competition and alternatives. But sometimes the customer voice gets lost.

Sometimes I look at the situation as an independent analyst/writer not beholden to anyone and decide someone has to speak up for the customer.

by Gary Mintchell | Jul 11, 2016 | Internet of Things, News, Operations Management, Organizations, Technology

The Industrial Internet of Things is a phrase encompassing a range of technologies and applications across consumer and industrial worlds. Where there is a technology and/or new application with suppliers poised to provide the technology or application expertise, there is an organization. And the organization exists to provide information.

The Industrial Internet Consortium (IIC), the global, not-for-profit, open membership organization formed to accelerate adoption and enablement of the Industrial Internet of Things (IIoT), announced the second edition of The Journal of Innovation. A biannual publication written by IIC members, the second edition of The Journal of Innovation features articles about the Industrial Internet technologies and services that are disrupting the global economy.

“IIoT technologies and processes are expected to generate remarkable business outcomes that will impact the global economy across all industry sectors. The IIC Journal of Innovation showcases innovations driving this transformation through the integration of people, processes, and data,” said Dr. Richard Soley, Executive Director, Industrial Internet Consortium.

The Journal of Innovation includes the following articles about disruptive IIoT technologies authored by IIC member companies:

- Organizations can expect business-model disruption from IIoT platform innovations – an example in transportation – InterDigital.

- The requirements for a connected, interoperable environment for the Industrial Internet – Thingswise/GE Global Research.

- Developing secure, interconnected medical systems – Real-Time Innovations, Inc./Massachusetts General Hospital/Partners HealthCare.

- Vertical Taxonomy Landscape – the business dynamics and technical considerations of IIoT by industry sector – MITRE.

- How IIoT technologies are transforming retail – Tata Consultancy Services.

Note the keywords that are important to the entire IIoT ecosystem.

- Interconnected (key enabler)

- Interoperable (the data must be in a form to be used by multiple applications)

- Secure (if we are connecting plant assets, security is essential)

- Business-model disruption (bright people in a myriad of industries are figuring out new ways of doing business by utilizing data and advanced data analytics)

I took a few vacation days last week, so only a couple of posts. Remember to check out my podcast on Deep Work. I’ll also be taking a couple of days off this week. Tuesday evening I will be moderating another Dell Think Tank (this one in suburban Chicago) on IIoT. Many people are interested in the concept. They just need to figure out what it means to them and how they can use it.

by Gary Mintchell | May 27, 2016 | Automation, News

The 2016 edition of Schneider Electric’s Foxboro/Triconex/Modicon user group meeting attracted a fair number of people. This is amazing given that advanced notice wasn’t very advanced.

The 2016 edition of Schneider Electric’s Foxboro/Triconex/Modicon user group meeting attracted a fair number of people. This is amazing given that advanced notice wasn’t very advanced.

It’s always great catching up with some of the industry’s thought leaders, as well as getting a glimpse of new and coming products. Among the themes that came across strongly included “security by design” and focus on customer’s assets not just control and automation.

The acquisition has turned out pretty much as I thought it would. Schneider Electric has brought financial stability and investment in research and development. Organization stability is getting there, but people are still moving around a little. The only surprise I had was Schneider’s view of software. I figured that since Schneider Electric had very little history with software that it might shop the division. In fact, the Aveva reverse acquisition (or whatever) seemed to prove the point. Yet, hallway conversations universally pointed to a different reality. Schneider senior management sees great possibility for its new software assets. Since one of its competitors just renamed its upcoming event by removing the word “software”, I find this a significant competitive move.

Different Project Ideas

In an interesting twist, the opening keynote was given by a customer—Sandy Vasser of ExxonMobil. Vasser had presented his vision at the ARC Forum in Orlando in February, so I had an idea what was coming—a challenge to Schneider Electric, and indeed all suppliers. The oil & gas industry faces many challenges and it is time to think differently about traditional automation practices and technologies. The key is lowering the cost of projects and time to first oil.

A new approach is required:

Reduce customization

- push customization to the software, use standard hardware

- eliminate the need for project specifications

- eliminate the need for the infrstructure to support customized solutions

Reduce complexity simplify designs

- reduce the component count and the number of divergent systems

- take full advantage of the capability of the installed systems

- reduce the number and simplify interfaces

Eliminate simplify or automate processes

Mitigate the effects of dependencies

Reduce the amount of automatically generate documentation

Take managed risks accept some compromises

Develop and enable trust with our suppliers and our contractors

Key enablers:

- Smart configurable I/O in standard field junction boxes

- Virtualization (runtime and engineering) completely separate hardware so can test software without hardware

- Customization pushed from hardware to software

- Autodetect/Autointerrogate/Autoconfigure/Autoenable/Autodocument I/O

New challenges for our key suppliers

- control systems age in place

- system architectures made simple

- systems consist of building blocks that can be easily upgraded to current technologies

- upgrades or repairs will not be intrusive, disruptive, or unnecessarily costly

- rip and replace will never be necessary

- control system selection for a facility will be for life; fully supported and sustained

We have heard Vasser’s challenge before. But this reinforcement shows how serious ExxonMobil is about moving project planning and implementation to a new level. Faster time to start up and greatly reduced cost. The challenge for suppliers such as Schneider Electric is to bring what the customer wants and still make money. If the customer drives the supplier to a point where profits are just not there, then innovation will cease. But a good challenge from a supplier can spur innovation. We’ll see.

by Gary Mintchell | May 6, 2016 | Internet of Things, Manufacturing IT, Operations Management

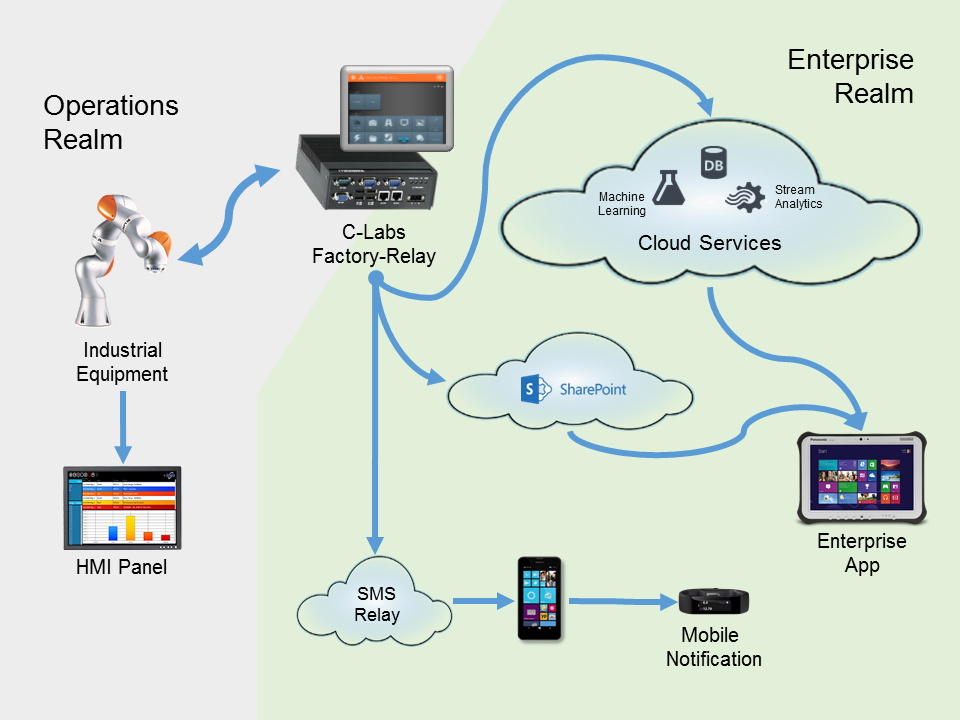

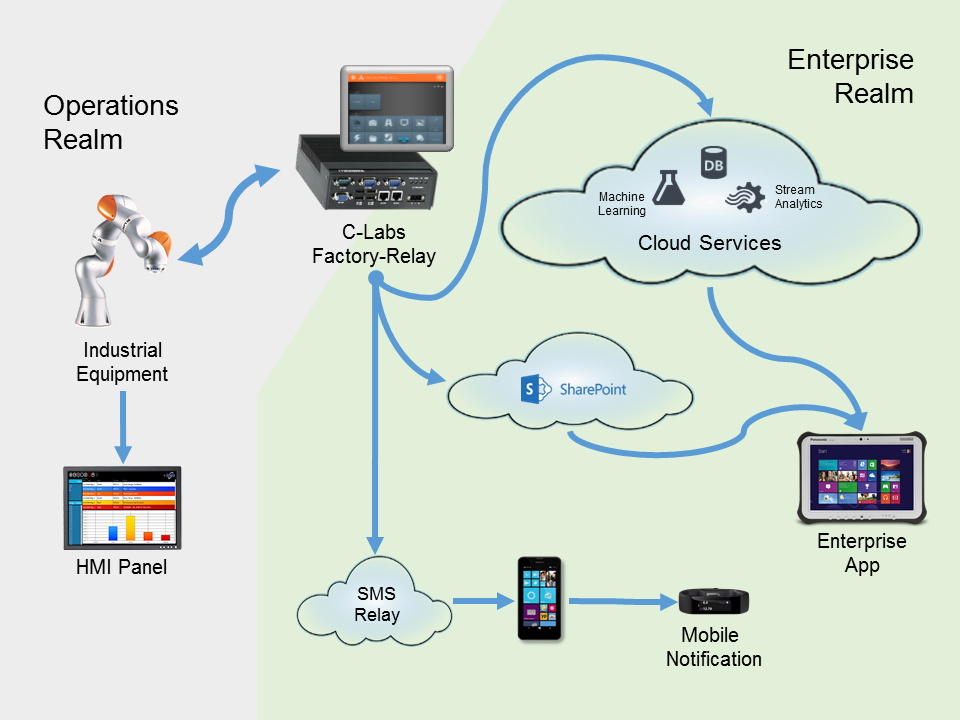

On Tuesday April 26 of the Hannover Fair, Dell and Intel gathered thought leaders from about ten partners into a “Think Tank.” We met in a conference room in the middle of the FairGrounds and discussed the Internet of Things for a solid two hours. It was my privilege to moderate the session.

On Tuesday April 26 of the Hannover Fair, Dell and Intel gathered thought leaders from about ten partners into a “Think Tank.” We met in a conference room in the middle of the FairGrounds and discussed the Internet of Things for a solid two hours. It was my privilege to moderate the session.

Present IoT situation is robust

Was IoT relevant to each company or organization rep resented? As each person introduced himself and his company, it was clear that every company was deep into understanding what IoT meant for their business and for their customers. Or, as I stated, “I guess we can’t generate any debate on whether IoT is relevant, so we can move on to co

resented? As each person introduced himself and his company, it was clear that every company was deep into understanding what IoT meant for their business and for their customers. Or, as I stated, “I guess we can’t generate any debate on whether IoT is relevant, so we can move on to co nsidering why anyone cares about IoT in manufacturing business.”

nsidering why anyone cares about IoT in manufacturing business.”

You can tell by some of the pictures that even though most of us were wearing conservative dark jackets each was passionate about the impact of IoT in our business. As we discussed the business drivers, we began with how connectivity enables this entire area. New database technologies were discussed.

The consensus of opinions focused on how IoT is a disruptive element in today’s manufacturing climate. Several noted that we can now build new models of doing business. The people in the room were each in their own domain working on models that disrupt what they’ve been doing and pointing tow ard new benefits for customers.

ard new benefits for customers.

Organizational IT Challenges remain

But all is not sanguine in IoT land. Customers are confused about what the Internet of Things is. There are so many names and it comes in so many flavors that customers are beyond trying to figure it out on their own. Members of the panel agreed that it is incumbent upon them and their companies to be able to articulate the Internet of Things clearly and coherently to the market.

The problem of bringing the IT group and the OT group together into some form of meaningful collaboration, and even resp ect, has been discussed for probably 20 years. Yet, this predominantly European group identified IT/OT convergence and the need for collaboration as a key challenge facing IoT implementation. This group of technology suppliers and integrators acknowledged that in

ect, has been discussed for probably 20 years. Yet, this predominantly European group identified IT/OT convergence and the need for collaboration as a key challenge facing IoT implementation. This group of technology suppliers and integrators acknowledged that in many of their customer’s sites, their meetings often are the first that bring the two groups together in the same room discussing a common problem. More of the same is needed.

many of their customer’s sites, their meetings often are the first that bring the two groups together in the same room discussing a common problem. More of the same is needed.

Customers and suppliers face the challenge of identifying opportunities where IoT will be a benefit to operations and business. This will require collaboration among many partners and groups.

The challenge “elephant in the room” was security. The topic was brought up gingerly, and no solutions were proposed other than security measures already in place. In other words, we probably need to continue to work on this topic.

Not unlike implementing other manufacturing IT projects, panelists noted the need for customers to rationalize their operations and understand architectures before beginning a comprehensive IoT strategy.

IoT in the future

What about the future of IoT and manufacturing? Some threw out ideas such as wearables and augmented reality (AR). I’ve been enchanted with the Silicon Valley use of bots—from Siri and Cortana to notifications. Panelists jumped all over the idea of bots. This technology is seen as the hot thing for the near-term future.

Dr. Valentijn De Leeuw, Vice President and analyst at the ARC Advisory Group, brought up an initiative in the European Union—Alliance for Internet of Things Innovation.

“The Alliance for Internet of Things Innovation (AIOTI) was initiated by the European Commission in order to develop and support the dialogue and interaction among the Internet of Things (IoT) various players in Europe. The overall goal of the AlOTI is the creation of a dynamic European IoT ecosystem to unleash the potentials of the IoT. This ecosystem is going to build on the work of the IoT Research Cluster (IERC) and spill over innovation across industries and business sectors of IoT transforming ideas into solutions and business models. The Alliance will also assist the European Commission in the preparation of future IoT research as well as innovation and standardisation policies.”

The US government, by the way, under the Obama administration has begun a few organizations working on digital manufacturing and smart manufacturing. I haven’t seen an equivalent of this one. Please point one to me if you know it.

Dell / Partner Ecosystem

Dell holds these think tanks in a number of areas to foster networking and collaboration among its various partners. I’m sure some companies do something similar behind closed doors. Dell records theirs for public consumption, also.

From the Dell point of view one of the main take aways identified was the need to collaborate across a partner ecosystem of vendors and service providers to address customers’ appetite for more efficient and higher quality solutions. Customer centricity and customization of solutions was another point that received general agreement. The group also identified data utilization, edge analytics, standardization and workforce changes as opportunities for collaboration within the full ecosystem of IoT solutions partners.

The future is alre ady here. As this market continues to evolve, staying on top of collaboration opportunities for advancements in IIoT, smart manufacturing and industry 4.0 and collaboration is key. The group agreed that better analytics will provide greater visibility to new revenue streams.

ady here. As this market continues to evolve, staying on top of collaboration opportunities for advancements in IIoT, smart manufacturing and industry 4.0 and collaboration is key. The group agreed that better analytics will provide greater visibility to new revenue streams.

One last comment of mine regarding edge analytics. There was often an unstated assumption about the value Dell brings to the table with its IoT solutions. Not only is the IoT Gateway an adaptation of its PC technology, but Dell also brings such extras as embedded analytics and applications not to mention bringing to larger partners its global service and support network.

Participants include representatives from: · Azeti · Dell · Intel · Knapp · Kepware Microsoft · MPDV Mikrolab · OSIsoft · Relayr · SAP · The Manufacturing Connection, Gary Mintchell (MODERATOR)

Several of the participants recorded interviews. I’ve linked to several here.

Here are summaries:

Ole Borgbjerg, Kepware, “IT and OT have different roles and agendas, get inside that and talk to both, we are getting more IT experience, we are company working on factory floor, but need to take benefit of devices on the edge. It will take some time to take off. curious but holding back but will take off.”

Oliver Niedung, Microsoft, “We operate in all areas of the integration, hybrid solutions, devices/software, cloud subsystems. Dell is a valued partner.”

Joseph Brunner, Relayr, “There exists a skills gap. We need to make abusiness case (save money or make money). We need hardware providers to unleash data, middleware company like us to mix and send up to business. It’s an infrastructure sale, and a strategic decision changing the way companies do business.”

Tim Kaufman, SAP, “Importance is in getting end-to-end data. There are configuration issues, we need more plug-and-play. Potential exists in the horizontal supply chain including track and trace.”

Dirk Sommerfeld, Azeti, “Need to bring many different companies together for project. We found out that many companies are working on IoT from many different directions.”

Once again, an industrial corporation striving for digitalization solutions looks to Silicon Valley. Industrial and automation companies continue to search outside the industry for talent. Often, they just don’t work out. The pace of change in industrial is so much slower and bureaucracies are so entrenched that they get frustrated and leave. This one from ABB is interesting. Will he be able to build a software division to rival GE? We’ll keep watching.

Once again, an industrial corporation striving for digitalization solutions looks to Silicon Valley. Industrial and automation companies continue to search outside the industry for talent. Often, they just don’t work out. The pace of change in industrial is so much slower and bureaucracies are so entrenched that they get frustrated and leave. This one from ABB is interesting. Will he be able to build a software division to rival GE? We’ll keep watching.

The 2016 edition of Schneider Electric’s Foxboro/Triconex/Modicon user group meeting attracted a fair number of people. This is amazing given that advanced notice wasn’t very advanced.

The 2016 edition of Schneider Electric’s Foxboro/Triconex/Modicon user group meeting attracted a fair number of people. This is amazing given that advanced notice wasn’t very advanced.

On Tuesday April 26 of the Hannover Fair, Dell and Intel gathered thought leaders from about ten partners into a “Think Tank.” We met in a conference room in the middle of the FairGrounds and discussed the Internet of Things for a solid two hours. It was my privilege to moderate the session.

On Tuesday April 26 of the Hannover Fair, Dell and Intel gathered thought leaders from about ten partners into a “Think Tank.” We met in a conference room in the middle of the FairGrounds and discussed the Internet of Things for a solid two hours. It was my privilege to moderate the session. resented? As each person introduced himself and his company, it was clear that every company was deep into understanding what IoT meant for their business and for their customers. Or, as I stated, “I guess we can’t generate any debate on whether IoT is relevant, so we can move on to co

resented? As each person introduced himself and his company, it was clear that every company was deep into understanding what IoT meant for their business and for their customers. Or, as I stated, “I guess we can’t generate any debate on whether IoT is relevant, so we can move on to co nsidering why anyone cares about IoT in manufacturing business.”

nsidering why anyone cares about IoT in manufacturing business.” ard new benefits for customers.

ard new benefits for customers. ect, has been discussed for probably 20 years. Yet, this predominantly European group identified IT/OT convergence and the need for collaboration as a key challenge facing IoT implementation. This group of technology suppliers and integrators acknowledged that in

ect, has been discussed for probably 20 years. Yet, this predominantly European group identified IT/OT convergence and the need for collaboration as a key challenge facing IoT implementation. This group of technology suppliers and integrators acknowledged that in many of their customer’s sites, their meetings often are the first that bring the two groups together in the same room discussing a common problem. More of the same is needed.

many of their customer’s sites, their meetings often are the first that bring the two groups together in the same room discussing a common problem. More of the same is needed.

ady here. As this market continues to evolve, staying on top of collaboration opportunities for advancements in IIoT, smart manufacturing and industry 4.0 and collaboration is key. The group agreed that better analytics will provide greater visibility to new revenue streams.

ady here. As this market continues to evolve, staying on top of collaboration opportunities for advancements in IIoT, smart manufacturing and industry 4.0 and collaboration is key. The group agreed that better analytics will provide greater visibility to new revenue streams.