by Gary Mintchell | Nov 24, 2014 | Automation, Data Management, Manufacturing IT, News, Operations Management, Software

This trend in manufacturing software I expect to see accelerated as we move through 2015. Although not everyone is sanguine about the efficacy of fully integrated (if indeed that is even possible) design to manufacture software. Even so, here is yet another first step.

This trend in manufacturing software I expect to see accelerated as we move through 2015. Although not everyone is sanguine about the efficacy of fully integrated (if indeed that is even possible) design to manufacture software. Even so, here is yet another first step.

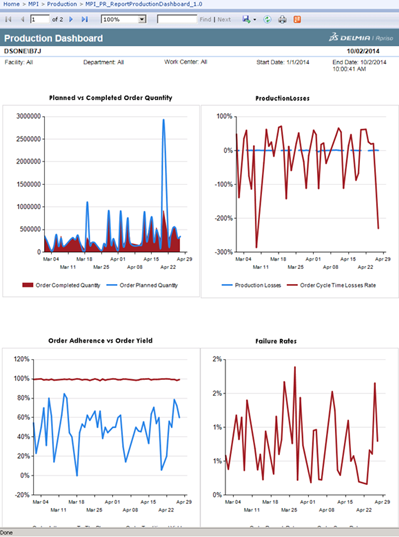

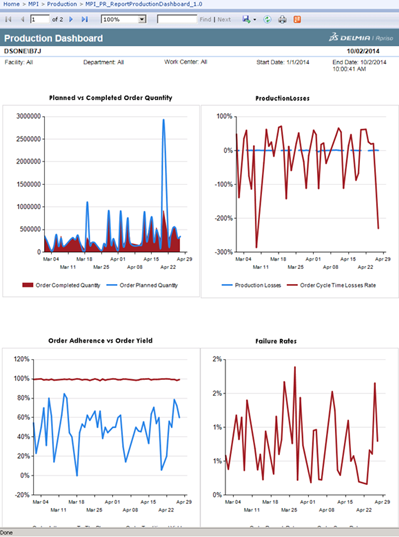

Apriso 9.7 is now available from Dassault Systèmes, with enriched integration to the company’s digital manufacturing applications. As the first significant new product introduction since Dassault Systèmes’ acquisition of Apriso Corp., the Apriso 9.7 application suite offers an improved business experience for Apriso users, with closer, out-of-the-box integration to other DELMIA Digital Manufacturing products, helping to better bridge the gap between the virtual and real worlds of manufacturing. This Apriso product portfolio update delivers enhanced digital continuity from design to execution, supporting paperless manufacturing initiatives while accelerating new product introduction.

“The launch of Apriso 9.7 represents an important first step to becoming part of the 3DEXPERIENCE platform. Apriso capabilities will be available by simply adding widgets to the platform, extending real-time visibility to manufacturing intelligence to engineers and other users of the platform,” said John Fishell, DELMIA Product Management at Dassault Systèmes.

Dassault Systèmes customers can use Apriso 9.7 to help ensure engineering designed work instructions are properly executed on the shop floor. Examples include manufacturing Bill of Materials (mBOM), routings and 3D work instructions. Presenting feedback from manufacturing to engineering through the 3DEXPERIENCE portal helps improve production process performance and validate whether virtual routings are optimal for a real world environment.

by Gary Mintchell | Nov 12, 2014 | News, Operations Management, Software

MOM Chronicles: ISA95 Best Practices

The International Society of Automation (ISA) Publications Department has awarded Charlie Gifford the Thomas G. Fisher Award of Excellence for a Standards-Based Reference Publication. The book, which Gifford assembled and edited, is “The MOM Chronicles: ISA-95 Best Practices Book 3.0”.

I have the book and highly recommend it to all who are trying to understand and implement the ideas and models of ISA95—the international standard for the integration of enterprise and control systems. Charlie is an internationally respected practitioner and teacher on manufacturing operations management (MOM).

Charlie offers this comment on the honor, “I sincerely thank ISA for this prominent award named for a distinguished man, Tom Fisher. As Primary Contributing Author and Chief Editor, I accept this award for all 50 contributing expert authors and reviewers of the ISA-95 Manufacturing Operations Management (MOM) Best Practices Working Group. This is the 2nd time the working group’s work products have been recognized for this award. In 2011, ‘When World Collide in Manufacturing Operations, Book 2.0’ was also selected. ISA continues to support the group’s work products of 23 applied technology white papers and 3 books. These documents enable manufacturing systems professionals worldwide to become a primary reference resource over the last 10 years.”

Here is a glimpse into MOM Chronicles:

- Chapter 1: Applying Global MOM Systems in a Manufacturing 2.0 Approach

- Chapter 2: The Role of Semantic Models in Smarter Industrial Operations

- Chapter 3: Applying Manufacturing Operations Models in a Discrete Hybrid Manufacturing Environment

- Chapter 4: Defining an Operations Systems Architecture

- Chapter 5: A Workflow-driven Approach to MOM

- Chapter 6: Scheduling Integration Using an ISA-95 Application in a Steel Plant

- Chapter 7: Intelligent Integration Interface: I3, A Real-world Application of ISA-95

Here’s a glimpse into When Worlds:

- Chapter 1: SOA for Manufacturing Overview

- Chapter 2: Data Architecture for MOM: The Manufacturing Master Data Approach

- Chapter 3: Building a Manufacturing Transformation Strategy with ISA-95 Methods

- Chapter 4: Work Process Management for Adaptive Manufacturing

- Chapter 5: B2MML, Integration Patterns, and Data Mapping

- Chapter 6: Integration of Manufacturing Intelligence with MOM

- Chapter 7: Lifecycle of Service Creation using the ISA-95 MOM

Charlie Gifford, PMP, is General Manager & Senior Advanced Manufacturing Consultant at Intelligent Manufacturing Institute, 21st Century Manufacturing Solutions LLC.

by Gary Mintchell | Oct 11, 2013 | Operations Management, Software

People have asked me for studies like this for many years. But I have never had the testing labs and time to accomplish this task and assure that it is accurate. If it is not accurate, then all you do is raise a firestorm of hate mail from the companies. [I’m not so worried about advertising revenue. The ads you see are not making me much money, anyway.]

People have asked me for studies like this for many years. But I have never had the testing labs and time to accomplish this task and assure that it is accurate. If it is not accurate, then all you do is raise a firestorm of hate mail from the companies. [I’m not so worried about advertising revenue. The ads you see are not making me much money, anyway.]

I know founder Matt Littlefield. We talked about business and analysis models after I left Automation World and was developing my own business. I am intellectually an analyst, but I didn’t know the business model. I like his method. We’ll see how it works.

LNS Research, a technology research firm focusing on the industrial space, decided to tackle that issue releasing Manufacturing Operations Management (MOM) Solution Selection Guide. Composed of 20 top software vendors, the guide aims to educate end-users on the manufacturing software market and aid the selection process. The MOM software space encompasses applications between the enterprise / business systems and industrial automation systems, including Manufacturing Execution Systems (MES), Enterprise Manufacturing Intelligence (EMI) software, Historian software and Manufacturing Process Workflow software.

The MOM Solution Selection Guide provides executives with valuable insights needed to make the complex decision around the short list of solutions they should actively consider for improving their manufacturing operations. It covers each vendor in depth, with individualized overviews and analyses on their business strategies, solution capabilities, industry expertise, geographic coverage, technology delivery models, and more.

According to Mark Davidson, Principal Analyst at LNS Research, “A MOM solution implementation has the potential to make a significant positive impact on an organization’s manufacturing operations, but at the same time, the selection process needs to include a wide number of factors in order to ensure the best strategic fit and ongoing results. This solution selection guide intends to greatly simplify the process of matching key considerations and requirements of manufacturing companies who are looking for pre-packaged software solutions.”

With a range of vendors in the space –each with relative strengths and weaknesses—the MOM Solution Selection Guide creates a concise landscape for executive consideration. Available on the LNS Research website upon the conclusion of site visitors taking a short manufacturing operations management survey, the guide synthesizes a combination of qualitative and quantitative analyses performed by the LNS Research team, working cooperatively with each vendor over recent months.

by Gary Mintchell | Jul 29, 2013 | Operations Management

Here is an interesting new product announcement. Interesting because in a world where so many programmable logic controllers (PLCs) have pretty much become commodity items, here is an MES supplier who is launching a new PLC–to enhance its MES solution.

I asked for an interview with a product manager to dive a little deeper into this. Suddenly I realized that a couple of weeks have passed with no further response from my media relations contact. So, this is as much as I know right now.

IQMS, a manufacturing ERP software and MES developer, has released its Process Monitoring Interface Unit (PMIU) Programmable Logic Controller (PLC). The PMIU88 OEM PLC is designed for the shop floor to control or monitor process variables. A “multitude of sensors” are available including thermocouples, pressure transducers and linear potentiometers and digital inputs that communicate directly to IQMS’ RealTime Process Monitoring system for control and SPC analysis.

“Through mounting of our own sensors, IQMS can offer a low cost option for cases where there is no PLC or controller at the work center, thus expanding the types of equipment that we can connect to,” said Glenn Nowak, vice president at IQMS. “By offering PLCs that are designed specifically to interface with EnterpriseIQ, we can deliver a more comprehensive offering for our MES solution.”

Shipped complete with its i-TRiLOGI ladder + BASIC software and a built-in Ethernet port with onboard web server, the PMIU88 PLC is ready for work center monitoring and configuration remotely over the network. For communication, Modbus communication protocols and RS232 and RS485 connections are included.

Once installed, the PMIU88 PLCs will push product data to the IP-based RealTime Process Monitoring system for correlation and analysis in real time. IQMS’ RealTime Process Monitoring solution is a flexible, robust manufacturing intelligence system that gathers and stores any process parameters necessary for accurate traceability back to the item number, work order, lot number and manufactured date and time.

Stored in an SQL-based data historian, Process Monitoring information can then be viewed dynamically in charts or gauges, including Overall Equipment Effectiveness (OEE) calculations. Additionally, data can then be analyzed in the EnterpriseIQ Statistical Process Control (SPC) module for accurate and instantaneous feedback, including business activity notifications through voice alerts or email/text warnings if products are trending out of specification.

This trend in manufacturing software I expect to see accelerated as we move through 2015. Although not everyone is sanguine about the efficacy of fully integrated (if indeed that is even possible) design to manufacture software. Even so, here is yet another first step.

This trend in manufacturing software I expect to see accelerated as we move through 2015. Although not everyone is sanguine about the efficacy of fully integrated (if indeed that is even possible) design to manufacture software. Even so, here is yet another first step.