by Gary Mintchell | Mar 1, 2016 | Automation, Internet of Things, Networking, Operations Management, Safety, Wireless

Enabling Industrial Internet of Things (IIoT), Reliability, Scalability, and pursuing Real ROI encompass the current mantra of Fluke. Maybe you only know that company for its multimeters or infrared cameras. Well, there is much more behind the curtain.

The company has focused product development on mobile solutions, wireless communications, and data. This quarter’s product releases reflect all of that.

Infrared

The new Fluke Ti450 Infrared Camera takes focus to a new level of clarity with MultiSharp Focus. An out-of-focus thermal image can give you data that may lead to misdiagnosis — potentially costing you thousands — with no way to correct it once it has been captured, short of taking new images. This new infrared camera solves this problem by delivering images automatically focused throughout the field of view.

The new Fluke Ti450 Infrared Camera takes focus to a new level of clarity with MultiSharp Focus. An out-of-focus thermal image can give you data that may lead to misdiagnosis — potentially costing you thousands — with no way to correct it once it has been captured, short of taking new images. This new infrared camera solves this problem by delivering images automatically focused throughout the field of view.

“We are excited to announce this new technology, because it makes a real difference in situations where you have objects at multiple distances that you want in focus. Places like substations, motors driving a long production line, or electrical panels with components at varying depths,” notes Chris Rayburn, thermography business director.

MultiSharp Focus is a new technology that rapidly takes multiple images and combines them to produce one in-focus image. The advanced focusing system enables users to capture an automated, focused image of multiple targets at once, delivering the image clarity needed by professional thermographers and maintenance managers to produce top-quality results and avoid costly rework.

Waveforms

Today’s industrial machinery is more reliable and efficient, but can also be more difficult to troubleshoot because of the complexities of its advanced systems. The new Fluke ScopeMeter 120B Series Industrial Handheld Oscilloscope features Connect-and-View technology that recognizes signal patterns and automatically sets up the scope’s triggering, amplitude, and time base eliminating the typical trial-and-error setup process. Once the waveform is captured, the new IntellaSet intelligent measurement detection automatically selects key measurements based on the acquired waveform type and displays the most relevant measurement values (for example, Vrms and Hz for a line voltage signal, or Vpeak-peak and Hz for a square wave), helping technicians easily identify and characterize potential signal faults.

Today’s industrial machinery is more reliable and efficient, but can also be more difficult to troubleshoot because of the complexities of its advanced systems. The new Fluke ScopeMeter 120B Series Industrial Handheld Oscilloscope features Connect-and-View technology that recognizes signal patterns and automatically sets up the scope’s triggering, amplitude, and time base eliminating the typical trial-and-error setup process. Once the waveform is captured, the new IntellaSet intelligent measurement detection automatically selects key measurements based on the acquired waveform type and displays the most relevant measurement values (for example, Vrms and Hz for a line voltage signal, or Vpeak-peak and Hz for a square wave), helping technicians easily identify and characterize potential signal faults.

The 120B Series also features Event Capture function that captures and identifies elusive intermittent events and lists all those events that exceed a predetermined threshold. This lets technicians identify key events quickly, rather than combing through large data sets, reading by reading.

Fluke Connect

The Industrial Internet of Things is all about connections and data. As part of Fluke Connect— a system of wireless test tools that communicate via the Fluke Connect app, or Fluke Connect Assets software, a cloud-based solution that gathers measurements to provide a comprehensive view of critical equipment status — the 120B Series can automatically record waveform data to the Fluke Connect app on smartphones or tablets ensuring accuracy and eliminating manual recording of data. Those measurements are then wirelessly uploaded to the cloud and can be combined with measurement data from multiple Fluke Connect test tools to create and share reports from the job site via email and collaborate in real time with other colleagues, increasing productivity in the field. Storing then comparing and contrasting waveforms of specific asset test points over time enables maintenance engineers to better identify and troubleshoot conditions that can lead to failures.

Work Orders

Fluke introduces Work Orders, the latest enhancement to the Fluke Connect Assets, an asset management software solution that works with the Fluke Connect system of wireless test tools. Using this new Fluke Connect Assets feature maintenance managers can:

Fluke introduces Work Orders, the latest enhancement to the Fluke Connect Assets, an asset management software solution that works with the Fluke Connect system of wireless test tools. Using this new Fluke Connect Assets feature maintenance managers can:

- View complete work order history coupled with measurement data related to a specific plant asset

- Create work orders from anywhere

- Confidently assign the job to the appropriate technician and balance the task with other work orders in the system.

Technicians are provided with actual measurement data right in the work order allowing them to better understand the problem and work instructions.

The Fluke Connect system allows entire maintenance teams to capture and wirelessly share data via their smartphones. Using the AutoRecord feature measurements are transferred directly from Fluke Connect wireless test tools – eliminating transcription errors – and can be uploaded to FlukeCloud storage. Measurements can be assigned to a specific asset for sharing and analysis. Technicians can collaborate with their colleagues to discuss problems while sharing data and images in real time with ShareLive video calls, which speeds problem solving, decision-making and approvals.

Clamp Meters

Often the most frustrating task for electricians and maintenance technicians is to troubleshoot intermittent faults because they rarely occur at convenient times. The new Fluke Connect-enabled 370 FC Series Clamp Meters log measurements to pinpoint intermittent faults precisely without the need for the technician to be present. Those measurements are then wirelessly transmitted to the Fluke Connect app on smartphones or tablets and automatically uploaded to the cloud, keeping technicians outside the arc flash zone and away from dangerous moving machinery, improving safety.

Often the most frustrating task for electricians and maintenance technicians is to troubleshoot intermittent faults because they rarely occur at convenient times. The new Fluke Connect-enabled 370 FC Series Clamp Meters log measurements to pinpoint intermittent faults precisely without the need for the technician to be present. Those measurements are then wirelessly transmitted to the Fluke Connect app on smartphones or tablets and automatically uploaded to the cloud, keeping technicians outside the arc flash zone and away from dangerous moving machinery, improving safety.

The CAT IV 600 V, CAT III 1000 V safety-rated clamp meters offer advanced troubleshooting performance to capture a wide range of measurements with a single tool, including:

- Proprietary in-rush measurement technology to filter out noise and capture motor starting current exactly as the circuit protection sees it;

- Integrated variable frequency drive low pass filter (376 FC and 375 FC models only) for accurate motor drive measurements;

- True-rms voltage and current for accurate measurements on non-linear signals;

- 500 mV dc measurement range to interface with other accessories (376 FC and 375 FC models only);

- Expanded measurement range to 2500 A ac with the iFlex flexible current probes, which provide access to large conductors in tight spaces.

As part of Fluke Connect— the industry’s largest system of software and more than 30 wireless test tools — technicians can wirelessly transmit measurement data from the 370 FC Series clamp meters and other test tools to their smartphones for secure storage on the Fluke Cloud and team access from the field. With the Fluke Connect smartphone app, technicians can combine measurement data from multiple Fluke Connect test tools to create and share reports from the job site via email and collaborate in real time with other colleagues with ShareLive video calls, increasing productivity in the field.

by Gary Mintchell | Dec 2, 2015 | Automation, Interoperability, News, Process Control, Standards, Technology

Here is an industrial automation announcement from the recent SPS IPC Drives trade fair held annually in Nuremberg, Germany. This one discusses a new open integration, some say interoperability, program based upon open standards.

This blog has now complete eight years—through three names and domains: Gary Mintchell’s Radio Weblog, Gary Mintchell’s Feed Forward, and now The Manufacturing Connection. Through these eight years one consistent theme is advocating for what I believe to be the user’s point of view—open integration.

Users have consistently (although unfortunately not always vocally) expressed the view that, while they love developing a strong partnership with preferred suppliers, they also want to be able to connect products from other suppliers as well as protect themselves by leaving an “out” in case of a problem with the current supplier.

The other position contains two points of view. Suppliers say that if they can control all the integration of parts, then they can provide a stronger and more consistent experience. Customers worry that locking themselves into one supplier will enable it to raise prices and that it will also leave them vulnerable to changes in the supplier’s business.

With that as an introduction, this announcement came my way via Endress+Hauser. That company is a strong measurement and instrumentation player as well as a valued partner of Rockwell Automation’s process business. The announcement concerns the “Open Integration Partner Program.”

I’m a little at a loss to describe exactly what this is—other than a “program.” It’s not an organization. Rather its appearance is that of a memorandum of cooperation.

The program promotes the cooperation between providers of industrial automation systems and fieldbus communication. To date, eight companies have joined the program:

AUMA Riester, HIMA Paul Hildebrandt, Honeywell Process Solutions, Mitsubishi Electric, Pepperl+Fuchs, Rockwell Automation, R. STAHL and Schneider Electric.

“By working closely with our partners, we want to make sure that a relevant selection of products can be easily combined and integrated for common target markets,” outlines Michael Ziesemer, Chief Operating Officer of Endress+Hauser. This is done by using open communication standards such as HART, PROFIBUS, FOUNDATION Fieldbus, EtherNet/IP or PROFINET and open integration standards such as FDT, EDD or FDI. Ziesemer continues: “We are open for more cooperation partners. Every market stakeholder who, like us, consistently relies on open standards is invited to join the Open Integration program.”

Reference topologies are the key

Cooperation starts with what are known as reference topologies, which are worked out jointly by the Open Integration partners. Each reference topology is tailored to the customers’ applications and the field communication technologies used in these applications. “To fill the program with life in terms of content, we are going to target specific customers who might be interested in joining us,” added Ziesemer.

Depending on industrial segment and market, the focus will be on typical requirements such as availability, redundancy or explosion protection, followed by the selection of system components and field instruments of practical relevance. This exact combination will then be tested and documented before it is published as a joint recommendation, giving customers concrete and successfully validated suggestions for automating their plant.

Ziesemer adds: “With this joint validation as part of the Open Integration, we go well beyond the established conformity and interoperability tests that we have carried out for many years with all relevant process control systems.”

by Gary Mintchell | Oct 16, 2015 | Asset Performance Management, Automation, News, Operations Management, Process Control, Security, Technology, Wireless

This is another long post—and it is a summary—running through many of the new products introduced to the press and analysts durning Emerson Exchange 2015. If any of these whet your appetite, visit the Emerson Process Website for more information.

Another place to catch up on happenings at the conference is Jim Cahill’s Emerson Process Experts blog. He also has been introducing readers to highlighted sessions.

Machinery protection

CSI 6500 ATG protection system, a stand-alone machinery protection solution that allows users to cost-effectively introduce prediction monitoring of critical assets from the same system. Predictive intelligence is a key component to increasing availability and improving the reliability of plant assets.

These multi-functional cards can be easily reconfigured for a wide range of measurements, including the impacting or peak-to-peak data used in Emerson’s unique PeakVue technology. In addition to monitoring the start-up and coastdown of critical turbo machinery for safe operation, users will be able to utilize PeakVue technology to identify the earliest indications of developing faults in gearboxes and bearings.

With the CSI 6500 ATG, it is no longer necessary to return to the control room or open cabinets in the field to view or analyze data. The CSI 6500 ATG can be networked over wired or wireless Ethernet to deliver asset health information to authorized users through a PC or phone application.

To facilitate easy system integration with third party systems, CSI 6500 ATG is the first protection system to include a secure embedded OPC UA server.

Gas ultrasonic flow meter

A new Daniel gas ultrasonic flow meter platform elevates its well-proven British Gas design by providing two meters and transmitters in a single body to help natural gas operators and pipelines improve reliability and efficiency. Designed to maximize capital budgets by permitting two completely independent measurements with the installation of just a single flowmeter, the new 3415 (four-path + one-path) and 3416 (four-path + two-path) gas ultrasonic flow meters combine a four-path fiscal meter with an additional check meter, while the new 3417 (four-path + four-path) meter provides two fiscal meters for full redundancy and equal accuracy within one meter body. This two-in-one redundant design delivers continuous on-line verification of custody transfer measurement integrity, device health and process conditions, and improves fiscal metering confidence while ensuring regulatory compliance.

Both Daniel 3415 and 3416 gas ultrasonic meters measure flow using four horizontal chordal paths in addition to a reflective path dedicated to verification of the primary measurement, enabling improved metering insight, more informed decision making and simplified flow meter verification. For enhanced immunity to pipe wall contamination, the 3416 meter is equipped with an additional vertical reflective path to detect liquid or very thin layers of contamination at the bottom of the meter that otherwise remain completely hidden in a direct-path meter design. This allows reliable monitoring of process changes before they affect measurement, thus reducing calibration frequency and enabling maintenance to be condition-based instead of calendar-based.

Electric actuator control

DCMlink Software, a unified electric actuator control, monitoring and diagnostics platform, will allow, for the first time, Emerson customers to diagnose, configure, and monitor all electric actuators from a central location independent of protocol, actuator or host system. The software extends the useful life of field assets by providing actuator data gathering, condition monitoring, events log and prioritization of actuator alarms in a unified and consistent user interface. Actuator configuration includes custom characterization, as well as the ability to import and export historical configuration profiles.

Whether it is viewing value torque profile, live trending data or actionable alarms straight from the actuator, plant operators will be able to access detailed monitoring and diagnostics data, allowing them to take action before a fault occurs. DCMlink offers advanced control and diagnostics, including torque profile curves, initiating partial stroke test or emergency shut down and alarms in NE-107 format. Current communications support included Modbus, TCP-IP, and Bluetooth.

DeltaV v13

Version 13 (v13) of the DeltaV distributed control system (DCS) new features focus on integration, advanced alarm management, and security with an overarching design that improves ease of use and minimizes the need for specialized expertise.

DeltaV v13 delivers technologies to bring sources together for easy operator access and use. These technologies include an Ethernet I/O card (EIOC) for integrating Ethernet-based subsystems and devices, including a direct interface with smart motor control centers and substations. It improves the factory acceptance testing (FAT) experience by providing enhanced safety instrumented system simulation capabilities and easy-to-use virtualization environment.

The new DeltaV Alarm Mosaic has an intuitive alarm display that enables operators to more quickly identify, analyze, and respond correctly to the root cause of an abnormal process condition. The new release also provides trend display optimizations for better visibility of process changes.

SCADA

OpenEnterprise v3.2 release adds a native interface to the AMS Device Manager asset management software, enabling users to remotely manage and maintain HART and WirelessHART devices in wide-area SCADA networks.

OpenEnterprise v3.2 together with AMS Device Manager allows asset owners to extend the reach of their predictive maintenance capability out to their remote assets, providing a powerful and proactive method of diagnosing potential device problems remotely. This results in reduced trips to the field and helps to avoid unplanned process shutdowns, improving safety, reliability, and profitability.

The native interface of OpenEnterprise v3.2 to AMS Device Manager enables the collection of wired and wireless HART digital device data over low bandwidth wide-area SCADA networks from Emerson ROC, FloBoss, and ControlWave RTUs without adding the additional complexity and expense of external HART multiplexers. Support for AMS Device Manager SNAP-ON applications, OpenEnterprise SCADA server redundancy, multiple deployment options, and data collection for up to 10,000 HART devices ensures flexibility and scalability for a wide range of remote oil and gas applications.

Machinery health in PowerGen

Emerson now offers its power generation and water/wastewater industry customers native machinery health monitoring and protection capability within the Ovation distributed control system.

Ovation Machinery Health Monitor leverages the Ovation platform through a high-performance I/O module dedicated to machinery health functions. Simply install by inserting the module into a spare I/O slot.

With the Ovation Machinery Health Monitor, operators receive alerts from a single set of common plant HMIs and no longer need to manually check machinery functions through a separate system.

The Ovation Machinery Health Monitor also reduces the risk of cyber attack by eliminating links to standalone systems and isolating process information – all of which can help facilities meet NERC CIP and other security regulations.

Silica sensing

Costly damage to turbine blades caused by silica deposition can occur due to a poorly monitored steam purity program. The new Rosemount 2056 Silica Analyzer provides continuous accurate measurements of silica in process streams with a range of 0.5 ppb to 5000 ppb. The 2056’s usability features make it one of the easiest -to-use and high performing analyzers.

Harsh duty pressure sensing

Rosemount 3051S Thermal Range Expander with new UltraTherm 805 oil fill fluid enables pressure measurements by direct-mounting a diaphragm seal system to processes that reach up to 410°C (770°F) without requiring the challenging impulse piping or heat tracing used in traditional connection technology. In applications where ambient temperatures drop below ideal operating conditions, system response time becomes slow, resulting in delayed process pressure readings. Traditionally, this problem is solved by using heat tracing which is costly, maintenance intensive, and difficult to install. By using the new thermal range expander dual fill fluid seal, the Rosemount 3051S can reliably measure pressure at extremely high process and low ambient temperatures.

The Rosemount 3051S Electronic Remote Sensors (ERS) System now has safety certification. The ERS System calculates differential pressure through a digital architecture — and is now suitable for SIL 2 and 3 applications.

Rosemount 3051S High Static Differential Pressure Transmitter provides reliable flow measurement in high pressure applications with capabilities up to 15,000 psi (1034 bar). The transmitter’s SuperModule platform and coplanar design reduce potential leak points by 50 percent compared to traditional designs, ensuring the highest differential pressure measurement accuracy, field reliability and safety.

Corrosion monitoring

The Roxar Corrosion Monitoring system, consisting of wireless-based probes, will provide refineries with flexible, responsive, integrated and highly accurate corrosion monitoring.

Combined with the Emerson’s non-intrusive Field Signature Method (FSM) technology, a non-intrusive system for monitoring internal corrosion at the pipewall, refinery operators will be able to access more comprehensive corrosion information and corrosion rates, leading to improved operator insight and control over assets.

The system will also help identify and track opportunity/high TAN crudes and their corrosive elements. Such crudes are less expensive but more corrosive than others with the new system enabling the maximum amount of such crudes to be blended into the mix without increasing corrosion risk.

Wireless pressure gauge

Emerson Process Management has introduced the industry’s first WirelessHART pressure gauge. The Rosemount Wireless Pressure Gauge enables remote collection of field data.

The Wireless Pressure Gauge eliminates mechanical gauge common weak points by removing the components that inhibit the device from reporting/displaying pressure and providing up to a 10-year life, which reduces maintenance cost and time. The large 4.5-inch gauge face provides easy field visibility.

by Gary Mintchell | May 7, 2015 | Asset Performance Management, Automation, News, Operations Management, Technology

Fluke invited a group of partners, customers, and bloggers to its Everett, WA corporate facility on May 6 in order to take a deep technology dive into where Fluke is and where it is going from a product/technology point of view. The tone of the gathering was one of conversation where Fluke presented ideas and asked for push back and ideas from us.

Fluke invited a group of partners, customers, and bloggers to its Everett, WA corporate facility on May 6 in order to take a deep technology dive into where Fluke is and where it is going from a product/technology point of view. The tone of the gathering was one of conversation where Fluke presented ideas and asked for push back and ideas from us.

And feedback was what they got. The small group I was part of came up with four flip chart pages of ideas regarding proposed new products and products we thought it should pursue.

We also toured labs and manufacturing. Here are some brief impressions.

Fluke has an impressive metrology lab, actually two. The electrical lab has been around for a long time. A new thermography lab has just been constructed. I’m familiar with measurement, but the level of measurement and the dedication to standards was amazing. The science behind all the Fluke tools is solid.

Manufacturing is probably a poster child for the Danaher Production System—the company’s Lean implementation. The facilities are clean, organized with information clearly posted at the cells.

Fluke is also moving further into software—databases and analysis. Initially, Fluke Connect was a cool collaborative app for smart phones. Now it is evolving into helping smaller companies who may not have CMMS or other systems improve asset management through the information gathered from Fluke tools.

This is a product that holds great promise for many who need to start along the predictive maintenance path. “We’d like to help change behaviors in the maintenance and reliability areas.”

Given that, here is the press release for the unveiling of Fluke Connect Assets.

Fluke Connect Assets is a cloud-based wireless system of software and test tools that gives maintenance managers a comprehensive view of all critical equipment — including baseline, historical, and current test tool measurement data, current status, and past inspection data — enabling them to set up and sustain a predictive maintenance (PdM) or condition-based maintenance (CBM) system easily with minimal investment.

It features one-touch measurement transfer from more than 30 Fluke Connect-enabled test tools, eliminating manual recording of measurements so maintenance managers can be confident that the equipment history is accurate.

The company says it’s easy to set up with minimal investment and no need for support from the IT department.

The system’s features allow maintenance managers to analyze multiple types of predictive data (for example, electrical, vibration, infrared images) all in one program, side by side, in a visual format that enables easy scanning. In fact, it’s the first software that offers results across multiple deployments (smart phone, web browser). This intuitive display of multiple measurements enhances the productive use of data and the ability to identify a problem, since each measurement type tests a different aspect of equipment health and together they present a more complete picture.

Key features of Fluke Connect Assets include:

- Asset Health Dashboard — Asset Health is a hierarchy based overview of aggregated status over time, aggregated alarms over time, and equipment status timeline, all with drill downs with more details. This permits managers to quickly identify where they need to focus efforts as part of a morning routine. They can trend and compare thermal, electrical and vibration data over time for each piece of equipment and drill down to the data needed for repair/replacement decisions.

- Asset Status Dashboard — allows managers to quickly scan the most recent status updates for key assets so they can better monitor team and equipment activity.

- Asset Hierarchy and Test Points — allows managers to easily create inspection routes, schedules and instructions and assign technicians to measure specific test points to create repeatable, comparable data.

by Gary Mintchell | Feb 19, 2015 | Asset Performance Management, Commentary, Internet of Things, News, Operations Management, Software

OK, I can take a hint. Maybe. I keep looking at the latest manufacturing strategies—Industry 4.0 and Smart Manufacturing—and asking all of you for your thoughts. The silence screams louder than a pundit trying to stir up “stuff.”

OK, I can take a hint. Maybe. I keep looking at the latest manufacturing strategies—Industry 4.0 and Smart Manufacturing—and asking all of you for your thoughts. The silence screams louder than a pundit trying to stir up “stuff.”

Interesting things are happening at a quieter level under the covers of the grand strategies. I’d call these industrial software mashups. That is now an old term, but I think pretty relevant.

People are building applications on top of existing platforms. Let’s not reinvent the wheel, they say. Let’s leverage an ecosystem of developers and integrators, they say. Let’s get to market faster.

For example, check out this piece I wrote about an ERP vendor, Kenandy, who built atop Salesforce. http://mfgconnection.wpengine.com/2015/01/manufacturing-software-cloud-supports-innovation/

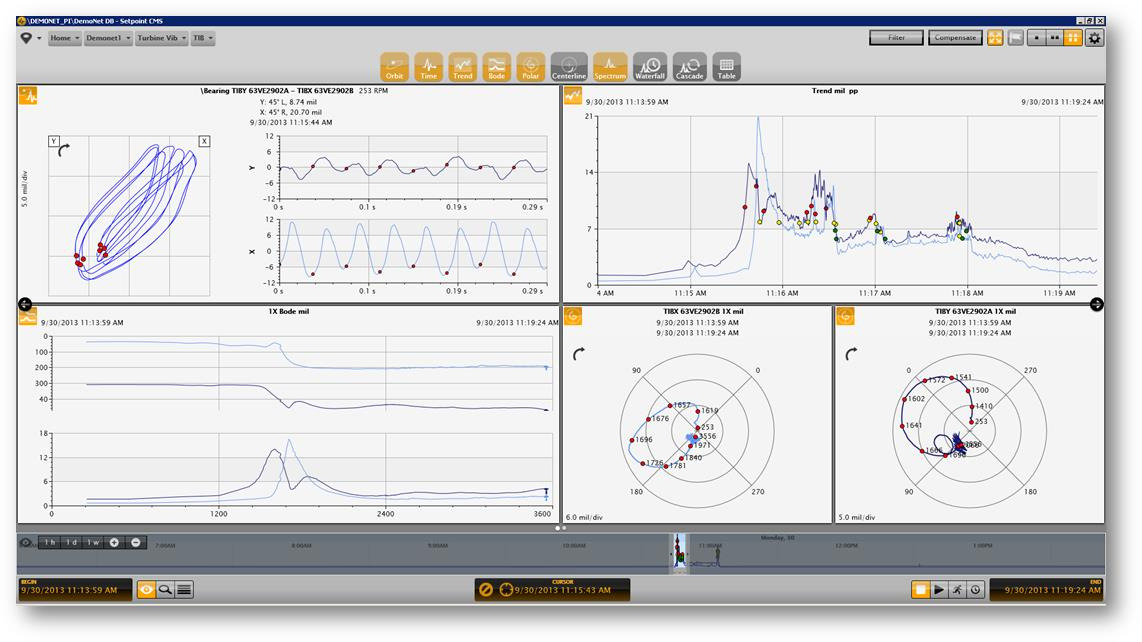

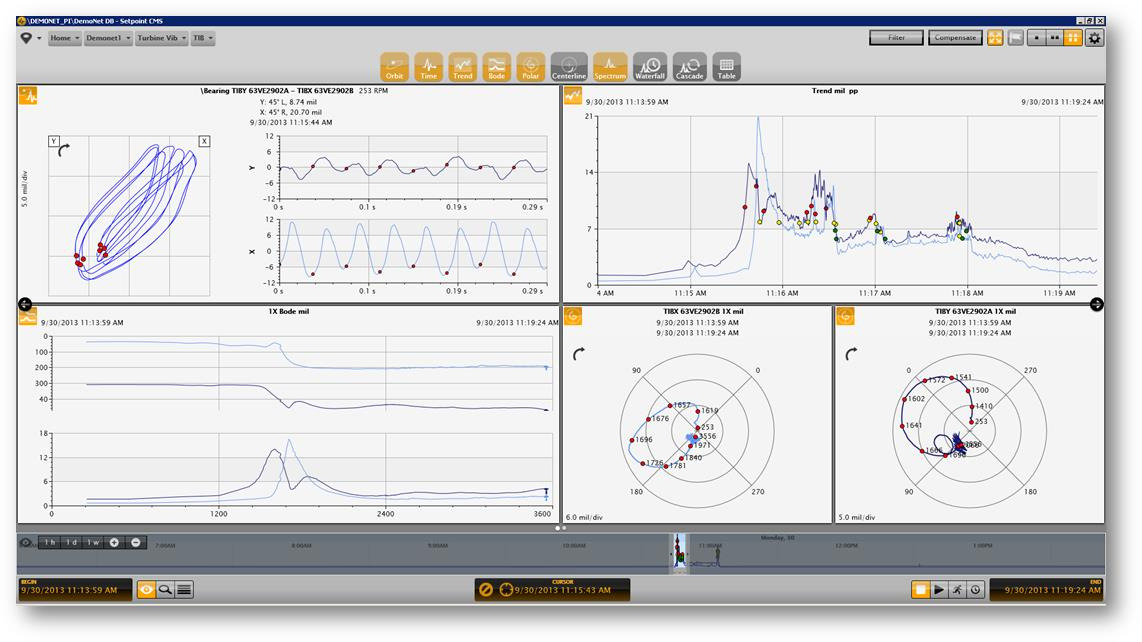

At last week’s ARC Forum, I met another one. Setpoint (by the way, its marketers like it in all caps so that it will shout out on a page, but I’m not reproducing the logo, just the name).

Setpoint is in the condition monitoring market. It began life as an initiative of Metrix Instrument but rapidly grew to a stand-alone company. Metrix wished to grow beyond sensors and transmitters into the systems market. So it build a system with former Bentley Nevada engineers.

Dozens of innovations were embedded in this new system, including a self-contained “universal” monitoring module (UMM) that could be configured do any required measurements in a single module type – making the addition of new measurements no more difficult than loading a new app on your smartphone.

Now that it had the system, to provide more value to its customers, Setpoint needed an industrial software application. Here’s the mashup part. Rather than building a stand-alone software infrastructure the team was entered into a partnership with OSIsoft, – maker of the PI System. Together, they showed that high-bandwidth, sub-millisecond vibration waveform data could be streamed directly into a PI database – something that had been routinely dismissed by the vibration industry as “impractical” or even “impossible.” Time to market was less than 12 months – unheard of in this industry – and during that time the performance capabilities of the PI System continued along its Moore’s Law trajectory, doubling in speed and making high-speed, online vibration data collection completely practical.

OSIsoft PI is an industry standard for historians and analysis. Developers and integrators are plentiful. This was a great way to jump-start a system.

Another benefit is the elimination of redundant computing, network, and software infrastructure. Further is OSIsoft’s ability to envision future market dynamics that could affect the businesses tomorrow. One such trend in the condition-monitoring industry is the drive toward data analytics and predictive maintenance strategies.

A third reason is that making quick and informed decisions on the condition of an asset requires real-time analysis of large volumes of data, also known as Big Data. OSIsoft is a leader in Big Data.

I don’t know what the grand strategies will bring you, but most of you will benefit greatly from this mashup trend.

You could also check out this video that demonstrates the system.

http://www.osisoft.com/Templates/item-abstract.aspx?id=10985

The new Fluke Ti450 Infrared Camera takes focus to a new level of clarity with MultiSharp Focus. An out-of-focus thermal image can give you data that may lead to misdiagnosis — potentially costing you thousands — with no way to correct it once it has been captured, short of taking new images. This new infrared camera solves this problem by delivering images automatically focused throughout the field of view.

The new Fluke Ti450 Infrared Camera takes focus to a new level of clarity with MultiSharp Focus. An out-of-focus thermal image can give you data that may lead to misdiagnosis — potentially costing you thousands — with no way to correct it once it has been captured, short of taking new images. This new infrared camera solves this problem by delivering images automatically focused throughout the field of view. Today’s industrial machinery is more reliable and efficient, but can also be more difficult to troubleshoot because of the complexities of its advanced systems. The new Fluke ScopeMeter 120B Series Industrial Handheld Oscilloscope features Connect-and-View technology that recognizes signal patterns and automatically sets up the scope’s triggering, amplitude, and time base eliminating the typical trial-and-error setup process. Once the waveform is captured, the new IntellaSet intelligent measurement detection automatically selects key measurements based on the acquired waveform type and displays the most relevant measurement values (for example, Vrms and Hz for a line voltage signal, or Vpeak-peak and Hz for a square wave), helping technicians easily identify and characterize potential signal faults.

Today’s industrial machinery is more reliable and efficient, but can also be more difficult to troubleshoot because of the complexities of its advanced systems. The new Fluke ScopeMeter 120B Series Industrial Handheld Oscilloscope features Connect-and-View technology that recognizes signal patterns and automatically sets up the scope’s triggering, amplitude, and time base eliminating the typical trial-and-error setup process. Once the waveform is captured, the new IntellaSet intelligent measurement detection automatically selects key measurements based on the acquired waveform type and displays the most relevant measurement values (for example, Vrms and Hz for a line voltage signal, or Vpeak-peak and Hz for a square wave), helping technicians easily identify and characterize potential signal faults. Fluke introduces Work Orders, the latest enhancement to the Fluke Connect Assets, an asset management software solution that works with the Fluke Connect system of wireless test tools. Using this new Fluke Connect Assets feature maintenance managers can:

Fluke introduces Work Orders, the latest enhancement to the Fluke Connect Assets, an asset management software solution that works with the Fluke Connect system of wireless test tools. Using this new Fluke Connect Assets feature maintenance managers can: Often the most frustrating task for electricians and maintenance technicians is to troubleshoot intermittent faults because they rarely occur at convenient times. The new Fluke Connect-enabled 370 FC Series Clamp Meters log measurements to pinpoint intermittent faults precisely without the need for the technician to be present. Those measurements are then wirelessly transmitted to the Fluke Connect app on smartphones or tablets and automatically uploaded to the cloud, keeping technicians outside the arc flash zone and away from dangerous moving machinery, improving safety.

Often the most frustrating task for electricians and maintenance technicians is to troubleshoot intermittent faults because they rarely occur at convenient times. The new Fluke Connect-enabled 370 FC Series Clamp Meters log measurements to pinpoint intermittent faults precisely without the need for the technician to be present. Those measurements are then wirelessly transmitted to the Fluke Connect app on smartphones or tablets and automatically uploaded to the cloud, keeping technicians outside the arc flash zone and away from dangerous moving machinery, improving safety.