Collaborative describes the latest and most important trend in robots. Even if I was summarily dismissed when I asked that question of the CEO of a robotic arm company at an IT event, I stand by that analysis.

Lately Mobile Industrial Robots (MiR) news came to my attention. I’ve put off writing until I connected with Ed Mullen, US VP of Sales for this Danish company.

He told me that MiR designs and manufactures Autonomous Mobile Robots (AMR) which are a bit like a quantum jump from the older Automated Guided Vehicles (AGVs) with which you may be familiar. Especially if you’re older, like me.

AGVs followed a path which was usually a wire laid in the floor. It followed its route around the facility. Cool, but not really very intelligent.

AMRs operate similar to modern autonomous technology using a 2D map of the facility and a location system plus laser scanning LIDAR. Tell it a place to go, and like a GPS it calculates the best route and directs the mobile robot to its destination—safely. I have actually interacted with one of the company’s earlier versions at a trade show where it continuously ran a route around the booth.

He tells me that the company is really more of a software company than hardware. The object is to take open source software and package it so that the customer has great flexibility for applications while usually going from unboxing to operations in under an hour.

Product news

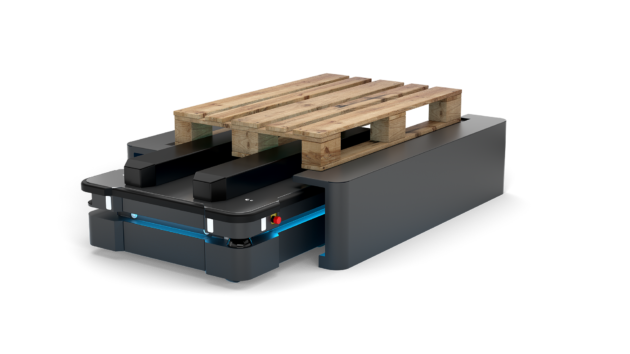

The latest product news is the launch of its MiR500 AMR. The robot has a lifting capacity of 500 kg (1102 lbs) and can automatically collect, transport and deliver pallets with speeds of nearly 4.5 miles per hour (mph). The MiR500 joins the MiR100 and MiR200 to form a complete fleet of flexible and easy-to-program MiR robots for both heavy and light transport that can optimize logistics throughout the entire production chain, from the warehouse to the delivery of goods.

“With the MiR500, we are extending the proven, strong technology and safety features that have made us the leading global supplier of autonomous mobile robots,” said Thomas Visti, CEO of Mobile Industrial Robots. “The MiR500 was developed to meet the needs of customers who have used our other robots and now see huge potential in the automation of the internal transport of heavy items and Euro-pallets. With MiR500, we’re setting new standards for how companies can use autonomous mobile robots.”

The user interface matches that used in the MiR100 and MiR200, which already optimize production processes in many of the world’s biggest multinational companies such as Airbus, Flex, Honeywell, Hitachi and Danone. The difference is the MiR500’s size, lifting capacity and areas of application.

“MiR500 is an extremely robust robot, so it’s perfect in industrial environments,” Visti said. “We’ve also incorporated the principles from the MiR100 and MiR200, where flexibility and user-friendliness are key attributes. This means that the MiR500 can be programmed without prior experience. It’s also simple to develop and replace top modules such as pallet lifters, conveyor belts and robot arms, so the robot can be used for different transport purposes.”

MiR has grown quickly since its founding in 2013, with sales rising by 500 percent from 2015 to 2016, and 300 percent from 2016 to 2017. With its second US office opening in San Diego this spring, and strong growth continuing worldwide, MiR expects to increase the number of employees from 65 to about 120 in 2018.

Acquisition

But wait, there’s more. Teradyne Inc. and the shareho6lders of Mobile Industrial Robots (MiR) announced the acquisition of privately held MiR of Odense, Denmark for €121 million ($148 million) net of cash acquired plus €101 million ($124 million at current exchange rate) if certain performance targets are met extending through 2020.

“We are excited to have MiR join Teradyne’s widening portfolio of advanced, intelligent, automation products,” said Mark Jagiela, President and CEO of Teradyne. “MiR is the market leader in the nascent, but fast growing market for collaborative autonomous mobile robots (AMRs). Like Universal Robots’ collaborative robots, MiR collaborative AMRs lower the barrier for both large and small enterprises to incrementally automate their operations without the need for specialty staff or a re-layout of their existing workflow. This, combined with a fast return on investment, opens a vast new automation market. Following the path proven with Universal Robots, we expect to leverage Teradyne’s global capabilities to expand MiR’s reach.”

MiR was profitable in 2017 with annual revenue of $12 million USD, more than triple 2016 revenues and had Q1’18 sales of $5 million.

“Joining Teradyne allows us to advance our engineering and development investments to provide greater value to our customers and further expand our market leadership in industrial autonomous mobile robots,” said Thomas Visti, CEO of MiR. “Teradyne’s worldwide reach, world-class engineering and support capabilities, financial strength and proven model for leveraging those strengths will help us grow in new and existing markets worldwide.”

“My main focus is to get our mobile robots out to the entire world,” said Niels Jul Jacobsen, CSO, founder of MiR. “With Teradyne as the owner, we will have strong backing to ensure MiR’s continued growth in the global market.”

Trackbacks/Pingbacks