I was actively involved with the MESA International organization when it developed the last MES Model. The organization changed and I gradually slipped away. But it is still busy promoting MES (or MOM) software applications although they’ve adopted the term Smart Manufacturing. They have adopted a new model. I like this because it blows up any pretense of the old pyramid structure. But I’m not so sure that it simplifies the complexity of the offerings of the many and varied MESA supplier/members. Take a moment and study where manufacturing software may be heading. Or, maybe where it has gone.

MESA International announces the release of a new MESA Model: A Framework for Smarter Manufacturing. The new model intends to help define the current and future landscape of “smart” manufacturing and production. It considers concepts that have been a part of manufacturing and production forever but dives deeply into how these concepts are made “smart” by integrating related functions and incorporating new or advanced technology.

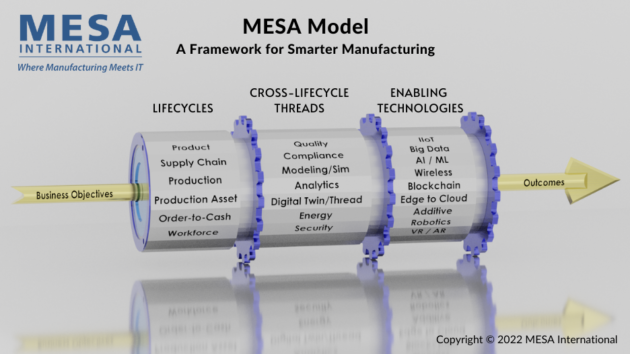

The MESA Smart Manufacturing Model integrates three related concepts: Lifecycles, Cross-Lifecycle Threads and Enabling Technologies. The Lifecycles represent business processes and value streams required in manufacturing that need to be optimized. The Lifecycles apply to all manufacturing and production enterprises, though they might vary in application across different industries or across enterprises with different levels of maturity. Cross-Lifecycle Threads help link together functions between different Lifecycles to achieve specific goals and ensure that Lifecycles operate cohesively rather than independently. The Enabling Technologies listed in the Model are just a few of the examples of modern technologies that enable the desired Smart Manufacturing outcomes.

MESA’s Knowledge Committee Chairman, Khris Kammer, stated about the new model, “For many years, industry has turned to MESA as a reliable source for actionable tools and guidance to maximize manufacturing and production operations through the use of software technology. In fact, it’s been almost three decades since MESA was created, and in that time, we’ve released three (now four) MESA models. Over those years, MESA models have been referenced in thousands of textbooks, articles, and technical journals. They have also been employed by manufacturers, producers and vendors to enable a common vocabulary and structure for discussions as solutions are designed and implemented. The newest MESA model will be the basis for ongoing efforts to develop additional written works, webinars, and other educational materials at MESA, and we expect that it will be used by countless other people and organizations in the ways that previous models have been referenced. We thank the many volunteers who have helped pull this model together, and we hope that others will join us to add additional content and context.”

MESA (Manufacturing Enterprise Solutions Association) International is a global, not-for-profit community of manufacturers, producers, industry leaders and solution providers who are focused on improving Operations Management capabilities through the effective application of Information Technologies, IT-based solutions, and best practices. To accomplish this, we:

• Enable members to connect, contribute, cultivate understanding, and exchange strategies to drive operations excellence.

• Collect, share, and publish best practices and guidance to drive greater productivity and the overall profitability of the manufacturing enterprise.

• Educate the marketplace on manufacturing operations best practices through the MESA Global Education Program.