by Gary Mintchell | Jan 2, 2018 | Asset Performance Management, Operations Management

The product Rockwell Automation executives most wanted to talk to me about at the last Automation Fair event was its new analytics platform.

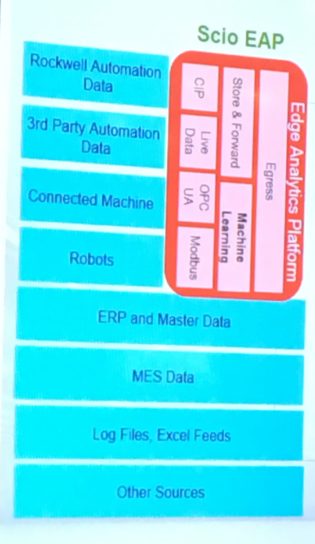

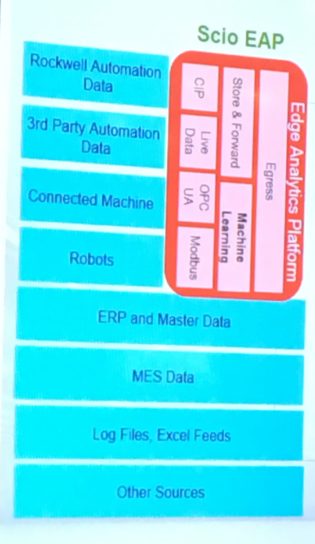

Immediately following the Rockwell event was Thanksgiving, then a trip to Madrid for a Hewlett Packard Enterprise event followed by catching up and Christmas. But I grabbed moments to contemplate the “Project Scio Edge Analytics Platform” (see image) and tried to place it in a context amongst all the platforms I saw this year. Which were many.

Executives including SVP and CTO Sujeet Chand and VP of Information Software John Genovesi were enthused over the new product. I wrote about it here.

I liked much of what I heard. There were many overtures to open connectivity that I have not heard at a Rockwell event—maybe ever. I even got an hour to discuss OPC UA and how Rockwell now intends to implement it. The demo during media days was also powerful.

I drew a mind map and exported an outline. Here is the list of positive things.

Positives

- Developed analytics from acquihire

- Good UX

- Platforms

- Open connectivity including OPC UA

- Should provide customers with insights into control systems and machine performance

However, I’m left with some questions—some of the same ones I often feel about Rockwell Automation. Check out the architecture diagram. It stops with machine level. I always expect to see more, but Rockwell always stops at the machine. Perhaps GE and Siemens have overreached with Predix and Mindsphere (and Schneider Electric with EcoStruxure?), so Rockwell stays closer to its roots on the plant floor? Is it more profitable and manageable that way?

I don’t know the answers. But I’m left thinking that with the rise of platforms [see for example Platform Revolution by Geoffrey G. Parker, Marshall W. Van Alstyne, and Sangeet Paul Choudary] and open ecosystems, Rockwell seems to have a much smaller vision. It talks of “Connected Enterprise”, but in the end I don’t see a lot of “enterprise” in the offerings.

Questions

- Is it platform or a piece of the Rockwell software stack that stops short of plantwide views?

- Is it anything that others (SIs and users?) can add to?

- Is there more coming?

- Is there a way to integrate supply chain and customer chain?

- Seems a natural to integrate with an asset management application–which Rockwell does not have.

I think they’ve done well for what they evidently set out to do. I also think there remains more to do to help customers leverage the Internet of Things and Digital Transformation. Interesting to see what next November brings.

by Gary Mintchell | Dec 1, 2017 | Data Management, Internet of Things, Operations Management

Hewlett Packard Enterprise (HPE) held its European customer conference, Discover, in Madrid this week. Points of emphasis that impacted me included Internet of Things business, high power computing, a view of the changes going on at HPE, and a look at the future of IT and the plant.

Bloggers and influencers

I was here as part of a blogger program separate from press and analysts. Bloggers are a livelier group than press. I think that I am the only independent blogger in manufacturing in the US (everyone else works for a magazine or analyst firm). There were 25 bloggers at Discover from countries as diverse as Denmark, Belgium, Germany, Italy, Spain, New Zealand, Canada, and the USA. Rather than attending press conferences our program included “coffee talks” that were live-streamed on the Web. These were informal presentations plus question-and-answer sessions.

There was one press conference I attended—the announcement of the partnership with ABB on the mini-data center product. Instead of conversation and give-and-take, one or two journalists asked questions in a challenging manner that were seldom designed to elicit more information. Note: I wrote about the partnership earlier this week.

Retiring CEO Meg Whitman used a quote from Gartner in her remarks. “The Edge will eat the cloud.” HPE has developed edge computing devices called Edgeline that I discussed in August after my first meeting with the company. These are powerful computing devices based on PXI platform technology from National Instruments. The blogger group devoted some time discussing how valid that comment was.

We concluded that you will need both. I have an example from a conversation I had with Rod Anilker, a technologist in the OEM group. Imagine taking the computing power and openness of the HPE platform to replace proprietary controllers such as CNC, PLC, DCS. These devices at the edge would solve many control and other edge applications with the additional capability of sending data to the cloud.

Now, imagine the storage and computing power HPE has accumulating vast amounts of data—maybe from a power generation fleet or a company’s many refineries—achieving scale sufficient to do some pretty cool pattern recognition. The predictive, prescriptive, and planning possibilities would be awesome.

Pieces of HPE Corporate Puzzle

Antonio Neri, President and COO and next year’s CEO, let general session with these main points.

• Intelligent Edge (where the action is->acquisition of Aruba so important)

• Secure platforms from edge to core to cloud

• Memory-driven computing (acquisition of Silicon Graphics another important piece)

• Artificial Intelligence (inside everything)

• Software-defined and multi-cloud platforms

• Partner ecosystem

• Flexible consumption (scale up, scale back)

• Advise and transform HPE PointNext

• Outcome-as-a-Service, future of enterprise computing

Edge-As-A-Service

PointNext is the services arm introducing the concept of Edge-as-a-Service. In face, HPE features “as-a-service” in many guises.

This concept seems to be modeled on ideas emanating from GE’s consumption of services mode. Capturing and processing data at source where action needs to happen as the foundation of the model. Then you provide IT in a way that scales, pay-as-you-go concept, subscription-based. Therefore, the customer has flexibility and reduced risk.

Take the expertise from a data center that runs 24/7 and put it at edge. Then it’s all about extracting data. Take this into machine learning. This starts to morph into the concept from the OEM group.

The model architecture takes HPE’s new GreenLake plus EaaS. GreenLake edge compute includes design services, information services, operational & support services, and pay-as-you-go. Upfront consulting to help evaluate the client’s requirements and business process and recommends solution packages.

Technology overview

David Chalmers, research and development executive, briefed us with a business and technology overview.

Hewlett Packard Enterprise is one of the two business left standing after Meg Whitman (and the board) split the company following some bad years of plans and leadership. Following the split, several businesses were divested.

Chalmers related HPE has been changing fast into an infrastructure/solutions company (he said, the world’s largest). “The strength of our portfolio is the best in 10 years, much from organic development. The SGI acquisition yielded more compute options (SGI acquisition), including low power, high performance computing. By 2022 60% of data will never get to data center, it’ll reside at the edge. Therefore intelligent edge is important. SGI brought high performance analytics.”

Another couple of tidbits. At the new HPE people bring business cases first, then talk about the technology solution. The OT world order of magnitude larger than IT world. (Hmmm)

Oh, and there were many new products. They don’t all apply to my areas of coverage. But the engineers have been busy.

IoT

I just realized I made it through the entire discussion without mentioning the technology that brought me to HPE Discover—Internet of Things. Much of that relates to the Edge and devices such as Edgeline. Obviously important IoT garnered significant floor space in the exhibition area.

There will be more in another post.

by Gary Mintchell | Nov 6, 2017 | Internet of Things, Manufacturing IT, Operations Management

While at the Dell IQT kick off event in New York last month, I learned more about the breadth of Dell’s thinking about the Internet of Things.

It began with morphing embedded computer as a gateway (with memory and processing power and multiple connections).,

Added partnerships.

Added platform (EdgeX Foundry).

But that hardly seemed like something that warranted Michael Dell’s time during his past three Dell World / Dell EMC World keynotes.

Revealing the coming together of the various divisions of Dell Technologies, I learned about VMware Pulse IoT Center, an enterprise-grade Internet of Things (IoT) infrastructure management solution that will enable IT and operational technology (OT) teams to have complete control of their IoT infrastructure and things.

Interestingly, the Internet of Things group has been promoted to division stature led by the VMware CTO Ray O’Farrell.

Here are a few details on the Pulse Center.

Solving the problems

Customers have challenges scaling from IoT proof-of-concept to production.

• on-board and manage of thousands to hundreds of thousands of connected devices;

• make sure those devices are working as they are supposed to; and

• keep the devices and data secure.

Dell cites core strengths of device and application management, infrastructure analytics, and security give us the IP and expertise to address these issues with an easy to use, single-pane-of-glass solution to help customers to more efficiently manage, operate, scale and protect their IoT projects from the edge to the cloud.

VMware Pulse IoT Key Features

• Edge Device Management – Support for heterogeneous things and gateways with different hardware, operating systems, and communication protocols

• Real-Time Infrastructure Analytics – Ability to identify anomalies with real-time monitoring and infrastructure analytics

• Sophisticated & Flexible Rules Engine- Ability to granularly define what, where and when things are updated

• Single point console- A single point of monitoring and management for the IoT infrastructure (across private networks comprising of edge systems and connected devices) for both IT and OT users

• OTA updates – Ability to provide over-the-air, real-time updates to all things/gateways no matter how remote the location

• Smart Data Orchestration- Delivery of relevant data where and when it is needed across the edge and in the cloud by integrating into enterprise systems

• Security Across IoT Value Chain- Provides security at thing, network and user level with software updates and NSX and VMware Identity Manager integration

• Visualize thing – gateway relationships- Provides pictorial representation of the topology of the IoT infrastructure – 2 tier or 3 tier – in a parent child relationship diagram

• Highly scalable – Supports hundreds of thousands of edge systems and IoT connected devices such as sensors and actuators.

• On Prem support– Offered as an on-prem solution for deployment flexibility and security. Future versions will also be offered as cloud-hosted.

• Enterprise Integrations- Quick and easy integration with existing server systems through a comprehensive API abstraction layer

Chief Customer Officer

I also met with Jim Ganthier, a Vice President who works in the office of the Chief Customer Officer. OK, there are lots of “Chiefs” running around corporations today. Since I am most interested in technologies and their uses in manufacturing and industrial, I didn’t have lots of questions. It was interesting to see that there is a “voice of the customer” at the executive level of a major corporation. We talked a lot about whether it was difficult for a global technology company to meet the varying privacy requirements found from nation to nation. He assured us that they had the technology to comply.

Chief Marketing Officer

A comment stood out in our conversation with Jeremy Burton, the corporation Chief Marketing Officer. “The last 20 years has seen technology used for efficiency. Now technology is a differentiator.”

Hmm, sounds like what I heard at Emerson. Maybe it’s a meme.

Disclaimer: Dell pays my expenses to its events and an occasional fee for posts. The views are always mine, and they never review before publication.

by Gary Mintchell | Oct 24, 2017 | Internet of Things, Operations Management

Just when I was saying last week that the The Industrial Internet Consortium (IIC) had been very busy, I interviewed Eric and Wael about this newly published the IIC Industrial IoT Analytics Framework Technical Report (IIAF). It is the first IoT-industry technical document to include a complete set of instructions that IIoT system architects and business leaders can use to deploy industrial analytics systems in their organizations.

People I talked with used to think that the Industrial Internet of Things was all about sensors, or the Internet, or Things. Actually, it is nothing without databases and analytics. And here is the IIC to provide a framework for systems architects.

From the news release:

IDC has predicted that by 2020 one tenth of the world’s data will be produced by machines. Yet without an analytics blueprint, that data could sit unused, never being analyzed and turned into useful insights. The IIAF is a first-of-its-kind blueprint for system architects and designers to map analytics to the IIoT applications they are supporting, to ensure that business leaders can realize the potential of analytics to enable more-informed decision making.

“Using analytics to provide insights is the holy grail of industrial IoT,” said Wael William Diab, IIC Industrial Analytics Task Group Chair, IIC Steering Committee Member and Senior Director at Huawei. “The IIC IIAF takes a holistic approach by developing the foundational principles of industrial analytics as well as looking at the complete picture from design considerations to creation of business value and functionality. This entire ecosystem approach is valuable to both business leaders as well as technologists, engineers and architects looking to deploy IIoT systems.”

The IIC IIAF is the first document to offer a broad scope of requirements and concerns for industrial analytics applied to IIoT systems. It shows IIoT system architects the steps involved in developing analytics for IIoT systems with state-of-the-art information, including definitions and information flows that shows how the technologies can be applied to the applications. Guidance is provided how and where to deploy industrial analytics based on the characteristics of the applications and outcome expectations. In addition, the IIAF looks at emerging technologies including artificial intelligence (AI) and big data, which are expected to play an increasingly important role in industrial analytics.

“Industrial Analytics is changing rapidly, from data lake to stream processing and machine learning. Our framework provides a common understanding and encourages interoperability across the IIoT ecosystem,” said K. Eric Harper, IIC Industrial Analytics Task Group Chair, IIC Steering Committee Member and Senior Principal Scientist at ABB. “With this foundation, it is more likely that applications will be able to adopt new technologies and techniques in the future without substantial rework.”

Analytics have been applied to other many other fields such as finance and retail to improve the customer experience and increase corporate revenue. The major differentiation in industrial settings is the physicality of the systems. For example, if IIoT systems are not configured correctly, or if their maintenance schedule is wrong, the systems can cause physical harm. Analysis and improvement of operational maintenance across multiple systems must be performed with extreme diligence, and are as important to technology leaders as they are to business leaders looking to increase profits.

“Industrial analytics are the engine that takes data from industrial systems and creates value and insight to get business results,” said Will Sobel, IIC Industrial Analytics Task Group Chair and Chief Strategy Officer at VIMANA. “The sophistication of analytical methods in other domains, such as finance and media, have been evolving at a breakneck pace, but little has been done to apply these techniques to industrial systems. The IIAF provides the special considerations one needs to consider before one uses these technologies in an industrial system.”

When analytics are applied to machine and process data, they help optimize decision-making and enable intelligent operations. These new insights and intelligence can be applied across all levels of any enterprise in any industry if the appropriate data can be collected, curated and analytics are applied correctly.

“In transforming machine raw data into actionable information, industrial analytics plays a crucial role in the industrial Internet just like refineries that turns crude oil into high energy fuel. The actionable information from the analytics is the fuel that drives the optimization of industrial operations and production, the creation of new revenue streams and the enablement of new business models,” said Shi-wan Lin, IIC Technology Working Group Chair and CEO and Co-Founder, Thingswise, LLC.

The full IIC Industrial IoT Analytics Framework Technical Report and list of IIC members who contributed can be found on the IIC website.

by Gary Mintchell | Oct 18, 2017 | Internet of Things, Operations Management, Software

There are two types of people in industry—operations technology and information technology. God forbid if they should actually talk with each other.

Everywhere I go there is talk of overcoming the OT/IT divide. Something just crossed my email stream where there was a survey about whether the departments have merged anywhere. They were shocked, shocked I say, that only about 1 in 10 companies have merged the two departments. I think the purveyors of that survey must have been on Mars for the past bunch of years.

These people just have different jobs to do. Different things they are measured on. Different ways they contribute to the common welfare of the corporation. However, the technologies they use are overlapping at an ever greater pace.

Here is a survey that once again reveals what is seemingly a disconnect between IT and OT. But I think that interfacing to ERP systems is non-trivial. I’m actually amazed and heartened by the progress we’ve made to date.

I’d take a look at this survey and consider how far we have come—and yet, how far we still need to go.

IFS has released a primary research study on how the Internet of Things (IoT) affects readiness for digital transformation in industrial companies.

According to survey of 200 IoT decision makers at industrial companies in North America, only 16 percent of respondents consume IoT data in enterprise resource planning (ERP) software. That means 84 percent of industrial companies face a disconnect between data from connected devices and strategic decision making and operations, limiting the digital transformation potential of IoT.

The study posed questions about companies’ degree of IoT sophistication. The study also explores how well their enterprise resource planning (ERP), enterprise asset management (EAM) or field service management (FSM)software prepares them for digital transformation and to consume IoT data within enterprise software.

Respondents were divided into groups including IoT Leaders and IoT Laggards, depending on how well their enterprise software prepared them to consume IoT data—as well as Digital Transformation Leaders and Digital Transformation Laggards depending on how well their enterprise software prepared them for digital transformation.

The two Leaders groups overlapped, with 88 percent of Digital Transformation Leaders also qualifying as IoT Leaders, suggesting IoT is a technology that underpins the loose concept of digital transformation.

Digital Transformation Leaders made more complete use of IoT data than Digital Transformation Laggards; Leaders are almost three times as likely to use IoT data for corporate business intelligence or to monitor performance against service level agreements.

Digital Transformation Leaders were more likely than Digital Transformation Laggards to be able to access IoT data in applications used beyond the plant floor. They were more than four times as lilkely to have access to IoT data in enterprise asset management software, twice as likely than Digital Transformation Laggards to be able to access IoT data in high-value asset performance management software, and almost twice as likely to be able to be able to use IoT data in ERP.

The data suggests a real need for more IoT-enabled enterprise applications designed to put data from networks of connected devices into the context of the business.

In reviewing the findings, IFS Chief Technology Officer for North America, Rick Veague, commented, “Are your planning and maintenance systems robust enough to make real time decisions using IoT-sourced data? Many are facing the reality of having to answer ‘no.’ ”

“Study data suggest that the most common use case for IoT in these industrial settings is condition-based maintenance. The benefits go beyond operational improvements and maintenance cost avoidance,” said Ralph Rio, Vice President of Enterprise Software at ARC Advisory Group. “It increases uptime that provides additional capacity for increased revenue. It also avoids unplanned downtime that interrupts production schedules causing missed shipment dates and customer satisfaction issues. When married to demand and scheduling systems in ERP, IoT becomes a revenue-enhancement tool improving the top line.”