Siemens Talks Manufacturing In America

A small group of journalists and writers trekked to the Detroit area March 12-13 to glimpse the future of Manufacturing in America sponsored by Siemens Industry and its local distributor/partner Electro-Matic. We toured the local Founders Brewery facility, visited with faculty and students of Industrial and Systems Engineering at Oakland University, and attended the annual thought leadership panel.

Food and Beverage

Founders Brewery, craft brewery founded in Grand Rapids, MI, built a smaller version of brewery/restaurant in downtown Detroit not far from Ford Field and Greektown. The automated part of the brewery and instrumentation was supplied by Siemens. We toured the brewery, had an awesome sandwich, and sampled some of the many craft beers from founders.

Education

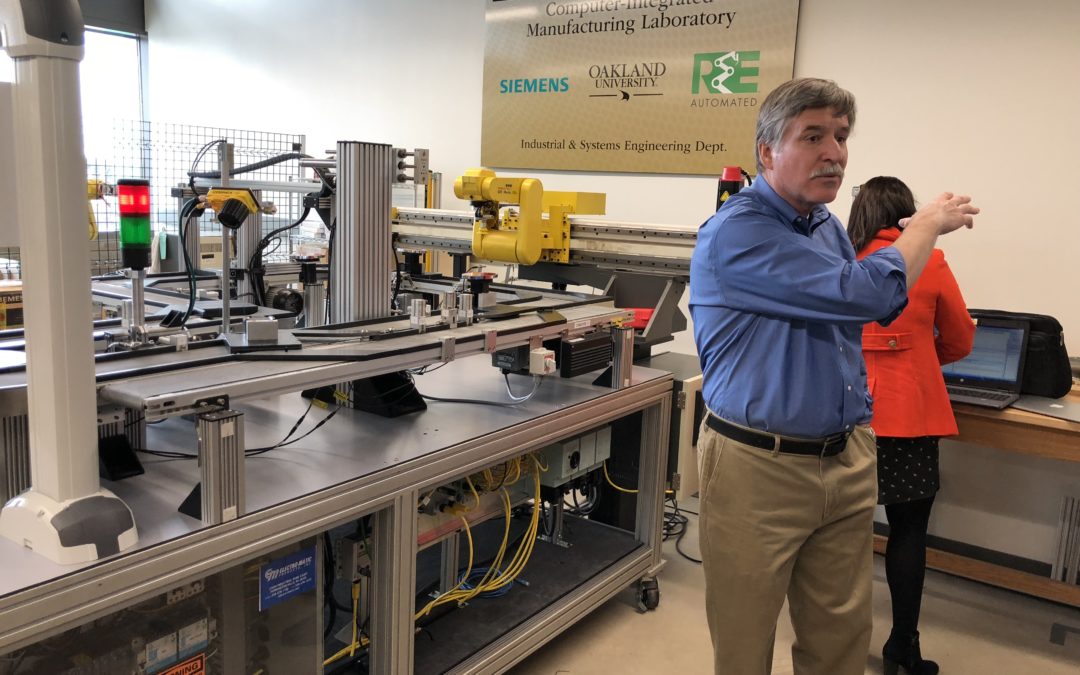

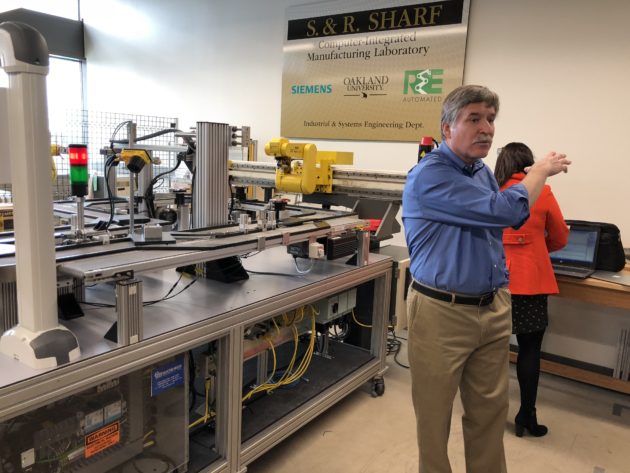

A complete change of pace (well, maybe not as I remember my college days) took us north to Rochester, MI to Oakland University. Robert Van Til, Ph.D., Pawley Professor of Lean Studies and Chair of Industrial and Systems Engineering (ISE), introduced us to his program and several students who explained their experiences both in class and working in local factories.

A complete change of pace (well, maybe not as I remember my college days) took us north to Rochester, MI to Oakland University. Robert Van Til, Ph.D., Pawley Professor of Lean Studies and Chair of Industrial and Systems Engineering (ISE), introduced us to his program and several students who explained their experiences both in class and working in local factories.

Siemens has donated much software and equipment to the program. Students explained how they had been trained in Siemens PLM software and used the simulation application to model real-world problems. They impressed me with a maturity I doubt that I had at that age, but also with how smoothly they integrated Lean Manufacturing concepts with their factory cell simulations.

-> An important point. I hold the impression left over from some years ago that young people view manufacturing negatively—as dark, dirty, unsafe, backwards places to work. Much to the contrary, these students all viewed manufacturing as a place to use their technical training to make an impact. They see how they can contribute to an organization immediately. I guess the work we’ve done over the past 20 years to clean up our factories and apply technology are being rewarded.

Finance 4.0

Nothing beats an early morning meeting to talk finance. Actually, it’s not that bad. Before the Wednesday summit meeting, we met with the Siemens Finance team. Note: we did this last year, as well.

Siemens has identified six challenges for manufacturers on the journey to Industry 4.0. Challenge No. 2 identifies access to finance for the scale of investment over time that manufacturers need to make in digital and automated technology platforms.

The team has released a white paper, “Practical Pathways to Industry 4.0 in the USA.” This would be Finance 4.0 for Industry 4.0. Snipping one section, “Integrated Strategic Finance,” here are a few points:

- Evaluate potential sources of finance for both OPEX and CAPEX

- Consider how you’ll finance all aspects of digital transformation

- Align with strategic growth vision and technology investment

- Find financing partners with willingness and skills for this journey

- Is your CFO a ‘virtuoso’ in linking initiatives to financial outcomes

Siemens Finance has many financial instruments in place to help from brownfield upgrades to greenfield projects—and for complete equipment financing, not only Siemens equipment.

Thought Leadership Summit

Raj Batra, President of Digital Factory for Siemens Industry Inc., took the ball from MC Eddie Murray (former NFL kicker), discussing how manufacturing executives in the US are very optimistic about the near future for manufacturing. One large problem is finding talented people to fill the positions. He also discussed Siemens technology and how it is helping manufacturers, for example like adidas who in this “order the latest fashion online” world need to shrink the 18 month timeline from concept to delivery of new shoes. Siemens PLM to the rescue.

Greg LaMay, Director Global. PLM Implementation for KUKA NA, showed how his team is using Siemens PLM applications to break silos within the company to improve time to ship and customer experiences.

John Greaves, IoT, RF, and Blockchain Solutions Architect (with a portfolio like that, he could probably bring the world to an end 😉 ) at Lowry Solutions, showed how Blockchain (the technology used by Bitcoin, for example) is already used for critical supply chain applications.

Alan Beaulieau, Ph.D., Economist, and President of ITR Economics (check it out, he wrote a column for me at Automation World for several years and he’s a great speaker), gave his usual well researched and reasoned view of the economic scene. Hint: it’s better than you might think reading the newspapers or listening to TV. itreconomics.com