by Gary Mintchell | Oct 16, 2013 | Automation, Events, News, Operations Management, Process Control, Software, Technology

This is day two of the Invensys industrial software user conference in Dallas. The atmosphere is on of energy and enthusiasm. It’s an impressive event.

This is day two of the Invensys industrial software user conference in Dallas. The atmosphere is on of energy and enthusiasm. It’s an impressive event.

Invensys people here, just as at the Foxboro/Triconex conference last month, are optimistic about the pending acquisition by Schneider Electric. By the way, the shareholders have approved the acquisition. Now the decision rests with all the various governmental regulatory agencies. Mike Caliel will be the Invensys lead on the integration team—which can’t do anything until all the approvals are received and the deal is final.

Mike took some time out of a busy schedule to chat about Schneider and the software business. Norm Thorlakson, global head of Invensys’ HMI and Supervisory software business, joined us for most of the conversation.

To get the Schneider conversation out of the way, I asked several questions about a post-acquisition Schneider and Invensys knowing that Mike couldn’t answer with any detail. He absolutely cannot comment on Citect—its history and place within the structure. Regarding the Invensys Wonderware partner ecosystem, he could only say that Schneider knows about the importance of partners as the way Invensys software goes to market. But although integration teams have been formed on each side, they cannot begin work until all the approvals are obtained.

My biggest takeaway from two Invensys conferences is the confident optimism of all the Invensys people. The company is filled with intelligent, experienced people, and the Schneider CEO is on record saying he respects that.

I’ll write more on the outlook of a post-acquisition Schneider in the market later. But the combined company should have a considerable impact on the market.

Spiral Crude Assay Management

Mike and Norm also discussed the trends in software that Invensys is capitalizing on—and leading in many ways. In the age of “Big Data”, contextualization is the key to information. The ability to synthesize date into actionable information so that customers have a safe and reliable plant continues to be the focus.

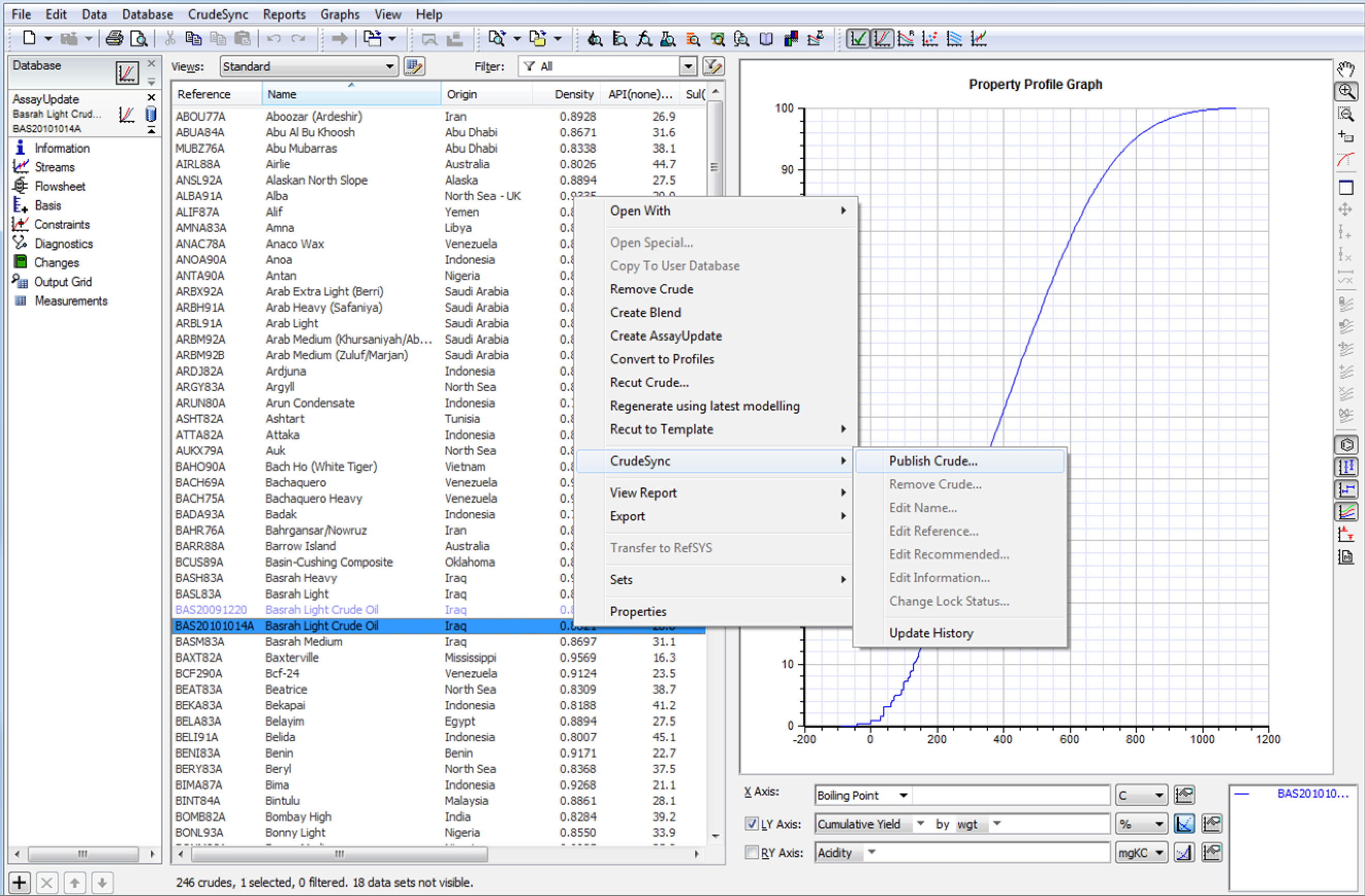

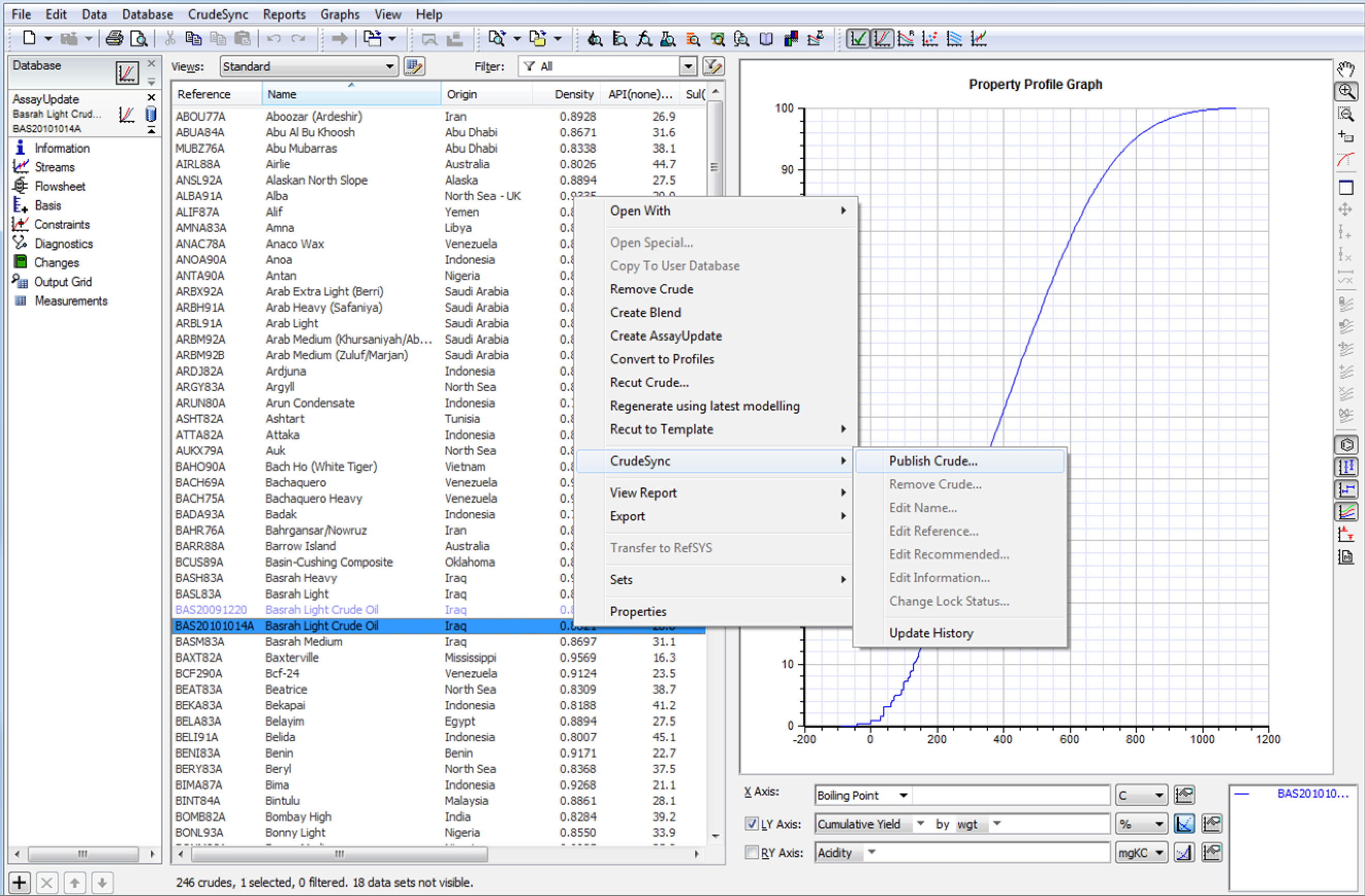

For example, they cited the following product announcement from the SimSci group. This assay management software is even more powerful (especially impactful if you’ve seen the demo) than even the press release says (I know, the reverse is the norm). Combining access to data and powerful modeling tools, an engineer can look at the characteristics of one type of crude on a graph, then perhaps look at other crudes waiting for processing. Perhaps the engineer checks the graphs and finds that two are quite similar. Then with just a click, looks at the characteristics resulting from blending the two. All this is done quickly and easily alleviating a tremendous amount of work, calculations, checking and re-checking that is necessary now.

The product release of the day comes from SimSci–Spiral CrudeSuite crude oil knowledge-management software with its SimSci PRO/II design and ROMeo optimization software. The new integrated offering gives the hydrocarbon processing industry a single-source software solution that enables seamless access of latest crude assay information for refinery design, analysis and optimization. The integrated Spiral CrudeSuite offering will provide accurate and complete crude assay information throughout plant lifecycle modeling from design through operations and performance optimization.

“Integrating our crude assay management, design and refinery optimization software fulfills the potential of the Spiral Software acquisition we announced last year,” said Harpreet Gulati, Ph.D., vice president, design software for Invensys. “We are now able to offer the only full-span refinery optimization solution on the market today, one that will help our customers reduce operating costs, increase throughput and maximize profit. Having complete and accurate crude information for improved design and optimization can help drive cost savings and margin improvements that could total millions of dollars each year.”

Spiral CrudeSuite is an enterprise toolset for sharing, managing and modeling crude oil information. It supplies rich, validated crude assay data so engineers can easily design accurate refinery processes using the company’s SimSci PRO/II software, and its comprehensive crude assay data helps engineers optimize the refinery for maximum profitability using the company’s SimSci ROMeo software.

“Combining our Spiral Crude Assay management, PRO/II design and ROMeo refinery optimization software capabilities allows us to provide a unique, end-to-end solution across the full hydrocarbon processing value chain,” Gulati said. “CrudeSuite software will help refiners understand their exposure to changes in feedstock costs, product demand and refinery operations, and it greatly increases the accuracy of their models and speeds up new designs and revamps. It is going to help our customers make the best possible business decisions using real-time market and operations data. We are excited about the business value and competitive differentiation this will provide to our clients.”

by Gary Mintchell | Oct 15, 2013 | Automation, Data Management, Operations Management, Technology

Rocking out to the Beatles “Revolution”, Invensys software announced “The Industrial Software Revolution Begins Now.” About 1,000 people gathered at the Hilton Anatole in Dallas for the second Invensys conference in a little over a month. Last month it was the process solutions side of the company. This conference focuses on Wonderware, SimSci-Esscor and Avantis.

Rocking out to the Beatles “Revolution”, Invensys software announced “The Industrial Software Revolution Begins Now.” About 1,000 people gathered at the Hilton Anatole in Dallas for the second Invensys conference in a little over a month. Last month it was the process solutions side of the company. This conference focuses on Wonderware, SimSci-Esscor and Avantis.

Expect a stream of new product announcements this week.

This morning I had breakfast with Saadi Kermani and Maryanne Steidinger to discuss mobile, cloud and related technologies. Hint—you can find an app on iOS, Android and Windows 8, just search SmartGlance in your app store. Invensys Wonderware has been on the leading edge of mobility for several years.

System Platform 2014

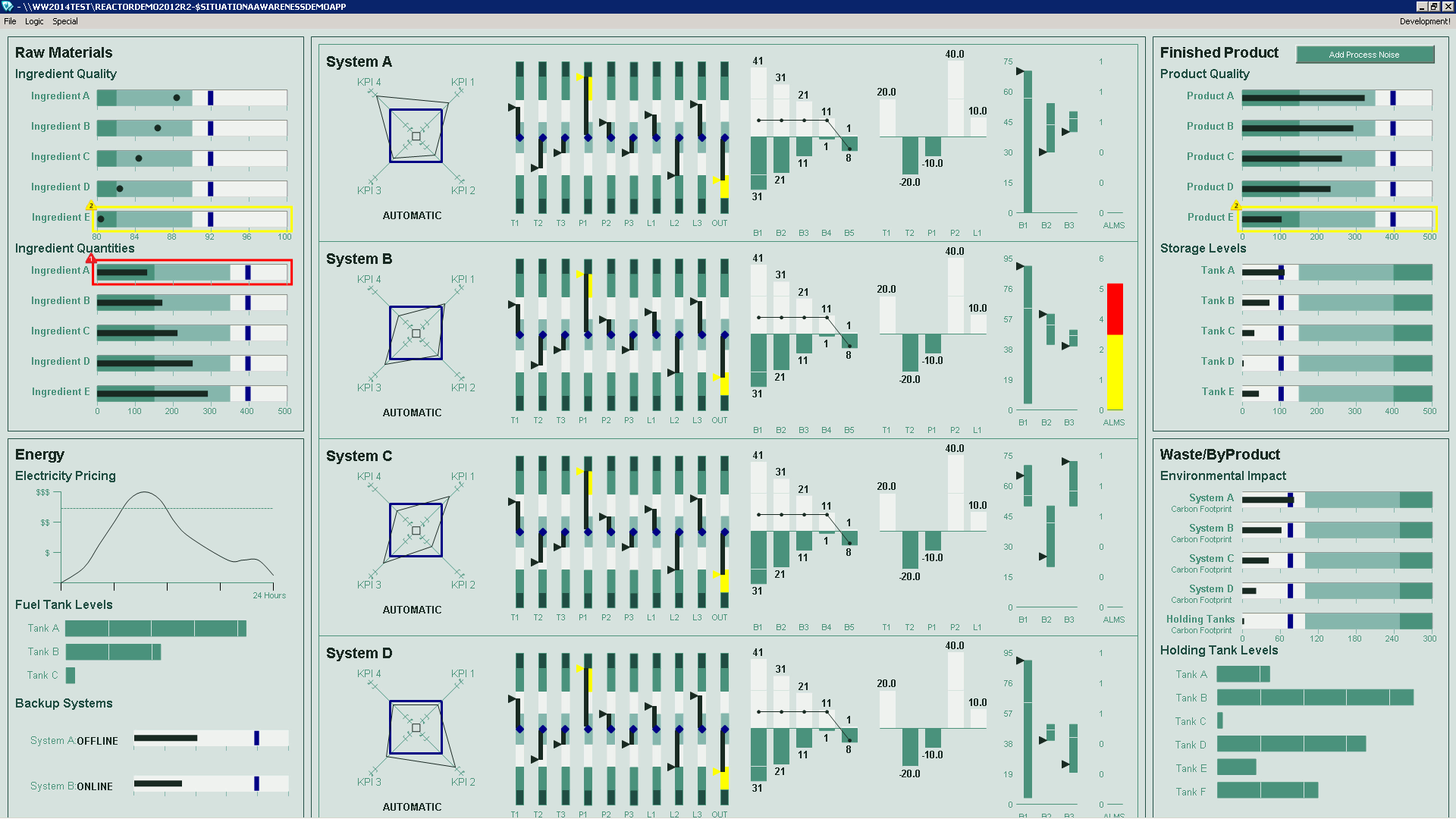

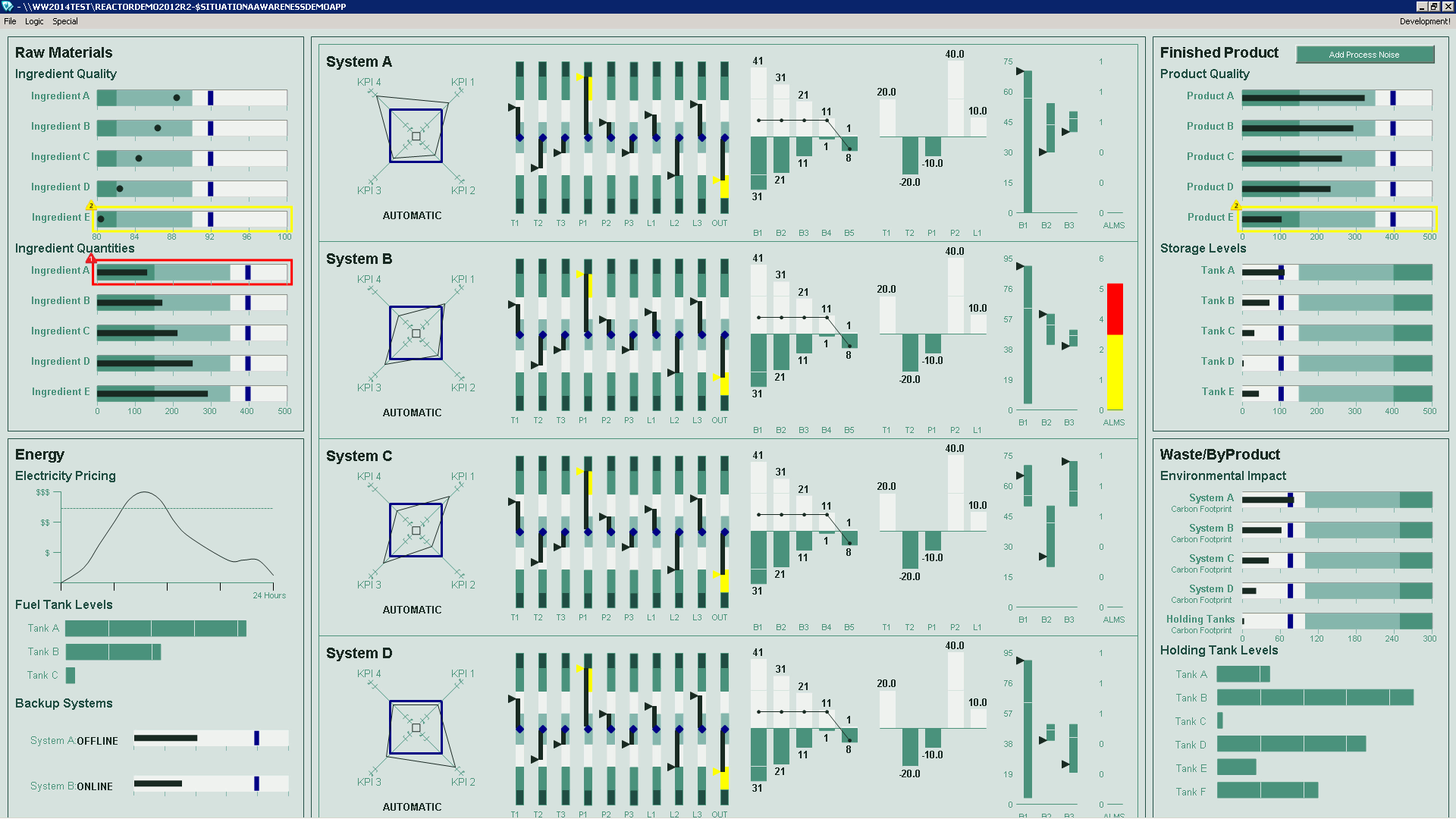

Invensys kicked off the event with the release of its Wonderware InTouch 2014 and Wonderware System Platform 2014 software. Delivering powerful, additional capabilities to its flagship HMI and supervisory offerings, the new software promises to improve operator awareness, optimize performance and minimize disruptions during startup, operation and shutdown.

“While other HMI providers have been focusing solely on graphics to improve the operator experience, Invensys has been collaborating closely with some of the world’s most recognized industrial companies—large and small—to understand their most pressing challenges and issues, and then devise the most innovative ways to solve them,” said John Krajewski, director of HMI and supervisory product management for Invensys.

One major operating challenge is the ability to more quickly identify and address abnormal situations before they impact operations. The company’s Wonderware InTouch 2014 and Wonderware System Platform 2014 software take what the company labels “a revolutionary new approach to HMI design” and supervisory systems by providing new capabilities in alarm management, color representation, information presentation and window navigation, all intended to maximize user performance.

The updates include new object templates; styles for consistent and standardized colors and fonts in HMI applications; and consistency in the way alarms are represented throughout systems, all simply managed from a central repository.

“Utilizing 15 years of human interface studies, we have delivered a toolkit that transforms the way industrial users design and interface with their HMI,” Krajewski said. “We’ve moved from simply presenting data to displaying information in context. Instead of developing a library of ‘graphics,’ these new capabilities enable application builders to focus on creating content, easily assembling the most effective HMI applications and user interfaces for abnormal situation management.

“Initial testing indicates that these new styles and standardized colors can help users reduce situation interpretation time by 40 percent and can lead to a five-fold improvement in detecting abnormal situations before they occur. After the initial detection, our enhanced navigation can improve the success rate for handling abnormal situations by as much as 37 percent, and we’ve seen a 41 percent reduction in the time required to complete tasks.”

These new capabilities implement and encourage best-practices to bring clarity, consistency and meaning to integrated data, allowing senior, experienced and entry-level operators to identify, understand, react to and resolve abnormal situations, thus optimizing their operations. The new capabilities can also empower and train new operators, helping companies address another major issue: the retiring workforce.

by Gary Mintchell | Oct 14, 2013 | Operations Management, Software

GE Intelligent Platforms has announced the immediate availability of “Proficy for Manufacturing Discrete (PfMD)”. This solution designed specifically for complex discrete manufacturing environments provides what the company calls “complete digitization of paper-based processes.”

GE Intelligent Platforms has announced the immediate availability of “Proficy for Manufacturing Discrete (PfMD)”. This solution designed specifically for complex discrete manufacturing environments provides what the company calls “complete digitization of paper-based processes.”

Proficy for Manufacturing Discrete provides digitized standard operating procedures, advanced dispatch capabilities and

structured capture of quality data to support real-time decision making and continuous process improvement, especially in complex, engineer-to-order and build-to-order environments.

“PfMD incorporates the best practices of GE’s own world-class manufacturing businesses,” said Don Busiek, General Manager, Manufacturing Software for GE Intelligent Platforms. “It incorporates our learnings in real-world discrete manufacturing environments, as well as our 25 years of MES expertise. In addition, we are seeing amazing results from implementation at GE sites.”

The company details its results:

- 70% reduced warranty investigation time

- 10% reduced WIP Inventory

- 20% reduced product cycle times

- 25% reduced rework and scrap

- 20% reduced manufacturing costs

PfMD is adaptable to multiple manufacturing environments ranging from the production of long-cycle, complex products engineered to order, to discrete products being configured to order. By digitizing work processes, PfMD enables the entire manufacturing workforce, including operators, production supervisors, manufacturing engineers and quality engineers to produce products faster, more efficiently, and consistently. PfMD has been designed to handle environments where more than 100,000 routes, hundreds of thousands of documents, and tens of thousands of quality forms required to support the products being produced.

Integrated with GE’s Proficy Manufacturing suite for consistency across products, PfMD provides standard connectivity to ERP and PLM systems for rapid deployments. It is modularized to deploy in phases for near-term and long-term benefits and features advanced architecture to integrate with existing plant floor controls and operations.

A key feature of PfMD is its Dispatch capability which enables operations to be dispatched to lines and/or work cells based on the route definitions in the form of jobs to be executed. The queue of jobs associated with a line and/or a work cell is made up of comparable operations from multiple orders. Also, the product’s documentation management capabilities allows production supervisors to manage the documents utilized within the system, including the creation, modification, and revision control of documents, which can be routed through an approval process prior to production. In addition, PfMD provides detailed order scheduling, product management, order execution, route management, labor tracking, WIP management, manufacturing instructions for operations.

Genealogy and Traceability features of PfMD capture a permanent record of as-built product data, including the material/BOMs, along with all quality data and routes/operations. The solution also captures quality data associated with the product and/or process through quality forms and configures the qualifications and/or certification levels of equipment and personnel to ensure the right people and/or equipment are allowed to perform the operations (i.e., execute the jobs).

Digitized information enables true real-time digitized WIP Visibility and Management to reduce cost and improve product manufacturing cycles. PfMD also Streamlines Supply Chain Management by capturing supplier and outsourced operation data.

“Digitizing MES processes is a critical enabler for achieving effective operations and supply chain optimization,” concluded Busiek. “PfMD delivers optimized performance today and a forward-looking foundational path for success tomorrow.”

by Gary Mintchell | Oct 14, 2013 | Marketing

During the ISA Marketing and Sales Summit in September in New Orleans, I had a chance to chat with Shari Worthington about why ISA decided to go ahead with this particular conference on marketing manufacturing solutions, what it means to manufacturing and marketing professionals, and what might be coming up in the future.

by Gary Mintchell | Oct 14, 2013 | Marketing

While I was attending the ISA Marketing and Sales Summit in New Orleans in September, I had a chance to talk about marketing manufacturing solutions to manufacturing professionals with Matt Leary of Solutions Insights. This is interesting to people on both sides of the desk.

And, yes, I was so swamped throughout August and September that I’m only now finally catching up. Assuming that there’s more news than I’ve seen for a while, I should be able to get more posts up.

This is day two of the Invensys industrial software user conference in Dallas. The atmosphere is on of energy and enthusiasm. It’s an impressive event.

This is day two of the Invensys industrial software user conference in Dallas. The atmosphere is on of energy and enthusiasm. It’s an impressive event.