Last winter I got sucked in by an advertisement from Verizon. My wife was due for a new iPad and could use a new iPhone. I was thinking about upgrading my 2-year-old iPhone. The ad looked like a good deal to trade in a bunch of stuff and walk out with new equipment. In the end, you never get the deal exactly as advertised because of nuances. But we did it.

I bet you’ve traded in a phone or two in your life. Ever wonder what happens to those old traded-in phones? You are about to find out.

A publicist I’ve known for a while who (unlike most these days) knows me and what I like to write about, pitched me a story about an actual user of automation. I said great, I’d like something beyond just a new feature in the software. Except the company was Assurant. I looked them up. An insurance company. In 25 years, I doubt that I’ve written about insurance once.

But she’s trustworthy and the application seemed appropriate, so here we are. A story about how a division of Assurant has built a big business taking in traded-in mobile phones and reinserts most of them back into the supply chain. If you’ve bought a refurbished phone, chances are it went through one of their facilities.

That’s how I wound up on a Microsoft Teams call with Brandon Johnson. He is the Senior Vice President of Engineering and Automation at Assurant, a leading global business services company that supports, protects and connects major consumer purchases. Johnson oversees all engineering and automation initiatives related to the mobile device lifecycle across 20 locations worldwide. His primary responsibility is to lead a team that implements innovative software and robotics technologies to enhance efficiency, safety, quality, and device value.

We’ll walk through the process they have developed for processing 15 million phones per year. Then we’ll look at how automation has improved workforce stability, worker safety, and throughput.

First, Johnson told me his background and education were industrial engineering and operations management. Automation was something he picked up along the way. Before automating anything in the processes at Assurant, though, he emphasized two things:

- They don’t automate simply to replace workers

- Every automation project must have a business purpose

So, what happens when your used phone hits one of their facilities?

Incoming material is all in boxes. There is no uniformity to the boxes. They must all be opened and the phones removed. The original process used people with razor box knives. These are a safety hazard (I know, I had a job using them once). The job also was not challenging which led to excessive attrition.

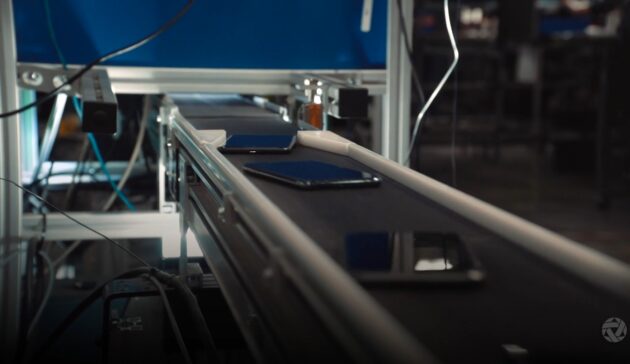

After phones are decartoned, they are provided with a QR Code ID. They proceed to a charging station as all need a minimum amount of charge for downstream processes. They go to a cosmetic grading station and then sorting into those who have potential high value and those not so much to those that will just be ground for recycling. Next comes a diagnostic test station where 65 tests are performed. Data cleaning comes next. This is a crucial step and Assurant is certified for data cleaning. They’ll perform and value-added repair if feasible. Then, on to the warehouse to be sold and shipped.

Automation has been added so far:

- Machine to slit the incoming boxes and cartons. This changed the job from manual knives to a technician job. That job is more stable and has value-added skills

- Cosmetic grading is highly complex and subjective. Assurant has developed a patented automation for inspection and grading the phones. Once again, a high-turnover job turned into technician roles leading to a more stable and trained workforce.

- Diagnostics testing has been upgraded from a single workstation where they’d dump a bunch of phones on a person and they’d perform all the tests on a single computer. Now there is a flow to the system easing the bottlenecks.

- A robotic feeder brings phones to the charging stations and plugs them in saving yet another rote job.

I asked about recycling the powder from groundup phones. They send to a third party who can extract the various metals from the powder for reinsertion into that supply chain.