by Gary Mintchell | Dec 5, 2014 | Automation, Data Management, News, Operations Management, Operator Interface, Software, Technology

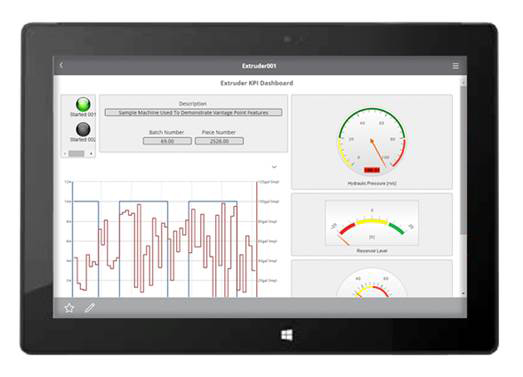

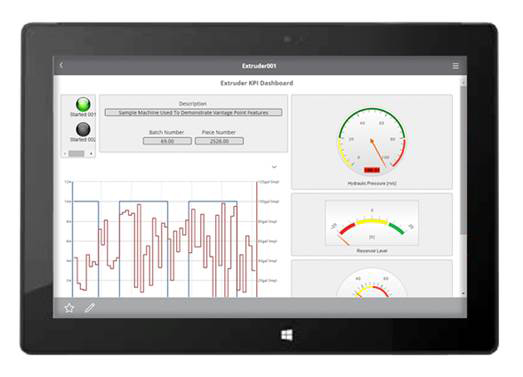

The consumer boom with mobile devices has not been ignored by production automation companies. Rockwell Automation showed FactoryTalk VantagePoint EMI v 6.0 enabling any digital device to access performance metrics and production data analytics from plant floors and machines.

The consumer boom with mobile devices has not been ignored by production automation companies. Rockwell Automation showed FactoryTalk VantagePoint EMI v 6.0 enabling any digital device to access performance metrics and production data analytics from plant floors and machines.

The VantagePoint v6.0 software now includes VantagePoint mobile, a component that enables users to create displays and interact with data across any HTML5-compliant browser and mobile platforms, such as iOS and Android. Users can now easily log in to the VantagePoint system and automatically view Web-based KPI content that is responsive to the device they are using – from smartphones to tablets to PCs. No user-specific configurations created by network administrators or IT staff are required, enabling manufacturers to quickly on-board more users and deliver value to increase productivity.

“The VantagePoint mobile component instantly detects the type of device being used to access information and adjusts the user experience for that screen,” said Angela Rapko, product manager for FactoryTalk VantagePoint software, Rockwell Automation. “This out-of-the-box solution will enable more users to access valuable operational insight while lowering the cost of delivering that data.”

Another new key capability is the “composer” feature, which allows VantagePoint v6.0 users to browse through data and easily customize content based on individual roles, priorities and viewing preferences. Using the software’s drag-and-drop interactive tools, users can create personalized displays to quickly find the information that is most important to them. The “favorites” capability also allows users to configure KPI data in the visual formats they prefer, from bar graphs to gauges to plant maps. They can then save the data or share it with a group using the VantagePoint mobile component.

“Customers have expressed a big need to drive usage of data across their organization for frictionless productivity,” said Kyle Reissner, mobility platform leader, Rockwell Automation. “With portability in mind, we wanted users to be able to move between devices seamlessly, allowing them to be more responsive and reducing time to solution. The VantagePoint mobile component is now at the core of the FactoryTalk VantagePoint software to deliver this ease of use.”

For OEMs, this streamlined connectivity provides the framework for delivering an information-enabled machine. Plus, they gain the ability to visualize data without the need for custom development.

For system administrators and integrators, improved diagnostics built into the VantagePoint v6.0 software on the server side – as well as more application-centric data sources – allow them to view and display the overall health of the system and specific applications. The VantagePoint v6.0 software also includes improved tag-provider templates to allow anyone initially building the model and applications – whether a system administrator or a customer – to accelerate design and deployment time.

All users will benefit from the flexibility of receiving and applying the VantagePoint software updates without having to uninstall, re-install and, in some cases, re-validate their current application.

“With the VantagePoint mobile framework, we intend to release software updates more frequently, including new display widgets and capabilities,” Reissner said. “We’re focused on eliminating friction, realizing productivity value, and ensuring users are able to do more with fewer barriers.”

by Gary Mintchell | Nov 5, 2014 | Automation, Industrial Computers, Operator Interface

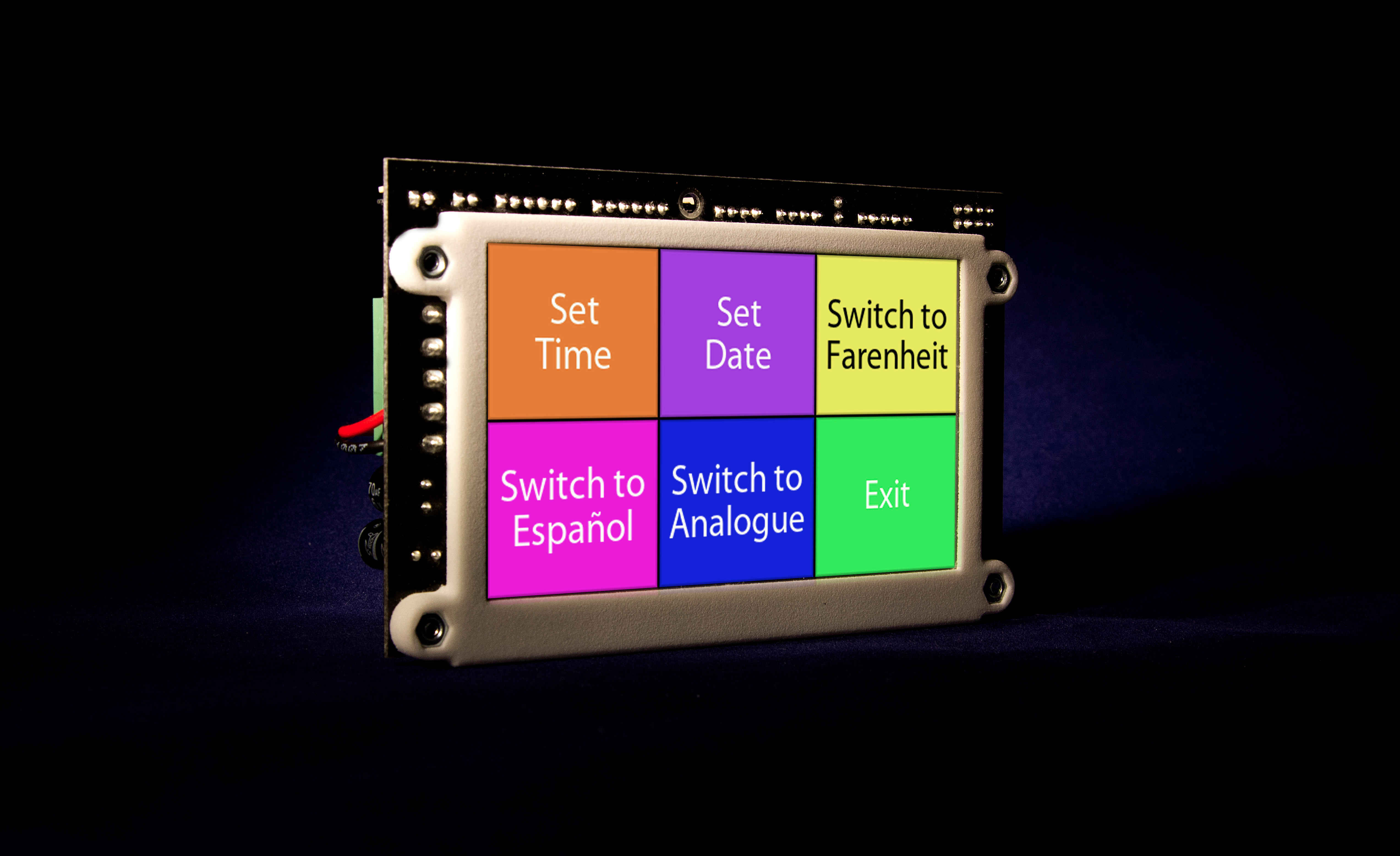

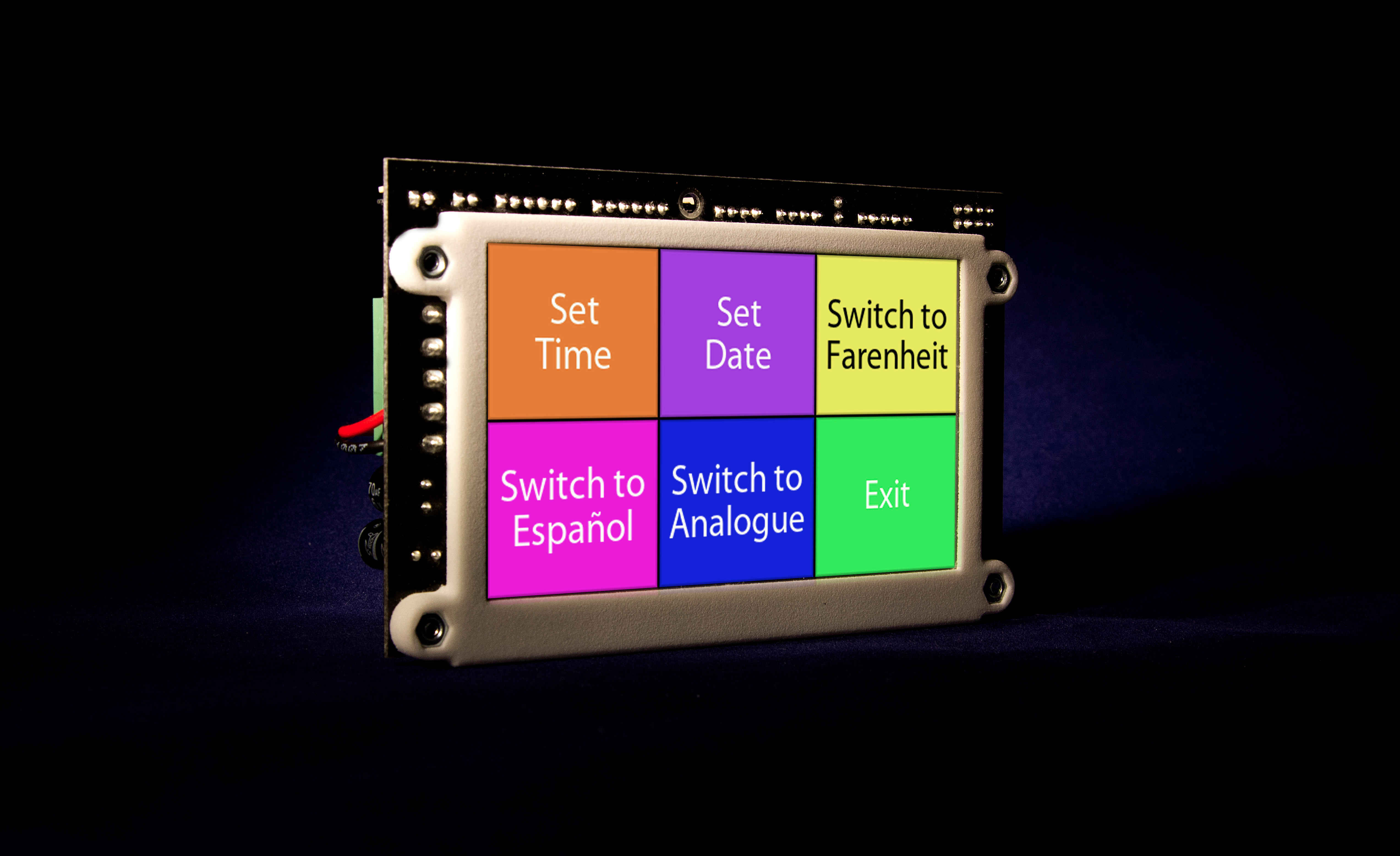

No doubt current trends in industrial controllers, programmable logic controllers (PLC) and human-machine interfaces (HMI) include driving down the cost of control. Here is one that is an integrated HMI/PLC for less than $400. Interestingly, this is the first product pitched to me in years that touts RS485 serial connectivity. I’d darn near forgotten all about those serial protocols.

No doubt current trends in industrial controllers, programmable logic controllers (PLC) and human-machine interfaces (HMI) include driving down the cost of control. Here is one that is an integrated HMI/PLC for less than $400. Interestingly, this is the first product pitched to me in years that touts RS485 serial connectivity. I’d darn near forgotten all about those serial protocols.

Anyway, here are some specifics from SPLat Controls.

The HMI430 board-level programmable logic controller (PLC) with an integrated 4.3-inch color touchscreen is available at nearly half the cost of previous products with similar functionality. With onboard, ruggedized digital I/O, analog I/O, and the SPLat MultiTrack built-in multitasking operating system, the HMI430 delivers “professional-quality control that is affordable and easy to program, minimizing development time.”

According to the press release, “With multiple serial ports HMI430 offers OEMs an ideal way to flexibly integrate a touchscreen into their solution for small- and medium-sized industrial control applications. The touchscreen—a 4.3-inch 470×272 pixel screen with resistive touch and 64K colors—comes with a repertoire of standard buttons, fonts, and other screen elements. With support for alpha blending, image files, and Z-ordering, HMI430 offers sophisticated visual effects at a price point that OEMs can afford.”

“With the advent of smartphones, all controller applications—medical, industrial, building control—are affected by the end-customers’ expectation of a GUI-driven interface,” noted David Stonier-Gibson, CEO of SPLat Controls. “The HMI430 with an integrated color touchscreen enables OEMs to respond to this ‘iEffect’ and provides the innovative edge that helps small- and medium-sized equipment manufacturers make their products smarter and more competitive.”

by Gary Mintchell | May 21, 2014 | Automation, Events, News, Operator Interface, Technology

The PAS Technology Conference is in session May 19-21. PAS bills itself as the “Human Reliability” company, and indeed reliability broadly speaking was a conference theme. This is also a celebration of PAS’s 20th anniversary, and historical references were everywhere.

PAS Founder and CEO Eddie Habibi

He was the first of several who talked about first looking at assets as data, then relating to the actual physical asset. Data can be collected, organized, contextualized, and displayed to help operations and maintenance make a reliable plant and increase the company’s profitability.

Inspiration, collaboration, invention

Habibi concluded, “Opportunities are there for us as a company that brings software solutions to great customer relationships. Customers bring inspiration, collaboration, and invention. We’re excited about it, and we want to be here another 20 years.”

At dinner the night before, I had the opportunity to talk to two of the conference’s keynoters who are both with production companies. Keith Dicharry is director of Controls and Instrumentation at BASF and Andy Geddes is controls and instrumentation manager for Scottish Power (as in the UK). Both were eloquent in their descriptions about the engineer’s role in helping maintenance and operations achieve a reliable plant.

Dicharry said in his keynote, “If we increase the reliability of equipment, we will increase our profitability. The goal for increasing reliability is to increase access to data. I want a rotating equipment engineer in Germany to be able to talk to a rotating equipment engineer in the US about a compressor where they can both look at all the data sets and figure out why one works well and the other has problems on a conference call rather than a flight across the pond.”

Harvey Ivey, manager of instrumentation and control systems and field support at The Southern Company, told the conference the story about how he worked with operators and others to develop displays that would give operations situational awareness of the health of their processes at a glance. His work, and collaboration with PAS, led to the development of the PowerGraphix product.

Alstom, in another conference announcement, has done much research on improving performance resulting in an agreement for it to become a reseller of PowerGraphix to its customers.

Security partnership

The day’s final announcement involved another partnership—this time PAS and Tripwire—a provider of risk-based security and compliance management solutions. The partnership is part of the Tripwire NERC Alliance Network Program that has been designed to foster collaboration on critical infrastructure compliance and security solutions to help companies efficiently and effectively achieve NERC CIP compliance.

According to PAS, the integration between the PAS Integrity Software Suite and Tripwire NERC Solution Suite will provide mutual energy customers with automation software that reduces the time and resources required to collect audit evidence. The integration brings a consistent approach to the management and maintenance of secure configurations across a wide range of devices including Industrial Control Systems (ICS), SCADA, Microsoft Windows and Windows Servers.

by Gary Mintchell | Mar 3, 2014 | Automation, Operator Interface, Process Control

Some of the most exciting technology companies have shown me during the past three years or so has involved deep work into providing better operator displays for industrial plant operations. In this case, “better” means working with the people who actually use the displays–maybe the entire team from operators to maintenance to engineering–in order to develop displays that show the state of the plant at a glance.

Those of you who were around in the late 80s, do you remember the beginnings of PC-based document design applications? PageMaker and Ventura Publisher were new. They offered lots of fonts. People designed brochures with six different fonts on one page–in patterns. Then we had the ability to draw really cool graphics on the screen. I had a customer with a waste water facility. They coded in pages to reflect the seasons of the year (I remember the frog croaking representing summer in the river at the end of the process.)

What I’m saying is that we had the technology and we used it as much as possible. Then we discovered that we were giving too much information in too confusing a format.

New Product

This latest announcement is from PAS Corp. in Houston. It has released PowerGraphiX 2.0, a high performance human-machine interface (HMI) package for the power generation industry. The company promises PowerGraphiX, “will revolutionize the way operators view information at power plants.”

PowerGraphiX is comprised of predesigned graphic templates, object libraries and best-practice guidelines for the design and implementation of operator interfaces at power generation plants. Companies choosing to implement the application can expect vastly improved graphics at significantly reduced costs when compared with traditional methods. (I’ve seen samples.)

According to PAS, the software was initially developed because Southern Company Services Inc. had a vision of consistent HMIs and improved situational awareness in control rooms across the operating fleet. PAS is now making the product commercially available for all utilities.

“Southern Company is committed to proprietary research and development in order to deliver solutions to our company and the industry,” said Harvey Ivey, Southern Company Manager of Instrumentation and Controls Design and Support. “This particular software was originally created to streamline information displayed in control rooms across our generating fleet, significantly improving operator effectiveness.”

The methodology behind developing PowerGraphiX was based on the industry-recognized book “The High Performance HMI Handbook” by Founder and CEO of PAS Eddie Habibi and Principal Consultant for High Performance HMI of PAS Bill Hollifield. It addresses the use of color, pattern recognition, standardization and other principles to transform data into actionable information, providing operators with a more holistic view of plant operating conditions.

“PAS is committed to empowering operators by delivering the precise information they need to improve plant safety and performance,” said PAS Vice President of Technology Mark Carrigan. “PowerGraphiX makes interpreting a plant’s current condition simply intuitive.”

by Gary Mintchell | Feb 21, 2014 | Automation, Operator Interface, Technology

Iconics’ MobileHMI app

Another announcement at ARC in Orlando last week came from software developer Iconics blending mobile HMI and the Internet of Things. The company introduced its new MobileHMI solution delivered to “Any Glass, Anytime!”

Iconics, always on the cutting edge of commercial technology trends, sees the increasing use of mobile devices in industry along with improved cloud technologies as a chance to develop new solutions. MobileHMI, an “app”, is now available from the major app stores, including those from Microsoft, Apple, and Google.

MobileHMI is a full HMI/SCADA client on any platform or smart device and runs on hundreds of smartphones, tablets, browsers and Web-enabled HDTVs, enabling users to tap into the Internet of Things (IoT) and access critical data anytime, anywhere. With MobileHMI, industry leaders such as executives, engineers, maintenance technicians and operators can now utilize a fully featured mobile client designed for operations on the go. Configuration enhancements simplify development of screens for mobile users, making it easy to provide a clean experience on all devices without incurring the extra cost of development time. Additionally, preconfigured templates and the ability to target specific devices with displays make MobileHMI ready to handle any combination of devices.

Russ Agrusa, Iconics CEO and President, says about the new release, “The new MobileHMI product is a technology marvel. Creating rich, real-time universal visualization for smartphones, tablets, Web browsers or Web-enabled HDTVs is effortless. Simply download the MobileHMI App from the Windows Store, Apple or Google app stores and youâre ready to get going. What makes the MobileHMI technology unique is its simple patented configuration technology that delivers secure visualization natively to any device such as iPhones, iPads, Samsung Galaxy S4, Windows Phone and Microsoft Surface, as well as HTML5-enabled devices.”

by Gary Mintchell | Feb 18, 2014 | Automation, Operator Interface

Industrial automation manufacturer Opto 22 has announced groov version 2.1, an update to its groov web-based mobile operator interface system for building and using effective, scalable operator interfaces on smartphones, tablets, and other mobile devices. groov 2.1 improvements include faster tag handling with OPC-UA servers, and improved data exchange with mobile devices for faster response times and lower mobile network costs.

groov lets industrial automation end-users, system integrators, machine OEMs, technicians, or any authorized person quickly and securely monitor and control PLCs and PACs like Allen-Bradley ControlLogix and CompactLogix, Siemens SIMATIC S7, Schneider Electric Modicon, GE PACSystems, and other controllers, all from a mobile device. groov gets important data out of processes, OEM machines, and manufacturing systems and into operators’ hands.

A major improvement in groov 2.1 is faster operator interface development due to new real-time OPC tag browsing. An OPC-UA server can have potentially tens of thousands of tags to choose from for an operator interface, and real-time browsing makes it faster to select tags and link them to on-screen indicators and controls.

groov 2.1 exchanges up to 75% less data with smartphones, tablets, and other devices running an operator interface than earlier groov versions, thanks to improved data handling and compression. Mobile devices operating over a cellular or other network with slower connections benefit with faster updates, faster interface responses, and lower mobile network costs.

groov 2.1 includes other improvements and new features:

- Webpage links can be added to interface screens, making it possible, for example, to incorporate an internal company webpage showing production targets and KPIs.

- Update/refresh rates can be individually set for IP camera widgets, so an IP camera monitoring a production machine, for example, can update twice a second, while a camera watching a loading area might update once every ten seconds.

- Slider controls and range/level indicators can be oriented horizontally or vertically. Orienting these items vertically saves screen space and is particularly useful for compact mobile devices.

- Using IP camera widgets on an interface screen no longer requires router configuration changes or opening firewall ports for each camera’s IP address. Instead, IP camera widgets can optionally use a reverse proxy server to communicate through the groov’s IP address.

What’s groov?

groov is a zero-programming, web-based way to build, deploy, and view effective, scalable operator interfaces to monitor and control systems and equipment using mobile devices and other computer-based systems. These operator interfaces can be viewed on almost any mobile device or computer regardless of its manufacturer, operating system, or screen size, including smartphones, tablets, PCs, and even smart high-definition televisions.

groov can augment existing human-machine interfaces (HMIs) and Supervisory Control and Data Acquisition (SCADA) systems by making important information available at any time and in any location. groov is available as either the standalone groov Box hardware appliance or the PC-based groov Server for Windows software.

groov uses a standard method of securely communicating with devices on the plant floor, including PLCs, DCSs, PACs, databases, and OPC-DA servers called OPC Unified Architecture (OPC UA). A fully functional version of groov Server for Windows is available to download and try so you can see your own system’s data on a smartphone, tablet, or other mobile device. groov operates for two hours without a license and can be restarted if more time is required.

groov works with Kepware Technologies’ KEPServerEX communications platform. Kepware has developed hundreds of device drivers for communicating with diverse automation systems, databases, building automation systems, and more.

groov 2.1 will be available on Mar. 3, 2014. Choose either the groov Box hardware appliance (GROOV-AT1) at a list price of $2895.00 USD, or groov Server for Windows software (GROOV-SVR-WIN) at a list price of $2695.00 USD. groov.com

The consumer boom with mobile devices has not been ignored by production automation companies. Rockwell Automation showed FactoryTalk VantagePoint EMI v 6.0 enabling any digital device to access performance metrics and production data analytics from plant floors and machines.

The consumer boom with mobile devices has not been ignored by production automation companies. Rockwell Automation showed FactoryTalk VantagePoint EMI v 6.0 enabling any digital device to access performance metrics and production data analytics from plant floors and machines.