by Gary Mintchell | Oct 1, 2013 | Automation, Data Management, Events, M2M, News, Operations Management, Process Control, Software

Emerson Pervasive Sensing Vision

Pervasive Sensing along with Integrated Operations Center and many new measurement devices from Micro Motion division highlighted the first day’s announcements from the Emerson Global Users Exchange as the process systems company revealed a new vision of the future.

Steve Sonnenberg, president of Emerson Process Management, welcomed 2824 registered attendees to the 2013 edition of Emerson Global Users Exchange in Grapevine (Dallas) Texas Monday Sept. 30. The attendance was expected to grow some during the week with late registrants.

Sonnenberg told the crowd that the business is showing growth, albeit a little slower in late 2013. He expects 2014 to begin slowly then accelerate. Meanwhile, Emerson has continued its investment in Process Management products and services throughout business cycles.

Sonnenberg’s key message was for Emerson to become the trusted advisor to its customers. He also touted Emerson as the technology leader in the industry pointing especially to continued investment and development in Human-Centered Design.

Peter Zornio, chief strategic officer, led attendees on a whirlwind tour of new products announced at the conference. Highlighted were the new Elite Coriolis meters from MicroMotion, a distributed RTU network, DeltaV safety integrated systems with electronic marshaling, the asset management product AMS Suite now working with Beamex and Meridium for smoother data flow, the CSI 2140 machinery health analyzer and a new wireless gateway that combines WirelessHART and WiFi in one box. (more on the MicroMotion products in the next post.)

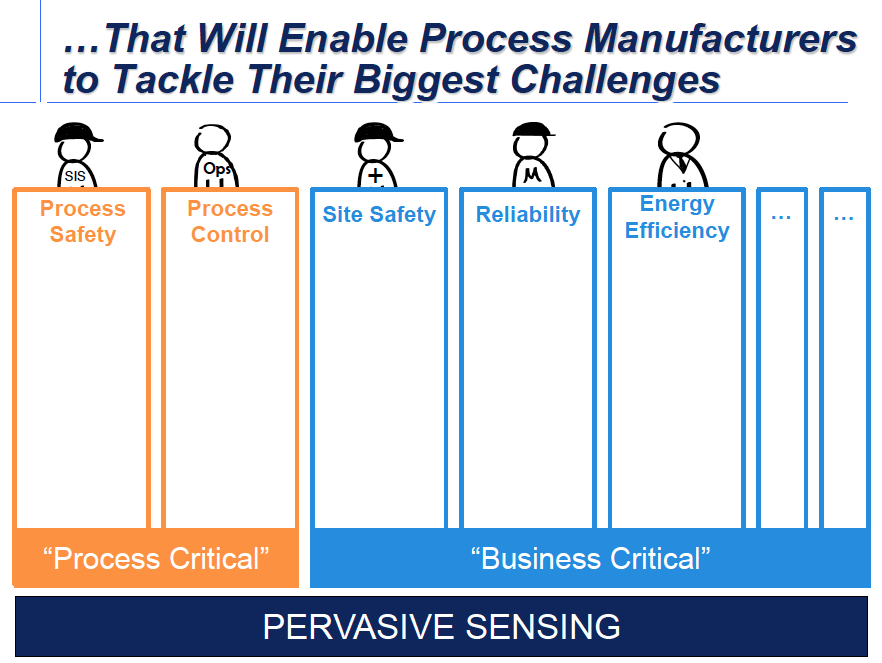

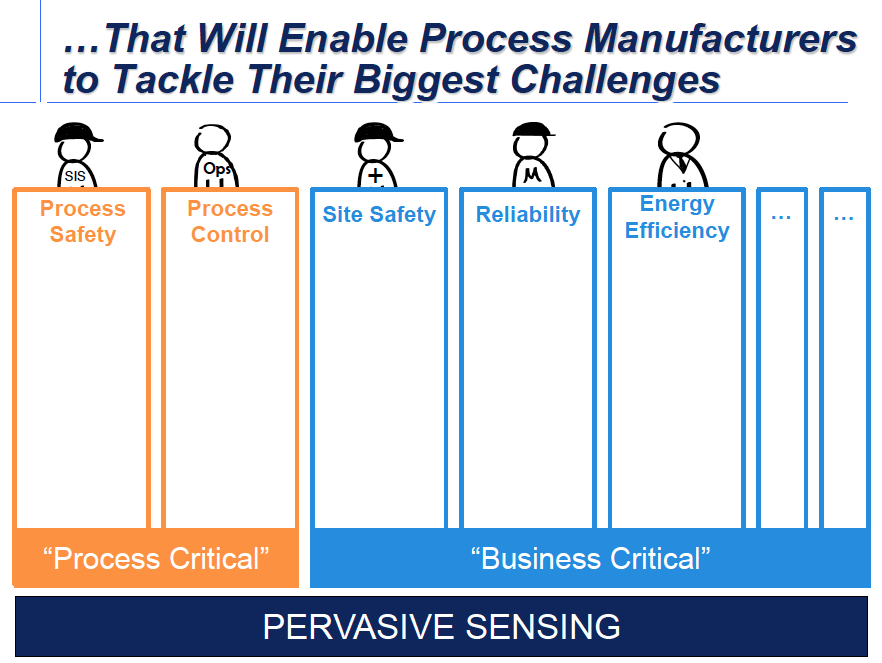

Zornio then moved into a look into the next generation vision. The industry has been focusing on process-critical information. The next generation of products and services will expand that view into business-critical information–Site Safety, Reliability, Security, and Energy Efficiency. These will all be enhanced with the implementation of many new sensors aided by wireless technology for cheaper, faster implementation. Emerson is calling this “Pervasive Sensing.”

Making sense of all this new sensor data will be the task of enhanced analytics that Emerson has already begun work on with Batch Analytics. The whole process will be brought together through the Integrated Operations Center (iOps) that the company has been developing.

I know that all this took tons of investment and engineering time, but it is the vision I’ve been preaching for several years–i.e., what are you going to do with all that wireless sensor data. The answer from the Emerson point of view is now clear. The vision of a better way to manage your plants is becoming reality. I applaud this–and I’m sure all of you who are out there managing your plants will, too.

Here are a few interesting facts and quotes from the official press release:

- Emerson estimates that over the next 10 years this additional served market will more than double the $16 billion traditional measurement market.

- For example, the risks associated with equipment degradation or failure were historically dealt with by periodic manual inspections and reactive maintenance, or energy losses were simply unidentified.

- With the advent of Smart Wireless technologies and advances in sensor technology and installation techniques, Emerson has overcome the cost/value barrier by providing lower cost of deployment, reliable non-intrusive installation, and low lifecycle costs, combined with unparalleled ease-of-use in sensor applications. New software applications and embedded sensor intelligence is also becoming available to interpret the data from these sensors and convert it into actionable information, enabling prompt response to potential problems and better insight for improved decision-making.

- “Our customers are like anyone else — they want actionable information that can make their lives safer, more predictable, and save them cost, risk and time,” said Peter Zornio, chief strategic officer at Emerson Process Management. “This goes beyond the control room and optimizing process performance. They want clarity and certainty of conditions for business-critical decision-making across all aspects of their operations. To achieve this, a more comprehensive network of sensors is needed. Pervasive Sensing provides the foundation for their insight.”

- “A great analogy we are all familiar with is the ongoing evolution of automobile sensors,” continued Zornio. “They have evolved from managing engine performance and simple ‘check engine’ alerts to providing actionable information about all aspects of car performance – such as precise tire pressure and fuel economy — to help maintain safety, economy, and provide failure prevention diagnostics.”

- Emerson is already seeing customers move aggressively to take advantage of pervasive sensing. An Eastern European oil processing plant is currently deploying a full wireless infrastructure to allow the addition of 12,000 Pervasive Sensing instruments – or 60% beyond the base of traditional process measurements — in order to better detect energy losses, equipment corrosion and safety releases.

- “The Pervasive Sensing opportunity grew out of Emerson listening to our customers and better understanding their needs,” said Steve Sonnenberg, president Emerson Process Management. “While the industry has widespread adoption of process related automation, the opportunities for utilizing technologies that make a profound, measureable business impact outside of the process have been elusive. Not any more. The combination of pervasive sensing with software and algorithms for interpretation and decision-making is empowering customers with actionable insights in places they never dreamed.”

- Examples of Emerson Process Management products that address the pervasive sensing market include ultrasonic and point sensors in the recently acquired NetSafety and Groveley product lines, corrosion and erosion detection technology from the Roxar acquisition, vibration sensing of rotating equipment from CSI, and the Rosemount wireless steam trap monitor and wireless bolt-on surface temperature probe.

by Gary Mintchell | Sep 25, 2013 | Automation, M2M, Operations Management, Software, Technology

Are we seeing practical adoption of M2M technologies finally. Meridium points to that as a key feature of its latest release of its Asset Performance Management software. Enhanced support for work process also fits snugly within the trends of the past few years.

Are we seeing practical adoption of M2M technologies finally. Meridium points to that as a key feature of its latest release of its Asset Performance Management software. Enhanced support for work process also fits snugly within the trends of the past few years.

Version 3.5.1 of its Asset Performance Management (APM) software enhancements include new work process dashboards for the end-to-end management of performance improvement opportunities, expanded monitoring policies to address process excursions and enhanced integration capabilities to enable machine-to-machine (M2M) communications.

“Every Meridium product release is a reflection of fulfilling customer needs,” said Bob DeMaria, Maintenance Engineering Technical Advisor at Dakota Gasification Co. “As a Meridium user, it amazes me how every release offers a new solution to our challenges. For example, in v3.5.1 they added a new analytical model, which allows us to ‘see’ the impact performing an inspection has on an asset’s risk ranking. This added functionality will provide huge efficiency gains by allowing us to optimize our inspection intervals.”

Meridium v3.5.1 Policy Manager boosts M2M integration with advanced analytics to drive the right actions from the wealth of information collected. This includes new monitoring capabilities to automatically trigger, close and analyze integrity operating window (IOW) excursions or other critical events. “Operation of assets outside the defined integrity operating window introduces unknown operating risk,” said Louise Pattison, Meridium Product Manager. “Conditions change, and if you are not tracking process excursions, you may be living under a veil of false security.”

by Gary Mintchell | Jun 7, 2013 | M2M

Ayla Networks Founders Friedman and CaceresConnections. That is the topic that most interests me currently. Therefore the name of my new Website–The Manufacturing Connection. Devices in the plant or factory are connected by ever-expanding means to each other, to the control system and to the operations management layer.

Ayla Networks Founders Friedman and CaceresConnections. That is the topic that most interests me currently. Therefore the name of my new Website–The Manufacturing Connection. Devices in the plant or factory are connected by ever-expanding means to each other, to the control system and to the operations management layer.

We’ve been talking about the Internet of Things (or M2M, or Industrial Internet, or Pervasive Internet) for a long time. What we need is more of the binding that brings stuff together. Recently I talked with David Friedman, one of the founders and the CEO of Ayla Networks, a company that just emerged from stealth mode with a couple of announcements. I think that what they are doing is significant to manufacturing and production (and a lot more, as well).

Friedman pointed to the backgrounds and experiences of the founders, “We know what it takes to do the software to bind the IoT together,” he told me. “We also worked with hardware leaders, software preloaded in chips that people need to do this. It’s a technology and business model of service as a component to get rid of the monthly fees.”

The company announced a round of financing and a significan first customer.

Platform and financing

Ayla ProductIn the first news, Ayla formally unveiled the Ayla Platform, which allows manufacturers and service providers to transform thermostats, appliances, lighting and other everyday products into interactive connected devices quickly, easily and economically. The Sunnyvale, Calif.-based company also announced that it has raised $5.4 million in Series A financing led by investors Voyager Capital and Crosslink Capital.

Ayla ProductIn the first news, Ayla formally unveiled the Ayla Platform, which allows manufacturers and service providers to transform thermostats, appliances, lighting and other everyday products into interactive connected devices quickly, easily and economically. The Sunnyvale, Calif.-based company also announced that it has raised $5.4 million in Series A financing led by investors Voyager Capital and Crosslink Capital.

“We are at the beginning of a major evolutionary step for the Internet,” said Friedman. “We have built a platform that eliminates the hurdles involved in building great connected devices and bringing them to market. We have also created a business model with key partnerships to deliver on this vision.”

The company’s platform seeks to simplify and accelerate product development for manufacturers while enhancing usability from the consumer’s perspective, leading to greater overall satisfaction and lower costs for everyone. The efficiency by which the company can provide its service also minimizes the cost of connectivity so that consumers can start to enjoy great connected products without high ongoing monthly service fees.

The Ayla Platform consists of three distinct components, each working seamlessly together to provide a rich, secure, and highly flexible path for manufacturers to rapidly deliver Internet-connected products to market. These components include production-class Ayla-enabled Wi-Fi modules and IP gateways, Ayla’s cloud service for managing devices on behalf of manufacturers and consumers, and Ayla application libraries.

Ayla has created these components to work together so manufacturers do not have to write any networking, security, or connectivity protocols in their devices. Similarly, Ayla customers do not have to write any code to use the cloud service: a powerful UI is used to configure “virtual devices,” and the platform takes care of the rest.

Partnerships

Ayla has forged an ecosystem that includes world-class elements from leading companies such as Broadcom Corporation, STMicroelectronics, and Amazon Web Services. Ayla’s technology supports a wide variety of standards and platforms, including Android, iOS, Wi-Fi, ZigBee, Linux and others.

With Ayla’s technology, devices are available at all times, yet minimize the amount of bandwidth and energy required they consume. Hardware solutions and application interfaces can be configured for specific devices but also leverage common design elements to save money and reduce integration challenges. Smooth surfaces and ‘clean’ industrial designs will emerge as smart phones and apps replace buttons and switches to control appliances.

The founders of Ayla Networks all have deep expertise building solutions, technologies, and companies serving the Internet of Things. Adrian Caceres, Ayla’s head of engineering and another co-founder, previously worked at Amazon’s Lab126, where he was technical lead for the networking capabilities of the Amazon Kindle. Philip Chang, GM of Greater China previously helped establish a presence for ZeroG Wireless in China, and has been founder and executive at several early networking companies. Thomas Lee, a professor of electrical engineering at Stanford University who has helped create companies such as Matrix Semiconductor, is also a founder.

First Customer

The next news is that it is collaborating with SINA to bring a new generation of connected devices and interactivity to consumers in China.

With more than 500 million registered users worldwide, SINA is the most recognized Internet brand name among Chinese communities globally. SINA’s digital media network also includes Sina.com (web portal) Weibo.com (social networking) and Sina.cn (mobile.)

The first device to come out of the collaboration is the SINA Wi-Fi Weather Station which provides SINA customers with targeted, up-to-date weather information and forecasts for their home, office or any other place of interest where one of the devices is located. The key is the cloud: SINA’s personal weather stations feed location-specific information about temperature and precipitation to a cloud-based service that SINA customers can access through smart phones and other devices. Ayla’s cloud platform for the Internet of Things provides the technology and foundation to seamlessly and securely link the weather station to SINA’s services.

Once things can be easily connected to rich cloud-based services, the possibilities for what comes next are almost limitless. Appliances, lighting, thermostats and a broad array of other consumer electronics can all communicate together and through the cloud to provide a social network for things. Formerly mundane devices will offer a rich new way for users to interact with them.

by Gary Mintchell | May 30, 2013 | M2M

Glen Almendinger of Harbor Research has been following the Internet of Things / M2M / Pervasive Internet space for years. Much of the original intent was to use cellular technology as the broadband. That probably held things back a little, since in the early days cellular service was seen as unreliable. That service is improving, though, and here are some of his thoughts on CDMA technology and the IoT.

The overwhelming potential for the Internet of Things (IoT) requires that elements like basic enablement, network connectivity, middleware services, value-added services, and other device management functions are properly functioning and well-aligned. It’s not until these elements are in place that new modes of asset intelligence, collaboration, and decision-making will be enabled.

As we head down this path, devices will shift from being ‘simple’ to becoming connected and ‘smart’ – and thereby enabling a new host of machine-to-machine (M2M) services. With its high security levels, network longevity, ubiquitous coverage, high bandwidth, spectral efficiency, low latency, energy efficiency, and “always-on” connectivity, one cellular technology is particularly well-suited to make this transition: CDMA2000.

Since its initial development in 1985, CDMA (Code Division Multiple Access) technology has continually evolved to meet the ever-changing needs of the CDMA ecosystem. Today, CDMA technology is available in 121 countries and territories and with its global reach and reliable reputation, it is no surprise that CDMA2000 technologies and networks have become the go-to choice for companies offering M2M products and services. From consumer telematics and e-health, to connected homes and remote monitoring opportunities, OEMs and service providers are able to provide a host of new services – and recognize a host of benefits – enabled by CDMA2000 technology.

“As the market opportunity for connected devices and services continues to grow, CDMA technologies offer significant benefits for delivering M2M services and applications. Technical advancements such as CDMA2000 1X Rev. F enable operators to provide their M2M partners more optimized service delivery through increased data rates, decreased connection times and lower power consumption. Even as much attention is focused on 4G deployments, operators will maintain their CDMA networks for many years to come in support of their M2M customers,” said Perry LaForge, founder and executive director of the CDG.

This new paper from Harbor Research explores the application opportunities, technology requirements and business benefits arising from M2M communication and provides a range of case studies from companies that have leveraged CDMA2000 technologies to increase sales, reduce costs and improve the customer experience.

by Gary Mintchell | May 21, 2013 | M2M, Operations Management, Software

Most of you are aware that I have left active participation with Automation World magazine. After 10 years and a small ownership shuffle, I just felt like there wasn’t anything left for me to create there. Hopefully, you are all still following my column there. I also do some small projects from time to time.

I have been more intrigued by digital technologies than print for a long time. Combining that with a passion for what’s next in manufacturing (and add in an area that is significantly undercovered by media right now), I’m focusing on the connected manufacturing enterprise.

This connected enterprise begins with all the connected devices in the plant or factory. This could be called Internet of Things or Industrial Internet or Connected World or M2M. This connection feeds into Manufacturing Operations Software–previously called MES–that is enabling a smarter and more effective manufacturing and production. And it all leads to better decision-making at all levels of the enterprise.

I find it interesting that, after a long and successful career at Invensys (and Foxboro and Wonderware), Mark Davidson has popped up as an analyst for Matt Littlefield–who in turn has left corporate life to start up a new analyst company, LNS Research.

Mark has a recent blog post about Manufacturing Operations that captures my ideas perfectly.

IBM taught me during my first “MRP” class in 1977 that you should first know what your manufacturing systems are, then optimize the system you have, then, and only then, should you apply computer technology.

We have new phrases, but it’s the same idea. Mark writes about seven steps toward “Aligning Manufacturing Goals with the Organization.”

- Understand and Articulate Strategy: have a clear and universally understood manufacturing strategy that is in support of the corporate business strategy

- Translate Strategy into Specific Goals: turn that strategy into specific goals for business groups and associated supply chains, as well as plants, units, and production lines

- Map Goals and Specific Measures for Success: use a cross-functional team to map each detailed translation across the enterprise

- Determine Key Performance Indicators: develop a set of manufacturing KPIs to measure progress toward your goals

- Establish Communication Procedures for KPIs: make sure the right information is getting to the right people in a timely manner

- Set Processes for How to Act on KPI Information: determine best practices for individuals from the shop to top floor to interact with KPI data

- Match Performance Incentives to Aligned Goals: reinforce the effectiveness of measuring KPIs by incentivizing progress

So you do that. What are the common MOM and Enterprise IT applications that companies can use to support monitoring, analysis of, enforcement, and visibility of progress toward these goals? Mark lists nine:

1. Enterprise Resource Planning (ERP): software that captures cost performance, order and materials performance information.

2. Supply Chain Management (SCM) and Supplier Relationship Management (SRM): software that captures supplier performance information.

3. Enterprise Quality Management Systems (EQMS): that can correlate quality and cost of quality performance information.

4. Asset Management / CMMS software: to provide asset and maintenance performance information.

5. Collaboration website and Mobile software: to organize and distribute appropriate performance information across a manufacturing organization.

6. Advanced Process Control & Optimization software: to model and predict complex manufacturing interactions and suggest optimum manufacturing set points within safe and profitable limits.

7. Historians, Batch Management and Manufacturing Execution Software: that captures the real-time manufacturing activity and performance from manual and automation / machine generated information sources.

8. Enterprise Manufacturing Information / Operations Intelligence software: that can correlate information from all of the above sources and present summary reports and live dashboards to guide manufacturing workers.

9. Human Machine Interface (HMI) software: that can display real-time graphical representations and trends of performance information from MOM software and automation / machine generated information sources.

This captures the core of what I want to cover at The Manufacturing Connection. You can go there now and sign up to be notified when we go live.

Right now, you can just stay here until we switch over. And if you’re a supplier in that space, contact me to get in on the ground floor as an advertiser or sponsor (yes, I’ll need to make some money on this hobby).

by Gary Mintchell | May 6, 2013 | M2M

“Machine to machine” (M2M) is proving to be as transformative as any technology innovation since the beginning of the Internet age. Survey findings released from a study conducted by Harris Interactive on behalf of SAP AG (and check out the newsroom) highlight that almost 30 percent of IT decision makers (ITDMs) agree that smart cities would be the most beneficial outcome of deployment of M2M technologies. This would include highly intelligent cities capable of collecting and analyzing large amounts of data from smart, connected devices and citizens’ social media activity in real time to vastly improve urban life. Additionally, the clear majority of respondents expect M2M to provide businesses and employees with greater insight, including the ability to respond to real world events, as well as increased efficiency, productivity and collaboration. The ability to increase mobility among the work force was also identified as a big opportunity for M2M in the workplace.

The survey results found that most ITDMs in all six countries view M2M as the natural evolution of the “consumerization of IT,” with India and China at 92 percent and 90 percent respectively. The majority of Brazilian, German, UK and US ITDMs agreed, with a combined average of 81 percent.

“The number of ‘things’ connected to the internet is expected to reach 50 billion by 2021 and consumers are playing a central role in this transformation,” said Sanjay Poonen, president of Technology Solutions and head of Mobile Division, SAP. “Today, M2M technology is primarily being used to collect vast amounts of machine and people-based data. The ‘Internet of Things’ concept goes one step further by not only integrating machines, people, ERP and CRM systems, and other information sources like social media, but also analyzing and making use of all the data. Soon, people will interact with devices that in turn interact with data to deliver personalized products and services directly to the consumer in real time.”

Global Alignment on the Power of M2M Survey respondents in all six countries expressed a strong belief in M2M representing a natural step in the evolution of technology and widely agree with the need for, and benefits of, the broader adoption of M2M. In fact, an average of 70 percent of the ITDMs in all six countries surveyed agree that companies that fail to implement M2M technologies will fall behind their competitors. This is likely due to most ITDMs from the countries surveyed perceiving tangible benefits of M2M, including:

Enabling businesses to respond to real world events: China (92 percent), India (86 percent), Brazil (82 percent), Germany (82 percent), US (78 percent) and UK (73 percent)

Those surveyed also view the following as presenting the biggest opportunities for M2M in the workplace:

Increased efficiency was the No. 1 response in Brazil (54 percent), UK (53 percent) and US (49 percent)

Increased productivity for employees was the top selection in China (69 percent), significantly higher than any other countries surveyed

Increased employee collaboration was the No. 1 opportunity in Germany (63 percent)

Increased mobility among the workforce was the biggest opportunity in India (65 percent)

Obstacles to M2M

Before any of the opportunities and benefits can be fully realized, an overwhelming majority of those surveyed in all six countries cited at least one obstacle to M2M adoption. ITDMs from all countries except China were most likely to see a lack of expertise needed to manage the adoption and security of M2M as presenting the biggest impediment to adoption: India (66 percent), Brazil (62 percent), US (57 percent), Germany (56 percent) and UK (50 percent). In China, while a substantial majority of ITDMs still cited a lack of expertise as the biggest obstacle (63 percent), a slightly higher proportion said “how to manage and analyze all the real time data resulting from M2M” (65 percent).

ITDMs from all six countries were also emphatic that the availability of broadband infrastructure, such as LTE/4G, will be instrumental in allowing M2M technologies to flourish in the future. ITDMs themselves, however, will most likely not serve as a barrier to the success of M2M as majorities in nearly all countries surveyed acknowledge that M2M will have an impact on the workforce (average of 62 percent for the combined six countries) and yet a majority are not concerned about a disruption due to M2M (average of 55 percent).

Discussing the survey with me, Benjamin Wesson, Vice President of Product Management at SAP, noted, “M2M is not something new. We are just trying to get beyond the hype. SAP’s MII product (the former Lighthammer product) fits within the scope of this process.

Later, Salvatore “Sam” Castro, Director – LoB Manufacturing at SAP and a member of the Lighthammer team, commented that M2M can be a sort of bad name because it leaves out the machine-to-people angle. Most of the industrial applications that SAP has involve reporting back from large equipment, such as the huge front-end loaders in mining applications or remote assets such as wind turbines. But it does have a connector to CNC systems to bring back data from machining operations.

Watch for the launch of The Manufacturing Connection coming soon. “Connecting things, data and people in a digital world promoting manufacturing excellence.”