by Gary Mintchell | Aug 1, 2022 | Asset Performance Management, Internet of Things, M2M, Operations Management

The people who introduced me to the M2M concept, or machine-to-machine (later called IIoT), extolled a prime use case—OEMs could connect with their installed base of machines. This would enable service contracts as they monitored performance and components. They could also monitor components to grade suppliers.

This turned out to be difficult to implement. IT departments placed roadblocks to outside connectivity. Concerns about leaking proprietary information posed another roadblock.

Best practices and improving technology have overcome many of the roadblocks. Enough so, that a major technology provider such as Honeywell can introduce an “Industry 4.0 solution helps increase end user equipment uptime and satisfaction while reducing OEM service and maintenance costs.”

Honeywell introduced on June 28, 2022 its Connected OEM (original equipment manufacturer) offering, an Internet of Things (IoT) solution that allows OEMs and skid manufacturers to remotely monitor the health and condition of their installed base. Equipment such as compressors, furnaces, pumping stations, analyzer houses and skids at end-user locations around the world can be monitored through the offering.

Through a cloud-based central asset management system securely connected to equipment assets, OEMs can obtain a consolidated view of their global installed base through a customizable key performance indicator dashboard. Users can apply data analytics and tools to troubleshoot and fix equipment, predict failures, plan maintenance and make informed business decisions in areas such as R&D.

I’ve written recently on LinkedIn and Twitter about a major social media company who blatantly proclaims that all its recent changes were in service to its own benefit with no mention of benefit to users or customers. Here, Honeywell notes specific user benefits to the new solution.

Honeywell Connected OEM was developed in response to a longstanding issue facing OEMs: the inability to monitor the performance of their installed assets. Prolonged sub-optimal asset operation results in high operating expenses for end users, and OEMs with performance contracts are unable to guarantee or justify assets’ operating outcomes. In addition, OEM service engineers must often rush to a site for unplanned maintenance and troubleshooting, incurring high travel costs if the assets are geographically dispersed. The net result is poor quality service and maintenance that can lead to the loss of repeat business for OEMs.

by Gary Mintchell | Feb 2, 2015 | Automation, Internet of Things, M2M, Manufacturing IT, Networking, News, Operations Management, Software, Technology

This report from Accenture looking at technology trends that will affect manufacturing among other businesses shows how people outside of the depths of automation, manufacturing, production arena are amazed by many technologies that we take for granted.

This report from Accenture looking at technology trends that will affect manufacturing among other businesses shows how people outside of the depths of automation, manufacturing, production arena are amazed by many technologies that we take for granted.

Check out the list of five trends, though. We already do some, but there are others that we will be adopting. Do you have your plans, yet?

Accenture report

Annual technology forecast highlights 5 technology trends affecting tomorrow’s digital businesses.

In its annual outlook of global technology trends, Accenture has identified a 180-degree shift to what it calls the “We Economy” that is re-shaping markets and changing the way we work and live. According to Accenture Technology Vision 2015, pioneering enterprises are tapping into a broad array of other digital businesses, digital customers and even digital devices at the edge of their networks to create new digital “ecosystems.”

These leading companies have already begun using technology to transform themselves into digital businesses and are now focusing on combining their industry expertise with the power of digital to reshape their markets. These businesses see great potential to make a difference – and a profit – by operating as ecosystems, not just as individual corporate entities, and driving the emergence of the “We Economy.”

This shift to the “We Economy” was confirmed in a related Accenture global survey of more than 2,000 IT and business executives, which found that four out of five respondents believe that in the future, industry boundaries will dramatically blur as platforms reshape industries into interconnected ecosystems. While 60 percent of those surveyed said they plan to engage new partners within their respective industries, 40 percent said they plan to leverage digital partners outside their industry and 48 percent said they plan to engage digital technology platform leaders.

“In last year’s Technology Vision report we noted how large enterprises were reasserting leadership in their markets by adopting digital to drive their processes more effectively and transform how they go to market, collaborate with partners, engage with customers and manage transactions,” said Paul Daugherty, chief technology officer, Accenture. “Now that digital has become part of the fabric of their operating DNA, they are stretching their boundaries to leverage a broader ecosystem of digital businesses as they shape the next generation of their products, services and business models to effect change on a much broader scale.”

The Accenture Technology Vision 2015 report offers examples of how, in the rapidly growing Industrial Internet of Things – i.e., the interconnection of embedded computing devices within the existing Internet infrastructure – companies are using digital ecosystems to offer new services, reshape experiences and enter new markets. This is supported by the Accenture survey, which found that 35 percent of respondents are already using partner APIs to integrate data and collaborate with business partners, with an additional 38 percent planning to do so. One example is Home Depot, which is working with manufacturers to ensure that all of the connected home products it sells are compatible with the Wink connected home system – thereby creating its own connected home ecosystem and developing potential new services and unique experiences for Wink customers.

Philips is taking a similar approach, teaming with Salesforce to build a platform to reshape and optimize the way healthcare is delivered. The envisioned platform will create an ecosystem of developers building healthcare applications to enable collaboration and workflow between doctors and patients across the entire spectrum of care. The ecosystem to achieve these improved outcomes is vast including electronic medical records as well as diagnostic and treatment information obtained through Philips’ imaging equipment, monitoring equipment, and personal devices and technologies.

Accenture Technology Vision 2015 notes that by tapping into digital ecosystems, Home Depot, Philips and other companies have the ability to grow and generate new sources of revenue in ways they could not achieve alone. The report also highlights five emerging technology trends that reflect the shifts being seen among the digital power brokers of tomorrow:

- The Internet of Me: Our highly personalized world. As everyday objects are going online, so too are experiences – creating an abundance of digital channels that reach deep into every aspect of individuals’ lives. The range of emerging channels that companies report they are using or experimenting with to engage customers includes wearables (cited by 62 percent of survey respondents), connected TVs (68 percent), connected cars (59 percent) and smart objects (64 percent). Forward-thinking businesses are changing the way they build new applications, products and services, and reaping benefits as a result. To gain control over these access points to individuals’ experiences, businesses are creating highly personalized experiences to both engage and exhilarate customers — but having to do it while making sure to not violate customer trust. The majority (60 percent) are seeing a positive return on their investment in personalization technologies. Companies that succeed in this new “Internet of Me” will become the next generation of household names.

- Outcome Economy: Hardware producing hard results. Intelligent hardware is bridging the last mile between the digital enterprise and the physical world. As leading enterprises come face-to-face with the Industrial Internet of Things, they are uncovering opportunities to embed hardware and sensors in their digital toolboxes and using these highly connected hardware components to give customers what they really want: not more products or services, but more meaningful outcomes. In fact, 87 percent of survey respondents acknowledged a greater use of more intelligent hardware, sensors and devices on the edge of networks, leading organizations to increasingly shift from selling products or services to selling outcomes. And 84 percent of respondents touted a deeper level of understanding of how products are being used and outcomes customers want resulting from embedded intelligence in products. These “digital disrupters” know that getting ahead is no longer about selling things, but about selling results. This is the new “outcome economy.”

- The Platform (R)evolution: Defining ecosystems, redefining industries. Digital industry platforms and ecosystems are fueling the next wave of breakthrough innovation and disruptive growth. Increasingly, platform-based companies are capturing more of the digital economy’s opportunities for growth and profitability. In fact, 75 percent of survey respondents believe the next generation of platforms will be led not by large tech companies but by industry players and leaders. And nearly three-quarters (74 percent) are using or experimenting with industry platforms to integrate data with digital business partners. Rapid advances in cloud and mobility are not only eliminating the cost and technology barriers associated with such platforms, but opening up this new playing field to enterprises across industries and geographies. In short, platform-based ecosystems are the new plane of competition.

- Intelligent Enterprise: Huge data + smarter systems = better business. Until now, advanced software has been geared to help employees make better and faster decisions. But with an influx of big data – and advances in processing power, data science and cognitive technology – software intelligence is helping machines make even better-informed decisions. This is the era of software intelligence where applications and tools will take on more human-like intelligence, according to eighty percent of our respondents. And 78 percent of respondents believe software will soon be able to learn and adapt to our changing world and make decisions based on learned experiences. The next level of operational excellence and the next generation of software services will come out of the latest gains in software intelligence, which will drive new levels of evolution and discovery, propelling innovation throughout the enterprise.

- Workforce Reimagined: Collaboration at the intersection of humans and machines. The push to go digital is amplifying the need for humans and machines to do more, together. The majority of survey respondent companies (57 percent) are adopting technologies that enable business users to complete tasks that previously required IT experts, such as data visualization. Advances in natural interfaces, wearable devices and smart machines are presenting new opportunities for companies to empower their workers through technology. This will also raise new challenges in managing a collaborative workforce of people and machines. Seventy-eight percent of the executives surveyed agree successful businesses will manage employees alongside intelligent machines – ensuring collaboration between the two. And 77 percent of respondents believe that within three years, companies will need to focus on training their machines as much as they do on training their employees (e.g., using intelligent software, algorithms and machine learning). Successful businesses will recognize the benefits of human talent and intelligent technology collaborating side by side – and will embrace both as critical members of the reimagined workforce.

“Rather than simply focusing internally, on improving their own operations, successful companies are looking externally to create and become part of digital ecosystems,” said Daugherty. “They’re beginning to see the importance of selling not just products and services, but outcomes — and that requires weaving their businesses into the broader digital fabric that extends to customers, partners, employees and industries.”

For nearly 15 years, Accenture has taken a systematic look across the enterprise landscape to identify emerging IT trends that hold the greatest potential to disrupt businesses and industries. For more information on this year’s report, visit www.accenture.com/technologyvision or follow the conversation on Twitter with #TechVision2015.

About the Methodology

Accenture’s Technology Vision is developed annually by the Accenture Technology Labs. For the 2015 report, the research process included gathering input from the Technology Vision External Advisory Board, a group comprising more than two dozen executives and entrepreneurs from the public and private sectors, academia, venture capitalists and startup companies. In addition, the Technology Vision team conducted nearly 100 interviews with technology luminaries, industry experts and Accenture business leaders. The team also tapped into the vast pool of knowledge and innovative ideas from professionals across Accenture, using Accenture’s collaboration technologies and a crowdsourcing approach to launch and run an online contest to uncover the most-interesting emerging technology themes. More than 1,700 Accenture professionals participated in the contest, contributing valuable ideas and voting on others’ input.

In parallel, Accenture Research conducted a global survey of 2,000 business and IT executives across nine countries and 10 industries to capture insights into the adoption of emerging technologies. The survey identified key issues and priorities for technology adoption and investment. Respondents were mostly C-level executives and directors, with some functional and line-of-business leads, at companies with annual revenues of at least US$500 million, with the majority of companies having annual revenues greater than US$6 billion.

by Gary Mintchell | Dec 10, 2014 | Automation, Internet of Things, M2M, Manufacturing IT, Motion Control, Networking, News, Operations Management, Organizations, Technology

Here is announcement that foretells significant impact on industrial Ethernet and potentially all the suppliers. I bet it’s also an alliance that you’ve never heard of. Think audio-visual for AV. The AVnu Alliance has launched work on an open standard for deterministic Ethernet creating capability for standard Ethernet to meet the needs of industrial market while embracing the future promise of IoT. As I understand it, this work feeds back into the IEEE standards. Even more significant.

Here is announcement that foretells significant impact on industrial Ethernet and potentially all the suppliers. I bet it’s also an alliance that you’ve never heard of. Think audio-visual for AV. The AVnu Alliance has launched work on an open standard for deterministic Ethernet creating capability for standard Ethernet to meet the needs of industrial market while embracing the future promise of IoT. As I understand it, this work feeds back into the IEEE standards. Even more significant.

As I chatted with Todd Walter of National Instruments, Dan Sexton of GE, and Paul Didier of Cisco, I began to envision a standards-base, open technology that can be implemented in what will become standard Ethernet silicon. Let your imagination work for a minute. This could be a significant advance.

[Note: I’ve asked for feedback from a couple of suppliers. I’m sure that I’ll get some comments after the digest the information and construct a response.]

The group notes that standard Ethernet continues to expand its range, functionality and applications with the evolution of the Audio Video Bridging (AVB) standard into Time Sensitive Networking (TSN). The new capabilities of TSN provide the Industrial community with the ability to use standard Ethernet to support highly reliable and precise synchronized networking appropriate for industrial control.

New AVnu members

With the expansion into the Industrial Control market, AVnu Alliance announced three new members, Belden, with its Hirschmann, Tofino Security, GarrettCom and Lumberg Automation brands, is a global leader of mission-critical industrial network infrastructure; General Electric, global leaders in creating an electrical infrastructure with advanced technologies to safely and reliably distribute, protect and control electricity; and National Instruments, a leading test, measurement and embedded systems provider for engineers and scientists. These companies, as leaders in the industrial, automation and IT infrastructure space, are driving forces in the recent expansion, working within the Alliance to develop the foundational elements needed for industrial applications, based on the common elements of AVB/TSN. The industrial segment is also supported by existing AVnu Alliance members such as Broadcom, Cisco, Intel, Interval Zero, Marvell, Micrel, Vitesse, Xilinx and XMOS.

Supporting quotes

“It is incredibly important for GE to support and stay up to date on the evolving open standards in the industrial control market. Since AVnu Alliance is the only community consortium driving the expansion of AVB and TSN standards, we are excited to join and offer our expertise to the efforts,” said John Garrity, Product Line Leader for General Electric Intelligent Platforms. “AVnu certification will ensure interoperability across multi-vendor solutions and our continued contribution to the TSN standards will help us deliver the next generation of reliable networked products to our customers. We are excited to join AVnu Alliance and contribute to the workgroups as the Alliance expands into this new market and continues to build on the open standards that are currently evolving. Our work with TSN better enables our customers to easily and rapidly create innovative next generation control systems transmitting real time traffic.”

“IEEE and AVnu Alliance’s work to bring open standards to industrial applications provides a great venue to amplify Belden’s long history of standards work, and we recognize the immense value open standards offer to our customers,” said Andreas Dreher, Strategic Technology Manager at Belden. “TSN technology shows promise to be the core technology for high-end industrial Ethernet communications in the future, solving challenges faced by our customers in demanding, high-performance and high-precision industries, like motion control, robotics and high-speed manufacturing. Our plan for joining with the Alliance aligns well with our long-standing work in bringing innovation, standardization and awareness to the industrial market for new and emerging open standards.”

“TSN promises through standard silicon to converge the previously disparate technologies needed for standard Ethernet communication, for deterministic high speed data transfer, and for high accuracy time synchronization. These developments will create a common foundation that will impact numerous applications and markets ranging from machine control and asset monitoring to test cells and vehicle control. Key technology and equipment providers to the industrial market are supporting the effort. National Instruments is happy to collaborate within the solid ecosystem that AVnu Alliance is building,” said Mike Santori, Vice President, Product Marketing, National Instruments.

The Alliance notes, “Standard Ethernet is evolving to enable next generation control systems. This will allow convergence of low latency control traffic and standard Ethernet traffic on the same network for demanding applications like multi-axis motion control, providing a foundation for more advanced manufacturing and production models where data can be shared more flexibly between layers of the control system and where Internet of Things (IoT) technology can be applied into production environments. The new capabilities of these open standards enable high-speed closed loop control networks to support any Ethernet device using standard IT components and creates the needed foundation for IoT integration with industrial production.”

“As a founding member of AVnu Alliance, Intel is committed to advancing open standards that deliver time-sensitive communication” said Anthony Neal-Graves, Vice President, Internet of Things Group, Intel. “This is particularly important for cyber-physical-systems where multiple compute nodes cooperate to control physical systems ranging from industrial robots to autonomous vehicles and smart buildings. Intel has been a leader in this industry for more than two decades and we look forward to seeing the new opportunities TSN will bring to our customers.”

The Alliance has previously announced support for TSN in automotive applications such as drive-by-wire and autonomous driving. The Industrial market, which parallels work that AVnu Alliance members have been doing in the Automotive segment, is a $150 billion a year market space and creates a pathway to the future of IoT.

“This new segment is very exciting for the Alliance. Adding new members who are from this space and the evolution of the standards makes AVnu Alliance and Time Sensitive Networking poised for rapid growth in this market. As a founding member, Cisco’s contribution to AVnu Alliance will help guide the expansion and the standards work being done within the industrial segment,” said Kip Compton, VP and General Manager of the Internet of Things (IoT) Systems and Software group, Cisco. “AVnu Alliance remains dedicated to its core work in professional audio and video, consumer electronics and automotive. Broad market expansion of AVB/TSN with wide deployment will only benefit all members and markets – both from a cost perspective as well as assuring long-term support for the capabilities in standard components.”

“As a founding member of AVnu Alliance, Broadcom has been involved in the support of a variety of evolving market segments and expansion into the industrial control space is the next natural move for the Alliance,” said Nicholas Ilyadis, Broadcom CTO, Infrastructure & Networking Group. “As the industrial market continues to expand, AVnu Alliance will become an important driver in the interoperability and certification of networked devices and ensuring the deployment of reliable solutions in global markets.”

AVnu Alliance is responsible for guiding the specification for new applications to simplify the process for engineers and designers to build products. AVnu Alliance has created an Industrial Advisory Council for manufacturers and end users to learn more about the Alliance and the standards.

by Gary Mintchell | Dec 5, 2014 | Automation, Internet of Things, M2M, Operations Management, Technology

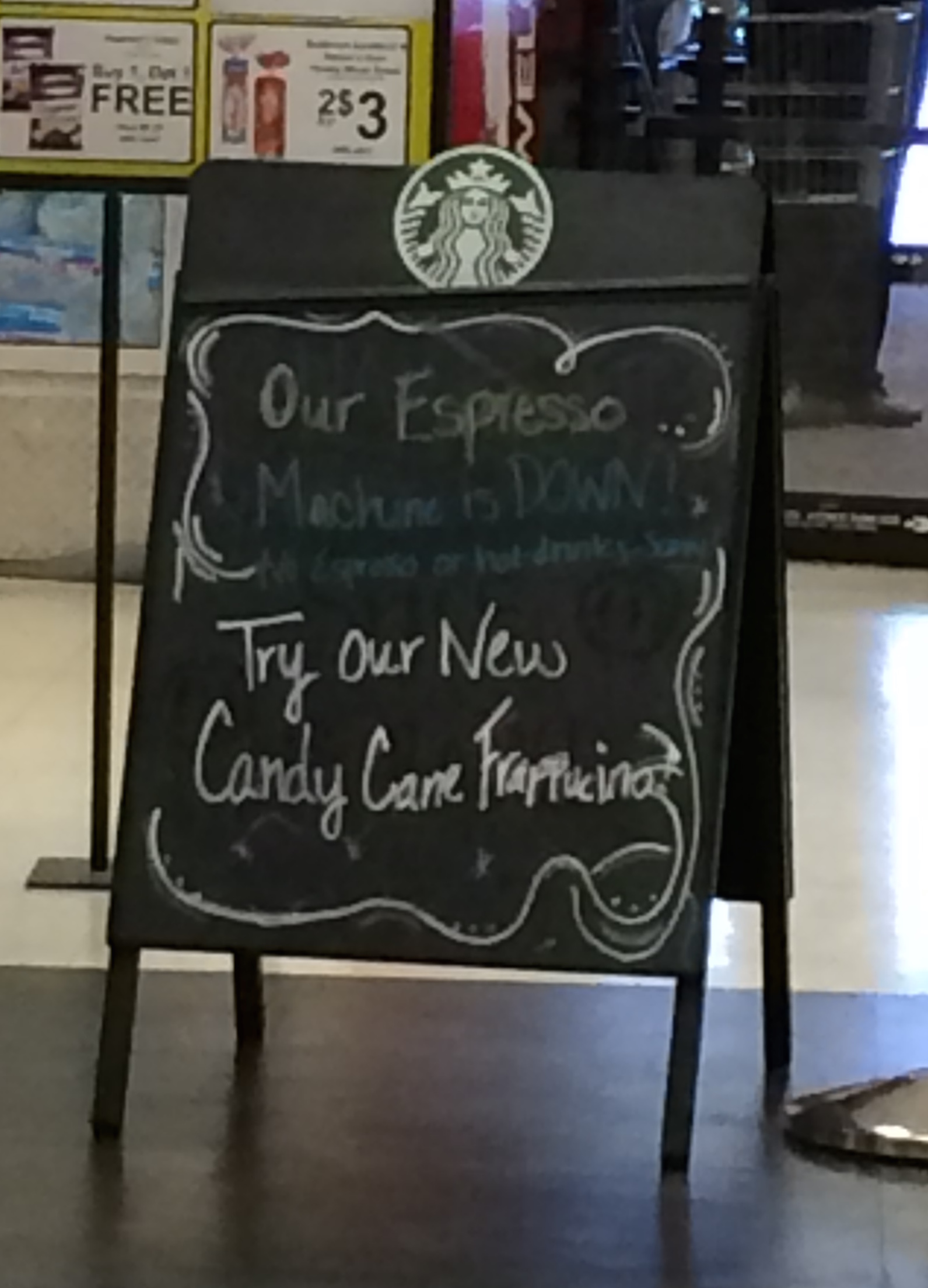

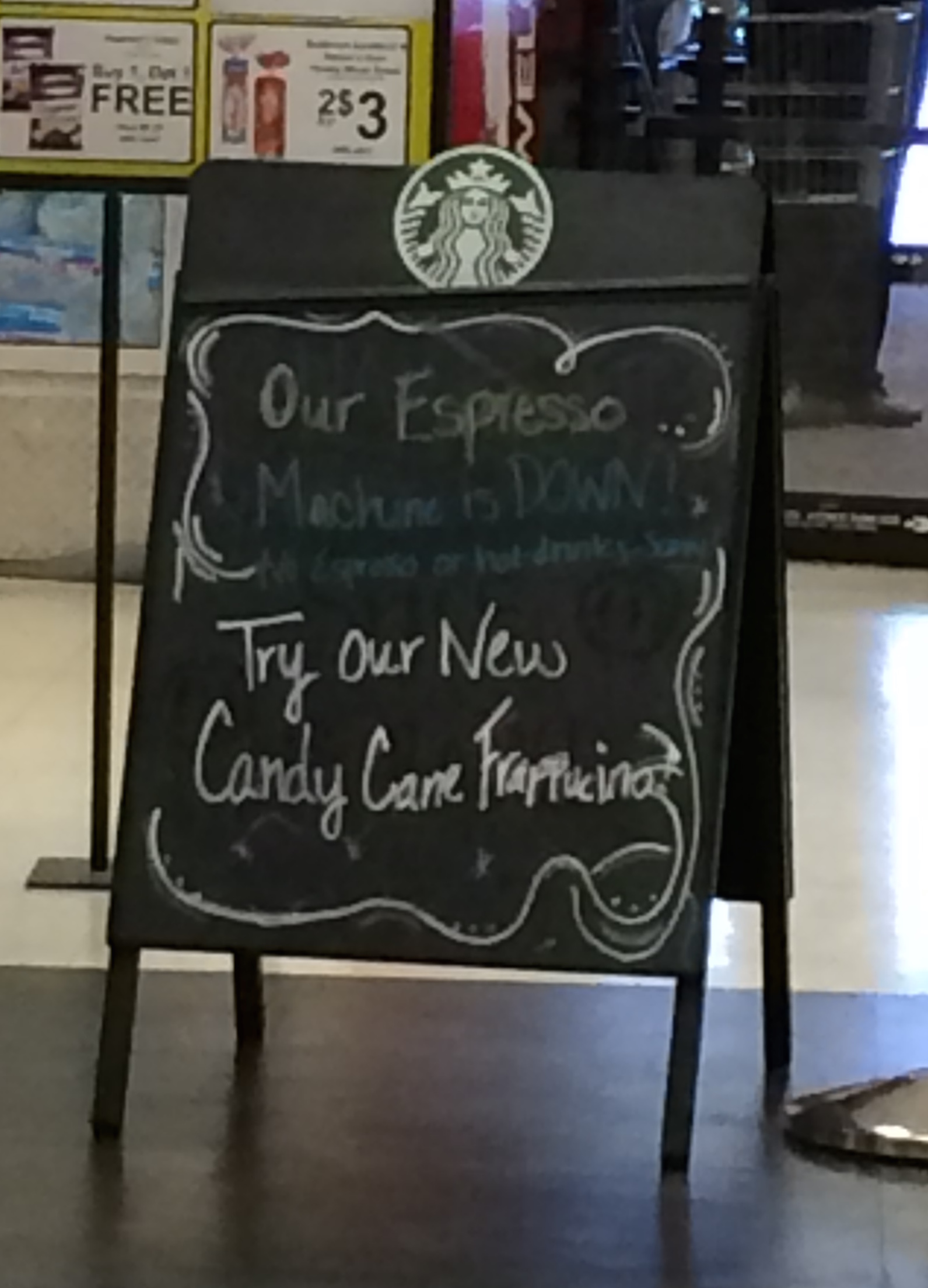

This sign greeted customers at my local office…er, Starbucks.

This sign greeted customers at my local office…er, Starbucks.

“Our Espresso machine is down!”

It seems that the Starbucks regional people sent in a tech to perform “routine preventive maintenance” last night. The machine is down today. Wonder how much that’s cutting out production–and profits?

I used to write a column for a maintenance magazine. I’d broach this occasionally. Predictive maintenance is, of course, much better. A company that is in the forefront of using technology for payment surely has the talent, or at least the vision, to add some sensors to a machine and monitor it to predict when it needs help.

Take a lesson, as they used to say.

by Gary Mintchell | Oct 29, 2014 | Automation, Internet of Things, M2M, Operations Management, Technology

In my last newsletter (you can sign up on the right sidebar for my special content newsletter), I discussed the many press releases issued during the past few weeks on the Internet of Things (IoT) for industry.

In my last newsletter (you can sign up on the right sidebar for my special content newsletter), I discussed the many press releases issued during the past few weeks on the Internet of Things (IoT) for industry.

Maryanne Steidinger, director product marketing operations for Schneider Electric software, posited in a blog post that control and process engineers have actually been implementing the IoT for many years. Let’s consider the control and information buses such as DeviceNet, Profibus, CC-Link, EtherCAT, PowerLink, and the like, to be the beginnings of networking things.

Carl Henning, deputy director of PI-NA (the Profibus/Profinet organization), writes, “Maryanne is right. And even before fieldbuses, the proliferation of electrical and electronic sensors and actuators was paving the way. As more were added, the more we needed fieldbuses.”

Much of the interest is generated by consumer applications. That generates a lot wider media coverage. This industry is not always behind the technological curve.

by Gary Mintchell | Oct 23, 2014 | Automation, Internet of Things, M2M, Manufacturing IT, News, Operations Management, Security, Software, Technology, Wireless

I guess this industrial internet thing has legs. Check this announcement (one of several) from GE.

GE announced recently it is on track to deliver over $1 billion in incremental revenue this year from more than 40 Industrial Internet offerings, with $1.3 billion in orders, helping customers improve asset performance management (APM) and business operations across the company.

In addition, Predix, GE’s software platform that powers the Industrial Internet, will be made available to any company in 2015, allowing them to create and deploy their own customized industry apps at speed and scale to better manage the performance of their assets.

“The tools are in place to realize the potential of the Industrial Internet to increase productivity for our customers and for GE,” said Jeff Immelt, Chairman & CEO of GE. “The more we can connect, monitor and manage the world’s machines, the more insight and visibility we can give our customers to reduce unplanned downtime and increase predictability. By opening up Predix to the world, companies of any size and in any industry can benefit from the investments GE has made by eliminating the barrier to entry.”

GE’s new APM solutions, launched today, focus on power optimization, providing customers 24×7 access to a remote monitoring and diagnostics platform, predictive maintenance insight and incremental power when needed.

Distributed Power’s current suite of data-driven solutions – On Site Power Visibility and On Site Power Performance – help to optimize the performance of GE’s aeroderivative gas turbines, reduce life-cycle costs, improve uptime, increase efficiency and drive profitability.

The Predictable Asset Toolbox for Industry: Predix + Predictivity + APM

GE currently monitors and analyzes 50 million data elements from 10 million sensors on $1 trillion of managed assets daily to move customers toward zero unplanned downtime. Powered by Predix, APM enables customers to put streams of data to work to proactively make the right decisions at the right time to keep assets safe, help them run better, consume less fuel, receive service more efficiently and minimize unplanned downtime.

Kristian Steenstrup of Gartner said, “Increased usage of APM solutions and services will help asset owners and operators reduce maintenance costs and operational risk while boosting reliability. The ultimate goal for any organization is the ‘perfectly predictable asset.’ For immature organizations, this might appear to be an unachievable goal. However, the pursuit is worthwhile, given the many benefits that accrue from getting closer to it. APM will be at the center of efforts to get there.”

GE will leverage its high-margin services backlog of more than $180 billion to develop new APM technologies, growing its dollars of revenue per installed base 3-to-5 percent annually. Reinforcing the importance of this opportunity, Immelt said: “The Industrial Internet is a win-win for GE and our customers. Our offerings will increase GE’s services margins and boost organic industrial growth, with the potential to drive as much as $20 billion in annual savings across our industries.”

For example, AirAsia is on track to save $10 million in fuel costs in 2014 by using Flight Efficiency Services. The solution enables airlines to optimize traffic flow aircraft sequence management, flight path design, and more by revealing patterns and transforming data into actionable insights. AirAsia fuel savings alone are expected to grow to $30 million by 2017.

Jonathan Sanjay, Regional Fuel Efficiency Manager at Air Asia, said, “If you generate a small savings on each flight it translates to big savings at the end of the year. Even a one percent savings can translate into millions of dollars.”

In addition, E.ON has achieved up to 4 percent more power output from 283 of its wind turbines enrolled in GE’s Wind PowerUp, a customized software-enabled platform that increases a wind farm’s output by up to 5 percent, taking into account environmental and site conditions.

This increased output results in an additional 40 gigawatt hours of annual energy production, the equivalent energy to power approximately 4,000 American homes for a year.

“E.ON is always innovating, and we are happy that GE’s PowerUp technology has made some of our best wind farms even better,” said Patrick Woodson, chairman, E.ON North America. “Advancements in wind energy technology, like PowerUp services, will continue to make renewable energy even more competitive in the energy market.”

To help businesses accelerate the adoption of Industrial Internet solutions, GE also announced a new APM tool that helps customers assess their current operations and identify the assets and processes that would benefit the most from increased connectivity, data analysis, and optimization. This initial assessment is the first step in realizing bottom line savings and minimizing unplanned downtime.

Designing Apps for Industry that Matter: Predix App Factory

To further the value of APM, GE today launched the Predix App Factory, an advanced methodology for rapidly prototyping, validating, and developing Industrial Internet applications that shortens typical development cycles from months to weeks. GE pioneered this collaborative approach with customers to drive innovation at scale, bringing together experts from user experience and design, data science, machine connectivity, and agile software development. GE is using the App Factory process at its state-of-the-art Design Center in San Ramon, California to develop new solutions that lead to better customer outcomes such as reduced resource consumption, improved operational efficiency, and lower risk. For example, GE Aviation created an industry app allowing airline and plane operators to blend current information with advanced analytics to actively monitor more than 30,000 jet engines for real-time detection and response to issues.

The Security Standard to Protect Critical Infrastructure: Wurldtech

Securing critical infrastructure is vital to the Industrial Internet, but it holds a unique set of complexities that are different from protecting a traditional IT environment. GE is focused on safeguarding operations technology and improving the reliability of the Industrial Internet for customers and industries. To do this, GE acquired Wurldtech earlier this year to leverage its Achilles industrial security products and services to certify GE and non-GE products and customer environments. GE plans to use Achilles as a standard for securing all of its technology for delivering security enhancements through Predix and GE Products.

Bill Ruh, Vice President, GE Software, said, “Protecting sensor networks and critical infrastructure is paramount to the reliability and safety of industrial operations as more machines and systems are brought online and connected to people at work. At GE, we are well positioned to help respond to this dynamic by bringing together three elements that include our industrial big data platform, an ecosystem of partners, and vigorous cyber security management through the acquisition of Wurldtech. All of these important elements will require continued progress across innovation to transform not just the industrial world, but the global economy as organizations realize the benefits of the Industrial Internet.”

Global Network Connectivity

GE also announced new global alliances with Softbank, Verizon, andVodafone to provide a wide range of wireless connectivity solutions optimized for Industrial Internet solutions. In addition, GE continues to fuel innovation with AT&T by connecting its machines and assets such as locomotives, fleet, and aircraft engines through the AT&T global network and highly secure cloud. Together, these relationships enable GE to provide its industrial customers with advanced connectivity services in virtually any geography.