by Gary Mintchell | May 8, 2018 | Automation, Networking

Ever wonder about the need for the elusive IT/OT convergence? Rockwell Automation announces Factory Talk Network Manager software for its Stratix line of managed (Ethernet) switches. Rockwell OEMs switches from Cisco built to its specifications. Cisco builds good equipment, but it is famous in the networking world for somewhat, shall we say, complex management software.

Control engineers and plant-floor technicians who have growing Ethernet networks to connect all this Internet of Things stuff need something that is closer to their language.

By the way, I still have plenty of catching up to do with things I learned both at Hannover (where I spent many hours with Hewlett Packard Enterprise) and the following week at Dell Technologies World in Las Vegas. I’m finally home and getting organized.

This new management software enables engineers and technicians to monitor the health of their Allen-Bradley Stratix managed switches, troubleshoot switch issues, and quickly configure new managed switches all from one easy-to-use software interface.

“Many plant-floor personnel struggle to piece together information about managed switches and devices from different sources,” said Lorenzo Majewski, product manager, Rockwell Automation. “With the FactoryTalk Network Manager software, they can access this information in one collective spot. In addition, real-time alarms and events from network switches can help them conduct faster, more precise troubleshooting.”

FactoryTalk Network Manager software automatically discovers assets, their associated IP addresses, and creates a topology of these connected devices. The software’s intuitive interface offers grouping of equipment along with dashboard information, so users can organize devices into specific areas or analyze them individually.

The software also uses user-created configuration templates to get new switches up and running faster and more efficiently. These templates can be shared across an organization, or with OEMs and system integrators to further ease network deployments, commissions and maintenance efforts.

The FactoryTalk Network Manager software provides role-based access control with auditing capabilities to help track user-specific activities and changes. The software supports multiple protocols, including Simple Network Management Protocol (SNMP), Common Industrial Protocol (CIP), Modbus, BACnet and PROFINET. Access to the web-based platform is available via a personal computer in a control room or a mobile device on the plant floor.

by Gary Mintchell | Nov 16, 2015 | Automation, News, Technology

In advance of this week’s Automation Fair at Chicago’s McCormick Place, Rockwell Automation has announced a couple of new product extensions–SoftwareStudio 5000 development environment and ControlLogix 5580.

In advance of this week’s Automation Fair at Chicago’s McCormick Place, Rockwell Automation has announced a couple of new product extensions–SoftwareStudio 5000 development environment and ControlLogix 5580.

“The addition of these applications [to SoftwareStudio 5000] significantly enhances our integrated development environment,” said Mike Brimmer, product manager, Rockwell Automation. “The expanded environment simplifies the design process and reduces the need for multiple tools, providing a more seamless system development experience.”

The Studio 5000 environment now includes the following:

- The new Studio 5000 Architect application is the central point within the Studio 5000 environment where users can view the overall automation system; configure devices such as controllers, HMIs and EOIs; and manage the communications between the devices. The Studio 5000 Architect application also exchanges data with other Studio 5000 applications and third-party electrical design tools to simplify the development experience.

- The Studio 5000 Logix Designer application is the design and maintenance software for the Allen-Bradley Logix5000 family of controllers and is used to configure discrete, process, batch, motion, safety and drive control. It simplifies the design process by providing an application-centric view of code; enhanced work flows for more efficient re-use of content; and collaborative tools that make it easier for multiple people to work together.

- The new Studio 5000 View Designer application is the design and maintenance software for Allen-Bradley PanelView 5500 graphic terminals. The Studio 5000 View Designer application provides an intuitive, modern design environment that helps users more easily build contemporary systems. It enhances integration between the control system and operator interface to improve programming efficiency and runtime performance.

- The new Studio 5000 Application Code Manager speeds system development by helping users build libraries of re-usable code that can be managed and deployed across their entire enterprise. Creating projects with Application Code Manager helps improve design consistency, reduce engineering costs, and achieve faster time-to-market and commissioning.

In addition, Rockwell Automation has updated the Studio 5000 environment with enhanced security and localized batch control. New security features include more user-authentication and access-control options, and a new privilege escalation capability. These features help improve productivity and system uptime by granting users the right level of access at the right time. Localized batch control allows controller-based batch sequencing and eventing to simplify system architecture for single-unit control and process skids.

The new ControlLogix 5580 controller provides up to 45 percent more application capacity and includes an embedded 1-gigabyte Ethernet port to support high-performance communications, I/O and applications with up to 256 axes of motion.

The new ControlLogix 5580 controller provides up to 45 percent more application capacity and includes an embedded 1-gigabyte Ethernet port to support high-performance communications, I/O and applications with up to 256 axes of motion.

“With this new controller, users can meet future capacity and throughput needs as they design smart machines and work toward building a Connected Enterprise,” said Dennis Wylie, global product manager, Rockwell Automation. “The new port and additional capacity cuts the amount of control and communications hardware required, reducing system complexity, costs and required panel space.”

In addition, the product selection process is easier with the ControlLogix 5580 controller because users can now select the appropriate model using the total number of Ethernet nodes required. A single ControlLogix 5580 controller can support up to 300 Ethernet nodes.

The controller also supports enhanced security as part of a defense-in-depth approach to help protect facilities, assets and intellectual property. The controller incorporates advanced security technologies and software features, such as digitally signed and encrypted firmware, change detection and audit logging.

by Gary Mintchell | Feb 5, 2015 | Automation, News, Technology

This was an interesting email. Siemens invited me to a webinar where I could learn how easy it now is to use TIA Portal software for automation and control development work building upon my knowledge of Rockwell Automation’s Studio 6000 software.

When I sold Allen-Bradley back in the 90s, I went head-to-head with Modicon (remember it?). Just as I left for greener pastures called Control Engineering, Schneider Electric acquired Modicon. That was the end of effective competition in the automation and control space in North America. There are a number of companies—all good companies with good products—which remain niche players here. We can count B&R, Beckhoff, Automation Direct, Mitsubishi, Omron.

Aside from Automation Direct, which had always carefully calculated its space and structured the company to capitalize on its space with a profitable business plan, executives from each of the others has proclaimed to me that they will be the one to knock off Number One Rockwell from its perch in North America.

Siemens

Back in the 90s again, I had a few customers using TI PLCs. One of them bought a PLC 5 from me. The other one told me he could get the same thing he was buying from a new company that sent him a catalog—PLCDirect, which became AutomationDirect. I thought, wow, PLCs by mail. This is becoming a commodity market.

What had happened was that TI sold its PLC business to Siemens. I figured it was an opening for me to sell against. I batted .500.

I used to joke that Siemens bought the business and then successfully drove market share from 4% to 2%. It just kept hanging on. Not unlike Rockwell in Siemens’ home turf in Europe.

Then a couple of things happened. First, Chrysler got into financial trouble (again) and sold to first one then another European company. Suddenly Siemens had a strong entry point into North American automotive manufacturing. Second, Siemens brought a couple of smart and visionary leaders into its North American division—Helmuth Ludwig and Raj Batra.

I no longer have a feel for market share, but given all the dynamic factors, I believe that Siemens has made more inroads than any of its predecessors. Rockwell has not indicated any concern, yet, with any counter moves. But things are heating up.

Siemens is pressing hard. This webinar that shows the capability of TIA Portal is a start. (I’ve seen the product. It looks good. But then, so does Studio 5000. Competition is a wonderful thing for customers.)

Siemens is also making the biggest company splash at next week’s ARC Forum in Orlando. The huge Yokogawa and Mitsubishi parties are in the distant past. GE has an invitation-only breakfast (read as, no competitors allowed). ABB has a lunch. But Siemens is sponsoring the Wednesday evening dinner and party at Epcot with a special press event preceding.

As I’ve often said, I love competition.

by Gary Mintchell | Dec 2, 2014 | Automation, Motion Control, News, Operations Management, Process Control, Software, Technology

Every Rockwell Automation software executive and product manager who talked with me at Automation Fair almost gushed over the latest and major release of Rockwell Software Studio 5000 Logix Designer v24 (with a name that long, it’d better be good).

Every Rockwell Automation software executive and product manager who talked with me at Automation Fair almost gushed over the latest and major release of Rockwell Software Studio 5000 Logix Designer v24 (with a name that long, it’d better be good).

According to the press release, “Engineers have new design capabilities that can dramatically increase automation productivity, improve start-up time and reduce costs throughout a project’s life cycle. The new additions include an application-centric view of code, enhanced work flows for more efficient re-use of content, and new collaborative tools that make it easier for multiple people to work together.”

“Many machine builders and manufacturers struggle to support production changes due to unstructured code that is not easily understood and organized,” said Mike Brimmer, product manager, Rockwell Automation. “The Studio 5000 Logix Designer v24 software improves the design experience by more intuitively aligning the control system with the manufacturing operation, thus leading to enhanced automation productivity.”

As part of a contemporary automation engineering design environment, the Studio 5000 Logix Designer v24 software is used to configure Allen-Bradley Logix5000 controllers from Rockwell Automation for discrete, process, batch, motion, safety and drive control.

The Studio 5000 Logix Designer v24 software features a new logical organizer that arranges program code based on the users’ applications – rather than how the programmable controller executes. Logical organization of program code can help users identify and troubleshoot code faster for improved downtime recovery.

New library management workflows, meanwhile, ease the ability to store and re-use intellectual property. Users can simply drag and drop modules of code from the Studio 5000 Logix Designer v24 library into a new project. The new workflows enable design engineers to re-use sections of code, which reduces design time and eases the ability to make future operational changes.

Automation system design and maintenance teams are increasingly global and specialized by function. This highlights an increasing need for more powerful collaborations tools. The Studio 5000 Logix Designer v24 software is addressing this need by building on its already strong baseline of multiuser capabilities, which allows many users to work separately and then bring their work back together.

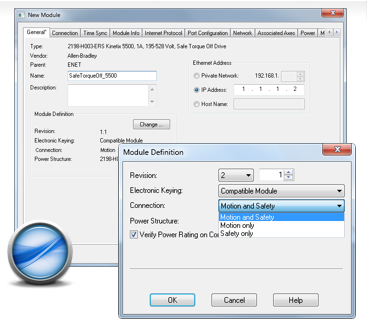

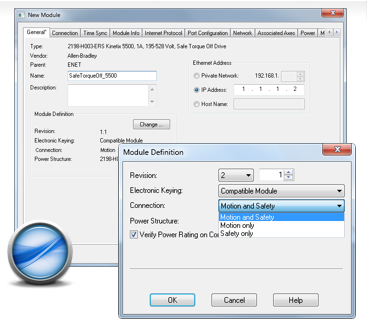

In addition, the Studio 5000 Logix Designer v24 software supports the Allen-Bradley Kinetix 5500 servo drive with integrated safety to help machine builders reduce development and installation time. It also provides support that allows the Allen-Bradley PowerFlex 527 AC drive to be the first variable frequency drive to exclusively use the motion instruction sets within the Studio 5000 Logix Designer v24 software for machine control and motor synchronization.

Additionally, the Allen-Bradley Dynamix 1444 integrated condition-monitoring system allows manufacturers to leverage the Rockwell Automation Integrated Architecture system, rather than an isolated condition-monitoring device. It helps assess current equipment health, predict potential issues, and help avoid damage to critical machinery.