by Gary Mintchell | Jun 22, 2020 | Asset Performance Management, Operations Management, Software, Technology

Emerson marketing called us together for a virtual press conference and demonstration of its take on Augmented Reality (AR) integrated with it Plantweb Optics asset performance platform. I’ve seen many demos of AR over the past many years. The technology inspires imaginative thinking, but somehow companies have just not managed to make it ready for prime time.

Emerson’s evidently is. Not only could they show a demo, it is due to be released later this summer with the next release of Plantweb Optics software. Better yet, it does not require glasses or other peripheral equipment other than the smart phone or device people are already using.

The tag line from Emerson: Analytics and live remote assistance improve productivity and safety.

What does it do, really? Well, it delivers enhanced access to real-time diagnostics and analytics, as well as live remote assistance, to industrial plant workers responsible for maintaining and optimizing plant equipment. With AR technology integrated into Plantweb Optics, companies can improve productivity, collaboration and operational performance, without being limited by shortages of skilled workers or travel restrictions.

“Successful digital transformation programs that lead to Top Quartile performance have people and work practices as a key focus. Adopting innovative technology like augmented reality and institutionalizing best practices enable workers to add more value than ever to operational and business performance,” said Stuart Harris, group president for Emerson’s digital transformation business. “With these new Plantweb Optics technologies, customers can experience significant improvements in equipment reliability and the safety of their facilities.”

Plantweb Optics leverages artificial intelligence, machine learning analytics, and data contextualization to provide real-time visibility into plant reliability and operational performance. Unlike standalone AR solutions that require custom engineering, AR is integrated into Plantweb Optics, providing immediate access to a wealth of data and translating into easier, less costly implementation and a faster return on investment. For use by manufacturers in the life sciences, food and beverage, chemical, metals and mining, power and water, pulp and paper and energy industries, Plantweb Optics is part of Emerson’s award-winning Plantweb digital ecosystem of technologies, software and services.

Augmented reality for Plantweb Optics transforms the way field technicians accomplish complex tasks through enhanced situational awareness, live remote assistance and analytics delivered in context of the plant. As a field technician walks an industrial plant with a mobile device, Plantweb Optics uses spatial computing technology to map assets and provide technicians with critical maintenance information relevant to their location. Plantweb Optics overlays real-time analytics, equipment health status and technical support documentation on their field of view, so technicians can safely resolve issues sooner.

The augmented and virtual reality market is projected to grow annually at 40% from 2017 through 2025, according to multiple research reports. Much of this spending will come from manufacturers around the globe using AR technology to help upskill their workforce for digitalized operations.

With live remote assistance, field technicians can be virtually shadowed by experts, either on-site or off-site, from Emerson, their own company or another service provider. Experts can talk, type or augment the technician’s mobile display with graphics to guide the next action. Live remote assistance enables technicians and experts to collaborate for safe troubleshooting and repairs, regardless of location and without travel costs. Live remote assistance sessions, best practices and notes from experienced engineers and step-by-step troubleshooting procedures can be logged into a knowledge library for use by all engineers at a site. The knowledge library is a resource for companies to standardize procedures and ensure engineers of all experience levels understand an asset’s history and are using best practices for safe, efficient operations.

by Gary Mintchell | Nov 12, 2018 | Manufacturing IT, Software

Wondering what Rockwell Automation is going to net out of its $1B investment in PTC that also netted John Genovesi a major promotion within the company? I have been. And here is the first release.

The companies have launched FactoryTalk InnovationSuite, powered by PTC, a software suite that enables companies to “optimize their industrial operations and enhance productivity by providing decision makers with improved data and insights.” The new suite delivers visibility of operations and systems status from one source of information inside the organization. The collaborative offering is the first to integrate technologies from both companies following the strategic partnership announcement in June.

FactoryTalk InnovationSuite, powered by PTC, improves connectivity to operational technology (OT) devices on the plant floor, natively supporting the rapid, scalable, and secure connection of the most commonly used industrial equipment. Combined with data from information technology (IT) applications and systems, decision makers can now gain a complete digital representation of their industrial equipment, lines, and facilities from anywhere in the enterprise.

“Our offering is unique in its ability to improve how companies capitalize on the IIoT by combining expertise from industry, technology, and plant-floor professionals,” said John Genovesi, incoming senior vice president, Enterprise Accounts & Software, Rockwell Automation. “Now we’re bringing innovative solutions from PTC together with leading analytics and Manufacturing Operations Management (MOM) from Rockwell Automation for a differentiated industry solution.”

“We’re moving the needle on how leading-edge technology is applied in industrial environments,” said Catherine Kniker, Head of Strategic Alliances, PTC. “Manufacturers have seen digital technology rapidly change, but their execution continues to follow practices established for the legacy business. This bundled offering will help organizations accelerate time to value and reinvent how they compete by breaking down barriers across their operations through a comprehensive approach to operational intelligence.”

Included in this collaborative offering are the FactoryTalk Analytics and MOM platforms, as well as PTC’s ThingWorx Industrial IoT Platform, which includes industrial connectivity from Kepware, and the Vuforia augmented reality solution.

Key features of applications within the new collaborative offering include:

Intuitive, user-friendly interfaces that give users a view of the operations by combining data from multiple IT and OT sources and tailored to their role. An operations manager, for instance, can view overall performance of a facility, or multiple facilities, before researching the performance of specific equipment or factors impacting OEE.

Automated advanced analytics of IT and OT sources transform massive amounts of raw data into actionable or proactive information to improve performance and reduce the impact of downtime. Leveraging powerful artificial intelligence (AI) technology to simplify complex analytical processes, users can now proactively respond to issues ahead of any critical failures.

Augmented reality (AR) delivers more efficient and effective ways of looking at digital information within the physical world. AR enables more efficient training, wider knowledge sharing, and better first-time fix rates. Through the bundled offering, maintenance, for example, can receive digitized work instructions containing real-time performance and service history information so technicians can better diagnose and fix equipment correctly the first time.

FactoryTalkInnovationSuite.com

by Gary Mintchell | Oct 10, 2018 | Commentary, News

Which companies are leading us into the Fourth Industrial Revolution? The World Economic Forum has completed a study and named nine of the best factories in the world—certainly an audacious task. Dubbed “lighthouses”, they were selected from a survey of over 1,000 manufacturing sites based on a successful track record of implementing technologies of the Fourth Industrial Revolution.

Three of the nine “lighthouse” sites are in China, five are in Europe and one is in the United States.

The aim of this effort is to build a network of “manufacturing lighthouses” to address problems confronting industries in both advanced and emerging economies when it comes to investing in advanced technologies. Earlier work by the Forum identified that over 70% of businesses investing in technologies such as big data analytics, artificial intelligence, or 3D printing do not take the projects beyond pilot phase due to unsuccessful implementation strategies. To aid the learning and adoption of technologies by other companies, all nine lighthouses in the network have agreed to open their doors and share their knowledge with other manufacturing businesses.

“The Fourth Industrial Revolution is expected to deliver productivity gains amounting to more than 3.7 trillion USD. But we are still at the beginning of the journey” said Helena Leurent, Head of the Shaping the Future of Production System Initiative and Member of the Executive Committee at the World Economic Forum. “Our efforts to create a learning platform with the lighthouses as the cornerstone are part of the giant leap needed to capture the benefits for the larger manufacturing ecosystem including multinationals, SMEs, start-ups, government and academia”.

“The Fourth Industrial Revolution is real. Workers and management equally get augmented with technology. These pioneers have created factories that have 20-50% higher performance and create a competitive edge,” said Enno de Boer, Partner and Global Head of Manufacturing at McKinsey & Company, which collaborated with the Forum on the project. “They have agile teams with domain, analytics, IoT and software development expertise that are rapidly innovating on the shop floor. They have deployed a common data/IoT platform and have up to 15 use cases in action. They are thinking “scale”, acting “agile” and resetting the benchmark.”

The nine “lighthouses” have comprehensively deployed a wide range of Fourth Industrial Revolution technologies and use cases at scale while keeping humans at the heart of innovation. One example from each of the sites is highlighted below:

- Bayer Biopharmaceutical (Garbagnate, Italy): ‘Using data as an asset’- While most companies use less than 1% of the data they generate, Bayer’s massive data lake has led to a 25% reduction in maintenance costs and 30-40% gains in operational efficiency

- Bosch Automotive (Wuxi, China): ‘Supporting output increase’ – By using advanced data analytics to deeply understand and eliminate output losses, simulate and optimize process settings, and predict machine interruptions before they occur

- Haier (Qingdao, China): ‘User-centric mass customization model’ – Artificial Intelligence led transformations include an ‘order-to-make’ mass customization platform and a remote AI supported, central intelligent service cloud platform to predict maintenance needs before they happen

- Johnson & Johnson Depuy Synthes (Cork, Ireland): ‘Process-driven digital twinning’ – This factory used the internet of things to make old machines talk to one other, resulting in 10% lower operating costs and a 5% reduction in machine downtime

- Phoenix Contact (Bad Pyrmont and Blomberg, Germany): ‘Customer-driven digital twinning’ – By creating digital copies of each customer’s specifications, production time for repairs or replacements has been cut by 30% Procter & Gamble (Rakona, Czech Republic): ‘Production agility’ – A click of a button is all it takes production lines in this factory to instantly change the product being manufactured, which has reduced costs by 20% and increased output by 160%

- Schneider Electric (Vaudreuil, France): ‘Factory integration’ – Sharing knowledge and best practices across sites has helped this company make sure all its factory sites enjoy the highest energy and operational efficiencies, reducing energy costs by 10% and maintenance costs by 30%

- Siemens Industrial Automation Products (Chengdu, China): ‘3D simulated production line optimization’ – Using 3D simulation, augmented reality and other techniques to perfect the design and operations of its factory, employees helped increase output by 300% and reduced cycle time

- UPS Fast Radius (Chicago, USA): ‘Balancing capacity with customer demand’ – Meeting increasing consumer demand for fast-turnaround customized products has been made possible through a combination of globally distributed 3D printing centres with real-time manufacturing analytics

The World Economic Forum, committed to improving the state of the world, is the International Organization for Public-Private Cooperation. The Forum engages the foremost political, business and other leaders of society to shape global, regional and industry agendas.

by Gary Mintchell | Sep 5, 2018 | Automation, Technology

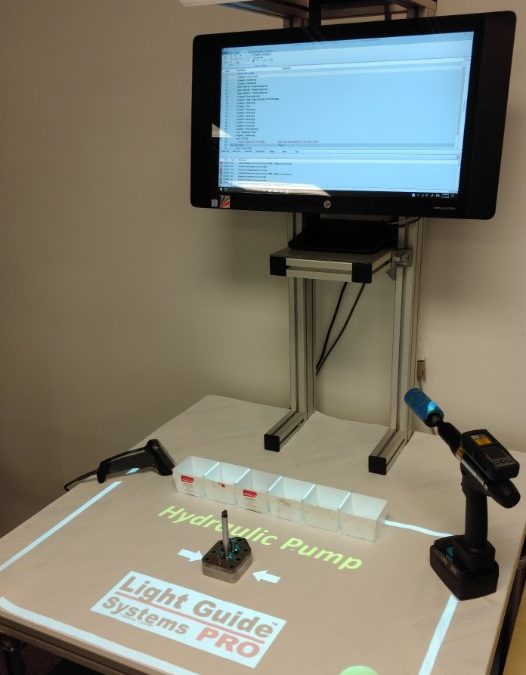

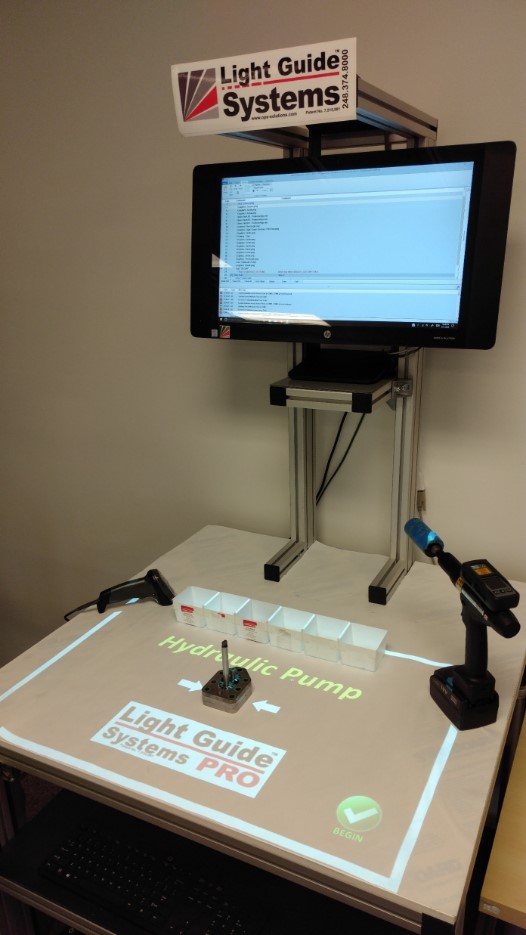

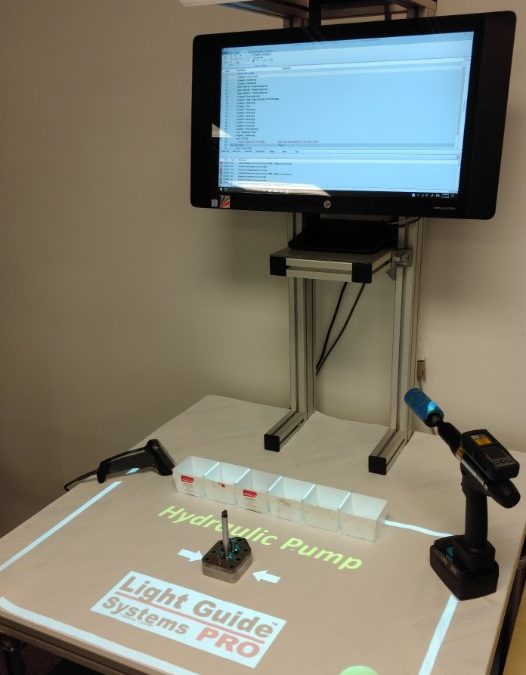

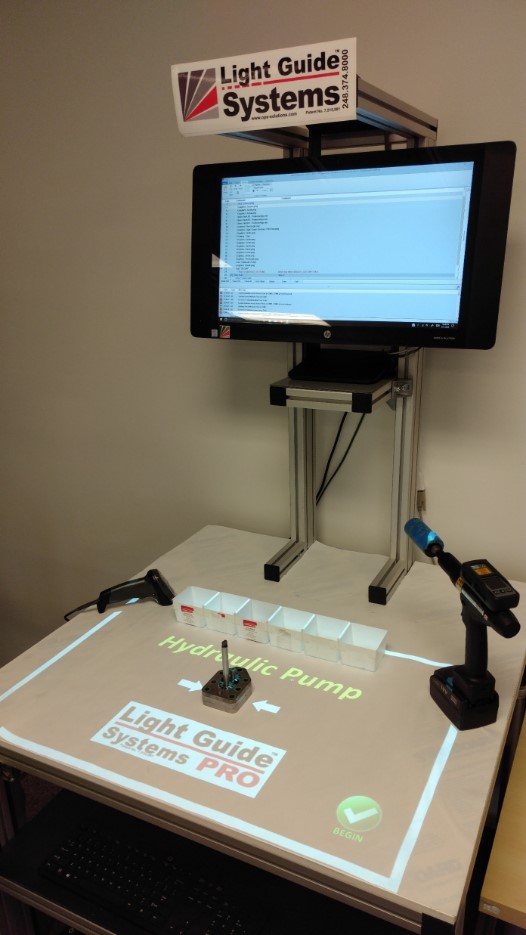

Humans are still essential for many manufacturing processes. Especially for assembly. But assuring the correct parts go in the assembly in the correct orientation is essential. Enter an augmented reality (AR) tool to help.

Light Guide Systems partnered with information technology company HP Inc. to release a tech tool an augmented reality (AR) dubbed Light Guide Stratus. Leveraging Sprout Pro computing platform by HP, Light Guide Stratus provides a flexible, adaptable benchtop platform for assembly processes.

Light Guide Stratus builds on the company’s initial product Light Guide Systems Pro, which launched in 2016. The Stratus system integrates the Sprout Pro directly into a bench structure to increase the display surface area and free up critical space on the workstation. This expanded workspace can be used to integrate new types of applications and tools for a particular assembly sequence.

“The launch of Light Guide Stratus is a testament to the growing demand for flexible and powerful AR guidance systems,” said Paul Ryznar, OPS Solutions founder, president and CEO. “We knew that Light Guide Systems Pro brought a critical level of functionality and flexibility to improve outcomes for nearly any industry. We expect Light Guide Stratus to address even more applications and become an integral part of assembly and manufacturing operations for companies in every space, from medical to auto to aerospace and energy.”

Light Guide Systems projects a digital operating “canvas” onto virtually any work surface to provide audio and visual prompts, guidance, pacing, and direction. Light Guide Systems Pro takes the tool to the next level by incorporating its proprietary software into the Sprout Pro PC platform. Light Guide Stratus takes user experience into account with a flexible and repeatable design that opens up the workspace.

“HP’s Sprout Pro with Light Guide Systems reduces training time and improves quality in manufacturing assembly through projection and scanning in an augmented reality platform,” said Louis Kim, vice president and general manager of Immersive Computing, HP Inc. “Light Guide Stratus demonstrates the flexibility of the Sprout Pro platform combined with Light Guide’s innovation and leadership.”

by Gary Mintchell | Jul 30, 2018 | Commentary, Technology

Everybody has a list of transformative technologies. A news release from an advisory firm, ABI Research, came my way a few weeks ago. Its analysts came together and compiled a list of eight technologies they feel will be transformative in manufacturing and then they fit them with Smart Manufacturing. That latter phrase is one of the descriptors for the new wave of manufacturing strategy and technology.

We will have difficulty contesting the list. Most of these are, indeed, already well along the adoption path. I find it interesting that they refer to IIoT platforms, but they don’t view those as transforming technologies but rather as a sort of sandbox for the technologies to play in.

[This is a Gary aside—when an analyst firm makes a list of suppliers, I’d advise not considering it to be comprehensive. Rather the list is usually comprised of companies that the firm’s analysts get to sit down with and receive in-depth briefings.]

The ABI report identifies eight transformative technologies:

1 Additive manufacturing

2 Artificial intelligence (AI) and machine learning (ML)

3 Augmented reality (AR)

4 Blockchain

5 Digital twins

6 Edge intelligence

7 Industrial Internet of Things (IIoT) platforms

8 Robotics

From the ABI news release, “The manufacturing sector has already seen increased adoption of IIoT platforms and edge intelligence. Over the next ten years, manufacturers will start to piece together the other new technologies that will eventually lead to more dynamic factories less dependent on fixed assembly lines and immobile assets. Each step in this transformation will make plants and their workers more productive.”

“Manufacturers want technologies they can implement now without disrupting their operations,” says Pierce Owen, Principal Analyst at ABI Research. “They will change the way their employees perform jobs with technology if it will make them more productive, but they have no desire to rip out their entire infrastructure to try something new. This means technologies that can leverage existing equipment and infrastructure, such as edge intelligence, have the most immediate opportunity.”

ABI summary of its research

The transition towards a lights-out factory has started, but such a major disruption will require an overhaul of workforces, IT architecture, physical facilities and equipment and full integration of dozens of new technologies including connectivity, additive manufacturing, drones, mobile collaborative robotics, IIoT platforms and AI.

IIoT platforms must support many of these other technologies to better integrate them with the enterprise and each other. Those that can connect and support equipment from multiple manufacturers, such as PTC Thingworx and Telit deviceWISE, will last.

After decades of producing little more than prototypes, the AM winter has ended and new growth has sprung up. GE placed significant bets on AM by acquiring Arcam and Concept laser in 2016, and Siemens announced an AM platform in April 2018. Other leading AM specialists include EOS, Stratasys, HP and 3D Systems.

ML capabilities and simulation software have made digital twins extremely useful for product development, production planning, product-aaS, asset monitoring and performance optimization. Companies with assets that they cannot easily inspect regularly will significantly benefit from exact, 3D digital twins, and companies that manufacture high-value assets should offer digital twin monitoring as-a-service for new revenue streams. Innovative vendors in digital twins and simulation software include PTC, SAP, Siemens, and ANSYS.

The above technologies have already started to converge, and robotics provide a physical representation of this convergence. Robotics use AI and computer vision and connect to IIoT platforms where they have digital twins. This connectivity and AI will increase in importance as more cobots join the assembly line and work alongside humans. The robotics vendors that can integrate the most deeply with other transformative technologies have the biggest opportunity. Such vendors include the likes of ABB, KUKA, FANUC, Universal Robots, Rethink Robotics and Yaskawa.

“The vendors that open up their technologies and integrate with both existing equipment and infrastructure and other new transformative technologies will carve out a share of this growing opportunity. Implementation will go step-by-step over multiple decades, but ultimately, how we produce goods will change drastically from what we see today,” concludes Owen.