by Gary Mintchell | Jan 26, 2017 | Automation, Industrial Computers, Security

Bedrock Automation has built a good automation platform with built-in security and toughness. I’ve been watching to see just how disruptive it might be in the market. In this announcement, it is showing further growth in its go-to-market strategy of working with integrators. It has signed a memorandum of agreement with Jacobs Engineering Group Inc., one of the world’s largest and most diverse providers of full-spectrum technical, professional and construction services. Under the agreement, the companies will pursue selected projects with automation system requirements for potential implementation of the Bedrock Open Secure Automation (OSA) system.

Bedrock Automation has built a good automation platform with built-in security and toughness. I’ve been watching to see just how disruptive it might be in the market. In this announcement, it is showing further growth in its go-to-market strategy of working with integrators. It has signed a memorandum of agreement with Jacobs Engineering Group Inc., one of the world’s largest and most diverse providers of full-spectrum technical, professional and construction services. Under the agreement, the companies will pursue selected projects with automation system requirements for potential implementation of the Bedrock Open Secure Automation (OSA) system.

“Our clients are increasingly concerned about both cyber security and advanced automation and we have been creating innovative service packages to meet these needs. Bedrock Automation has excellent experience and superior designs in this area. I am impressed with their comprehensive background and knowledge in the industrial DCS and PLC arena,” said Jacobs’ Mission Solutions Chief Technology Officer Dr. Tommy Gardner.

The Bedrock control system is known for its patented Black Fabric Cybershield architecture, which provides an intrinsic cyber secure automation platform to protect user hardware, software and applications. Unlike other conventional industrial control systems, Bedrock was designed from a clean sheet of paper with advanced components and architecture to be simple, scalable and secure.

“Jacobs is taking a leadership role in integrating the next generation of information and automation technologies for its clients,” added Bedrock Automation President Bob Honor. “We see this as a tremendous opportunity to bring our technology and our vision of holistic cyber security to a much larger audience. We look forward to an exciting and mutually beneficial relationship with Jacobs.”

by Gary Mintchell | Sep 21, 2016 | Automation, Internet of Things, News

Hannover Messe brought a slice of its automation trade show to this year’s International Manufacturing Technology Show (IMTS)—a venue known for huge machine tools. This was the second time, and it seems to be gaining some traction. Most exhibitors seemed to be central European, but there was a presence from a number of other North American automation companies not to mention many from Asia.

I stopped by a large number of stands. Below are five that had press releases new for the show. Opto 22 was at the show with an opportunity to see its recently released product with a RESTful API in the real plastic, so to speak. That plus a promised MQTT support maintains Opto’s usual spot as an early adopter, if not first adopter in many cases, of IT technologies in its OT products. I also stopped by to talk with Tom Burke and Stefan Hoppe at the OPC Foundation stand. Its news was reported here last week.

(My two-day silence was caused by travel to California and participating in the Inductive Automation Ignition Customer Conference. More on that later.)

Companies addressed below:

- Dell Technologies

- Beckhoff Automation

- Bedrock Automation

- Universal Robots

- Carbon (3D printing)

Dell Technologies

Appearing at IMTS in the automation hall for the first time, Dell Technologies showed its IoT Gateway and Embedded capabilities along with several partners that help it provide a complete Internet of Things solution from data collection through storage, analysis, and uploading to the cloud.

The major solution thrust for Dell thus far in its first year of existence has been predictive analytics especially for predictive maintenance applications. One of the featured partners was IBM Watson, using the famed supercomputer power for predictive analytics and EAP—its predictive maintenance solution.

Eigen showed a real-time quality application with in-process inspection. Some real-time analytics are performed in the gateway before sending data asynchronously to the cloud for further analysis.

Software AG, a partner from the beginning, provides a predictive maintenance software module that provided high speed streaming analytics in an ice cream factory. The module can also create service requests, see anomalies, order spare parts.

Beckhoff Automation

Check me out in these cool Microsoft Hololense Augmented Reality (AR) glasses. In this demo, I could see live data streaming from a robotic application. Beckhoff also showed support for MQTT and AMQP transport technologies (it also has OPC UA embedded), an Internet of Things coupler to Microsoft Azure cloud, and power over Ethernet on EtherCat P.

Check me out in these cool Microsoft Hololense Augmented Reality (AR) glasses. In this demo, I could see live data streaming from a robotic application. Beckhoff also showed support for MQTT and AMQP transport technologies (it also has OPC UA embedded), an Internet of Things coupler to Microsoft Azure cloud, and power over Ethernet on EtherCat P.

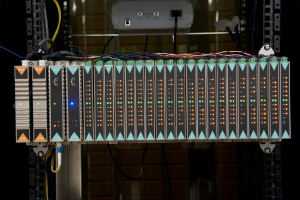

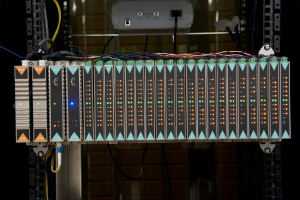

Bedrock Automation

Bedrock Automation has built an entirely new automation and control platform from the ground up. Security is designed in, even to the point of designing and manufacturing its own chips. It offers single, double, and triple redundancy, IEC 61131 programming along with a powerful function block editor that brings it into the DCS world. And it features software configurable I/O, software configurable serial module (5 to a card can be RS-232, RS-422, RS-485), and software configurable Ethernet card (think Profinet, EtherNet/IP, etc.).

Bedrock Automation has built an entirely new automation and control platform from the ground up. Security is designed in, even to the point of designing and manufacturing its own chips. It offers single, double, and triple redundancy, IEC 61131 programming along with a powerful function block editor that brings it into the DCS world. And it features software configurable I/O, software configurable serial module (5 to a card can be RS-232, RS-422, RS-485), and software configurable Ethernet card (think Profinet, EtherNet/IP, etc.).

At IMTS it announced its new intelligent, standalone power supply. The SPS.500 Secure Power Supply provides deep trust cyber security authentication and onboard intelligence for diagnostics and secure Ethernet communications. Encased in a NEMA 4X sealed aluminum enclosure, users of any PLC, SCADA RTU, PAC or DCS can retrofit to the new SPS.500 inside or outside enclosures, anywhere in a plant and in harsh environments.

At IMTS it announced its new intelligent, standalone power supply. The SPS.500 Secure Power Supply provides deep trust cyber security authentication and onboard intelligence for diagnostics and secure Ethernet communications. Encased in a NEMA 4X sealed aluminum enclosure, users of any PLC, SCADA RTU, PAC or DCS can retrofit to the new SPS.500 inside or outside enclosures, anywhere in a plant and in harsh environments.

Additional features include:

- Ethernet and OPC/UA communications, enabling local or remote monitoring of power supply health for greater system reliability and plant safety

- A powerful cyber secure microprocessor and onboard memory for diagnostics and software-defined functionality

- A built-in redundancy module, which simplifies installation and increases reliability by eliminating the need for an external redundancy module

- Two built-in, software-configurable Form C contact relays, which provide operating and diagnostic status

Universal Robots

One of the big things in automation this year is collaborative robots, or cobos. A leader in this area is a new entrant—Universal Robots. This Danish company showed its products at IMTS. It also announced two unique new initiatives.

- Universal Robots+: an ecosystem of products and applications, users choosing accessories, end-effectors, and software solutions from Universal Robots+, both distributors and end-users, get high security and predictability that applications will run well from the start.

- +YOU: a unique, free-of-charge developer program, offering a powerful marketing and support platform for the flourishing eco-system of UR-robot application developers.

Alongside the launch of Universal Robots+, a new update for the robot arm’s operating software has been published. The new release (Software Version 3.3) includes updates such as the Profinet IO device functionality. The new compatibility with Profinet protocols opens up numerous additional areas of deployment and activities for robots. “A key feature of the update supporting the Universal Robots+ platform is the ability for providers to now offer solutions that interface seamlessly with the UR software,” says Østergaard.

Carbon 3D

Carbon 3D announced new funding from strategic investors toward the goal of bringing additive technology to more customers transitioning from prototyping-only use cases, to applications requiring final production quality parts with great surface finish, broad and expanding material options and the plans to transition to mainstream manufacturing. A Silicon Valley 3D printing company working at the intersection of hardware, software and molecular science, Carbon also plans to offer its proprietary CLIP technology internationally and is accelerating production to meet worldwide demand for its M1 printer.

The expansion is supported by $81 million from new investors GE Ventures, BMW, Nikon and JSR, as well as existing investors, bringing Carbon’s funding total to $222 million. More details of additional strategic investors involved in this round of financing will be announced in 2017 along with details of their manufacturing projects that utilize Carbon’s technology.

by Gary Mintchell | Nov 25, 2015 | Automation, Security, Technology

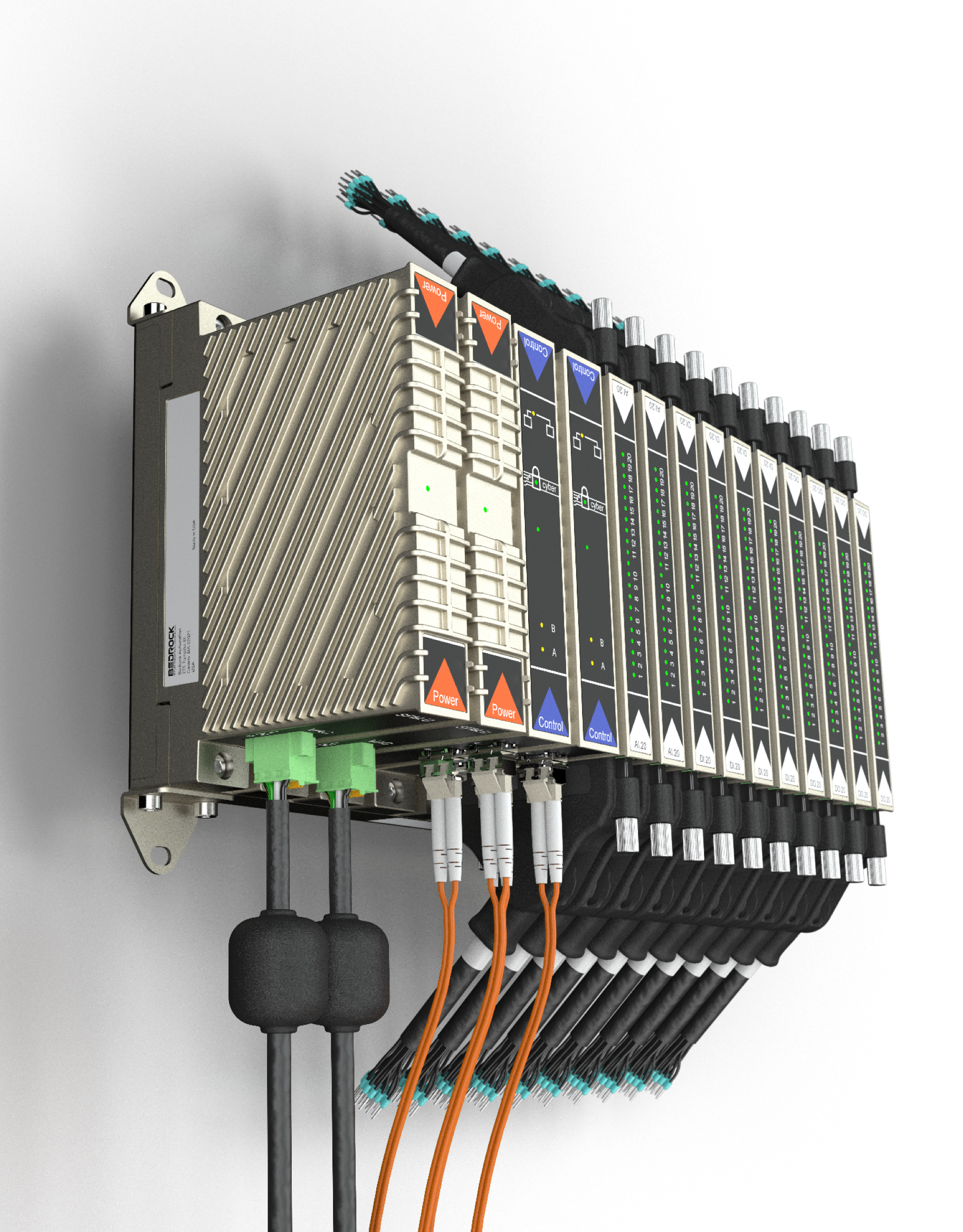

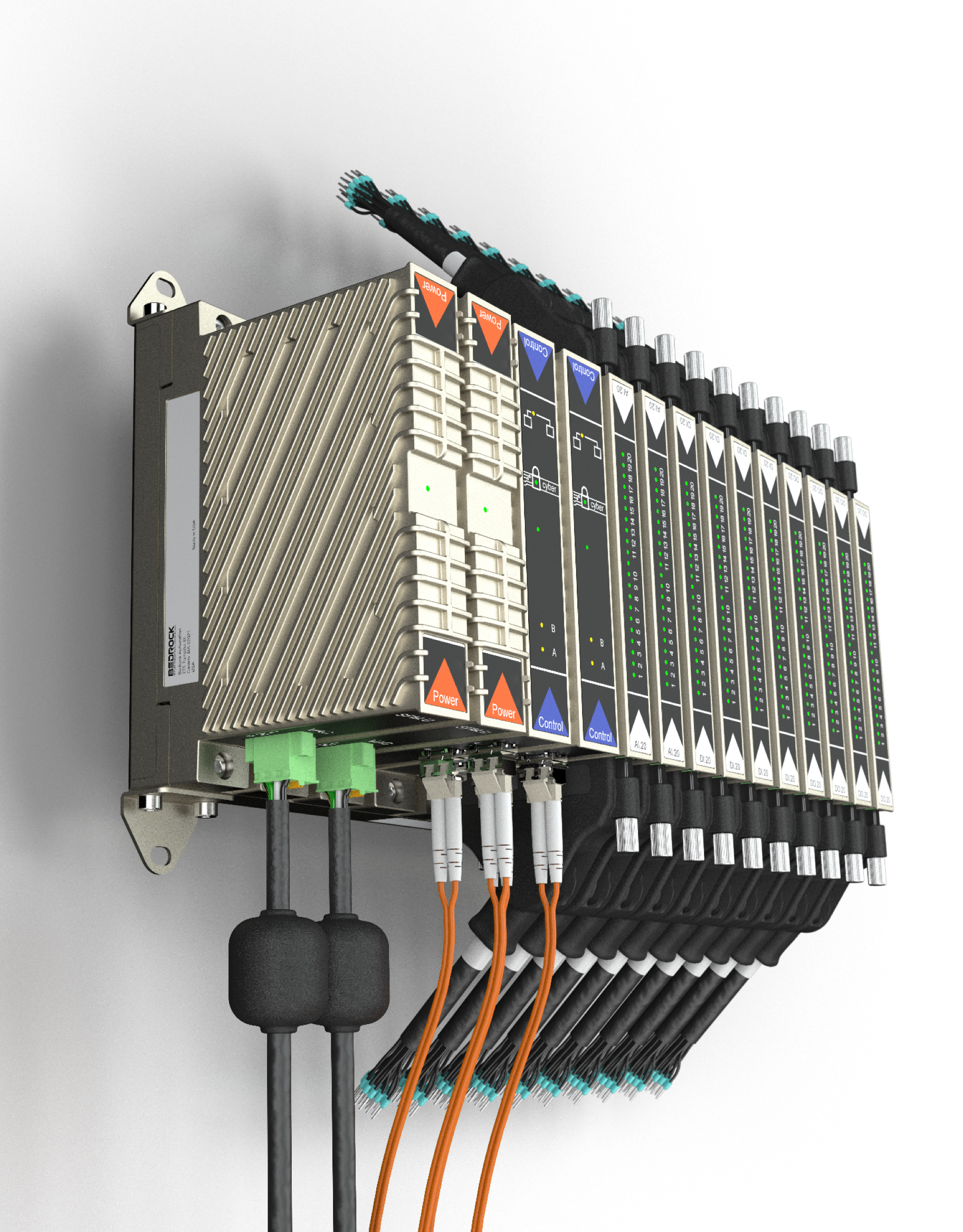

Bedrock Automation extends to the industrial Ethernet domain its commitment to deliver “Simple, Scalable and Secure” automation. The SIO4.E Ethernet I/O module plugs into the Bedrock pinless electromagnetic backplane to receive Bedrock’s patented Black Fabric cyber security protection.

Bedrock Automation extends to the industrial Ethernet domain its commitment to deliver “Simple, Scalable and Secure” automation. The SIO4.E Ethernet I/O module plugs into the Bedrock pinless electromagnetic backplane to receive Bedrock’s patented Black Fabric cyber security protection.

Each of the module’s five I/O channels is independently software configurable. The initial library of Ethernet protocols includes EtherNet/IP. Modbus TCP, OPC UA, and Profinet are slated for future releases on firmware updates. All channels also deliver Power over Ethernet (PoE).

Ethernet as a real-time control variable

Tightly coupling Ethernet into the process control and I/O network enables deployment of a wide range of edge device and enterprise data into real-time control logic, much in the same way an engineer incorporates more typical process sensor and actuator data. This results in real-time communication channels for the exchange of data between OT production and IT enterprise systems.

“Unlike an Ethernet switch traditionally sitting at Purdue levels 3 to 5 with the operations and business networks, the SIO4.E module delivers Ethernet as secure I/O at levels 0 and 1 with the sensor, actuator and process control logic. This collapses the legacy hierarchical ICS model into a simplified and inherently more secure automation architecture. Equally empowering is the deployment of OPC UA on any of the SIO4.E Ethernet I/O channels, opening up a world of opportunity and innovation while reducing all aspects of software lifecycle cost. This is the way of the future,” says Bedrock CTO and Engineering VP, Albert Rooyakkers.

Securing Ethernet I/O

Ethernet is becoming widely adopted for open industrial control system (ICS) applications because it builds on proven, high-speed stacks that have been enhanced for use on industrial devices such as robots, PLCs, sensors, CNCs and other industrial machines. Bedrock secures Ethernet I/O in many ways, including by connecting the FIPS compliant anti-tamper SIO4.E I/O module on a pinless electromagnetic backplane, embedding authentication logic, true random number generation (TRNG) and cryptographic keys into the semiconductor hardware, and by isolating information flow within each channel by way of separation kernel functionality in a secure real-time operating system (RTOS).

“Robust ICS cyber security is just part of the tremendous value that the new Bedrock module brings to process automation,” says Bedrock Automation President Bob Honor. “The fact that each channel can be software configured adds new levels of flexibility and scalability. No other I/O module allows process engineers to program so much communications capability into one system component. We are especially excited about the positive impact for ICS users. That user experience is increasingly configurable and Bedrock uniquely offers the tools and platform to shape it securely to their advantage.”

Pricing and availability

The Bedrock SIO4.E Ethernet I/O module is available at a price of $2000, about the same as a traditional Ethernet IP card. But unlike a typical Ethernet card, the five channel SIO4.E is cyber secure, software configurable for multiple protocols, and has more bandwidth, higher computing power and additional performance advantages.

by Gary Mintchell | Jul 14, 2015 | Automation, Industrial Computers, News, Security, Technology

Potentially viable start-ups are rare in the industrial automation space. Recently Russ Fadel, Rick Bullotta, and John Richardson did it with ThinkWorx an Internet of Things oriented software they sold to PTC. That was their second effort having previously sold Lighthammer to SAP.

Potentially viable start-ups are rare in the industrial automation space. Recently Russ Fadel, Rick Bullotta, and John Richardson did it with ThinkWorx an Internet of Things oriented software they sold to PTC. That was their second effort having previously sold Lighthammer to SAP.

Now we have Albert Rooyakkers, CTO and inventor, and Bob Honor, president and former VP at Rockwell Automation and GE Intelligent Platforms, releasing a new industrial control system and company—Bedrock Automation. This company was introduced to Manufacturing Connection readers last December.

This is a tough area for an entrant. I’ve watched the rise and fall of PC-based control from back in the late 90s. Rockwell Automation and Siemens are so entrenched in the market. The next tier is solid with AutomationDirect, B+R Automation, Beckhoff Automation, Mitsubishi, and Schneider Electric.

When you develop a product for a crowded market, you basically have to execute one of two strategies. Either you think that the products have reached commodity status and that you can make them better, faster, cheaper (at least the last two). Or, you totally disrupt the industry by bringing out something that does what others do better—and adds some significant new features and benefits.

Disruptive?

Bedrock Automation executives believe they have accomplished the latter. The design begins with built-in cyber security. Its patented architecture features a pin-less, electromagnetic backplane. It addresses “virtually all control applications with fewer than a dozen part numbers, reducing cyber attack vectors, cutting lifecycle costs, and simplifying engineering, commissioning and maintenance.”

“Starting from a blank sheet of paper while inventing and deploying advanced semiconductor, mechanical design, cyber computing and communication technologies has resulted in a completely new automation platform. The future is now,” said Bedrock Automation CTO and Engineering VP, Albert Rooyakkers.

Commitment to simple, elegant design is a core tenet of the system. Bedrock delivers I/O, power and communications across the pin-less electromagnetic backplane with a parallel architecture that supports ultra fast scan times regardless of I/O count. The removal of I/O pins improves reliability and increases cyber security while forming a galvanic isolation barrier for every I/O channel. This innovative backplane also allows installation of I/O modules in any orientation and location for “unprecedented” flexibility in I/O and cable management.

Secure I/O modules use layers of advanced technology to deliver software-defined I/O for universal analog, discrete, Ethernet and Fieldbus signal types. A secure power module is functionally and physically coupled to the backplane to deliver single and dual redundant cyber secure power for the control system. A secure universal controller can run virtually every application independent of size or control task: discrete, batch, continuous, or multivariable control from one device that supports as few as ten, to as many as thousands of I/O points. No longer are separate programmable logic controllers (PLC) and distributed control systems (DCS) required.

“As cyber threats to all industries grow, traditional control system vendors respond by adding cost and complexity to their legacy technology. With deep roots in both automation and semiconductors, and unburdened by legacy, Bedrock Automation has created not only the most cyber secure system available today but we have also established new benchmarks for performance, scalability and affordability,” said Bedrock Automation President, Bob Honor.

Layers of protection

Replacing pins with an electromagnetic backplane is one of many layers of cyber security protection that Bedrock Automation has implemented. Additional cyber security layers include:

- A real time operating system with the highest safety (SIL 4) and security (EAL6+) rating of any RTOS available today

- Cyber secure microcontrollers with encrypted keys and TRNG embedded in all system modules including the controller, power supply and I/O

- All modules encased in anti-tamper metal that is impenetrable without metal cutting tools

- Authentication extending throughout the supply chain, including third party software and applications

Adding so many layers of protection to a conventional DCS, SCADA RTU, PAC or PLC would add cost and complexity and degrade performance. With Bedrock, they were built in from the start.

“Brown Engineers is excited to join the Bedrock revolution. Clients in our focus markets of electric, water, and sewer utilities, are increasingly concerned about cyber security and are confident that installing Bedrock will give them peace of mind to tell their ratepayers and their board members that they are taking every precaution to protect their processes. Brown Engineers demonstrates its continued commitment to keeping clients on the forefront of technical innovation,” said Dee Brown of Brown Engineers, an industrial systems integration firm based in Little Rock, Arkansas.

Open, flexible engineering

Bedrock delivers an Integrated Development Environment (IDE) based on an open IEC 61131 software toolset that supports embedded OPC UA. The IDE enables users to develop, operate and authenticate control for a vast array of PLC, SCADA and DCS applications. Fewer components means fewer panel layouts and wiring diagrams to contend with. Software configurable I/O can be changed in the field with the click of a mouse. Ninety percent fewer I/O module types means fewer spare parts to keep and manage. Such innovations contribute to reducing overall engineering design costs by up to 33 percent.

“Bedrock is the first unique platform to enter the control market in the last 15 years. It diverges radically from the typical platforms and is superior in terms of processing power, redundancy, scalability, security and cost efficiency. We plan to use it as a point of differentiation for our business,” said Chris McLaughlin of Vertech, a Phoenix-based industrial systems integrator.

Pricing and availability

The Bedrock control system is available now in baseline configuration starting at $20,000 MSRP. A growing network of world-class system integrators and automation solution providers is available to provide local sales and support.

For more information about the Bedrock revolution, download the first white paper in the series: Revolution – Chapter One: The Backplane.

Bedrock Automation has built a good automation platform with built-in security and toughness. I’ve been watching to see just how disruptive it might be in the market. In this announcement, it is showing further growth in its go-to-market strategy of working with integrators. It has signed a memorandum of agreement with Jacobs Engineering Group Inc., one of the world’s largest and most diverse providers of full-spectrum technical, professional and construction services. Under the agreement, the companies will pursue selected projects with automation system requirements for potential implementation of the Bedrock Open Secure Automation (OSA) system.

Bedrock Automation has built a good automation platform with built-in security and toughness. I’ve been watching to see just how disruptive it might be in the market. In this announcement, it is showing further growth in its go-to-market strategy of working with integrators. It has signed a memorandum of agreement with Jacobs Engineering Group Inc., one of the world’s largest and most diverse providers of full-spectrum technical, professional and construction services. Under the agreement, the companies will pursue selected projects with automation system requirements for potential implementation of the Bedrock Open Secure Automation (OSA) system.

Check me out in these cool Microsoft Hololense Augmented Reality (AR) glasses. In this demo, I could see live data streaming from a robotic application. Beckhoff also showed support for MQTT and AMQP transport technologies (it also has OPC UA embedded), an Internet of Things coupler to Microsoft Azure cloud, and power over Ethernet on EtherCat P.

Check me out in these cool Microsoft Hololense Augmented Reality (AR) glasses. In this demo, I could see live data streaming from a robotic application. Beckhoff also showed support for MQTT and AMQP transport technologies (it also has OPC UA embedded), an Internet of Things coupler to Microsoft Azure cloud, and power over Ethernet on EtherCat P. Bedrock Automation

Bedrock Automation At IMTS it announced its new intelligent, standalone power supply. The SPS.500 Secure Power Supply provides deep trust cyber security authentication and onboard intelligence for diagnostics and secure Ethernet communications. Encased in a NEMA 4X sealed aluminum enclosure, users of any PLC, SCADA RTU, PAC or DCS can retrofit to the new SPS.500 inside or outside enclosures, anywhere in a plant and in harsh environments.

At IMTS it announced its new intelligent, standalone power supply. The SPS.500 Secure Power Supply provides deep trust cyber security authentication and onboard intelligence for diagnostics and secure Ethernet communications. Encased in a NEMA 4X sealed aluminum enclosure, users of any PLC, SCADA RTU, PAC or DCS can retrofit to the new SPS.500 inside or outside enclosures, anywhere in a plant and in harsh environments.