by Gary Mintchell | Nov 14, 2016 | Automation, News, Operations Management, Software, Technology

I put on the pair of magic glasses. Immediately I was transported to a magic land of another reality. I saw things floating in front of me. I could walk around objects and view them from every angle, but I couldn’t touch them.

There was a white dot. I focused on the dot and brought my hand up to eye level forming a fist with fingers on top. Then I opened my fist like a jasmine bud you drop into hot water to make fragrant tea. And a computer screen appeared before my eyes. I raised a finger, pointed to a button, brought my finger down and then back up as if clicking. And a machine started.

No, I had not smoked something. (Although people suspect that in my days at university… well that’s another topic for another day!)

Perhaps you’ve seen the TV ads for the Samsung phone with Virtual Reality (VR) goggles? I was wearing a real product–the Microsoft Hololense. This is Augmented Reality (AR). I could see people walking through the first machine. I could see the actual machine in the second scenario. I controlled the fan speed of the real machine without touching anything. People watching would only see me waving my hand.

Yes, this was last week in Atlanta at Automation Fair sponsored by Rockwell Automation. At a stand called modestly enough The Future of the Connected Enterprise, they showed these working examples of AR in a manufacturing setting.

Innovation

Let’s be honest. In 20 Automation Fairs I’ve attended, I’ve never felt like I’ve seen the bleeding edge of technology. Cool new products? Sure. Rockwell kept advancing with the times. The Logix engine was an advance in the state of the art followed by Studio 5000. But that has been some time ago. This year just felt differently.

First there was a live demo during the media day that included information solutions. Next was the Innovation Zone demo of AR. Finally was a dive into Information Solutions–something initially highlighted by new CEO Blake Moret.

First an admission and some definitions. I stole the headline of the piece from both ControlGlobal and Automation World. I think I saw it in both places on the Web last week. Now the description–Rockwell calls “Software” its software for HMI, programming, and the like. What really has been building is “Information Solutions.” More accurately, the headline should have been, “Rockwell Automation, An Information Solutions and Services Company.”

An Information Solutions Company

Information Solutions and Process Solutions are headed by the same VP/GM, John Genovesi. Process had been growing for several years, but it seems to have leveled off lately. Information Solutions was front and center featured this year. My industry research this year revealed that IS accounts for the bulk of revenue increases within the “Connected Enterprise” strategy. And that makes sense.

Information Solutions and Process Solutions are headed by the same VP/GM, John Genovesi. Process had been growing for several years, but it seems to have leveled off lately. Information Solutions was front and center featured this year. My industry research this year revealed that IS accounts for the bulk of revenue increases within the “Connected Enterprise” strategy. And that makes sense.

One of the deep-dive interview opportunities offered me this year was the Information Solutions group. Spokesperson Khris Kammer told me that there were four pillars to discuss this year–Scalable MES, Scalable Analytic, Connected Services, and Collaboration/Teams. I’ll have more detail on product releases from the first two. Connected Services was touted by Moret during our interview.

The traditional challenge for MES has been its monolithic nature. If you want MES, you must buy a big chunk. Rockwell has been working on this customer challenge and barrier to entry. Rockwell introduced “suites”, but that did not address the entire problem. Now are “fit-for-purpose” apps–quality, production, performance. Read more below.

Analytics became the domain of data scientists through “Enterprise Manufacturing Intelligence” (EMI) which was a spin-off from enterprise Business Intelligence. Rockwell partners with Microsoft PowerBI, but it also worked on the scalable aspect to bring customers in a little at a time. Built upon existing products Historian and VantagePoint, developers built Analytics for Devices and Analytics for Machines–a cloud-based broader solution. Read more below.

Connected Services blends service in networks, security, and managed services. This has been a growing part of Rockwell’s business and now receives the attention and focus of landing as part of the Connected Enterprise strategy.Collaboration features a Web-based, HTML5 app called TeamOne. The team demonstrated it to media in perhaps the first live demo at a Rockwell keynote. Figuring that pretty much everyone already brings a smart phone to work, this app is IT-friendly and allows chatting, information access, video capability, and more among selected members of a team. These personnel may be in the same area, scattered around a facility, or even remote if necessary.

Scalable Analytics

“Our Connected Enterprise vision has always had analytics and collaboration at its core,” said Genovesi. “As we expand our Information Solutions offerings, a primary goal is to make analytics more approachable and right-sized for the customer. New analytics solutions help our customers move ahead on their Connected Enterprise journey, no matter where they are today.”

The new offerings expand capabilities for analytics across the plant floor for devices, machines and systems, as well as throughout the enterprise. In this approach, analytics are computed and gain context closest to the source of decision at the appropriate level in the architecture to return the highest value – from edge devices to the cloud on a variety of new appliances, devices, and on- or off-premise cloud platforms.

FactoryTalk Analytics for Devices appliance provides health and diagnostic analytics from industrial devices. It crawls your industrial network, discovers your assets and provides analytics by transforming the data generated into preconfigured health and diagnostic dashboards. The system also delivers “action cards” to your smartphone or tablet if a device requires attention.

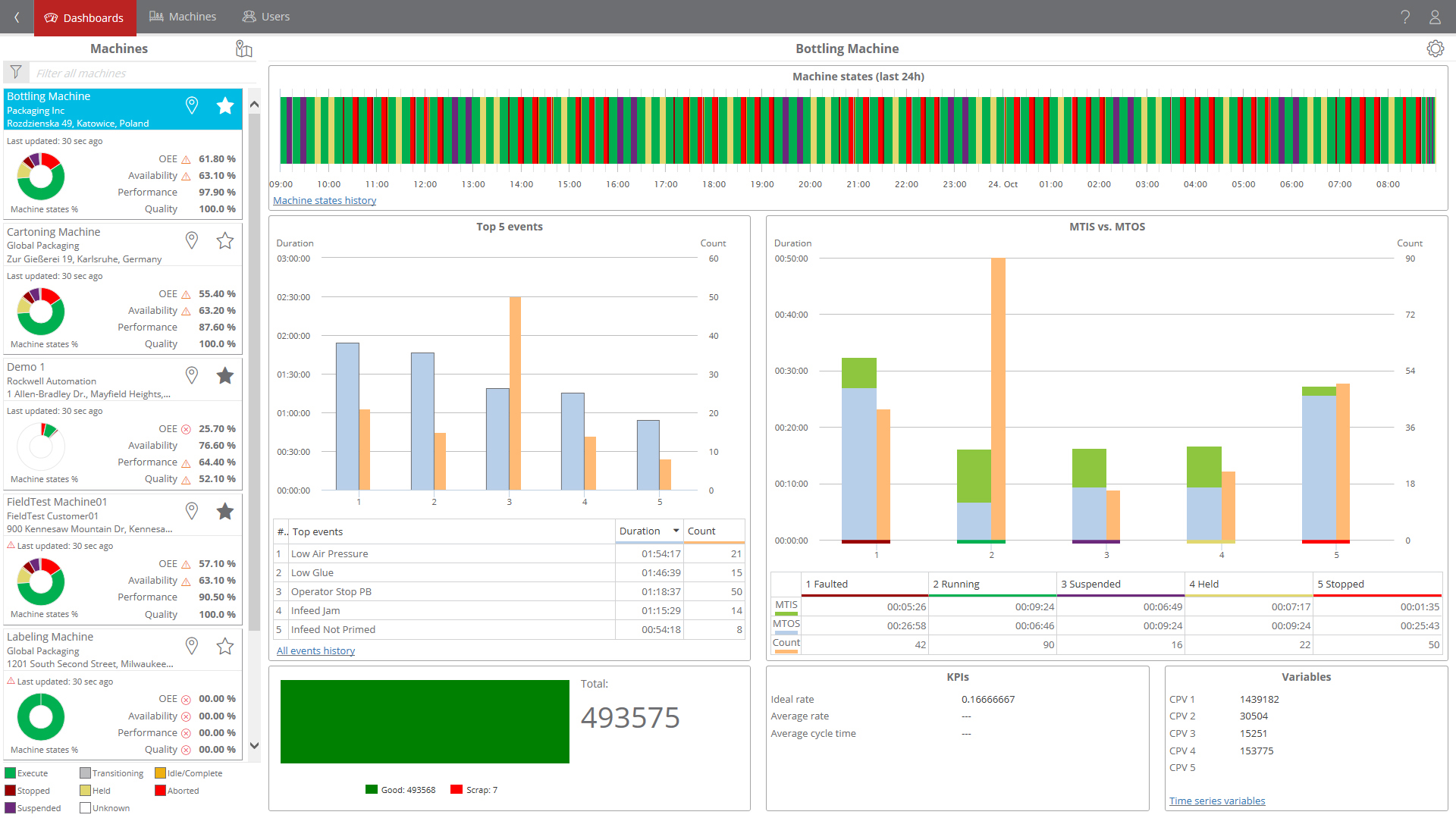

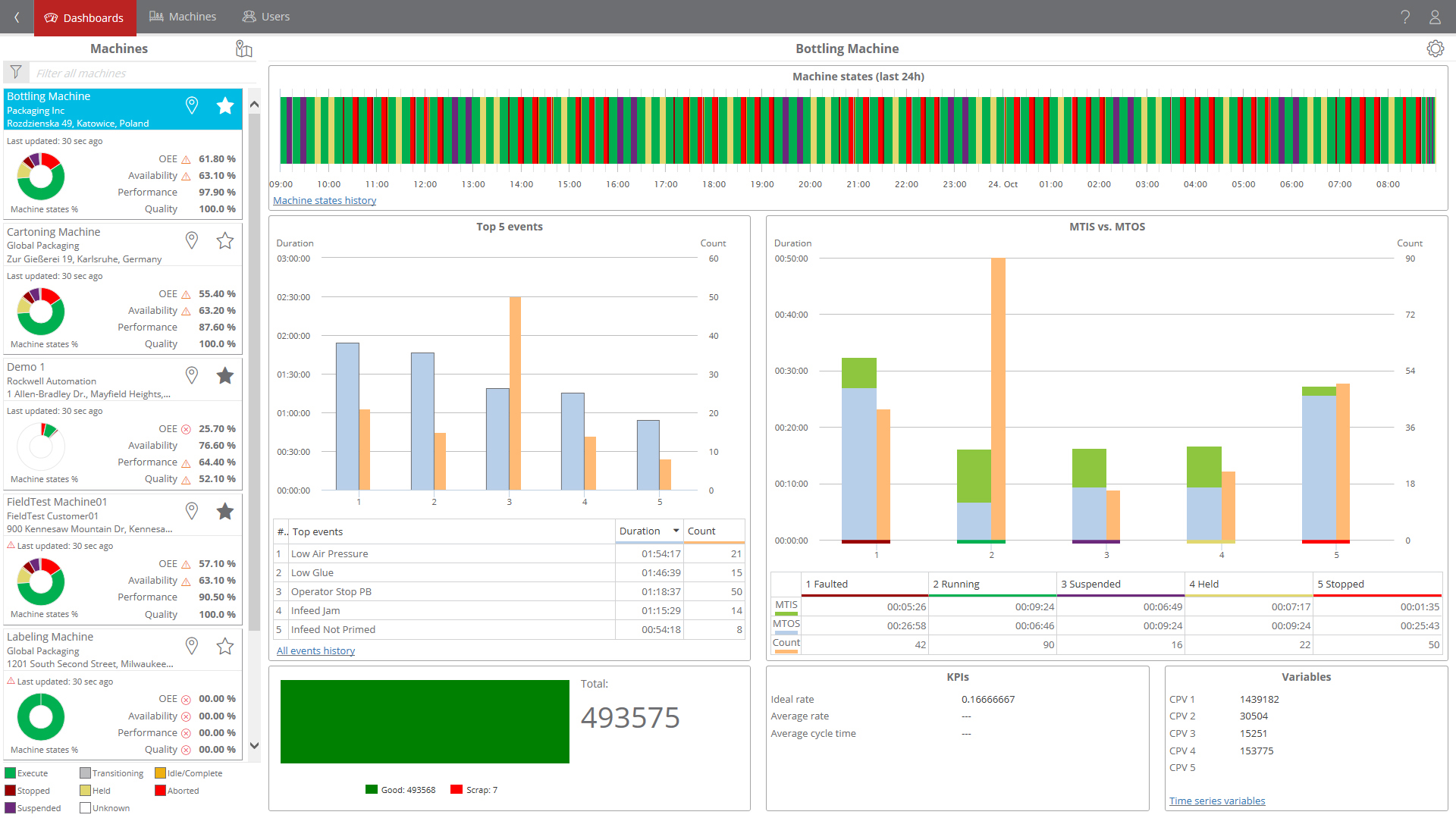

At the machine level, FactoryTalk Analytics for Machines cloud application provides equipment builders access to performance analytics from deployed systems to help support their customers via the FactoryTalk cloud. For manufacturers, this capability capitalizes on connected technologies to help drive higher availability and output while reducing maintenance costs.

Rockwell Automation now provides a predictive maintenance solution that can predict failures before they happen and generate a maintenance work order to avoid costly downtime.

Scalable MES

Rockwell Automation has released the following applications, with more to come in the future:

FactoryTalk Production Application a scalable MES solution that addresses the challenges associated with enforcing processes in manufacturing. This application integrates with ERP, and tracks the order and recipe parameters necessary for production.

FactoryTalk Quality Application allows manufacturers to easily and efficiently model and enforce their plant’s in-process quality regimens at a scalable rate. Manufacturers can use the Quality application on a project basis and scale up when value is proven.

FactoryTalk Performance Application is a modular application that assists manufacturing companies with factory efficiency and production improvement. By providing visibility into the operations performance, this application allows for lean and continuous improvement, preventive manufacturing, improved asset utilization and operational intelligence.

Each expanded MES application is implemented on thin clients for a modern user experience and reduced, IT infrastructure cost. Users can add on each application to their current framework, helping protect their current investments while realizing these additional benefits.

by Gary Mintchell | Nov 11, 2016 | Automation, News, Technology

Every year as part of the Automation Fair experience for media and analysts, Rockwell Automation hosts a “Perspectives” forum on the Tuesday prior to the two-day trade show. Executive and guest experts discuss trends and technologies affecting manufacturing, production, and automation.This is a short introduction. I had two days of deep dives into technology. A bunch of posts to follow. The photo is a panel led by CTO and SVP Sujeet Chand.

This year’s event featured several Rockwell executives plus guest speakers from McKinsey & Company, Microsoft, Cisco, and Georgia Tech. Reflecting a new mood within the company, the Architecture and Software group featured a couple of demos including some bantering and “gee whiz” moments. I have long felt that a technology company should show off some products that way. They did a good job–especially for a first effort.

Bob,Stemfels, senior partner, McKinsey & Company, gave a strategic overview presentation. “Digital disruption will fuel the next industrial revolution,” he noted. Some of the underlying drivers include increasing levels of data, ubiquitous connectivity, pervasive sensing, analytics driving understanding, and advance in cyber physical systems.

John Genovesi, vice president and general manager of Information Solutions and Process Solutions, provided an update on digitization in his areas. First, of course, Rockwell’s vision is based upon EtherNet/IP (did I hear “standard, unmodified Ethernet” again?). Genovesi pointed out that the cost of Ethernet is dropping enough so that devices of around $100 can be networked.

Fran Wlodarczyk, vp gm control and visualization, discussed Integrated Architecture. It is built on EtherNet/IP. They are working with “industry leading PLM suppliers” to build interfaces to integrate Design into the process. The Operate function is enhanced through analytics born in the automation system featuring self-aware devices. Maintain function is enhanced through the new TeamOne product—a mobile friendly app that incorporates chat, sharing pictures/videos and then also the thin client products added through the acquisition of ACP.

Scott Lapcewich, VP and GM of the Services business, discussed Connected Services–the latest addition to the Connected Enterprise. One of the key features about the offering involves managed services and remote services. These are sold on a subscription model involving operating budget monies while avoiding capital expenditure hassles. Network services, also involving Panduit, Cisco, and VMware, is the fastest growing segment.

There was more, but I’ll cover the topics discussed in depth later.

by Gary Mintchell | Nov 9, 2016 | Automation, News, Software

There is a discernible change in atmosphere around Rockwell Automation these days. The statement is not meant in anyway to reflect on former President and CEO (and still chairman) Keith Nosbusch. Newly elected President and CEO Blake Moret appears to be settling in to the new role, and he brings a distinctly new personality to leadership.

There is a discernible change in atmosphere around Rockwell Automation these days. The statement is not meant in anyway to reflect on former President and CEO (and still chairman) Keith Nosbusch. Newly elected President and CEO Blake Moret appears to be settling in to the new role, and he brings a distinctly new personality to leadership.

I was greatly honored that due to some schedule changes that created disruption with the usual media interviews on Tuesday he still worked out some time late Monday afternoon for a private interview.

When I left my last position, I searched for a focus and name for a new, Web-based media site. The Manufacturing Connection made the most sense—and I could get the domain name. Then I went to the first Rockwell Automation event following and found a new theme—Connected Enterprise. We’re all thinking about the importance of connections.

Moret started with the Connected Enterprise theme. His vision for the company’s direction includes and expands upon the theme. It’s not only EtherNet/IP (they still talk about “standard, unmodified Ethernet”). Networking is important. Beyond the network are connecting people, projects, services.

Not only did Moret present the importance of the Information Solutions business, the topic came up later in a general session. Rockwell has definitely grown the capabilities of its software solutions. Its analytics capabilities appear to be robust (Rockwell is using it internally in its own manufacturing processes) with the goal of continually improving its ease of use.

The foundation of Rockwell Automation’s Connected strategy lies with plant floor devices. “Since the majority of devices come from us,” Moret said, “we can connect easily to obtain the information necessary for the MES and enterprise levels.”

Several integrators pinged me before my trip to ask me to investigate the repercussions of the acquisition of system integrator Maverick Technologies. “We’ve always had a dual approach,” Moret told me. (That reminded me of my sales engineer days in the 90s when I had Rockwell quote a couple of projects as the integrator.) “We have no intention of walking away from our partners. But there are customers who want a single source of responsibility. We can handle those projects now.”

“And, by the way,” he added, “we doubled the number of Chemical Engineers in the company with this acquisition. We added a lot of domain expertise.”

The transition seems to be smooth so far. Leadership changes are a critical event in an organization. Handled well, the organization gains renewed vitality and direction. Rockwell Automation is on the right path.

by Gary Mintchell | Nov 3, 2016 | Internet of Things, Manufacturing IT, Software

Back in the day when the Industrial Internet of Things (IIoT) was called Machine-to-Machine (M2M), the promised benefit was for OEMs monitoring their machines on customer sites. Providing that the customer allowed it, the OEM could collect data on performance of the machine and its components, offer maintenance services, and alert customers to potential problems.

Customers generally were leery about allowing connectivity to the outside world. This could become an open port for hacking and even open a gateway for stealing Intellectual Property. Over the ensuing 15 years, many improvements have been made in networking and security. Now, Rockwell Automation is releasing a gateway and cloud analytics platform that hopes to deliver just such benefits.

As Rockwell states in its release, “IoT-enabled assets and machines can improve operations when information that matters is delivered to the people who can use it best. Yet, equipment builders who invested heavily to build smart machines often are blind to the use and performance of their products after deployment.” Rockwell Automation announced FactoryTalk Analytics for Machines cloud application – a new Microsoft Azure cloud-enabled capability that empowers equipment builders with information.

As part of the company’s expanded Information Solutions strategy, the application provides access to performance analytics from deployed systems in order to gain valuable insight to support their customers. For manufacturers going through a digital transformation, this capability capitalizes on connected technologies to help drive higher availability and output while reducing maintenance costs.

“The sophistication of plants today has made specialization and collaboration essential,” said Axel Rodriguez, SaaS/Cloud products manager, Rockwell Automation. “Your manufacturing operations and maintenance teams have a lot on their plates. Allowing your equipment builders – who know their machines like the backs of their hands – to become collaborators in performance analytics can free up the best minds to focus on optimizing entire lines, plants or applications.”

OEMs can embed a FactoryTalk Cloud gateway device onto the machines they provide. Once commissioned, the machine starts collecting data. The data from selected controllers is sent to the FactoryTalk cloud application securely with minimal configuration by the equipment builder or the end user. The equipment builder then has access to real-time analytics and actionable information via prebuilt dashboards. It’s that simple!

by Gary Mintchell | Oct 11, 2016 | Operations Management, Software

Manufacturing Execution Systems (MES) exists to help manufacturers manage the execution layer of a manufacturing enterprise. MES unfortunately can be quite complex. Moving a company from spreadsheet-driven execution to a specifically written application can take years of effort by a team of engineers.

Understandably that makes companies, especially medium sized ones, leery of even contemplating a move to the modern era.

Application developers, aware of this roadblock, have rushed to develop and deploy solutions that are easier to purchase and implement.

Enter Rockwell Automation’s latest entry into this arena. It has developed scalable and application-specific products to address this need. Solutions can start at the machine or work-area level with a single application and with minimal infrastructure requirements, and scale to an integrated MES solution as ROI is realized.

Rockwell Automation has released the following applications, with more to come in the future:

FactoryTalk Production Application – The FactoryTalk Production application addresses the challenges associated with enforcing processes in manufacturing. This application integrates with ERP, and tracks the order and recipe parameters necessary for production. The Production application supports end-to-end production management within a facility, offering a platform for continuous improvement.

FactoryTalk Quality Application – The newly expanded Quality application allows manufacturers to model and enforce their plant’s in-process quality regimens at a scalable rate. Manufacturers can use the Quality application on a project basis and scale up when value is proven. The application can be expanded to include other functionality within the FactoryTalk ProductionCentre MES system or run as a standalone.

FactoryTalk Performance Application – Performance is a modular application that assists manufacturing companies with factory efficiency and production improvement. By providing visibility into the operations performance, this application allows for lean and continuous improvement, preventive manufacturing, improved asset utilization and operational intelligence.

Each expanded MES application is implemented on thin clients for a modern user experience and reduced IT infrastructure cost. Users can add on each application to their current framework, helping protect their current investments while realizing these additional benefits.

Information Solutions and Process Solutions are headed by the same VP/GM, John Genovesi. Process had been growing for several years, but it seems to have leveled off lately. Information Solutions was front and center featured this year. My industry research this year revealed that IS accounts for the bulk of revenue increases within the “Connected Enterprise” strategy. And that makes sense.

Information Solutions and Process Solutions are headed by the same VP/GM, John Genovesi. Process had been growing for several years, but it seems to have leveled off lately. Information Solutions was front and center featured this year. My industry research this year revealed that IS accounts for the bulk of revenue increases within the “Connected Enterprise” strategy. And that makes sense.

There is a discernible change in atmosphere around Rockwell Automation these days. The statement is not meant in anyway to reflect on former President and CEO (and still chairman) Keith Nosbusch. Newly elected President and CEO Blake Moret appears to be settling in to the new role, and he brings a distinctly new personality to leadership.

There is a discernible change in atmosphere around Rockwell Automation these days. The statement is not meant in anyway to reflect on former President and CEO (and still chairman) Keith Nosbusch. Newly elected President and CEO Blake Moret appears to be settling in to the new role, and he brings a distinctly new personality to leadership.