by Gary Mintchell | Nov 5, 2014 | Automation, Industrial Computers, Operator Interface

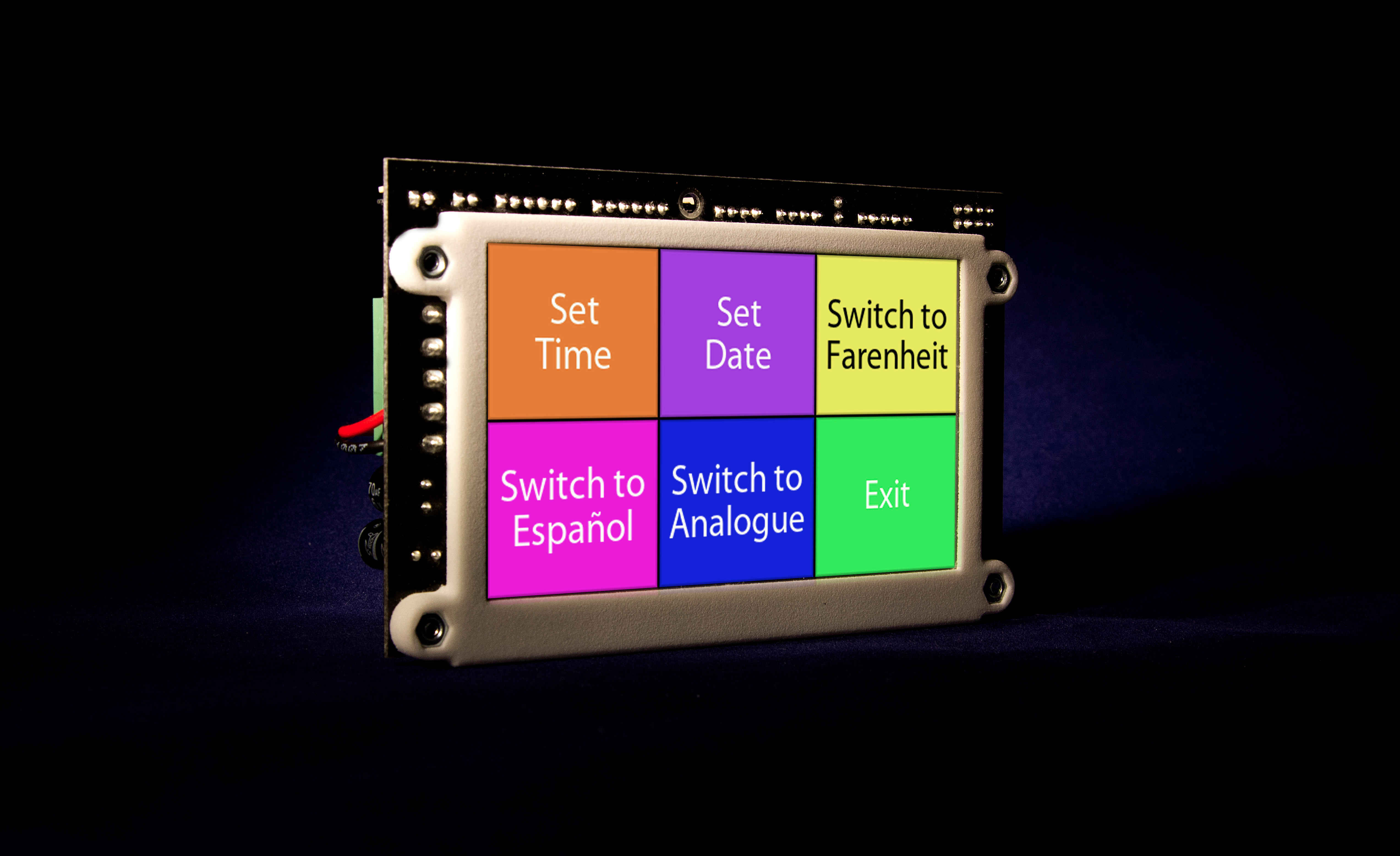

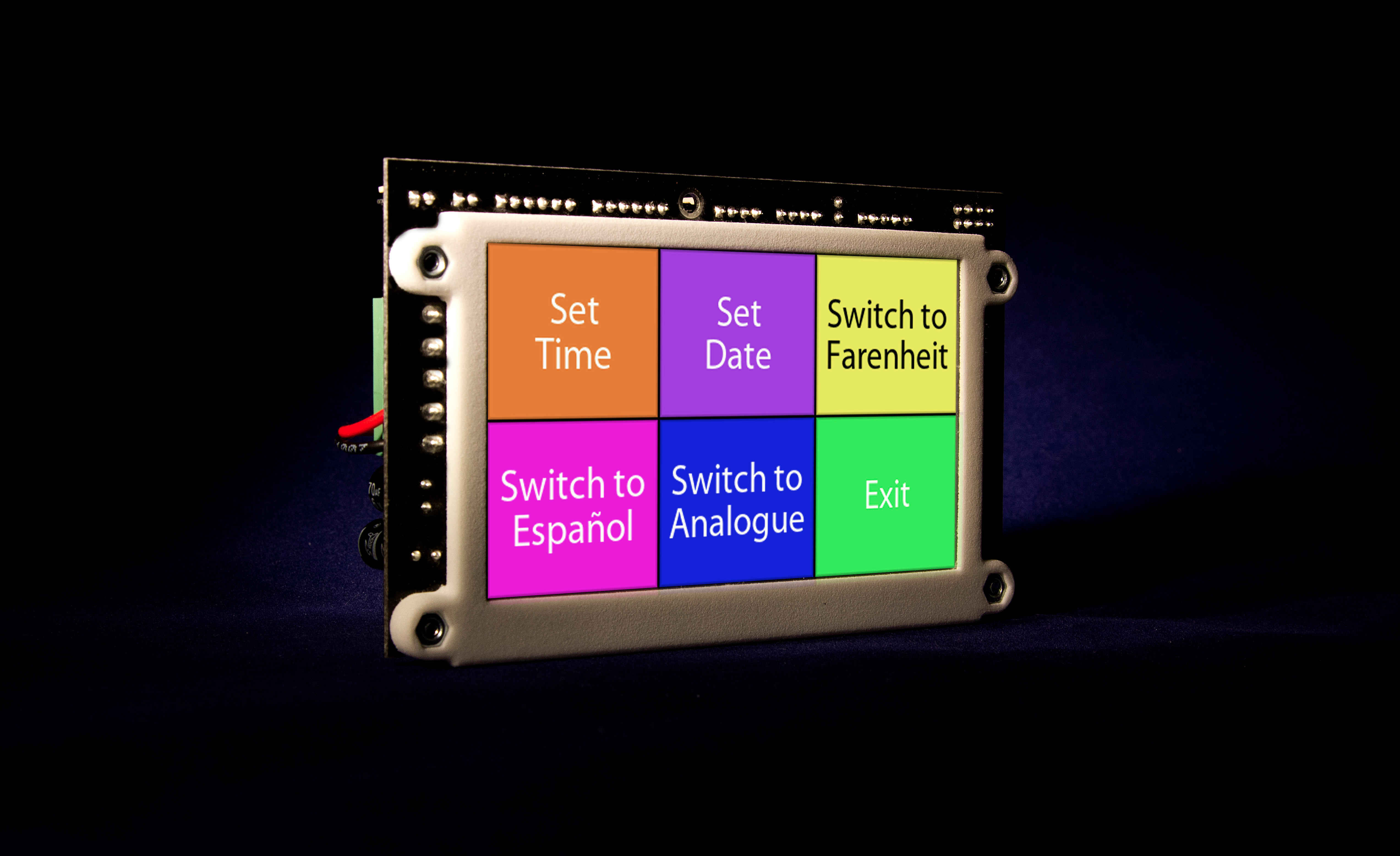

No doubt current trends in industrial controllers, programmable logic controllers (PLC) and human-machine interfaces (HMI) include driving down the cost of control. Here is one that is an integrated HMI/PLC for less than $400. Interestingly, this is the first product pitched to me in years that touts RS485 serial connectivity. I’d darn near forgotten all about those serial protocols.

No doubt current trends in industrial controllers, programmable logic controllers (PLC) and human-machine interfaces (HMI) include driving down the cost of control. Here is one that is an integrated HMI/PLC for less than $400. Interestingly, this is the first product pitched to me in years that touts RS485 serial connectivity. I’d darn near forgotten all about those serial protocols.

Anyway, here are some specifics from SPLat Controls.

The HMI430 board-level programmable logic controller (PLC) with an integrated 4.3-inch color touchscreen is available at nearly half the cost of previous products with similar functionality. With onboard, ruggedized digital I/O, analog I/O, and the SPLat MultiTrack built-in multitasking operating system, the HMI430 delivers “professional-quality control that is affordable and easy to program, minimizing development time.”

According to the press release, “With multiple serial ports HMI430 offers OEMs an ideal way to flexibly integrate a touchscreen into their solution for small- and medium-sized industrial control applications. The touchscreen—a 4.3-inch 470×272 pixel screen with resistive touch and 64K colors—comes with a repertoire of standard buttons, fonts, and other screen elements. With support for alpha blending, image files, and Z-ordering, HMI430 offers sophisticated visual effects at a price point that OEMs can afford.”

“With the advent of smartphones, all controller applications—medical, industrial, building control—are affected by the end-customers’ expectation of a GUI-driven interface,” noted David Stonier-Gibson, CEO of SPLat Controls. “The HMI430 with an integrated color touchscreen enables OEMs to respond to this ‘iEffect’ and provides the innovative edge that helps small- and medium-sized equipment manufacturers make their products smarter and more competitive.”

by Gary Mintchell | Nov 4, 2014 | Automation, Security

Patrick Coyle writing on his Chemical Facility Security blog notes a long term campaign that has been compromising industrial control system security. The following is from his blog. Check out his site.

This evening the DHS ICS-CERT published an alert about a long term anti-ICS campaign that has been compromising various control systems from multiple vendors since at least 2011. ICS-CERT is reporting that, at a minimum, HMI from GE, Advantech and Siemens have been compromised in this campaign. They are not currently reporting any damage to control systems or to operations that are controlled by those systems.

ICS-CERT is publicly providing detailed information about how these compromised HMI can be identified and it is asking all potentially affected system owners to check their systems and notify ICS-CERT if evidence of compromise exists.

As one would suspect with something that is apparently as serious as this, ICS-CERT has released an alert (ICS-ALERT-14-281-01P) on the US-CERT secure portal and has already published an update to that alert. ICS-CERT is also taking the unusual step of publicly describing that alert and notifying “US critical infrastructure asset owners and operators” that they can request a copy of the alert by email ( [email protected]).

As I have already mentioned on TWITTER, this is the most detailed ICS-CERT alert that I have ever seen, especially on an initial publication. This is the type of information that we should be able to expect from ICS-CERT. This is also the type problem that we really need to be able to expect them to delve deeply into. I suspect, however, that we will be receiving the bulk of our information on this from private sector researchers who will have more resources and expertise to throw at this problem. That would be a good topic for a congressional investigation.

BTW: Here is an interesting question about this issue from Chris Sistrunk: “Could the BlackEnergy ICS malware be related to the vulns discovered by Z0mb1E and amisto0x07 from ZDI and the Metasploit mods they wrote?”

BTW: The alert contains a link to the GE security page. Nothing specific there except a brief note that: “The CIMPLICITY Webview server that existed in prior versions of CIMPLICITY, has been removed due to security concerns.” No further information available.

by Gary Mintchell | Oct 1, 2014 | News, Operations Management, Software

Several executives from Schneider Electric over the past few years and Invensys executives early this year discussed with me their approach to integrating acquired properties. In the distant past Schneider had difficulty integrating new companies leading to much politics and infighting.

Many of us are quite surprised, to be honest, how the integration of Invensys software (Wonderware, Avantis, SimSci) has gone thus far. There is positive energy. Optimism. Investment. Stability of top management.

And a further stroke of genius–the previously divided divisions of software and process control are now reporting into completely separate groups within Schneider. No more infighting between the Foxboro people and software people. (The downside for me is that any discussion of the former Invensys always drove my readership to new highs.)

One highlight of the week is always the announcement of the winners of the customer excellence awards. Customers submit applications and papers describing an application of one or more of the [now] Schneider products. I have judged the papers in the past (not this year) and love to read about the creativity and successes of people using and applying the technology.

2014 Excellence Awards

- Asset Excellence – Shell Chemical using Avantis software

- HMI/Supervisory Control Excellence – Aena for an airport application in Barcelona

- Manufacturing Operations Management Excellence – F&N, Thailand

- Operational Excellence – Campbell Soup

- Optimization Simulation Excellence – Chevron

- Production Information Excellence – Carpenter

- Pinnacle Award (overall winner) – Chevron

Congratulations to all.

by Gary Mintchell | Mar 12, 2014 | Automation, Data Management, Operations Management, Technology

Mitsubishi Electric Automation has been somewhat quietly building out a version of the connected manufacturing enterprise for several years. Known for machine control and motion control, it first made a splash by partnering with ILS Technology to develop e-F@ctory. This is connecting technology moving data from the control system to enterprise databases.

It recently announced an “e-F@ctory Alliance Program” that included several connectivity companies. It’s latest announcement is that eWON, which offers industrial VPN routers and Ethernet modems for remote access to PLCs and machines, is the newest member.

eWON devices allow original equipment manufacturers, systems integrators and end users to support their systems remotely. Consequently, eWON’s participation in the e-F@ctory Alliance Program gives Mitsubishi Electric’s customers greater options for anywhere, anytime access to their systems. eWON access options include remote HMI capability to monitor the machines using a built-in web server, data logging capabilities and alarming features.

As with all e-F@ctory Alliance Program products, Mitsubishi Electric has thoroughly tested the eWON solutions to ensure ease of implementation and compatibility with its own products. No programming of Mitsubishi Electric hardware is required to use eWON devices, other than setting the correct IP addresses.

“With the addition of eWON to our e-F@ctory Alliance Program, OEMs, systems integrators and end users can remotely access their systems across the globe,” said Robert Miller, senior manager, strategic collaborations and partnerships, Mitsubishi Electric Automation, Inc. “This eliminates the need for an engineer’s on-site presence to access a system, saving both time and money.”

Mitsubishi Electric’s e-F@ctory Alliance Program is a third-party referencing program with other automation hardware and software vendors that allows customers to select solutions that best solve their automation challenges. Through pre-engineered integration, the latest technologies are easier to use and more cost effective. Complete documentation, including quick start guides, sample programs and maintenance screens when required, are available for each solution, drastically reducing the time necessary to implement and maintain the solutions.

eWON joins third-party hardware and software vendors Balluff, COGNEX, LEM®, MDT Software, eWON, Kepware Technologies, Ocean Data Systems – Dream Report, CC-Link Partner Association and Powerit Solutions in the Mitsubishi Electric Automation e-F@ctory Alliance Program.

by Gary Mintchell | Mar 3, 2014 | Automation, Operator Interface, Process Control

Some of the most exciting technology companies have shown me during the past three years or so has involved deep work into providing better operator displays for industrial plant operations. In this case, “better” means working with the people who actually use the displays–maybe the entire team from operators to maintenance to engineering–in order to develop displays that show the state of the plant at a glance.

Those of you who were around in the late 80s, do you remember the beginnings of PC-based document design applications? PageMaker and Ventura Publisher were new. They offered lots of fonts. People designed brochures with six different fonts on one page–in patterns. Then we had the ability to draw really cool graphics on the screen. I had a customer with a waste water facility. They coded in pages to reflect the seasons of the year (I remember the frog croaking representing summer in the river at the end of the process.)

What I’m saying is that we had the technology and we used it as much as possible. Then we discovered that we were giving too much information in too confusing a format.

New Product

This latest announcement is from PAS Corp. in Houston. It has released PowerGraphiX 2.0, a high performance human-machine interface (HMI) package for the power generation industry. The company promises PowerGraphiX, “will revolutionize the way operators view information at power plants.”

PowerGraphiX is comprised of predesigned graphic templates, object libraries and best-practice guidelines for the design and implementation of operator interfaces at power generation plants. Companies choosing to implement the application can expect vastly improved graphics at significantly reduced costs when compared with traditional methods. (I’ve seen samples.)

According to PAS, the software was initially developed because Southern Company Services Inc. had a vision of consistent HMIs and improved situational awareness in control rooms across the operating fleet. PAS is now making the product commercially available for all utilities.

“Southern Company is committed to proprietary research and development in order to deliver solutions to our company and the industry,” said Harvey Ivey, Southern Company Manager of Instrumentation and Controls Design and Support. “This particular software was originally created to streamline information displayed in control rooms across our generating fleet, significantly improving operator effectiveness.”

The methodology behind developing PowerGraphiX was based on the industry-recognized book “The High Performance HMI Handbook” by Founder and CEO of PAS Eddie Habibi and Principal Consultant for High Performance HMI of PAS Bill Hollifield. It addresses the use of color, pattern recognition, standardization and other principles to transform data into actionable information, providing operators with a more holistic view of plant operating conditions.

“PAS is committed to empowering operators by delivering the precise information they need to improve plant safety and performance,” said PAS Vice President of Technology Mark Carrigan. “PowerGraphiX makes interpreting a plant’s current condition simply intuitive.”

No doubt current trends in industrial controllers, programmable logic controllers (PLC) and human-machine interfaces (HMI) include driving down the cost of control. Here is one that is an integrated HMI/PLC for less than $400. Interestingly, this is the first product pitched to me in years that touts RS485 serial connectivity. I’d darn near forgotten all about those serial protocols.

No doubt current trends in industrial controllers, programmable logic controllers (PLC) and human-machine interfaces (HMI) include driving down the cost of control. Here is one that is an integrated HMI/PLC for less than $400. Interestingly, this is the first product pitched to me in years that touts RS485 serial connectivity. I’d darn near forgotten all about those serial protocols.