by Gary Mintchell | Nov 22, 2016 | Automation, Manufacturing IT, Networking, News, Technology

Last week was GE Digital’s Minds + Machines Conference in San Francisco. This Industrial Internet (or Internet of Things to the rest of us) gathering showcases the latest of GE’s digital portfolio–including GE Automation and Control (the successor to GE Intelligent Platforms, successor to GE Fanuc Automation, whew).

Jim Walsh

Rich Carpenter

I tried to arrange my schedule to make it out there, but there had been too many trips in Sept., Oct., and Nov. for my time and expense budget to make it. So, we had a conference call meeting with Jim Walsh, President and CEO of GE Automation & Controls, and Rich Carpenter, Product GM of Control Platforms also at GE Automation & Controls. We talked about the Industrial Internet, digitalization, and new products.

Included in my news below are additional news from the M+M event including acquisition and product news.

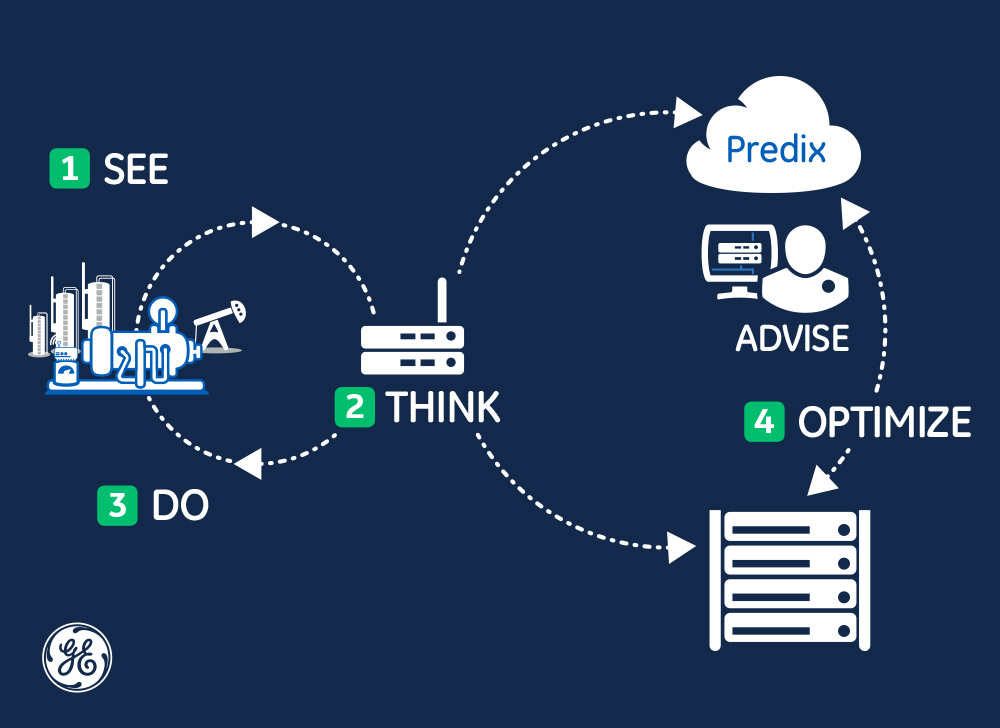

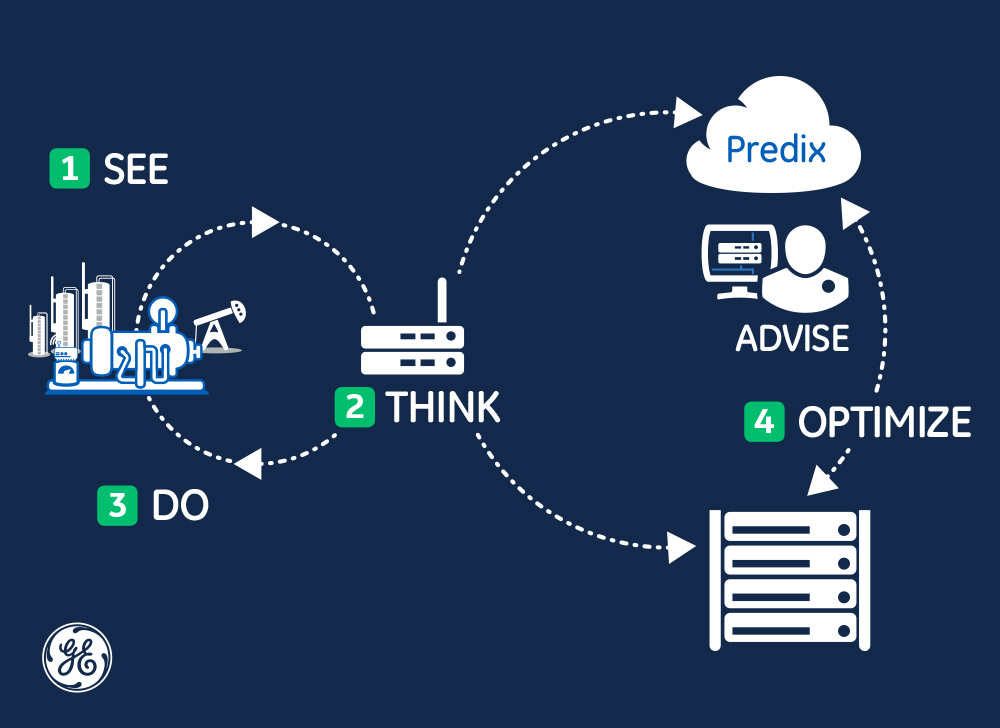

The point most interesting was Walsh and Carpenter discussed the edge device of the network as the controller (PLC). (See the graphic) Almost all of the other companies I talk with are developing an edge device separate from the controller. Carpenter described the closed loop control as “see-think-do”, and then the Industrial Internet plus Predix (GE’s cloud-enabled software product) analytics adds an “optimize” loop to the controller. It can then reflect back on experience and make changes as necessary.

Take for example large pumps in a water/wastewater application. They, of course, are energy consumers. By adding analytics from Predix, the controller could be modified to operate in a more energy efficient manner. One example proved out a $1.5 million per year savings. Another benefit is productivity improvements which Walsh said they had witnessed personally. They referred to the Industrial Internet Control System (IICS), which I will discuss later [Note: much like my Automation Fair update, this one will be long, because there is so much.]

And now, on to the news.

- GE releases new suite of Predix applications and services; introduces the Predix System

- Acquisition of Bit Stew Systems enables efficient data ingestion for industrial applications

- Acquisition of Wise.io strengthens machine learning and data science capabilities for Predix and enables enhanced Digital Twin development

- Meridium acquisition places GE in the lead for Asset Performance Management app development; acquisition of ServiceMax positions GE to lead in service transformation

- Ecosystem expands with independent software vendor program to speed industrial application development; more than 19,000 developers now building on Predix

- Digital orders on track to exceed $7B, a growth of 25%+ in 2016

- Digital thread productivity exceeds $600 million and accelerating into 2017

In 2016, orders from GE’s portfolio of software solutions are on track to climb 25%+ to more than $7 billion. Demonstrating the strength of Predix within GE, digital thread productivity will exceed $600 million, accelerating into 2017.

“The opportunity for industry is now,” said Bill Ruh, Chief Digital Officer of GE and CEO, GE Digital. “The Industrial Internet is profoundly transforming how we operate and our ability to deliver greater productivity for GE and for our customers. Connected machines, coupled with deep machine learning, are more powerful than anything we have seen. These strategic investments in both the Predix platform and our partners continue to attract industrial companies and provide them with tools they need to embark on their own digital industrial transformations.”

EXTENDING PREDIX FROM THE EDGE TO THE CLOUD

GE unveiled a new suite of software and applications.

This release will focus on expanding the platform and scaling development of Digital Twins – virtual representations of physical assets that comprise the world’s industrial infrastructure – through Predix apps and toolkits.

This new set of components can run on a variety of operating systems, devices and form factors – from sensors and controllers to gateways, server appliances and the cloud – making Predix a distributed system for the Industrial Internet and a complete “edge-to-cloud” offering.

GE also launched new Predix-based solutions, designed to help customers harness the power of the Industrial Internet:

Current, designed to analyze and optimize energy use and operational efficiency use across lighting, HVAC and other systems.

Digital Substation, extends maintenance optimization to the electricity grid.

Health Cloud, Cloud-enabled patient outcomes are linking clinical feedback to transformative radiology pathways.

Predictive Corrosion Management, a new Asset Performance Management (APM) solution that provides continuous inspection data and cloud-based analytics of pipe conditions to help operators manage corrosion-related risk.

Digital Power Plant software for gas, steam and nuclear plants, which features new tools to help customers reduce unplanned downtime by up to 5%, reduce false positive alerts by up to 75%, and reduce operations and maintenance costs by up to 25%.

Digital Hydro Plant, a suite of apps combining both software and hardware solutions designed to support Hydro customers globally, helping them get the most out of assets over the lifetime of a plant.

ACQUISITIONS

GE Digital announced it has acquired Bit Stew Systems to bring its data intelligence capabilities to Predix and other industrial solutions. Bit Stew applies its machine learning and artificial intelligence (AI) capabilities to automate the process of data modeling, mapping and ingestion, accelerating time to value for customers, such as BC Hydro, Pacific Gas & Electric and Scottish & Southern Energy. This acquisition will help GE Digital provide a solution to organize large amounts of data through efficient data organization at the edge or at the source of the data – the asset.

GE Digital also acquired Wise.io, a leading machine learning and intelligent systems company. This acquisition will enable GE Digital to further accelerate development of advanced machine learning and data science offerings in the Predix platform. The Wise.io team deepens GE’s machine learning stack and will spearhead innovative solutions in GE’s vertical markets to develop its machine learning offerings.

GE also announced a program dedicated to independent software vendors (ISVs), aimed at spurring development of industrial solutions and extending the reach of the Predix platform. Through these partnerships, GE will share its industry expertise and allow partners to use Predix as the building block for new industrial applications to enhance various components of industrial operations – such as maintenance, content development and asset management.

Inaugural launch partners include: Box, Decisyon App Composer, Entercoms, Ericsson, Mobideo, Nurego, OAG Analytics, Pitney Bowes and Splunk. The addition of ISVs enhances the growing ranks of the GE Digital Alliance Program, which launched in February. The alliance program now boasts more than 270 partners around the world, including major enterprise players such as AT&T, EY, Intel, Microsoft and Tata Consultancy Services (TCS).

GE’s Industrial Internet Control System

GE’s Automation & Controls business introduced GE’s new Industrial Internet Control System (IICS) at its 2016 Connected Controls Symposium at the company’s Global Research Center in Niskayuna, NY. IICS delivers new levels of productivity for industrial assets and processes by integrating controls with Industrial Internet analytics – at scale yet modular and flexible for industrial settings worldwide.

Early IICS adopters report a +7% gain in asset performance and 22% increase in efficiency. By leveraging GE’s deep domain and controller expertise, the IICS solution empowers customers to improve operational efficiency, optimize production and unlock new revenue opportunities.

The system utilizes GE’s Field Agent technology as the gateway between the asset and the Industrial Internet. Field Agent provides a rugged, pre-configured solution for secure data collection and conveyance from the machine to fuel analytics that improve operations.

GE’s Industrial Internet Control System also includes:

- Industrial Cloud Platform – Provides real time process optimization and control; minimalizes disruption to deployed application; Creates new value over time without having to retrofit

- Secure Cloud Connectivity – Predix ready; Provides secure data collection; Enables advanced analytics; Form factors to meet the need

- Outcome Optimizing Controllers – Real-time control; Defense in-depth security; Decreases time to market; Helps reduce unplanned downtime and enhance system performance

- Mix & Match I/O – Remote, real-time diagnostics; Wide range of communication options; Modularity-simple scalability; Drives improved availability and simplified maintenance

- Professional Services – Real Time control; Security at its core; Decreases time to market; Helps reduce unplanned downtime and enhance system performance

- Intelligent Apps – Real Time Control; Security at its core; Decreases time to market; Helps reduce unplanned downtime and enhances system performance

IICS features dual or quad core configuration which provides safe and secure communication with either cloud-based or locally hosted algorithms and applications.

Two structural innovations make the new solution “future proof” for customers, who want hardware assets to be long-lived but remain optimally functioning.

- Industry-first Hypervisor control technology that separates operations from software so that the software can be upgraded without affecting the physical controller, allowing the hardware to stay in place and up to date.

- ComExpress processor technology that allows the processor to be updated as needed, again without replacing the controller. This is critical to support the growing computational power available from the Industrial Internet, including GE’s Digital Twin predictive model for optimizing assets with minimal interruption.

by Gary Mintchell | Sep 15, 2016 | Asset Performance Management, News, Operations Management

While checking emails walking the IMTS show floor, I found one announcing GE Digital announced acquisition of Meridium, a supplier of Asset Performance Management (APM) software. Leveraging the Industrial Internet of Things for asset performance has been GE’s goal from the beginning, so this one makes sense.

The goal of the combination includes providing a solution to customers that unifies real-time analytics with reliability-centered maintenance best practices. Meridium customers will gain access to GE’s deep domain expertise in real-time data management and advanced industrial analytics.

In July 2014, GE made an initial investment in Meridium for a 26 percent stake in the company. The total acquisition, inclusive of the original investment, was executed for an enterprise value of $495 million.

Leveraging the Predix platform, GE’s APM offering helps deliver on the promise of the Industrial Internet by enabling industrial companies to maximize the reliability and availability of their industrial assets, while minimizing operational cost and risk. APM powered by Predix combines GE’s broad expertise in advanced asset-centric analytics, industrial software and value-added services to offer a unique and complete solution, helping customers deliver targeted asset uptime and performance.

The addition of Meridium’s enterprise software solutions brings additional capabilities and processes focused on asset-centric industries – such as oil & gas, power and chemicals – that complement GE’s existing offerings. The combination of the companies’ technologies helps strengthen the connection between real-time asset performance and reliability-centered maintenance strategies and work processes.

“As we forge ahead in the Industrial Internet journey, APM is clearly the first application that can leverage the Predix platform to help industrial customers benefit from increased productivity,” said Bill Ruh, CEO, GE Digital. “With Meridium joining the GE Digital family, we can immediately complement our existing portfolio with the Meridium expertise in cognitive analytics, reliability centered maintenance, operational risk management and asset health, as well as intelligent asset strategies. Meridium also has a mature software development culture, which will help us enhance our bench of deep technology talent.”

“This move gives Meridium access to GE’s substantial industrial portfolio – and provides a deeper connection to core industrial businesses and GE’s depth of domain expertise in the Industrial Internet,” said Bonz Hart, Founder and CEO, Meridium. “We are excited to join GE Digital and expand Meridium’s capabilities into more industries.”

After GE’s initial investment in Meridium, this acquisition is a natural step in the relationship. As a key area GE Digital plans to expand rapidly on Predix, Meridium’s APM products are already integrated into the Predix platform. The transaction is complete.

by Gary Mintchell | Feb 13, 2015 | Asset Performance Management, Automation, News, Operations Management

Asset performance management joined the Industrial Internet of Things as a key topic at the 2015 ARC Forum in Orlando. Here is a release from Meridium that reflects many of the trends—data collection, analysis, configurable display, mobility.

Meridium Inc., global supplier of asset performance management (APM) software and services, announced the availability of Asset Answers V2.0. The company claims this as the only cloud-based asset performance diagnostics solution that provides comparative analytics, delivering instant visibility into asset data, and supplying organizations with the insights to drive safer, more informed, and more profitable decisions.

Asset Answers 2.0 delivers next-generation APM insights into industrial assets and their health and overall performance, an improved user interface that includes dashboards and enhanced mobility on a variety of handheld devices that provides true anywhere/anytime availability. Since the introduction of Asset Answers to the market, more than 130 sites in the Petrochemicals, Oil & Gas, Power & Utilities, and Manufacturing industries rely on Asset Answers to support continuous improvement initiatives with the ultimate goal of achieving operational excellence.

For example, Dow Chemical was able to collect and analyze reliability audit report data for 25 production units across 4 plants in less than 1 day, saving 175 man-days of effort and remain focused on cost, availability, and reliability optimization for the company. Another Asset Answers client, Profertil, reduced costs for 30 straight months and was able to readily identify and highlight savings of $900,000 and counting.

According to Roy Whitt, Senior Vice President and General Manager for Asset Answers, “For organizations in asset-intensive industries, Asset Answers 2.0 uncovers the true cost, reliability and availability of asset groups and individual pieces of equipment with the click of a mouse. Subscribers can easily view performance criteria across sites and benchmark themselves anonymously against global industry peers. Combining data mining and preconfigured metrics, reliability engineers can investigate equipment data to identify assets that represent the best opportunities for improving maintenance costs and reliability. With access to the objective truth about asset performance, management can act with confidence to intelligently cut costs while increasing production, especially in times of shrinking margins.”

Asset Answers can identify and evaluate better performing equipment manufacturers and highlight predominant failure modes for specific equipment models. With this analysis, Asset Answers also can create opportunities for equipment improvements and automatically track the savings these improvements have provided.

Whitt also added that, “Asset Answers uses comparative analytics or ‘intelligent benchmarking’ that enables organizations to conduct ‘apples to apples’ comparisons of industrial equipment in production units across multiple plants within an organization. That same information helps organizations compare the relative performance of their assets against industry peers to gain a deeper understanding and a competitive advantage, optimize total cost of ownership (TCO) for critical assets and make better asset purchasing decisions.”

This approach both improves collaboration between Reliability, Engineering & Maintenance and also enables continuous and systematic improvement of operations and production output over time. Benefits of Asset Answers 2.0 include:

- A proven, systematic and secure approach to continuous improvement and Operational Excellence

- Improved plant and operator safety

- Mitigated operational and financial risk

- Improved insight into non-financial performance

- Lower asset total cost of ownership (TCO)

by Gary Mintchell | Feb 4, 2015 | Automation, Internet of Things, News, Operations Management, Software, Technology

Predictive technology in the asset performance arena seems to be the trend of the week. I wrote yesterday about a solution. Today brings another announcement. I think I’ll learn more about this one next week at the 2015 ARC Forum in Orlando. (By the way, if you’re there, please look me up.)

Predictive technology in the asset performance arena seems to be the trend of the week. I wrote yesterday about a solution. Today brings another announcement. I think I’ll learn more about this one next week at the 2015 ARC Forum in Orlando. (By the way, if you’re there, please look me up.)

The headline for this article came from GE. I’ve heard of predictive maintenance (which many aspire to and few achieve) and condition-based maintenance (similar but, I guess, different). Here they combine the two. Check it out and let me know what you think.

GE’s Measurement & Control business and Meridium Inc. introduce Production Asset Reliability (PAR), an integrated Asset Performance Management (APM) offering for an all-in-one view of equipment health. Combining GE Measurement & Control’s System 1 condition monitoring and diagnostic applications with Meridium’s suite of enterprise performance management and asset strategy solutions, PAR provides a holistic and quantifiable view of operations, maintenance, availability and overall operating performance for production assets.

System 1, GE’s patented condition monitoring software, helps users quickly diagnose potential equipment and instrument health issues which can lead to equipment failure. Meridium’s applications provide structured processes and analytics to identify critical assets and failure modes, calculate equipment reliability and determine downtime impacts. The integrated PAR solution provides an end-to-end process that connects the machine diagnostics to the business context and execution to drive optimized maintenance practices and production loss management for all asset-intensive industries.

“Today’s measurement, monitoring and management systems are disconnected, and, as a result, organizations fail to leverage quality data for actionable insights,” said Art Eunson, general manager for Bently Nevada, GE Measurement & Control, a GE Oil & Gas division. “GE and Meridium’s integrated PAR offering empowers our customers with the ability to connect identification, evaluation and execution for greater asset optimization and productivity.”

Asset intensive organizations are challenged to maximize production, minimize costs, follow regulations and manage risk. To balance the demanding requirements, operators require a more cohesive system that assesses equipment performance and manages the resulting data. GE and Meridium provide this comprehensive solution for customers to effectively measure, monitor and manage each connected asset.

“With greater availability of big data and connected assets, there is an end-to-end picture of plant operations waiting to be tapped by organizations from the plant floor to the corporate office in order to stay competitive on a global scale,” said Bonz Hart, Meridium Founder and CEO. “PAR measures performance, quantifies risk and delivers analytics in real-time, providing customers with the insight needed to effect real change, improve efficiency and reduce maintenance costs.”

The Oil & Gas industry demand solutions that can grow with business demand and adapt rapidly to changing technical environments. That is why GE’s industrial solutions such as System 1 are standardizing on GE’s software platform for the Industrial Internet, Predix.

by Gary Mintchell | Sep 25, 2013 | Automation, M2M, Operations Management, Software, Technology

Are we seeing practical adoption of M2M technologies finally. Meridium points to that as a key feature of its latest release of its Asset Performance Management software. Enhanced support for work process also fits snugly within the trends of the past few years.

Are we seeing practical adoption of M2M technologies finally. Meridium points to that as a key feature of its latest release of its Asset Performance Management software. Enhanced support for work process also fits snugly within the trends of the past few years.

Version 3.5.1 of its Asset Performance Management (APM) software enhancements include new work process dashboards for the end-to-end management of performance improvement opportunities, expanded monitoring policies to address process excursions and enhanced integration capabilities to enable machine-to-machine (M2M) communications.

“Every Meridium product release is a reflection of fulfilling customer needs,” said Bob DeMaria, Maintenance Engineering Technical Advisor at Dakota Gasification Co. “As a Meridium user, it amazes me how every release offers a new solution to our challenges. For example, in v3.5.1 they added a new analytical model, which allows us to ‘see’ the impact performing an inspection has on an asset’s risk ranking. This added functionality will provide huge efficiency gains by allowing us to optimize our inspection intervals.”

Meridium v3.5.1 Policy Manager boosts M2M integration with advanced analytics to drive the right actions from the wealth of information collected. This includes new monitoring capabilities to automatically trigger, close and analyze integrity operating window (IOW) excursions or other critical events. “Operation of assets outside the defined integrity operating window introduces unknown operating risk,” said Louise Pattison, Meridium Product Manager. “Conditions change, and if you are not tracking process excursions, you may be living under a veil of false security.”