by Gary Mintchell | Nov 8, 2019 | Automation, Technology

Artificial Intelligence, or AI, is not necessarily the dystopian technology portrayed in books and movies. Although neither artificial or intelligent, AI can be a powerful tool in the engineer’s kit.

Recently Carl Palme of Neurala chatted with me introducing the company and what it means by AI in its vision systems. We both have some sheet metal work in our backgrounds, so we found common cause with one of the powerful applications—finding small surface anomalies.

There is also company news. In short:

- IHI Corporation Selects Neurala to Enable Industrial Visual Inspection and Analysis Powered by AI

- One of the Largest Global Heavy-Industry Manufacturers Partners With Leader in Automated Visual Inspections to Build Vision AI-Powered Industrial Solutions

AI-powered visual inspection pioneer Neurala announced a partnership with IHI, one of the largest manufacturers in the world.

IHI is a leading producer of aircraft engines and turbochargers for vehicles and industrial machines, along with additional transport-related machinery and more. Neurala’s automated visual inspection platform will be deployed as a key component of IHI’s workflow, improving manufacturing optimization and enabling more efficient industrial inspections.

“Automation is an area of critical focus as we further strengthen our reputation as the leading manufacturer of transport-related machinery worldwide,” said Ms. Nobuko Mizumoto, Director of IHI Corporation. “Today, we are collecting data on our workflow that needs to be carefully analyzed. AI-assisted data analysis is the future of manufacturing processes, and Neurala has the industrial and manufacturing inspection expertise we require in an AI solution. As we lead IHI into Industry 4.0, we are proud to partner with Neurala to deploy a reliable AI that can function in settings that are subjective and change rapidly, without requiring any downtime on our production lines.”

IHI will leverage Neurala’s automated visual inspection platform to review product and workflow processes, cementing its reputation as a leader in safety and efficiency. AI-powered inspections allow manufacturers to accelerate new initiatives without sacrificing a gold standard of quality workmanship. IHI will use Neurala’s Brain Builder, the first cost-effective AI tool that allows users to build, deploy and analyze custom vision AI solutions with instant feedback on performance. Brain Builder simplifies the process and reduces the time to deployment in subjective settings, using on-the-fly learning to increase accuracy as the user adds data.

“We are thrilled to partner with IHI as we illustrate the critical role AI will play in manufacturing, improving efficiency in a field in which optimization is essential,” said Massimiliano Versace, co-founder and CEO of Neurala. “We look forward to building upon our strong presence in the APAC region through an industry leader like IHI. IHI selected Neurala to bolster its offerings as the industrial sector continues to evolve; our partnership will demonstrate the value of implementing AI to solve challenges of visual inspection on factory floors and to improve automation.”

Neurala is the company behind Brain Builder: a SaaS platform that dramatically reduces the time, cost and skills required to build and maintain production-quality custom vision AI solutions. Founded in 2006, Neurala’s research team invented Lifelong-DNN (L-DNN) technology, which reduces the data requirements for AI model development and enables continuous learning in the cloud or at the edge. Now, with customers in the industrial, drone, robotics, and smart devices verticals, Neurala’s technology has been deployed on 53 million devices globally.

by Gary Mintchell | Oct 30, 2019 | Automation, Technology

Years ago I dabbled in machine vision integration. It was fun and creative. My customers and I did some pretty cool quality control applications. So I maintain a liking for the technology even though the price of the hardware plummeted and ease-of-use skyrocketed. So, I bring you this interesting news.

Honeywell is collaborating with Papertech to develop and market TotalVision, a connected, camera-based detection system for the flat sheet industries. The system enables customers to identify and resolve defects on the production line, improving quality and efficiency. The fully integrated total quality control solution is designed for flat sheet and film processes in which surface detection and production break monitoring capabilities are critical for competitive success. This new solution is designed for paper, pulp, tissue, board, extruded film, calendaring, lithium-ion battery, copper and aluminium foil producers.

Combining Honeywell’s ExperionMX technology with market-leading Papertech’s TotalVision defect detection and event capturing capabilities, the solution provides a single-window operating environment for all aspects of process and quality control. Customers benefit from faster root cause determination of runnability and quality problems, thereby saving significant time in lost or downgraded production. When integrated with connected offerings such as Honeywell QCS 4.0, system data and analytics can be accessed anytime, anywhere, from any device.

“Honeywell represents an ideal collaborator for Papertech as our industry-leading WebInspector WIS and our WebVision web monitoring system (WMS) single platform TotalVision camera system seamlessly integrate with Honeywell’s quality control systems for a range of industries,” said Kari Hilden, CEO of Papertech Inc. “We look forward to working with the global Honeywell team and their customers.”

Honeywell will continue to support existing camera system users with parts and services, while offering an easy migration path to the new solution. Given the collaborative nature of the agreement, customers can choose to take a single party, single-window approach or to engage with Honeywell and Papertech separately.

“As the world moves from plastic to biomaterial-based packaging, and from hydrocarbon-based transportation to electric vehicles, flat sheet producers are under increased pressure to ensure output consistently meets a variety of performance and safety requirements,” said Michael Kennelly, global business leader for sheet, film and foil industries, Honeywell Process Solutions. “By bringing together Honeywell’s core strengths of measurement, control, connected applications and services in flat sheet production with Papertech’s leadership in web monitoring and inspection systems, we uniquely provide customers with that capability along with industry-beating lifecycle costs.”

Papertech is the global industry-leading machine vision system supplier for a range of web-based production lines with more than 1200 TotalVision installations in 42 countries. It is part of the IBS Paper Performance Group, a company with a more than 50-year history in delivering papermakers a full range of proven machine efficiency and product quality optimization solutions.

For more information visit Honeywell Quality Control Systems and Papertech TotalVision solutions.

by Gary Mintchell | Sep 5, 2018 | Automation, Technology

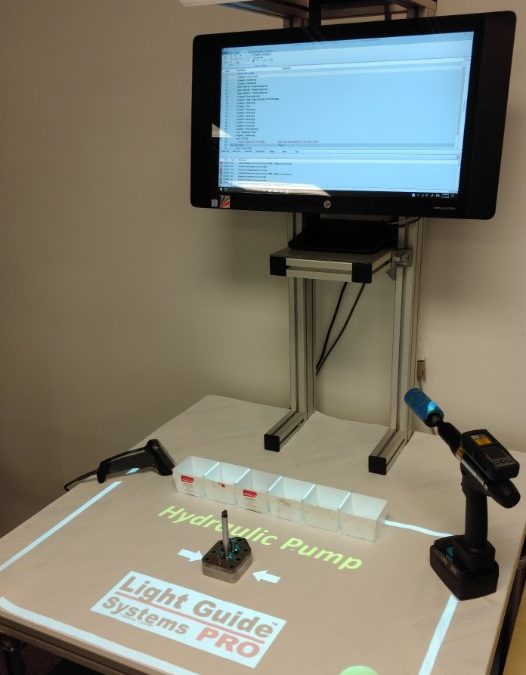

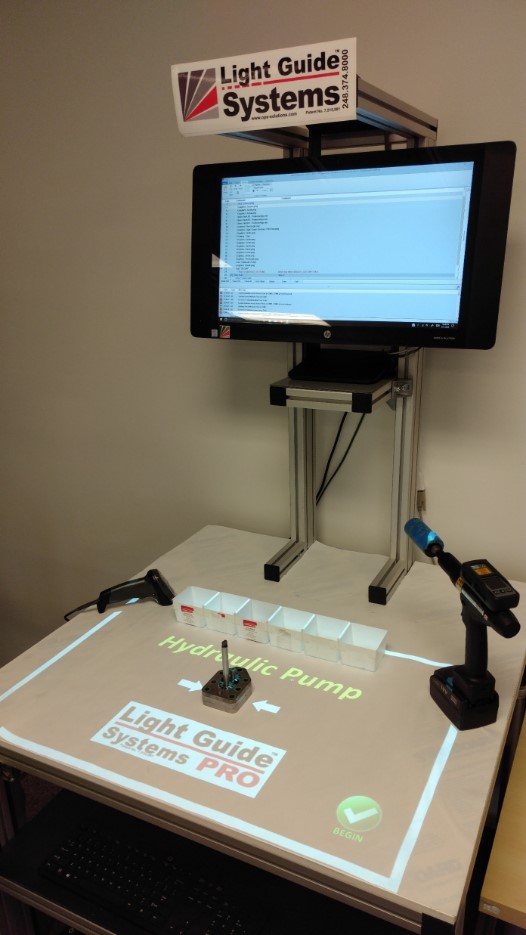

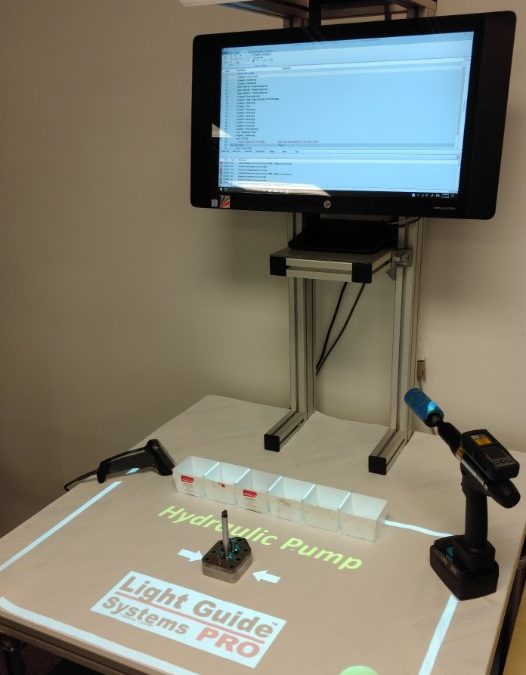

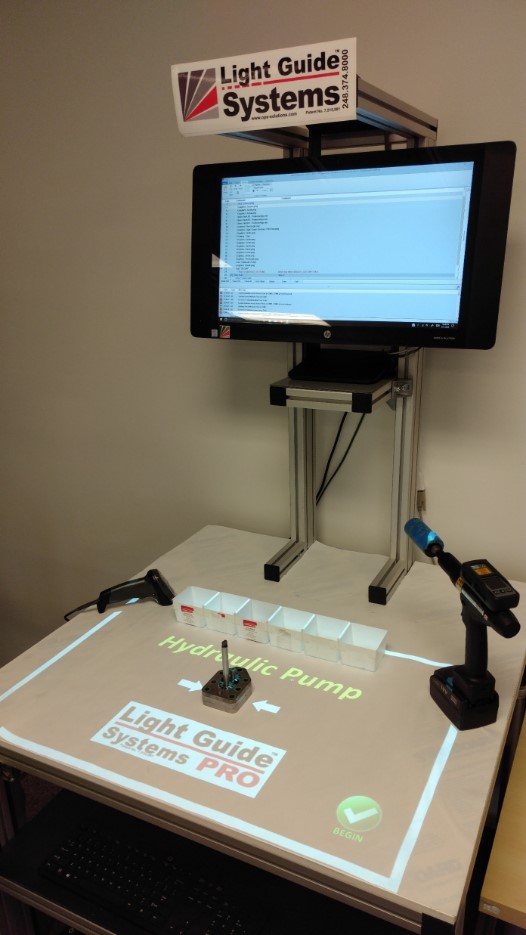

Humans are still essential for many manufacturing processes. Especially for assembly. But assuring the correct parts go in the assembly in the correct orientation is essential. Enter an augmented reality (AR) tool to help.

Light Guide Systems partnered with information technology company HP Inc. to release a tech tool an augmented reality (AR) dubbed Light Guide Stratus. Leveraging Sprout Pro computing platform by HP, Light Guide Stratus provides a flexible, adaptable benchtop platform for assembly processes.

Light Guide Stratus builds on the company’s initial product Light Guide Systems Pro, which launched in 2016. The Stratus system integrates the Sprout Pro directly into a bench structure to increase the display surface area and free up critical space on the workstation. This expanded workspace can be used to integrate new types of applications and tools for a particular assembly sequence.

“The launch of Light Guide Stratus is a testament to the growing demand for flexible and powerful AR guidance systems,” said Paul Ryznar, OPS Solutions founder, president and CEO. “We knew that Light Guide Systems Pro brought a critical level of functionality and flexibility to improve outcomes for nearly any industry. We expect Light Guide Stratus to address even more applications and become an integral part of assembly and manufacturing operations for companies in every space, from medical to auto to aerospace and energy.”

Light Guide Systems projects a digital operating “canvas” onto virtually any work surface to provide audio and visual prompts, guidance, pacing, and direction. Light Guide Systems Pro takes the tool to the next level by incorporating its proprietary software into the Sprout Pro PC platform. Light Guide Stratus takes user experience into account with a flexible and repeatable design that opens up the workspace.

“HP’s Sprout Pro with Light Guide Systems reduces training time and improves quality in manufacturing assembly through projection and scanning in an augmented reality platform,” said Louis Kim, vice president and general manager of Immersive Computing, HP Inc. “Light Guide Stratus demonstrates the flexibility of the Sprout Pro platform combined with Light Guide’s innovation and leadership.”

by Gary Mintchell | Oct 12, 2015 | Automation, Internet of Things, Manufacturing IT, Networking, News, Operations Management, Security, Technology

Cisco held a Global Editors’ Conference during which I was traveling and could not attend. However, here is news gleaned from the press releases and other sources.

Cisco has been building partnerships in the industrial and manufacturing space for quite some time. Emerson partnered as part of its wireless solutions. Rockwell Automation has become a valued partner even reselling Cisco switches and routers in industrially hardened configurations.

Rockwell has also partnered with Fanuc, the robot and CNC supplier. The primary reason for the partnership I would guess would be that each helps the other penetrate more deeply into some large accounts such as GM. However, the Fanuc on the technology front has developed EtherNet/IP connectivity for its products. This enables them to share data on a standard Ethernet network.

Connectivity between Rockwell and Fanuc products along a Cisco Ethernet platform becomes interesting. Indeed, note the announcement below where Fanuc is now partnering directly with Cisco.

Cisco postulates that forty percent of today’s leading companies will be displaced from their market position by digital disruption in the next five years, yet 75 percent of these companies have yet to address this risk by prioritizing their digital strategy, according to research conducted by the Global Center for Digital Business Transformation.

To help customers navigate this important transition. Cisco is introducing four new digital solutions for industries – manufacturing, transportation, utilities, and oil and gas. The solutions aim to help customers connect machines and assets, break through information silos, and digitize data in an integrated way across the business.

Additionally, Cisco is announcing a new, industrial Internet of Things (IoT) security solution. Customers will use the Cisco IoT System Security and professional services from Cisco and partners to mitigate the risk of system disruption – and efficiently assure compliance.

Removing Barriers to Efficiency

To remain competitive, industries like manufacturing, utilities, oil and gas, and transportation need to increase productivity, deliver more value, and create better experiences for customers and end users. Some of the greatest obstacles to efficiency are operational silos. Silos separate people, machines, systems, information, and complete areas of a business; they separate information from operational technology. Breaking through silos with a more holistic and connected architecture connects people, streamlines communication and drives a more agile operation.

Four New Digital Solutions:

- Connected Machines for Digital Manufacturing: A connected architecture that redefines secure, efficient, and visible operations. This solution enables rapid, standards-based, repeatable machine connectivity, and global factory integration while enabling OEM digitization and new business models – including highly secure remote access, monitoring and serviceability of machines. FANUC America and Cisco announced that they intend to implement the solution to enable robot connectivity and analytics for proactive maintenance. At an event in San Jose, high-tech manufacturer Flex outlined how it is already using the Connected Machines solution and FANUC Robots to drive efficiency and quality in its operations. Cisco is also today announcing a series of attractively priced solution bundles to simplify and accelerate infrastructure digitization for customers for the Factory Network, Factory Wireless and Factory Security.

- Smart Connected Pipeline for Digital Oil and Gas: A connected, highly secure architecture that allows oil and gas companies more control over their pipelines, helping to protect assets from accidents or cyber-attacks. Operations are safer, more efficient – and more secure. Schneider Electric and Cisco are collaborating to bring the Smart Connected Pipeline solution to market, and are already working with customers such as Italian multinational oil and gas company, ENI.

- Substation Security for Digital Utilities: A connected and timely architecture that enables highly-secure power grids for reliable, more efficient service across the utilities industry. Now, more than ever, the nation’s power grid needs additional layers of safety and security. Utility companies in North America must comply with the North American Electric Reliability Corporation Critical Infrastructure Protection (NERC/CIP) Version 5 mandated standards. South Carolina utility SCANA will be the first to deploy Cisco’s Substation Security Solution – a solution designed to enable utilities to comply with these regulations.

- Connected Mass Transit for Digital Transportation: A connected architecture that will enable the delivery of greater safety, mobility – and a better passenger experience. Through a converged network architecture that is based on the Cisco IoT System, transit systems can enhance automation, collaboration, video, cloud-to-fog agility and business intelligence. From the management control center to the transit station – onto the roads, the rails, and onboard mass transit vehicles themselves – the Cisco solution puts safety and security first. Situated on the River Danube, the Austrian City of Linz is implementing the solution to streamline operations across its tram network.

- IoT System Security: The IoT System Security product-portfolio helps deliver highly secure connectivity, visibility and control to assure that IoT initiatives deliver competitive advantage for customers across all verticals. The Cisco IoT System Security product portfolio includes IoT-specific security with the introduction of a new, dedicated security appliance (ISA-3000 for application visibility, policy enforcement and threat defense) and a Fog Data Services security solution. With today’s announcement, the IoT network can now act as a sensor and enforcer to provide security policy enforcement within router and switches. It also provides solutions for IoT physical security with video surveillance cameras, physical access control, and video surveillance manager with advanced security analytics. Cisco will continue to expand its IoT System security offering through additional developments and collaboration with key ecosystem partners, including Rockwell Automation.

A Few Quotes

Rick Schneider, North America CEO, FANUC: “Preventing unplanned downtime is a huge savings for our customers and makes the FANUC robots with ZDT a tremendous value. With Cisco, we are helping our customers access this new value and also re-imagining our go-to-market strategy for after-sales service and support. This has the potential to have the biggest impact of anything I’ve seen in my 35-year career.”

Murad Kurwa, Senior Vice President of Engineering, Advanced Engineering Group at Flex: “Cisco’s vision of the power of Industrial IoT was realized through joint collaboration using automation as the enabler. With Universal Mechanical Assembly process partnering with FANUC, we are now able to get data to create a pool of knowledge. This helps us take action through analytics and ultimately leads to a more robust ‘process’ performance – leading to a world class, smart factory.”

Ed Rodden, CIO, SugarCreek: “We are using Cisco’s Connected Machines solution as we build our new 418,000 square foot factory of the future. Cisco’s new Industrial IoT platform will provide us the ability to use all our company’s available pieces of data, including video and security, from all kinds of devices and to tie them all together to drive more operational efficiency in the new factory.”

Sujeet Chand, Sr. Vice President & CTO, Rockwell Automation: “The Cisco IoT System Security solution will make an immediate impact for customers by accelerating secure IT-OT convergence with an end-to-end security solution, simplifying compliance and mitigating threat vectors. Together with Cisco, we are helping industrial operations maintain the integrity and confidentially of their network in support of holistic enterprise risk management strategies throughout a Connected Enterprise.”

James Bielstein, CIO, Advanced Manufacturing Deployment for GE’s manufacturing facilities worldwide: “In order to start down the path to becoming a Brilliant Factory, the first step is to deploy a modern IT infrastructure. This infrastructure will give our plants the flexibility and security needed to develop a ‘digital thread’ from product design to shipping. Cisco is part of GE’s Brilliant Factory architecture.”

Georg Linhard, Project Manager for LINZ AG TELEKOM: “We decided to build on our existing Cisco network and channel its agility and simplicity to incorporate new security, mobile, and analytics technologies that help us achieve our goals and gain greater business insight.”

Patrick Albos, SVP, Oil and Gas Segment, Schneider Electric: “The Smart Connected Pipeline brings SCADA and IT infrastructure together in a converged, secure, easy to deploy and use platform, and brings significant business value in optimizing and reducing cost of pipeline operations.”

by Gary Mintchell | Oct 5, 2015 | Automation, Motion Control, News, Technology

The Association for Advancing Automation (A3) today published a white paper entitled “Robots Fuel the Next Wave of U.S. Productivity and Job Growth” in which data from the Bureau of Labor Statistics and a wide range of manufacturing firms document how and why increasing the use of robots is associated with increased employment.

Key statistics from the A3 white paper show that during the non-recessionary periods – 1996-2000, 2002-2007, and 2010-2014 – general employment and robot shipments both increased. Since 2010, the robotics industry in the United States has grown substantially. Even during this period of record-breaking robot sales, U.S. employment increased. This new data is in stark contrast to media coverage and a perception that increasing use of robots causes higher rates of unemployment in the U.S.

At a glance:

- Robots save and create jobs

- Robots take care of the dull, dirty, or dangerous jobs

- Robots extend workplace functionality, improving the bottom line

- Robots are reviving American manufacturing

- Robots create better, safer, higher paying jobs

“We are seeing concrete shifts in the factors that resulted in cuts to the U.S. manufacturing work force over the past few decades,” said Jeff Burnstein, president of A3. “Manufacturing automation increasingly provides the flexibility in the variety of tasks robots perform to drive improvements in overall product quality and time to market.”

Burnstein concluded, “One of the biggest challenges we now face is closing the skills gap to fill jobs. Robots are optimizing production more than ever, increasing global competitiveness, and performing dull, dirty and dangerous tasks that enable companies to create higher-skilled, better-paying, and safer jobs where people use their brains, not their brawn.”

Correlation does not equal causation

The white paper overlays graphs of robot sales and US employment. I asked Burnstein if he is trying to show causation from the correlation. He said that was not the intent. “It is not so much to show causation as it is simply to refute the argument,” he told me in an interview preceding the release. Taking the argument that robots cause unemployment, one would expect climbing robot sales to be reflected in declining employment. Statistics do not support that supposition.

Anecdotal evidence

As companies seek to bring manufacturing operations stateside while remaining cost-competitive, they continue to turn to automation to help lead the new wave of productivity and job growth in the U.S.

“The whole premise for our company is to bring manufacturing back to this country, and our new robot fits perfectly with that master plan,” said Geoff Escalette, CEO of faucet-maker RSS Manufacturing & Phylrich in Costa Mesa, California. “Our robot not only makes it possible to increase production speed without buying additional CNC machines, but also helped us open up 30 percent more capacity on existing machinery.”

Robotics also helps companies stay competitive when seeking new talent—particularly those who are interested in long-lasting careers working with technology.

“It’s really an opportunity for us to grow,” reports Matt Tyler, president and CEO of Vickers Engineering, a contract precision engineering manufacturer in Michigan. “Because we have robotics and are able to compete on a global scale, it makes the U.S. more competitive in manufacturing, and that’s good for all of us.”

The white paper includes notes from other manufacturers who both acquired additional automation and people.

The Association for Advancing Automation is the global advocate for the benefits of automating. A3 promotes automation technologies and ideas that transform the way business is done. A3 is the umbrella group for Robotic Industries Association (RIA), AIA – Advancing Vision + Imaging, and Motion Control & Motor Association (MCMA). RIA, AIA, and MCA combined represent some 850 automation manufacturers, component suppliers, system integrators, end users, research groups and consulting firms from throughout the world that drive automation forward.