by Gary Mintchell | Oct 17, 2018 | Automation

Beckhoff Automation had a sizable booth at Pack Expo this week. Much to my surprise, when I asked about whether there was something new (I don’t expect new product introductions in automation at Pack Expo) the answer was yes. Well, I had a glimpse at Hannover in April.

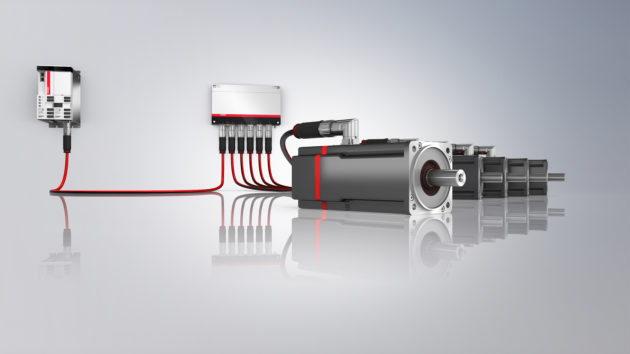

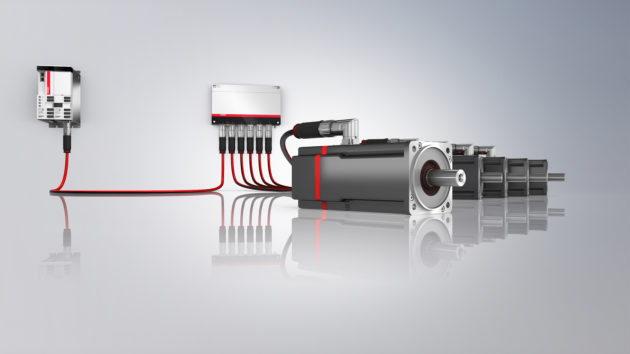

The AMP8000 servo system has an innovative design where the integrated drive is placed on the end of the servo motor rather than the usual side. This design allows for maximum heat dissipation from the motor. They were able to package the drive and motor that only added 75 mm to the length of the motor.

By combining a servo drive and servomotor into one device, the AMP8000 system reduces overall packaging machine footprint and space requirements inside control cabinets and enclosures. A single coupling module can operate up to five drives using the EtherCAT P One Cable Automation solution that supplies industrial-grade power and EtherCAT industrial Ethernet communication.

Requiring Requiring no alterations to the existing machines, the AMP8000 boasts power ratings from 0.61 to 1.23 kW and standstill torque ratings from 2.00 to 4.8 Nm at an F4 flange size or power ratings from 1.02 to 1.78 kW and standstill torque ratings from 4.10 to 9.7 Nm with an F5 flange. The servo drive system also represents the Beckhoff commitment to promoting safety technology in all areas via integrated STO and SS1 safety functions.

TwinCAT software updates have added a number of important tools for packaging machine builders and end users, including expanded data processing through TwinCAT Analytics and HTML5-enabled TwinCAT HMI for industrial displays and mobile devices. In addition, TwinCAT Motion Designer supplies additional tools to commission entire motor, drive and mechanical systems in software, whether integrated into the TwinCAT 3 platform or used as a stand-alone motion system engineering tool.

by Gary Mintchell | Sep 7, 2017 | Automation, Networking, News, Process Control

Here is some news regarding control and networking. Bedrock Automation is a recent entrant into the control and automation space, while Time Sensitive Networking (TSN) holds great potential to be a disruptive force.

Control

I seldom write about automation company “wins”, but this one shows some direction for a new company. Bedrock Automation is a young automation company that has built a new control platform from the ground up for not only the latest in control but also for security.

My curiosity has focused on where it would find a market. I don’t see it displacing Rockwell Automation and Siemens any time soon, but the platform is robust and adaptable. This looks like a perfect application.

Pinnacle Midstream, a Houston-based supplier of storage and processing services for the oil and gas industry, has selected the Bedrock control system as the automation platform for its crude oil receipt and delivery points. The Bedrock system will coordinate flow of product from partners, through the Pinnacle processing facilities and onto refiners and shippers. Pinnacle chose Bedrock system for its scalability, ease of engineering, ruggedness, cost efficiencies and intrinsic cyber security.

“We are expanding to the meet the growing need for midstream services and need a secure way to centralize control of flow amongst our facilities. The Bedrock system provides an economical solution in a small, easy-to-implement system that can coordinate edge control today, while also scaling easily and economically to the full DCS functionality we expect to need in the future. We also liked the rugged Bedrock housing, which will resist the dust that gets into everything around here,” said Mike Hillerman, VP of Engineering and Operations for Pinnacle Midstream.

Networking

Avnu Alliance, the industry consortium driving open standards-based deterministic networking through certification, is co-hosting the 2017 Time Sensitive Networks and Applications (TSN/A) Conference with WEKA FACHMEDIEN on September 20-21 at the Mövenpick Hotel Stuttgart Airport in Germany.

The TSN/A Conference is a combination of the “TSNA Conference” and the “Industrial Ethernet TSN Kongress” and offers attendees insights into Time-Sensitive Networks and usage in applications for Automotive, Industrial, Professional Audio/Video and more. The conference spans two days of technical sessions, panel discussions, vendor demonstrations, and participant networking.

“We are excited to bring together experts and thought leaders from around the world to the TSN/A Conference in Germany this year” said Kevin Stanton, Avnu Alliance Chairman, who will also deliver a conference presentation on Time Synchronization on Wired and Wireless Infrastructure. “It’s been a pleasure to join forces with WEKA FACHMEDIEN as the speakers present both the technology of TSN and its implications across our industries.”

On Wednesday, September 20, the first day of the conference, programming will feature two keynotes from Avnu Alliance members. Wolfgang Schenk of Hirschmann Automation and Control will present on “Time-Sensitive Networking: Enabling Technology for the Automation Model of the Future,” analyzing the transformation of the automation pyramid towards an automation pillar and discussing why TSN is the enabling technology for this transformation. Avnu Alliance Member BMW representative Dr. Kirsten Matheus will give a keynote on the “Use of AVB and TSN in the Automotive Industry.” Specifically, the presentation will describe the results of two workshops that Avnu Alliance held to gauge the need in the automotive industry for different Audio Video Bridging (AVB)/TSN functions.

I am happy to see momentum building for the technology. Can’t wait to see applications.

by Gary Mintchell | Apr 13, 2017 | Networking

Time Sensitive Networking (TSN) will be the most important addition to Ethernet and networking since WiFi. The standard has not yet been adopted, but it is close. So Belden is jumping into the fray early with a “TSN ready” product.

While I’m in Hannover in a couple of weeks, this is one of the things that I’ll be researching.

Belden is to release a software update for the modularly-managed Hirschmann switch types RSPE35 and RSPE37. The update, which will be available in the second half of this year, will enable Time-Sensitive Networking (TSN) features. As a visible sign, the devices will have a “TSN ready” logo on the front panel. In addition, older switches of both RSPE types can also be upgraded for the new real-time technology. The “TSN ready” logo is not exclusive to the RSPE35 and RSPE37: other Hirschmann industrial Ethernet Switches with fitting capabilities will display the logo as well in the near future.

“For the first time, TSN allows a simultaneous transfer of time-critical and non-time-critical data with a guaranteed end-to-end latency via Ethernet in accordance with IEEE 802.1 and 802.3,” says Dr. Oliver Kleineberg, advanced development manager at Belden. He adds: “Because of the comprehensive functions and high bandwidths, the technology is suitable for nearly all automation applications. Moreover, since TSN is not a proprietary system like many other established real-time solutions, it can be used with devices from different manufacturers, which paves the way for the Industry 4.0 in modern heterogeneous industrial networks.”

The managed switches of the RSPE product family consist of a basic unit with eight twisted pair and four combo ports, which can be expanded through the various media modules. The RSPE35 and RSPE37 versions support the Precision Time Protocol (PTP) in accordance with IEEE 1588-2008 and feature a FPGA module (Field Programmable Gate Array), which means it’s possible to implement selective hardware-based redundancy mechanisms such as HSR (High-availability Seamless Redundancy), PRP (Parallel Redundancy Protocol) and DLR (Device Level Ring) directly in the field. The new software update, which also enables TSN, can now be loaded into the FPGA as an alternative to previous redundancy mechanisms. “This provides users with an additional possibility for responding flexibly to the wide range of requirements and building high-performance industrial IT infrastructures,” according to Dr. Kleineberg.

For additional information about TSN, please refer this white paper “TSN – Time Sensitive Networking”.

by Gary Mintchell | Dec 12, 2016 | Automation, Education, Manufacturing IT, Networking, Technology

Industrial IP Advantage has launched an eLearning course focused on IT/OT integration for Industrial Ethernet. This is the fourth in a series of training courses designed to meet the emerging needs of control engineers and IT professionals tasked with deploying a secure network architecture. These courses are jointly developed by Cisco, Panduit and Rockwell Automation and available on the Industrial IP Advantage website.

Controls engineers have the plant-level domain knowledge needed to identify and analyze new industrial technologies that will help improve production efficiency and flexibility. Meanwhile, IT engineers have the domain knowledge needed to present actionable information where it is needed within an enterprise and throughout the value chain. This new course provides both with a sufficient level of knowledge to collaboratively architect a smart, integrated control system.

“Convergence between the IT and OT worlds is demanding new skills and knowledge,” said Ricardo Borlone, product manager at Precision Inc. “These self-paced courses are filling the skills gaps, and allow each participant to advance in their own time, rhythm and learning capacity. I especially enjoy this training format as it provides me the opportunity to focus on areas that match my interest and needs.”

The online training brings together the combined knowledge, best practices and application-specific expertise of three industry leaders to help engineers build a holistic IP-based network architecture. The courses are designed to help engineers drive design decisions from the device-level to the enterprise-wide network, leveraging interactive, scenario-based training on topics, such as logical topologies, protocols, switching and routing, security, physical cabling and wireless considerations.

The four available courses include:

- Courses 1 and 2: Designing for the Cell/Area Zone

- Course 3: Designing for Industrial Zone

- Course 4: IT/OT Integration

The full training program is offered for $350 on the Industrial IP Advantage website.

“A critical mass of industrialized networking technology is now available. And for many manufacturers, the real challenge is finding qualified staff to design, deploy and maintain these networks,” said Paul Brooks, networks business development manager, Rockwell Automation. “The eLearning courses offered by Industrial IP Advantage are designed to help fill this skills gap.”

“Building a skilled and competent workforce ready to deploy a converged architecture presents businesses with more than just greater connectivity. It offers tremendous productivity gains, process efficiencies, and business value,” said Paul Taylor, senior manager, Cisco.

“A structured, engineered approach to assessing, designing, deploying and monitoring the physical infrastructure is necessary to ensure that investments in critical manufacturing networks deliver optimum performance,” said Ryan Lepp, director of business development, Panduit. “These new training courses help both IT and OT professionals work together to deliver optimal network performance with adherence to industry standards.”

Industrial IP Advantage is a community established by Cisco, Panduit and Rockwell Automation – three like-minded organizations joining together to educate the market on the benefits of Ethernet, Internet Protocol and EtherNet/IP. Industrial IP Advantage was formed in cooperation with ODVA, the organization that manages and commercializes the EtherNet/IP specification and standard.

The vision of Industrial IP Advantage is enabling smart manufacturing with a workforce that is fully prepared to accelerate the transformation to secure information architectures with best practices, education and training that drive IT/OT convergence.

by Gary Mintchell | Nov 18, 2016 | Automation, Networking, Standards

News regarding Time Sensitive Networking continues to flow. The University of New Hampshire InterOperability Laboratory (UNH-IOL), an independent provider of broad-based testing and standards conformance services for the networking industry, announced the launch of three industry-specific time sensitive networking (TSN) consortiums – Automotive Networking, Industrial Networking, and ProAV Networking – designed to provide deterministic performance within standard Ethernet for real-time, mission critical applications. By providing high quality test plans, tools, and test beds for TSN, UNH-IOL allows businesses to improve products and accelerate market readiness.

“Standards-based precise time, guaranteed bandwidth, and guaranteed worst-case latency in a converged Ethernet network is a game-changer to many industries,” said Bob Noseworthy, Chief Engineer, UNH-IOL. “Through UNH-IOL’s industry-specific TSN consortiums, companies can be at the forefront and drive the technology forward by validating their solutions with a full suite of testing services, which will allow applications such as self-driving cars and the Industrial Internet of Things (IIoT) to take off.”

Originally established as a “best effort” network, Ethernet needs additional specific features to deploy mission critical applications. TSN standards enable deterministic real-time communication over Ethernet, allowing solutions to be built to provide extremely precise, predictable timing across the network. By adding features to Ethernet such as time synchronization, ingress policing, seamless redundancy, frame preemption, scheduled traffic, and stream reservation, TSN ensures mission-critical, time sensitive data is not held up on the network, promoting an interoperable ecosystem spanning across many industries. As TSN standards mature, UNH-IOL consortium members are able to support rapid development of conformance and interoperability solutions for emerging standards, validating their silicon and early products by gaining access to test solutions as well as multi-vendor test beds.

A major driving force behind the development of TSN standards is the emerging Automotive Ethernet market. The future connected, autonomous vehicle requires the time sensitivity and predictability in networking that TSN provides to support Advanced Driver Assistance System (ADAS) requirements, infotainment expectations from consumers, and other elements of vehicle electronics. Supporting automotive original equipment manufacturers (OEMs) and manufacturers supplying OEMs enabled with deterministic Ethernet solutions, the TSN Automotive Networking Consortium provides a setting for collaboration and participation in shaping the emerging standards through neutral, third party conformance and interoperability testing.

TSN’s importance is also emerging in industrial automation due to the rise in interest around the IIoT, specifically the mission-critical, time sensitive data that must be transferred and shared within strict bounds of latency and reliability. TSN enhancements for Industrial Ethernet provide standards-based determinism and reliability needed for these applications. The TSN Industrial Networking Consortium brings together stakeholders to realize the benefits of TSN – bandwidth, security, interoperability, and latency and synchronization for IIoT, robotics, assembly plants, and machines, as well as shape the standards and protocols for TSN in the industrial market.

Recent enhancements and certifications in the audio/video market have created a wider choice of compatible products and open technology that brings high-quality AV networking within the reach of any size Professional AV system. TSN enhancements provide the important timing audio and video systems need. The Pro AV Networking TSN Consortium is a testing ground for the promises of seamless redundancy, low-latency, and synchronization in the professional audio/video market.

UNH-IOL provides the test facility for stakeholders across multiple industries – automotive, industrial, and Pro AV – to drive the emerging, maturing TSN standards. To learn more about joining the new consortiums, please visit: Automotive Networking TSN Consortium, Industrial Networking TSN Consortium, Pro AV Networking TSN Consortium.