by Gary Mintchell | Aug 23, 2018 | News

There are many conferences and events this late summer/fall time frame. I used to try to make every event partly to gather information about the state of the market and partly in support of sales at the magazine I was at. These days, I cannot afford every trip at an average cost approaching $1,000 each. Those I don’t make, I’ll have phone interviews, I’m sure, to catch up on what’s happening.

Next week, it’s VMWorld (with Dell Technologies) in Las Vegas. (August 26-30). I have already been on two conference calls hearing about some really cool IoT announcements. I don’t have good contacts with VMWare (except the CTO, who doesn’t issue invitations), so I won’t be going. Watch for the news.

The next trip is IMTS / Hannover Messe US Digital Manufacturing at Chicago’s McCormick Place Sept. 10-15. This is a huge show that Hannover Messe has been trying to add a significant automation presence. That part is growing slowly. It will be interesting to see this year. I will be there for a couple of days. Tweet me if you would like to meet at @garymintchell.

The Inductive Automation Ignition Community Conference in Folsom (Sacramento), CA has become an annual event for me. There is always high energy, lots of interesting partners, and a peek into some new SCADA and IoT thinking. It’s Sept. 17-19 but it’s sold out.

Of course, I will be attending Emerson Global Users Exchange, San Antonio, October 1-5. Have not missed one since I started going in 2003. Always a good event and a chance to catch up with all my old editorial colleagues.

Hewlett Packard Enterprise is holding an Internet of Things Special Event in Houston overlapping Exchange. Looks like I will go to Exchange, go over to Houston to spend a day catching up on the IT side of things, then finishing the week back at Exchange. Two places at the same time? Not a problem—well, I make it work.

I had a Wonderware conference in my calendar, but Monday I found out that it wasn’t a media event. Instead I could get an invitation to the AVEVA World Summit, in Palm Springs October 9-11. I’d love to go. Guy Kawasaki is speaking. I’d love to hear him. At first I thought it was mostly AVEVA design engineering software, but looking at the agenda today, I see some Wonderware/Avantis content.

Would I like to make it three weeks in a row? Looks like I’ll visit Pack Expo October 14-17 in Chicago at McCormick Place. Planning on a couple of business meetings and a chance to check out the latest in machine control and automation.

Process Systems User Group and Automation Fair by Rockwell Automation will be November 12-15 in Philadelphia. I haven’t missed one since 1997. Hate to start a trend. Although it overlaps with an Internet of Things conference where I’m on the back up list as a speaker. I’ll probably be spending the week in Philadelphia.

Oh, and overlapping those two is the Schneider Electric Innovation Summit, Atlanta, November 13-14. This one is mostly power, energy, home automation—things I don’t cover deeply.

Finally there is the SPS/IPC/Drives conference in Nuremberg November 27-29. Looks like I will be attending after also attending a Siemens cybersecurity conference in Munich.

This trip overlaps another conference, one that I attended last year, the HPE Discover event in Madrid. I can’t do both. So, I’ll have to get reports from one.

As always a busy fall. That and I have seven more weeks of assigning referees to soccer matches in west central Ohio. That has become almost a full time job in itself.

by Gary Mintchell | Aug 22, 2018 | Internet of Things

Defining terms enhances effectiveness of communication—especially in this new Industrial Internet of Things (IoT) space. The Industrial Internet Consortium (IIC) leads the way bringing companies and people together to accomplish this sort of work.

I floated a definition of edge a little while ago and got an interesting reaction on Twitter. Let’s see how this one flies.

IIC announced V2.1 of the Industrial Internet Vocabulary Technical Report. Designed to reduce confusion in the marketplace, the report is a foundational document that provides a common set of definitions for IIoT terms used in all IIC documents. It is also intended as a reference for anyone working in IIoT, including those in IT, OT and vertical industries.

The report adds definitions for terms used in data management, edge and edge computing, IT/OT convergence, connectivity, interoperability, brownfield and greenfield.

“People from different backgrounds and different vertical industries will often use different terms to mean the same thing. Additionally, the industrial internet has core concepts that mean different things to different people,” said Anish Karmarkar, Co-Chair of the Vocabulary Task Group, and Senior Director, Standards Strategy & Architecture at Oracle. “Without an agreed upon vocabulary, there’s a lot of room for misunderstandings. For example, we’ve defined IT/OT convergence as a process of interweaving IT and OT in order to create IIoT systems. While IT/OT convergence is a hot topic today, not everyone is on the same page as to what it exactly means.”

The report provides definitions for data management, including data, data at rest, data in motion, data in use, data integrity and many others to make communication on this subject easier for IIoT stakeholders. The report also clears up confusion on “connectivity” and “interoperability,” which IIoT stakeholders often mix up. “Connectivity” means the ability of a system or app to communicate with other systems or apps via networks. “Interoperability” means the ability of two or more systems or apps to exchange and use that information.

“Edge and edge computing are hotly debated topics in IIoT this year,” said Marcellus Buchheit, one of the primary authors of the IIC IIoT Vocabulary Technical Report, and President & CEO, WIBU-SYSTEMS USA Inc. and Co-Founder, WIBU-SYSTEMS AG. “IIoT stakeholders in every industry have been asking ‘where is the edge,’ or ‘what is edge computing.’ The report defines the ‘edge’ as the boundary between pertinent digital and physical entities, delineated by IoT devices, and ‘edge computing’ as distributed computing that is performed near the edge, where the nearness is determined by the system requirements. At the moment, the IIC is the only consortia to provide definitions for ‘edge’ and ‘edge computing.’”

Read the IIC Journal of Innovation September 2017: Edge Computing to learn even more about edge computing. JOI articles show that by moving compute closer to data sources, edge computing allows for faster sense-analyze-response cycles, which is important for running mission-critical, real-time IIoT applications such as equipment monitoring or autonomous machinery.

by Gary Mintchell | Aug 21, 2018 | Internet of Things, Manufacturing IT

Quuppa introduced me to its unique location sensing technology at Hannover last April and I wrote about it here.

Today’s announcement concerns a partnership with Ubisense Group plc, a market leader in enterprise location intelligence solutions, as part of Ubisense’s strategy to integrate leading location and identification technologies with its open and sensor-agnostic SmartSpace software platform, enabling customers to create a truly enterprise-wide digital twin along the entire value chain of critical manufacturing activities.

Many of the world’s major manufacturers benefit from Ubisense SmartSpace systems which create a real-time, operational digital twin and use it to change factory behavior based on the locations of tools, people and work-in-progress. SmartSpace allows customers to integrate a broad range of sensing capabilities to address different use cases and a wide range of ROIs, and leverage existing location technology they may already be using. By working with Quuppa to support applications where the Quuppa Intelligent Locating System offers the best ROI, Ubisense also expects to extend the reach of SmartSpace further into the logistics, construction and healthcare markets.

Quuppa utilizes a unique combination of Bluetooth Low Energy (BLE) and the Angle of Arrival (AoA) methodology, as well as advanced location algorithms that have been developed over the course of more than 15 years, to calculate highly accurate, real-time indoor positioning, even in the most demanding environments. The low-power system is a reliable, highly-customisable, scalable and cost-efficient solution for providing an accurate “dot on the map.” The Quuppa solution provides another powerful source of information to drive location-aware applications within Ubisense’s SmartSpace platform. It complements the many sensors already integrated with SmartSpace, including Ubisense’s own market-leading UWB location systems (Dimension 4 and AngleID), other third-party location sensors, third-party passive RFID tag readers, and barcode systems.

Dr. Andy Ward, CTO at Ubisense, said: “One of the key benefits of our SmartSpace platform is the ability to integrate a wide range of data sources to facilitate building sensor-rich, industrial-scale systems, allowing us to propose the right location sensor technology for each application. We’re looking forward to seeing powerful additional use cases develop as customers explore our joint capabilities with Quuppa.”

Thomas Hasselman, chief marketing officer at Quuppa, said: “The Quuppa Ecosystem—now more than 90 partners strong—continues to flourish, bringing the power of highly accurate, reliable and scalable location services to a growing number of companies across a variety of industries through our commitment to BLE technology. In partnering with Ubisense, we are delivering new opportunities to SmartSpace customers that are using location as a business driver.”

by Gary Mintchell | Aug 20, 2018 | Automation, Technology

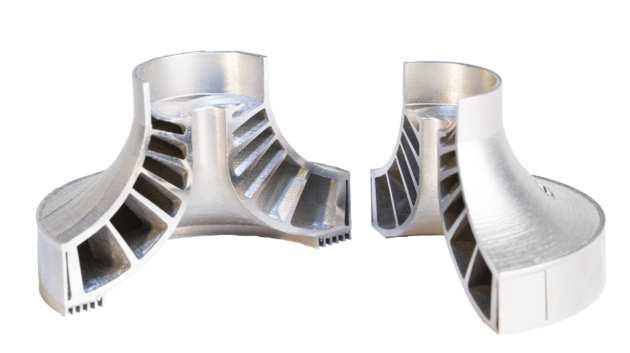

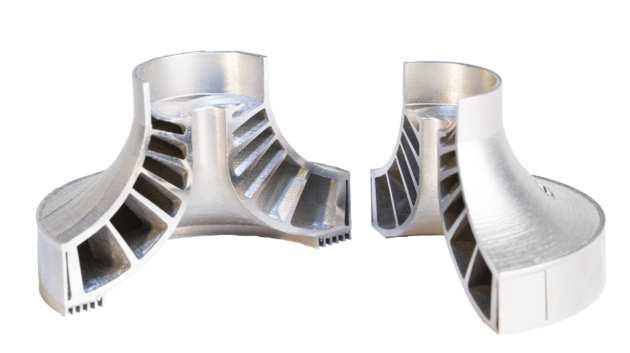

Moving additive manufacturing from plastics to metal and from hobbyist bench to the factory has attracted much attention. One of the problems with metal 3D printing (additive manufacturing) has been holding high tolerance for consistency. Velo3D today announced general release of its end-to-end metal additive manufacturing (AM) solution comprised of the Sapphire system, Flow print preparation software, and Intelligent Fusion technology. Together, the integrated solution solves some of the most difficult AM challenges including product design limitations, part-to-part consistency, process control and cost-effective manufacturing.

“Additive manufacturing has the potential to be revolutionary,” said Ashley Nichols, general manager at 3D Material Technologies (3DMT), a leading metal additive manufacturing services bureau. “Systems are getting bigger, but not delivering on the promises of metal additive manufacturing. Through a collaborative partnership, 3DMT and Velo3D are unlocking new applications, pushing the envelope of what is currently considered possible. We look forward to continued success, and to delivering on the promises of the potential of metal additive manufacturing.”

Sapphire System

The Sapphire system is a laser powder bed metal additive 3D printing system designed for high volume manufacturing. Sapphire is capable of building complex geometries including designs with overhangs that are less than five degrees and large inner diameters without supports – something previously unheard of in the AM industry. To deliver superior part-to-part consistency, Sapphire’s integrated in-situ process metrology enables first-of-its-kind closed loop melt pool control. To maximize productivity, the Sapphire system contains a module that enables automated change-over with offline unpacking.

Flow Print Preparation Software

Flow print preparation software includes support generation, process selection, slicing and simulation of complex part designs to validate execution feasibility before the build. Geometrical feature-driven processing enables low angles below five degrees. In addition, deformation correction technology enables the user to produce parts without the need for iterations, achieving a first print success rate of up to 90 percent. Flow minimizes the need for supports, reducing typical support volume by 3-5 times, which removes or reduces the laborious post processing necessary with conventional approaches.

Intelligent Fusion Technology

Enabling an end-to-end integrated workflow, Intelligent Fusion is the technology that powers Flow software and the Sapphire system. Intelligent Fusion optimizes the AM process by combining thermal process simulation, print prediction, and closed-loop control during print execution.

“Four years ago, we set out with the bold vision of creating technology that could manufacture parts with any geometry to take additive manufacturing mainstream,” said Benny Buller, founder and CEO of Velo3D. “Our approach relies on creating deep insights in physics fundamentals, enabled by research, characterizing and understanding of core mechanisms, developing intelligent process control through software simulation and in-situ metrology. Today, Velo3D is working with some of the top OEMs and service bureaus creating parts that were once considered impossible.”

Velo3D systems are currently used by original equipment manufacturers (OEMs) and manufacturing service providers.

www.velo3D.com.

by Gary Mintchell | Aug 20, 2018 | Internet of Things, Manufacturing IT, Operations Management

Siemens is serious about building out its IoT platform, Mindsphere, on it way to realizing the vision of the technology supplier of digital transformation in manufacturing. How else to describe the €0.6 billion (or about $700 million) acquisition of Mendix, a popular low-code application development platform.

Mendix, which was founded in the Netherlands but now has its headquarters in Boston, will continue to operate as usual and keep its name, but Siemens notes that it will also use the company’s technology to accelerate its own cloud, IoT and digital enterprise ambitions.

“As part of our digitalization strategy, Siemens continues to invest in software offerings for the Digital Enterprise. With the acquisition of Mendix, Siemens continues to add to its comprehensive Digital Enterprise and MindSphere IoT portfolio, with cloud domain expertise, cloud agnostic platform solutions and highly skilled people,” said Jan Mrosik, CEO of Siemens’ Digital Factory Division.

Mendix’s service is already deeply integrated into IBMs’, SAP’s and Pivotal‘s cloud services. Mendix co-founder and CEO Derek Roos notes that his company and Siemens first discussed a strategic partnership, but as those talks progressed, the two companies moved toward an acquisition instead. Roos argues that the two companies’ visions are quite similar and that Siemens is committed to helping accelerate Mendix’s growth, extend the company’s platform and combine it with Siemen’s existing MindSphere IoT system.

“If you’ve ever wondered which low-code platform will have the viability to invest and win in the long term, you no longer have to guess,” Roos writes. “This commitment and investment from Siemens will allow us to accelerate R&D and geo-expansion investments significantly. You’re going to see faster innovation, more reach and an even better customer experience from us.”

Over the course of the last few years, ‘low-code’ has become increasingly popular as more and more enterprises try to enable all of their employees to access and use the data they now store. Not every employee is going to learn how to program, though, so tools like Mendix, K2 and others now make it easy for non-developers to quickly built (mostly database-backed) applications. (See my last post on ERP and “consumerization”.)

Here is a longer explanation from Roos’ blog:

[https://www.mendix.com/blog/siemens-to-acquire-mendix/]

As the world around us gets increasingly connected, organizations are facing increasing challenges to cope with vast amounts of data and customers are increasingly expecting entirely new experiences and interactions. New technologies like VR, IoT and AI will drive an incredible convergence between the digital and physical worlds, creating entirely new industries and business moments in which people, data, businesses and things work together, dynamically.

This, once again, will put more pressure on business/IT organizations to adapt and change how apps are built and consumed, in ways that few can comprehend right now. And just like we’ve done for web and mobile applications, we also intend to set the direction and lead the market for our customers in this new era.

And this is where Siemens comes in.

As one of the world’s largest industrial powerhouses, there are few companies on the planet that are dealing more mission-critical data and better positioned to blur the lines between our physical and digital worlds. With millions of connected devices and systems, operations in more than 200 countries, and more than 15,000 software engineers, Siemens has access to know-how, expertise and reach few others can match. Even fewer software companies can attempt to compete with such scale in ‘things’.

Siemens has been on a mission to leverage its foothold and data-rich infrastructure in the physical world, to become a leader in the digital world, investing over $10B in the last decade to acquire and build out software businesses, and to create the Industrial IoT platform, MindSphere.

Our two teams first met over a year ago and what started as a discussion about a strategic partnership, gradually evolved into a much bigger vision. The more time we spent together, the more we realized how our visions were aligned. Together with Joe Kaeser, CEO Siemens AG, Jan Mrosik, CEO Digital Factory Division, and Tony Hemmelgarn, CEO PLM Software, we identified three strategic areas where we could win together:

- Accelerate Mendix’ leadership in low-code by doubling down on R&D investments and geographical expansion: By becoming a part of Siemens, we will be able to access an even bigger investment than going public, and we will immediately get access to an enormous global infrastructure that would take much longer to stand-up ourselves. We are committed to extending our leadership in low-code and will significantly accelerate investments in R&D, Customer Success and global expansion.

- Combine Mendix and MindSphere to create the digital operating system for the physical world: With billions of intelligent devices and machines connected to the cloud, organizations will require a new kind of platform to turn these massive amounts of data into real-time business value. By combining Mendix and MindSphere, we will be in a unique position to bridge the physical and digital worlds.

- Extend the Mendix platform to develop world-class and deeply integrated industry SaaS solutions: Becoming a part of Siemens gives us unprecedented access to deep industry know-how, network and expertise. Together with our partner ecosystem, we’ll be able to extend the Mendix platform with deeply integrated vertical solutions across a wide range of industries. Combining low-code with best-practice solutions and templates will provide even more value and speed to market for our customers.