by Gary Mintchell | Oct 18, 2018 | Internet of Things, Manufacturing IT

The company that organizes the successful Industry of Things conferences in the late winter in San Diego has launched Industry of Things East to be held in Orlando November 14-16. I will be speaking at a break out session on Thursday afternoon that week. Come and heckle me.

The event will include more than 40 interactive sessions and case studies, as well an IIoT Bootcamp. Here are all the formats you will be able to take part to:

IIoT Bootcamp: our partner MESA will take you on the journey towards Smart Manufacturing on November 14

4 Icebreaker sessions round tables on the evening before the first conference day

A Panel session on Society 4.0 – Engaging industry, policy makers, educators and institutions for a harmonious technological future

Over 25 Case studies from MIT, Monsanto, Continental, Siemens, Praxair and many more

12 World Cafés moderated by experts from Covestro, Merck or The Internet Association

2 co-located events: Pharma MES USA and Pharma TRACKTS! USA will gather 300 Manufacturing experts from the Industrial IoT, Pharma MES and serialization communities in one place.

Make sure to have a look at the event program to tailor an agenda fitting to your needs.

I have attended all three of the events in San Diego including participating as a moderator and table leader. This is the premier Internet of Things conference in the country. They also organize events in Berlin, Germany and Singapore.

The company is offering a special rate: simply sign up online before October 24* to take advantage of the $995 special.

by Gary Mintchell | Oct 17, 2018 | Podcast

More and more companies are going direct with their marketing communication activities and social media. It’s been a trend for a while and gaining momentum. They are doing their own webcasts, email marketing, newsletters, and even magazines. Rockwell Automation is expanding the offering by launching a podcast series. I have not listened to one, yet, just having received this notice. Give it a try if you work in the IoT or manufacturing software area.

Rockwell Automation is launching an executive podcast series, “State of the Industry: Your Guide to the Future of Smart Manufacturing.” The podcast is available on iTunes.

The show is hosted by David Vasko, director of Advanced Technology, Rockwell Automation, who is responsible for the company’s technology roadmap and leads their global research and development.

Vasko discusses a range of topics with business and academia thought leaders – from how industrial technologies, such as blockchain, will transform supply chains to how academic and business partnerships address workforce and upskilling challenges.

The latest episode features a discussion with Robert D. Atkinson, president of the Information Technology and Innovation Foundation (ITIF). They explore how robotics, machine learning and artificial intelligence will affect the next-gen workforce.

In another episode, Vasko and Mark Mone, University of Wisconsin-Milwaukee Chancellor, discuss industry-academia collaborations and how those partnerships integrate real-world industrial experience and higher education. In a separate episode, Vasko and Tim Biernat, a principal software architect in the Rockwell Automation Advanced Technology Lab, discuss the potential of using blockchain in industrial supply chains.

Go to iTunes, Overcast (my favorite), or at Rockwell.

by Gary Mintchell | Oct 17, 2018 | Automation

Beckhoff Automation had a sizable booth at Pack Expo this week. Much to my surprise, when I asked about whether there was something new (I don’t expect new product introductions in automation at Pack Expo) the answer was yes. Well, I had a glimpse at Hannover in April.

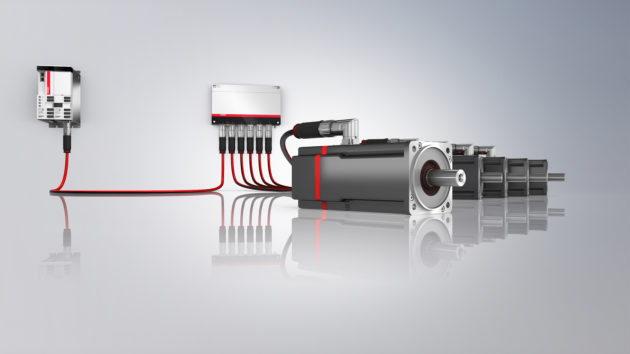

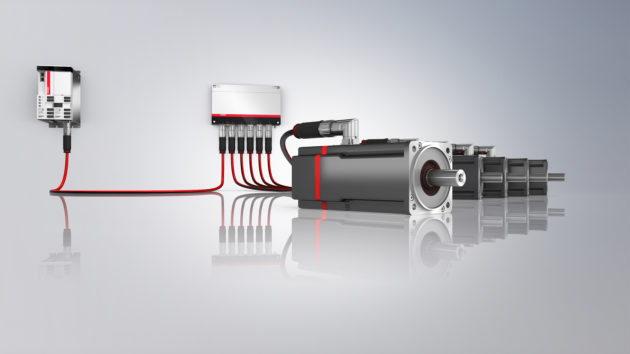

The AMP8000 servo system has an innovative design where the integrated drive is placed on the end of the servo motor rather than the usual side. This design allows for maximum heat dissipation from the motor. They were able to package the drive and motor that only added 75 mm to the length of the motor.

By combining a servo drive and servomotor into one device, the AMP8000 system reduces overall packaging machine footprint and space requirements inside control cabinets and enclosures. A single coupling module can operate up to five drives using the EtherCAT P One Cable Automation solution that supplies industrial-grade power and EtherCAT industrial Ethernet communication.

Requiring Requiring no alterations to the existing machines, the AMP8000 boasts power ratings from 0.61 to 1.23 kW and standstill torque ratings from 2.00 to 4.8 Nm at an F4 flange size or power ratings from 1.02 to 1.78 kW and standstill torque ratings from 4.10 to 9.7 Nm with an F5 flange. The servo drive system also represents the Beckhoff commitment to promoting safety technology in all areas via integrated STO and SS1 safety functions.

TwinCAT software updates have added a number of important tools for packaging machine builders and end users, including expanded data processing through TwinCAT Analytics and HTML5-enabled TwinCAT HMI for industrial displays and mobile devices. In addition, TwinCAT Motion Designer supplies additional tools to commission entire motor, drive and mechanical systems in software, whether integrated into the TwinCAT 3 platform or used as a stand-alone motion system engineering tool.

by Gary Mintchell | Oct 16, 2018 | Automation, Process Control, Technology

This week is another week on the road—five out of the last six—and now I’m in Chicago at Pack Expo. Much like IMTS, Pack Expo fills three halls of McCormick Place with machines. And machine components such as controls, drives, software, instrumentation, and the like.

Two weeks ago was Emerson Global Users Exchange. I wandered into the Emerson Automation Solutions booth not expecting much that was new. OK, got that one wrong.

If you want an indicator that Emerson has seriously expanded beyond oil & gas, keep on reading. It is now a serious player in this space, as well.

I once was an executive with a company that designed and built automated assembly machines. One interesting niche we had was an expert in helium mass spectrometry leak testing. I can give the sales pitch on the value of in-line, 100% testing of products.

Well, not as good as when Emerson explained its new food and beverage leak detection system.

Emerson’s RosemountTM CT4215 uses laser technology to detect leaks, reject defective packages with no production slowdown.

The Rosemount CT4215 is the first quantum cascade laser/tunable diode laser (QCL/TDL) continuous, inline detection system designed to help assure quality and safety, maximize production volume and decrease product waste for food and beverage products. The Rosemount CT4215 tests the seal and integrity of every bottle or package on a production line, detecting leaks at a sensitivity as low as 0.3 mm and automatically rejecting any defective bottle or package without slowing down production. This is in contrast to the traditional practice of testing occasional grab samples, which can leave a manufacturer vulnerable to low quality, unsafe food or beverages, reduced profitability and damaged reputation.

“In an industry being driven by an increasing consumer awareness of freshness and safety, manufacturers need solutions that allow them to assure these qualities while maintaining, or even increasing, efficiency,” said Peter Watmough, global leak detection product manager, Emerson Automation Solutions. “The Rosemount CT4215 provides packagers with an easy-to-install, easy-to-use assurance of freshness and safety. For the first time, food and beverage packagers can measure every package and bottle for leaks without having to compromise their production speed.”

Emerson further unveiled a new line of transmitters designed specifically for hygienic applications in the food and beverage industry with a compact form factor that will enable manufacturers to minimize downtime and lower production costs.

The new line of transmitters—Rosemount 326P Pressure, Rosemount 326T Temperature, Rosemount 327T Temperature and Rosemount 326L Level instruments—are designed to operate in the hygienic environments required by food and beverage manufacturers:

All comply with 3-A and FDA specifications, and are available with nine common industry process connections to ensure the right fit for new tanks and pipe fittings, as well as capability to be retrofitted on legacy systems. The new, small transmitters also can be mounted in tighter locations common on packaging machinery. Conventional 4-20 mA outputs and IO-Link connectivity make the transmitters easy to integrate with automation systems.

To give a sense of the breadth of Emerson Automation Solutions commitment to the space, following are some summaries of products.

Emerson’s ASCO G3 Fieldbus Electronics completely modular system plugs together via mechanical clips that allow easy assembly and field changes without dismantling the entire manifold, and its modules can be used in centralized or distributed applications.

One particular demonstration that will feature G3 Fieldbus Electronics is Emerson’s ASCO Bread Packing Machine. This state-of-the-art system provides full pneumatic automation control to ensure high-speed, repeatable packaging of food products. Its G3 Fieldbus integrates pneumatic control and provides real-time diagnostic data via an integrated webserver. It demonstrates flexible and energy-efficient design through proper sizing of pneumatic systems to fit any food packaging operation.

Emerson’s SolaHD Power Quality solutions remove limitations in the power architecture, allowing machine designers and operators to safely put power where they need it. These power supplies can be mounted directly on a machine, freeing packaging lines from design constraints; eliminating the complexity and cost of unnecessary enclosures and excess wiring; and providing the power for current and future automation capabilities.

Emerson’s Branson Ultrasonic Automated Cutting System provides precise food portioning with an almost frictionless cutting surface resulting in cleaner cuts, faster processing, minimal waste, longer blade life, higher productivity for greater throughput, and reduced downtime for cleaning.

Emerson helps packaging operations reduce process variation and decrease costly losses through technologies that deliver real-time insight into machine and process performance. With the accurate, relevant data in hand, packaging operations can achieve better reliability, reduce losses and contamination as well as ensure long-term performance.

With Emerson’s Micro Motion Filling Mass Transmitter (FMT), high-value packaging lines can accurately fill a wide range of container sizes and products with a single meter, eliminating the cumulative error associated with multiple-device measurement solutions. The Micro Motion FMT reliably measures fluids with entrained solids or gases or with changing viscosities, making it ideal for high-speed filling and dosing applications. Its Coriolis mass-based measurement is immune to variations in process fluid, temperature or pressure, and Automatic Overshoot Compensation (AOC) ensures repeatable fills even under valve performance changes. In addition, the Micro Motion FMT enables operators to track quality control and filling valve-performance data in real time to reduce filler maintenance and cost.

In addition, Emerson’s Micro Motion Multiphase Flow Meter technology can help complex process operations reliably log Gas Void Fraction and liquid density and concentration measurements. Utilizing Micro Motion Advanced Phase Measurement software, these meters also tolerate “real life” conditions of foaming, end-of-batch cavitation or slug flows to enable consistent measurements in challenging multiphase conditions. In addition, Smart Meter Verification delivers detection of coating or fouling within the meter for added clean-in-place efficiency and insight.

An interactive display illustrating pneumatics and IIoT features Emerson’s AVENTICS Smart Pneumatics Monitor, an IIoT hub allowing local data collection and analysis independent of the controller. The pick-and-place display illustrates “predictive maintenance” by showing the health and performance of valves, cylinders and shocks, which can minimize the risk of unplanned machine downtime to increase ROI.

To demonstrate how operators can protect personnel and reduce risk without impacting productivity. the Emerson booth will feature the Emerson ASCO 503 Series Zoned Safety Manifold (with G3 fieldbus electronics). It simplifies the design of a redundant pneumatic safety circuit with a manifold system that can be configured to shut down air and power only to the group of valves that controls the machine’s motion in the operator’s vicinity while the rest of the machine remains in operation. Multiple independent safety circuits can easily and cost-effectively be designed into a single pneumatic valve manifold, reducing the number of safety system components by up to 35 percent, requiring less plumbing, and shrinking the size of a safety system so that valuable real estate within the machine and manifold can be used for other purposes while still providing enhanced operator safety.

by Gary Mintchell | Oct 12, 2018 | News, Organizations

Here is the second news piece, and perhaps the biggest, from the ODVA annual meeting held this week in Georgia. Honeywell has become a principal member of ODVA alongside Bosch Rexroth, Cisco Systems, Endress+Hauser, Rockwell Automation, Omron and Schneider Electric. The primary focus of Honeywell’s activities in ODVA will be through Honeywell Process Solutions (HPS), part of Honeywell’s Performance Materials and Technologies strategic business group and an industry leader in automation control, instrumentation, software and services.

Honeywell Process Solutions has a 40-year history in process automation control. It has supported ODVA technologies and standards since the late 1990s with the integration of ControlNet into its distributed control system (DCS) offering. With the convergence of industrial control systems used in process and hybrid industries, Honeywell has seen both a growth in adoption and in opportunity for EtherNet/IP connectivity and now has integrated EtherNet/IP into multiple product lines including Experion Process Knowledge System (PKS) and ControlEdge PLC. Today HPS has its solutions installed in more than 10,000 sites around the world including various locations with EtherNet/IP.

ODVA has activities focused on the adoption of EtherNet/IP in the process industries. These activities include a technical working group focused on enhancements to The EtherNet/IP Specification for specific needs in the process industries. ODVA is also involved in industry-wide efforts to promote adoption of Ethernet in the process industries, such as its collaboration with FieldComm Group and PROFIBUS and PROFINET International to help promote adoption of Ethernet to the Field that will be made possible by forthcoming enhancements to the IEEE 802.3 Ethernet standard for long-reach single pair Ethernet.

“EtherNet/IP is an important platform for industrial control and, in the future, for overall digitization,” stated Brian Reynolds, senior director of engineering for HPS’ Projects and Automation Solutions business. “Honeywell leverages EtherNet/IP in its Connected Plant solutions, which allows customers to collect more meaningful data from devices to improve overall equipment effectiveness and safety. By joining ODVA as a principal member, Honeywell is increasing its contribution to the advancement of EtherNet/IP and related ODVA technology and standards, in order to increase productivity, reliability, safety, security and digitization in the process and hybrid industries.”

“Adoption of EtherNet/IP in the process industries is poised for vertical take-off within the next ten years,” said Katherine Voss, president and CEO of ODVA. “ODVA welcomes increased participation from Honeywell Process Solutions inside ODVA as we work together to bring the benefits of EtherNet/IP to users in an ever expanding range of industries within, and beyond, the process industries.”

ODVA introduced Honeywell as a principal member at its 2018 Industry Conference and 19th Annual Meeting of Members that was held October 9-11, 2018 in Stone Mountain, Georgia, USA. The introduction included an overview of HPS and its reasons for joining ODVA as a principal member along with an end-user perspective on EtherNet/IP in Action at DowDuPont. Presentations for Honeywell and DowDuPont may be viewed and downloaded with other proceedings from the ODVA online.