by Gary Mintchell | Nov 14, 2016 | Automation, News, Operations Management, Software, Technology

I put on the pair of magic glasses. Immediately I was transported to a magic land of another reality. I saw things floating in front of me. I could walk around objects and view them from every angle, but I couldn’t touch them.

There was a white dot. I focused on the dot and brought my hand up to eye level forming a fist with fingers on top. Then I opened my fist like a jasmine bud you drop into hot water to make fragrant tea. And a computer screen appeared before my eyes. I raised a finger, pointed to a button, brought my finger down and then back up as if clicking. And a machine started.

No, I had not smoked something. (Although people suspect that in my days at university… well that’s another topic for another day!)

Perhaps you’ve seen the TV ads for the Samsung phone with Virtual Reality (VR) goggles? I was wearing a real product–the Microsoft Hololense. This is Augmented Reality (AR). I could see people walking through the first machine. I could see the actual machine in the second scenario. I controlled the fan speed of the real machine without touching anything. People watching would only see me waving my hand.

Yes, this was last week in Atlanta at Automation Fair sponsored by Rockwell Automation. At a stand called modestly enough The Future of the Connected Enterprise, they showed these working examples of AR in a manufacturing setting.

Innovation

Let’s be honest. In 20 Automation Fairs I’ve attended, I’ve never felt like I’ve seen the bleeding edge of technology. Cool new products? Sure. Rockwell kept advancing with the times. The Logix engine was an advance in the state of the art followed by Studio 5000. But that has been some time ago. This year just felt differently.

First there was a live demo during the media day that included information solutions. Next was the Innovation Zone demo of AR. Finally was a dive into Information Solutions–something initially highlighted by new CEO Blake Moret.

First an admission and some definitions. I stole the headline of the piece from both ControlGlobal and Automation World. I think I saw it in both places on the Web last week. Now the description–Rockwell calls “Software” its software for HMI, programming, and the like. What really has been building is “Information Solutions.” More accurately, the headline should have been, “Rockwell Automation, An Information Solutions and Services Company.”

An Information Solutions Company

Information Solutions and Process Solutions are headed by the same VP/GM, John Genovesi. Process had been growing for several years, but it seems to have leveled off lately. Information Solutions was front and center featured this year. My industry research this year revealed that IS accounts for the bulk of revenue increases within the “Connected Enterprise” strategy. And that makes sense.

Information Solutions and Process Solutions are headed by the same VP/GM, John Genovesi. Process had been growing for several years, but it seems to have leveled off lately. Information Solutions was front and center featured this year. My industry research this year revealed that IS accounts for the bulk of revenue increases within the “Connected Enterprise” strategy. And that makes sense.

One of the deep-dive interview opportunities offered me this year was the Information Solutions group. Spokesperson Khris Kammer told me that there were four pillars to discuss this year–Scalable MES, Scalable Analytic, Connected Services, and Collaboration/Teams. I’ll have more detail on product releases from the first two. Connected Services was touted by Moret during our interview.

The traditional challenge for MES has been its monolithic nature. If you want MES, you must buy a big chunk. Rockwell has been working on this customer challenge and barrier to entry. Rockwell introduced “suites”, but that did not address the entire problem. Now are “fit-for-purpose” apps–quality, production, performance. Read more below.

Analytics became the domain of data scientists through “Enterprise Manufacturing Intelligence” (EMI) which was a spin-off from enterprise Business Intelligence. Rockwell partners with Microsoft PowerBI, but it also worked on the scalable aspect to bring customers in a little at a time. Built upon existing products Historian and VantagePoint, developers built Analytics for Devices and Analytics for Machines–a cloud-based broader solution. Read more below.

Connected Services blends service in networks, security, and managed services. This has been a growing part of Rockwell’s business and now receives the attention and focus of landing as part of the Connected Enterprise strategy.Collaboration features a Web-based, HTML5 app called TeamOne. The team demonstrated it to media in perhaps the first live demo at a Rockwell keynote. Figuring that pretty much everyone already brings a smart phone to work, this app is IT-friendly and allows chatting, information access, video capability, and more among selected members of a team. These personnel may be in the same area, scattered around a facility, or even remote if necessary.

Scalable Analytics

“Our Connected Enterprise vision has always had analytics and collaboration at its core,” said Genovesi. “As we expand our Information Solutions offerings, a primary goal is to make analytics more approachable and right-sized for the customer. New analytics solutions help our customers move ahead on their Connected Enterprise journey, no matter where they are today.”

The new offerings expand capabilities for analytics across the plant floor for devices, machines and systems, as well as throughout the enterprise. In this approach, analytics are computed and gain context closest to the source of decision at the appropriate level in the architecture to return the highest value – from edge devices to the cloud on a variety of new appliances, devices, and on- or off-premise cloud platforms.

FactoryTalk Analytics for Devices appliance provides health and diagnostic analytics from industrial devices. It crawls your industrial network, discovers your assets and provides analytics by transforming the data generated into preconfigured health and diagnostic dashboards. The system also delivers “action cards” to your smartphone or tablet if a device requires attention.

At the machine level, FactoryTalk Analytics for Machines cloud application provides equipment builders access to performance analytics from deployed systems to help support their customers via the FactoryTalk cloud. For manufacturers, this capability capitalizes on connected technologies to help drive higher availability and output while reducing maintenance costs.

Rockwell Automation now provides a predictive maintenance solution that can predict failures before they happen and generate a maintenance work order to avoid costly downtime.

Scalable MES

Rockwell Automation has released the following applications, with more to come in the future:

FactoryTalk Production Application a scalable MES solution that addresses the challenges associated with enforcing processes in manufacturing. This application integrates with ERP, and tracks the order and recipe parameters necessary for production.

FactoryTalk Quality Application allows manufacturers to easily and efficiently model and enforce their plant’s in-process quality regimens at a scalable rate. Manufacturers can use the Quality application on a project basis and scale up when value is proven.

FactoryTalk Performance Application is a modular application that assists manufacturing companies with factory efficiency and production improvement. By providing visibility into the operations performance, this application allows for lean and continuous improvement, preventive manufacturing, improved asset utilization and operational intelligence.

Each expanded MES application is implemented on thin clients for a modern user experience and reduced, IT infrastructure cost. Users can add on each application to their current framework, helping protect their current investments while realizing these additional benefits.

by Gary Mintchell | Jul 1, 2016 | Manufacturing IT, Operations Management, Software

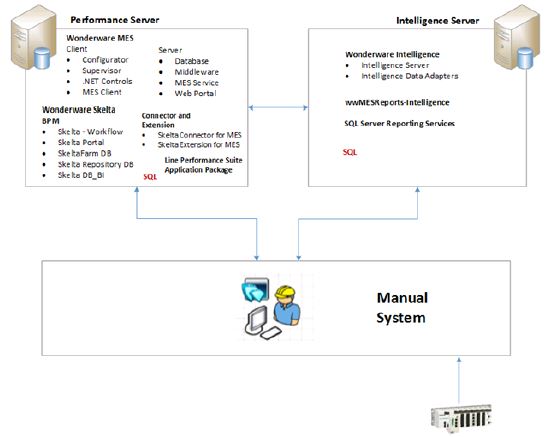

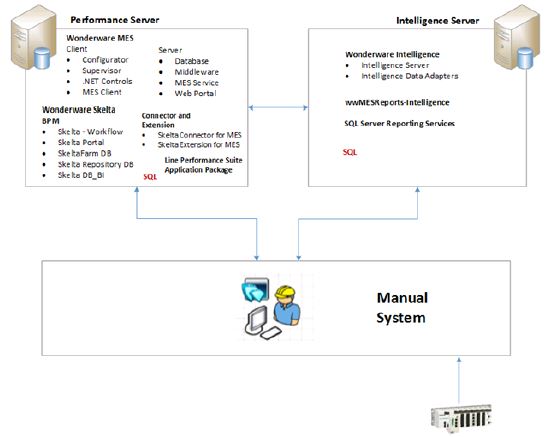

Schneider Electric software aims to boost process line improvement tool for food & beverage and consumer packaged goods (CPG) manufacturers. It announced yesterday availability of Line Performance Suite for Food & Beverage and Consumer Packaged Goods manufacturers.

Schneider Electric software aims to boost process line improvement tool for food & beverage and consumer packaged goods (CPG) manufacturers. It announced yesterday availability of Line Performance Suite for Food & Beverage and Consumer Packaged Goods manufacturers.

This single purpose app is built atop Wonderware MES software. These apps are a growing trend in the industry. Another trend is moving the investment in software from the capital expenditure budget (CapEx) to operations budget (OpEx). Schneider Electric has priced this offering as a subscription service to meet those customer needs.

Turnkey productivity improvement software

Addressing process improvement, Line Performance Suite offers a turnkey line enhancement and productivity improvement solution that can be used across operations.

“Users of the Line Performance Suite can unlock hidden capacity in production lines to help drive improved profitability, higher quality and enhanced Overall Equipment Efficiency (OEE),” said Doug Warren, Vice President, Industry Solutions at Schneider Electric Software. “Integrated reporting and analysis ensures packaging line output is optimized, providing greater understanding to locate process weaknesses and maintain maximum throughput. What results is better intelligence on line performance for more informed decision making.”

“Users of the Line Performance Suite can unlock hidden capacity in production lines to help drive improved profitability, higher quality and enhanced Overall Equipment Efficiency (OEE),” said Doug Warren, Vice President, Industry Solutions at Schneider Electric Software. “Integrated reporting and analysis ensures packaging line output is optimized, providing greater understanding to locate process weaknesses and maintain maximum throughput. What results is better intelligence on line performance for more informed decision making.”

Benefits

Identified benefits of Line Performance Suite include:

- Line Performance – remove bottlenecks, reduce downtime and increase availability to gain process metrics for both automated and manual production lines

- Product Quality – lower scrap rates and improve first pass yields to achieve better quality and right first time metrics

- Visibility to Process Metrics – gain visibility to Key Performance Indicators (KPIs) to achieve real-time access to critical operating parameters

Included in the offering is Schneider Electric’s Customer FIRST Software Maintenance and Support Program. This program enables access to the latest software upgrades, expert technical assistance and self-help tools to improve operational effectiveness.

Economic development

In one of those interesting coincidences, last week I had a breakfast meeting with two people from the Singapore Economic Development agency. They touted an investment by Schneider Electric in a large software development division. That division—it’s the Industry Solutions Business.

by Gary Mintchell | Jan 21, 2016 | Automation, Operator Interface, Technology

Apps are so last year. Now the topic of the future appears to be bots and conversational interfaces (Siri, etc.). Many automation and control suppliers have added apps for smart phones. I have a bunch loaded on my iPhone. How many do you have? Do you use them? What if there were another interface?

I’ve run across two articles lately that deal with a coming new interface. Check them out and let me know what you think about these in the context of the next HMI/automation/control/MES generations.

Sam Lessin wrote a good overview at The Information (that is a subscription Website, but as a subscriber I can unlock some articles) “On Bots, Conversational Apps, and Fin.”

Lessin looks at the history of personal computing from shrink wrapped applications to the Web to apps to bots. Another way to look at it is client side to server side to client side and now back to server side. Server side is easier for developers and removes some power from vertical companies.

Lessen also notes a certain “app fatigue” where we have loaded up on apps on our phones only to discover we use only a fraction of them.

I spotted this on Medium–a new “blogging” platform for non-serious bloggers.

It was written by Ryan Block–former editor-in-chief of Engadget, founder of gdgt (both of which sold to AOL), and now a serial entrepreneur.

He looks at human/computer interfaces, “People who’ve been around technology a while have a tendency to think of human-computer interfaces as phases in some kind of a Jobsian linear evolution, starting with encoded punch cards, evolving into command lines, then graphical interfaces, and eventually touch.”

Continuing, “Well, the first step is to stop thinking of human computer interaction as a linear progression. A better metaphor might be to think of interfaces as existing on a scale, ranging from visible to invisible.”

Examples of visible interfaces would include the punchcard, many command line interfaces, and quite a bit of very useful, but ultimately shoddy, pieces of software.

Completely invisible interfaces, on the other hand, would be characterized by frictionless, low cognitive load usage with little to no (apparent) training necessary. Invisibility doesn’t necessarily mean that you can’t physically see the interface (although some invisible interfaces may actually be invisible); instead, think of it as a measure of how fast and how much you can forget that the tool is there at all, even while you’re using it.

Examples of interfaces that approach invisibility include many forms of messaging, the Amazon Echo, the proximity-sensing / auto-locking doors on the Tesla Model S, and especially the ship computer in Star Trek (the voice interface, that is — not the LCARS GUI, which highly visible interface. Ahem!).

Conversation-driven product design is still nascent, but messaging-driven products are still represent massive growth and opportunity, expected to grow by another another billion users in the next two years alone.

For the next generation, Snapchat is the interface for communicating with friends visually, iMessage and Messenger is the interface for communicating with friends textually, and Slack is (or soon will be) the interface for communicating with colleagues about work. And that’s to say nothing of the nearly two billion users currently on WhatsApp, WeChat, and Line.

As we move to increasingly invisible interfaces, I believe we’ll see a new class of messaging-centric platforms emerge alongside existing platforms in mobile, cloud, etc.

As with every platform and interface paradigm, messaging has its own unique set of capabilities, limitations, and opportunities. That’s where bots come in. In the context of a conversation, bots are the primary mode for manifesting a machine interface.

Organizations will soon discover — yet again — that teams want to work the way they live, and we all live in messaging. Workflows will be retooled from the bottom-up to optimize around real-time, channel based, searchable, conversational interfaces.

Humans will always be the entities we desire talking to and collaborating with. But in the not too distant future, bots will be how things actually get done.

by Gary Mintchell | Oct 1, 2015 | Commentary, Software, Technology

I have heard from friends (non-editors) who attended the Wonderware software conference. I have edited their news items into what I hope is a coherent post. This news includes some significant information that I have not seen elsewhere, yet. I should get my friends to report more. Getting the point of view of users is valuable. I hope you agree.

This also shows what I was talking about Monday where an industry leader under attack can push the envelop a different direction in order to remain fresh and offer customers more.

1) “It’s getting really cloudy.”

They showed off a number of tools, some old, some new that are all based around a cloud platform or at a minimum communication with the cloud. They are continuing to push really really hard the Wonderware Online and Smart Glance products. Talking with Saadi Kermani, the main evangelist for them, they are in continual release mode and have a long list of planned features that will be rolling out over the coming months designed to keep them up with, or exceed, competitive offerings.

“Also the new version of Smart Glance is really nice and very modern look and feel.” The best part about something like smart glance is that it’s a relatively simple product to get up and running for your org. And pretty cost effective to boot. “My personal analysis is that what will make Wonderware Online super valuable is an ecosystem of partners building sophisticated apps in cloud platforms like Azure and others.”

Some other big cloud stuff. They previewed Wonderware Development Studio online. Now you can log on with a web browser, stand up an environment picking and choosing which machines you want, what software is installed on each, how the redundancy is configured, etc. Hit go and in some amount of time..maybe an hour or so… the machines are ready for you to login via remote desktop running on Azure. This seems like a really awesome setup for integrators that don’t want to maintain a bunch of different environments and versions. Supposedly there was no cost to have then configured. “My only concern is the pricing and how easy it might be to run up a $1K bill before you know it. I did ask about the idea of buying the IP and underlying system that did the automation so you can run it on premise. If I remember right the person I was talking to said it might be possible but wasn’t on the current roadmap.”

2) Hello IOT

A guy from Microsoft had a nice presentation on Monday afternoon talking about Azure and how Azure fits into the IOT space. It was a bit high level but I think we need all the education we can get right now.

During the intro sessions on Tuesday John Krajewski discussed a little more about IOT and specifically talked about their new MQTT OI Server. OI Server is the new name they have given to IO drivers. They are doing some different things with packaging and scalability but that’s incidental to the IOT discussion. Back to IOT, they have written a server that can talk MQTT natively so you can seamlessly push and pull data to/from System Platform with other devices talking MQTT just like you would a PLC.

Alvaro Martiniez the product manager admitted it was early Alpha stage for the product but I hope it opened some people’s eyes to possibilities. “I can’t wait to get my hands on it.”

An integrator presentation to a standing room only crowd discussed multiple aspects of IOT. It was really broken into three parts. The first was an overview of 5 of the major protocols one might come across when getting into the IOT space. Next was a technical deep dive on one of the protocols, MQTT. [Gary’s note: At the Inductive conference, I attended a session by one of the developers of MQTT. This is an important protocol, riding atop TCP/IP stack, that can standardize IoT messaging.] Next were 4 or 5 demos showing the use of MQTT inside or integrated with System Platform and the Historian. “My personal favorite was showing how you could build a simple set of code that read MQTT data and sent it directly to the Historian… which in theory means you could have 100% cloud infrastructure for piping device data straight over to the Wonderware Online historian.”

3) Next Gen

They have been working on revamping the System Platform look, feel, and function for the last few years. The 2014 releases have made some pretty big shifts in the functionality space but nothing major expected until the next release. Tim Sowell’s comments about a unified operations center are dead on with the vision.

The biggest change you are going to see.. and they talked about this very publicly so I don’t think I’m giving anything away, is that InTouch is no longer the shell for visualization. It is now essentially a compiled stand-alone app that is build from many panes that you create and configure from within the System Platform Graphics platform. The visualization engine will use the context of the graphics and objects to make navigation easier. “But the bigger concept is that this is now an operations center, not a simple HMI.”

Longer term there should be a play for higher end integrators and pure software plays to develop Apps that plugin to the operations center and provide additional value and context.

Lots and lots of discussion of context. When these apps are run inside the operations center they will automatically know what’s being displayed on the screens and can automatically adjust. A simple example is that you pull up a graphic with a tank farm. Maybe you have a video feed app with live cameras on the tanks and it automatically swaps to the correct camera view. Or you have another pane with customers orders from the ERP so you know what tanker trucks you should be expecting in the next few hours. “While this has technically been possible before I think the key is that they are going to be adding a lot of functionality to make these otherwise standalone functions a first class citizen within the Operations view.”

They are also making big changes in the development environment trying to make the engineering experience more user friendly. To me this is a clear play to make System Platform look a lot less intimidating and make the 15 minute demo a lot easier and more obvious. For high end engineers and integrators this new layout and development method will probably be a turnoff but I think it will help Wonderware tell the System Platform story easier and get newer, less sophisticated, customers on board.

by Gary Mintchell | May 26, 2015 | Automation, Commentary, Internet of Things, News, Operations Management

I saw some Google Internet of Things news on a new site called The Information. As the technology media consolidates and fights for page views in a fragmented advertising market, Jessica Lessen developed a digital site that is subscription only. No fighting over getting ads and eyeballs.

When I started this site two years ago, I gave some thought to ads. But that seemed like a losing proposition. So right now it’s free. And the newsletter is free. You can sign up for it by clicking the link on the sidebar.

Internet of Things

Everybody wants to get into the Internet of Things parade. The Information picked up on a new project at Google. Working through its Android software, The Information notes, “Google wants its software to power any electronic device that connects to the Internet, whether or not it has a digital screen.”

To that end, Google is working on technology that could run on low-powered devices, possibly with as few as 64 or 32 megabytes of random-access memory, according to people who have been briefed about the project.

The analysis is that the technology could make it easier for other companies to build everything from “smart” fridges and light bulbs to garden monitors. Note that this relates to the consumer IoT.

Keep in mind that ever since the PC-based control revolution of the late 90s, industrial automation and control have increasingly leveraged commercial technologies for industrial uses. If Google develops a low-power, low-footprint product, this will no doubt spur further development of industrial “things”.

And, this should have the twin benefits to customers of driving down costs and providing a more open ecosystem.

More from The Information

The project has been referred by the codename “Brillo” and appears to be separate from the upcoming release of the “M” version of Android. Like the open-source version of Android, Brillo could be more like a technology blueprint than a fully loaded operating system tied to apps and services, at first.

Google is expected to discuss the Brillo software, which is initially aimed at devices for the home, during the company’s annual conference for developers next week. Google last year offered a version of Android for smartwatches, called Android Wear, to certain partners.

Google considers Brillo to be a “platform” that will help streamline a fragmented market in which developers are creating or using lots of different operating systems to power Web-connected gadgets and sensors, says one of the people briefed about it. Because the software is so different from Android, Google hasn’t yet decided whether to fold it into the Android brand, this person says.

Having its software power a bevy of home gadgets would give Google valuable insight into people’s behaviors and habits.

Devices running the new Brillo software would be able communicate with devices made by Google’s Nest unit, which include a thermostat and smoke detector. Those have operating systems built using Linux software, and the thermostat is loaded with technology called Thread that could enable it to serve as a hub for communicating with a range of other devices.

Undoubtedly, Google also wants to head off efforts by Microsoft and Samsung Electronics to create similar software and hardware standards for connected devices.

Microsoft has announced a slimmed down version of Windows 10 that runs on a Raspberry Pi, a cheap microcomputer popular among device developers.

Samsung has Artik, a set of standardized circuit boards smart home developers can tap. It also bought SmartThings, which makes a $99 wireless hub and a free app to control compatible devices around the home. But developers have been reluctant to commit to the system because it depends on Samsung’s as-yet unproved ability build up a huge installed base of hubs.

Information Solutions and Process Solutions are headed by the same VP/GM, John Genovesi. Process had been growing for several years, but it seems to have leveled off lately. Information Solutions was front and center featured this year. My industry research this year revealed that IS accounts for the bulk of revenue increases within the “Connected Enterprise” strategy. And that makes sense.

Information Solutions and Process Solutions are headed by the same VP/GM, John Genovesi. Process had been growing for several years, but it seems to have leveled off lately. Information Solutions was front and center featured this year. My industry research this year revealed that IS accounts for the bulk of revenue increases within the “Connected Enterprise” strategy. And that makes sense.

Schneider Electric software aims to boost process line improvement tool for food & beverage and consumer packaged goods (CPG) manufacturers. It announced yesterday availability of Line Performance Suite for Food & Beverage and Consumer Packaged Goods manufacturers.

Schneider Electric software aims to boost process line improvement tool for food & beverage and consumer packaged goods (CPG) manufacturers. It announced yesterday availability of Line Performance Suite for Food & Beverage and Consumer Packaged Goods manufacturers. “Users of the Line Performance Suite can unlock hidden capacity in production lines to help drive improved profitability, higher quality and enhanced Overall Equipment Efficiency (OEE),” said Doug Warren, Vice President, Industry Solutions at Schneider Electric Software. “Integrated reporting and analysis ensures packaging line output is optimized, providing greater understanding to locate process weaknesses and maintain maximum throughput. What results is better intelligence on line performance for more informed decision making.”

“Users of the Line Performance Suite can unlock hidden capacity in production lines to help drive improved profitability, higher quality and enhanced Overall Equipment Efficiency (OEE),” said Doug Warren, Vice President, Industry Solutions at Schneider Electric Software. “Integrated reporting and analysis ensures packaging line output is optimized, providing greater understanding to locate process weaknesses and maintain maximum throughput. What results is better intelligence on line performance for more informed decision making.”