by Gary Mintchell | Feb 29, 2016 | Internet of Things, Operations Management

I just attended an amazing conference, Industry of Things World USA, in San Diego. Internet of Things was discussed from many angles. The nonstop pace is the reason for no posts for two days. The 400 attendees, about 10% women, gathered from 28 countries and 234 companies. 21 companies sponsored the event, and I was one of the media sponsors. The high profile speakers, ranging from an Undersecretary of the Dept. of Commerce to Harvard Business School professor and author Michael Porter.

I just attended an amazing conference, Industry of Things World USA, in San Diego. Internet of Things was discussed from many angles. The nonstop pace is the reason for no posts for two days. The 400 attendees, about 10% women, gathered from 28 countries and 234 companies. 21 companies sponsored the event, and I was one of the media sponsors. The high profile speakers, ranging from an Undersecretary of the Dept. of Commerce to Harvard Business School professor and author Michael Porter.

Check out the Twitter feed at #IoTClan.

The conference was organized from Berlin, Germany. So, how did they attract such an outstanding attendee list without running ads in major media sites–even major considered from the industry point of view. I heard about the conference from an email. Several people I talked with also heard about it from an email. The organizers, in fact, sent 1.5 million emails in the course of bringing the conference together.

They told me that it was emails and networking. A few people I talked with had been contacted by colleagues in Germany where the organizers have a track record.

Here are a few notes:

Willie May, Under Secretary of Commerce for Standards and Technology (NIST) called the IoT a new paradigm, “It’s going to be big.” NIST is working with industry and academia on standards and testbeds.

Jeff Jaffe, president of W3C–the worldwide web consortium, discovered the importance of metadata and interoperability of data among apps. RESTful interfaces lie on the standards roadmap. Everyone seems to want to rename the IoT in their own way. For Jaffe, it is the Web of Things. “The Web is fueling a transition from costly monolithic software to an open market of apps. Check out the diagram showing his idea that Web technologies can enable vertical & horizontal integration. These go vertically field level to business level (low to high levels of abstraction) and horizontally as integration along supply chain to integration along the value chain.

Jeff Jaffe, president of W3C–the worldwide web consortium, discovered the importance of metadata and interoperability of data among apps. RESTful interfaces lie on the standards roadmap. Everyone seems to want to rename the IoT in their own way. For Jaffe, it is the Web of Things. “The Web is fueling a transition from costly monolithic software to an open market of apps. Check out the diagram showing his idea that Web technologies can enable vertical & horizontal integration. These go vertically field level to business level (low to high levels of abstraction) and horizontally as integration along supply chain to integration along the value chain.

SAP, EVP for IoT Tanja Rueckert, said, “What will really be impacted by IoT are the business processes, disruptive business models, efficiency models.”

Tom Burke, president of the OPC Foundation, discussed the value of data in his presentation to a packed room during a breakout. That showed the amount of interest in the manufacturing side of things

Lead of PwC IoT practice, Kumar Krishnamurthy, in one of the better presentations I heard “IoT from Strategy to Execution”, calld for the right focus–creating value rather than technology. He noted, “Evolution of products, integrate digital with operations, reevaluate go-to-market, manage shifts in revenue model.” Continuing a conference theme, he proclaimed, “Digital transformation is not about technology…but about creating value using an enhanced set of asset base. Technology enabled devices do not make the machines smarter…rather they enable businesses to evolve their model to serve differently. Success is not all about data and analytics…but leveraging the information with judgement and expertise.”

Michael Porter predicted that IoT (or smart products) will expand industry boundaries as well as change organizational structure.

Finally, in a presentation “IoT, Fact or Fiction, Timothy Chou, a lecturer at Stanford and author, suggested that young students learn machine learning-static and dynamic-for the future. “Lots of sensors generate too much data. We must learn to deal with it–with machine learning a key.

He said, “Asset management was developed when things were very dumb. Now I can put a full computer in almost everything. Why not have the machine issue the work order? It is time to rethink middleware.”

by Gary Mintchell | Jan 18, 2016 | Asset Performance Management, Automation, Internet of Things, Manufacturing IT, Networking, Operations Management, Technology

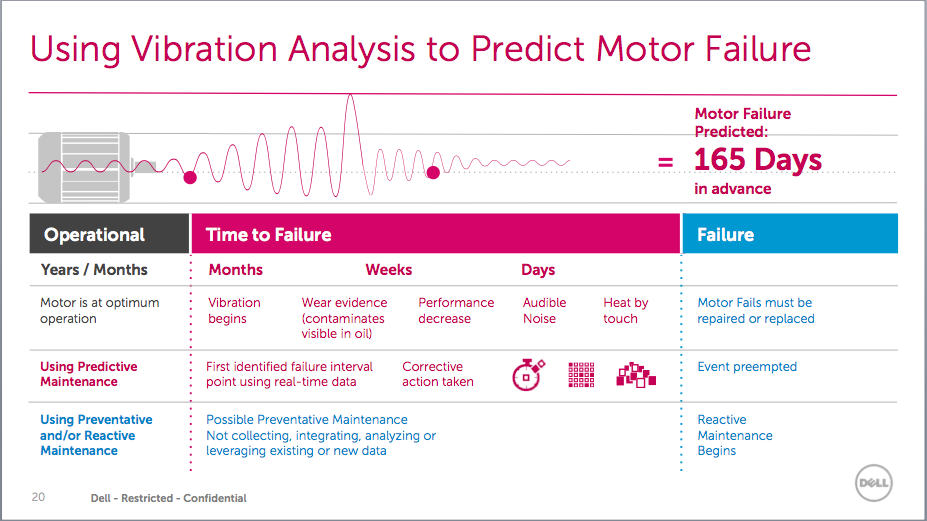

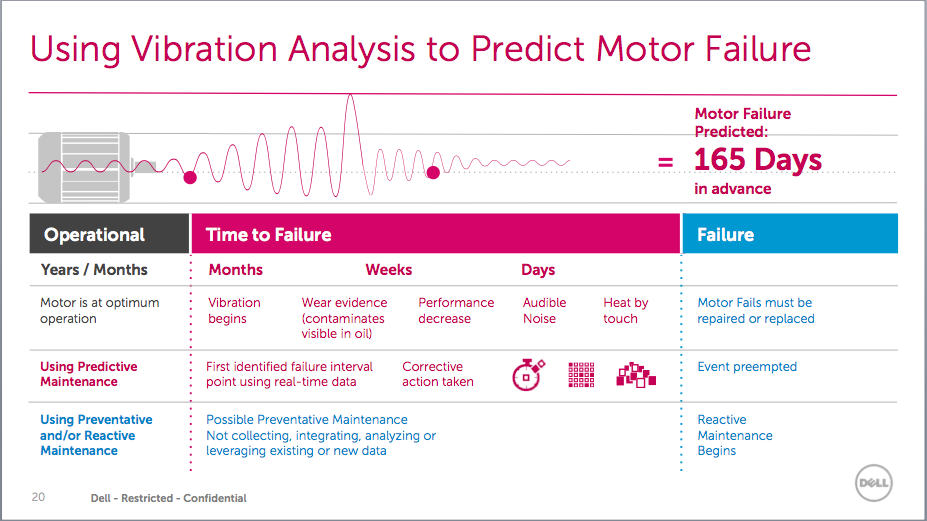

Predictive maintenance benefits more from implementation of the Internet of Things than perhaps any other function at this early stage of wide-spread adoption.

Predictive maintenance benefits more from implementation of the Internet of Things than perhaps any other function at this early stage of wide-spread adoption.

I have written on this topic several times over the past couple of years.

Predictive Condition-Based Maintenance

IoT Testbed For Condition Monitoring To Predictive Maintenance

Use Of Internet of Things Enhances Preventive Maintenance

10 Myths About Predictive Analytics (SAP)

A foulup at Starbucks, Preventive Maintenance Prevents Production

Cloud Platforms For Internet of Things

Predictive or Condition-Based

The asset management community has not made it easy for us generalists with its terminology and definitions. Searching for predictive maintenance (PdM) often serves up results for condition-based maintenance. I am not going to attempt a final definition, but I found something that made sense on the OSIsoft Website. “PdM defines methods to predict or diagnose problems in a piece of equipment based on trending of test results. These methods use non-intrusive testing techniques to measure and compute equipment performance trends.”

Condition-based maintenance (CBM) is a methodology that combines predictive and preventive maintenance with real-time monitoring. PdM uses CBM systems to detect fault sources well in advance of failure, making maintenance a proactive process. CBM accurately detects the current state of mechanical systems and predicts the systems’ ability to perform without failure.

Business Risk

The Aberdeen Group, Report: Building the Business Case for the Executive, December 2013, found that 40 percent of 149 manufacturing executives identified failure of critical assets as the top risk they face.

How do we mitigate this risk? Predictive maintenance and condition-based maintenance are methodologies that help. One thing that makes these strategies work is data. With sufficient data along with a model of the asset’s condition at operational efficiency, reliability engineers can begin to predict failures before they happen.

Just like your car, productive assets pick the worst time to fail. This unplanned downtime is exceedingly expensive. Using predictive technologies, managers can plan for shutdowns at an appropriate time. The right parts can be on hand, labor lined up, production schedules adjusted, all because everything can be planned.

I’ve been talking with Dell often since October when I attended Dell World and it unveiled its Internet of Things initiative.

The interesting thing about Dell compared to almost everyone else I cover is that they approach the IT/OT convergence issue from the IT side rather than the OT side.

Dell’s first IoT product is something I think we’ll see more of–analytics at the edge combined with gateway technology that can bring disparate sources of data together, massage them, send them off to the cloud for further analytics, storage, and visualization. Dell’s current partners are SAP for predictive maintenance and Statistica for analytics.

Expect to see more of these partnerships evolve. In some cases, such as PTC, we are seeing acquisitions to add IoT capability. On the other hand, larger companies who do not have enough in common overall to merge will forge partnerships to offer complete solutions to customers.

We see some of this through the rise of Industrial Internet and IP organizations.

Collecting, moving, analyzing, and displaying data is becoming a big and important business. Customer executives will come to appreciate the work as their companies gain efficiency–and profits.

by Gary Mintchell | Jan 11, 2016 | Asset Performance Management, Automation, Internet of Things, Operations Management, Technology

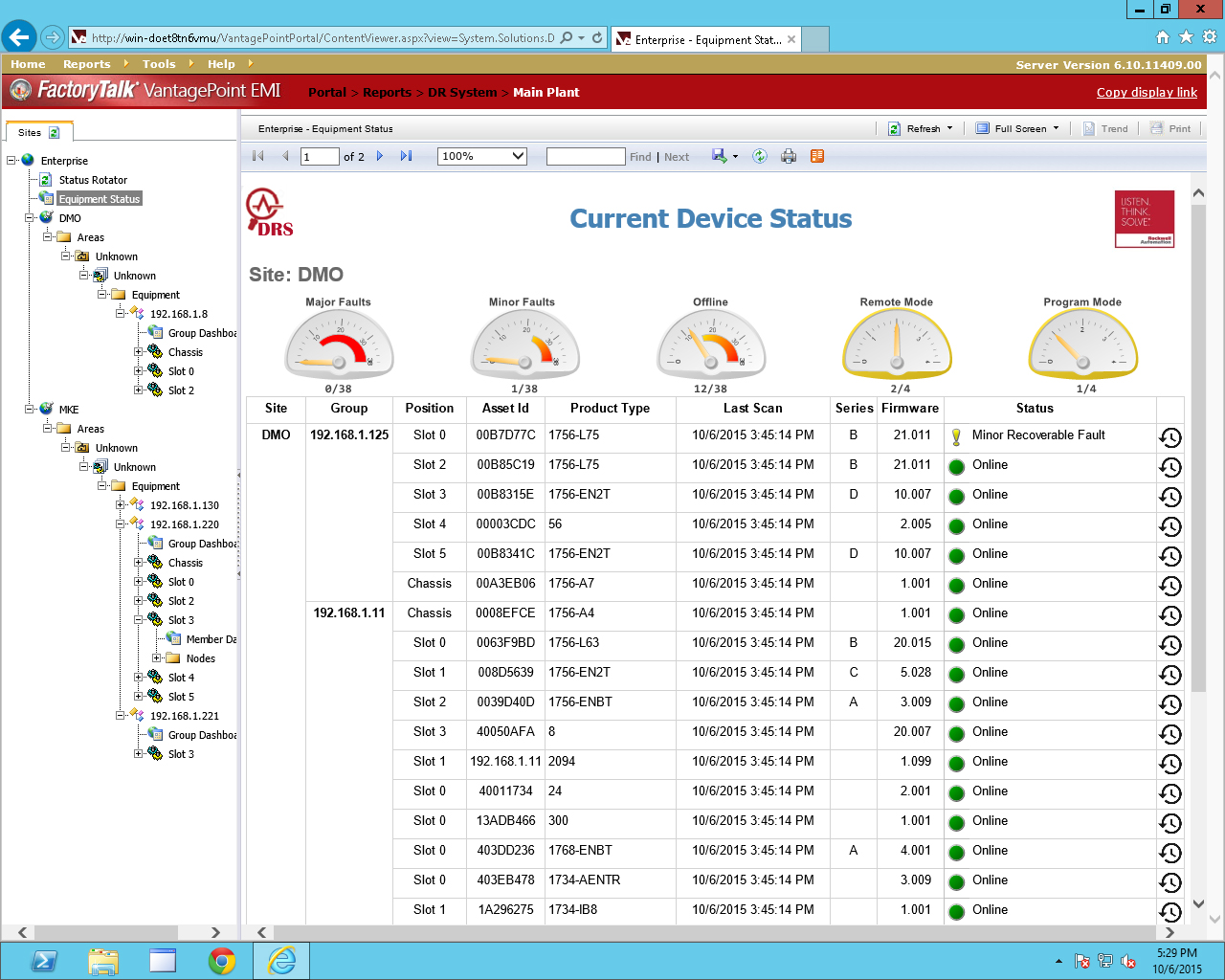

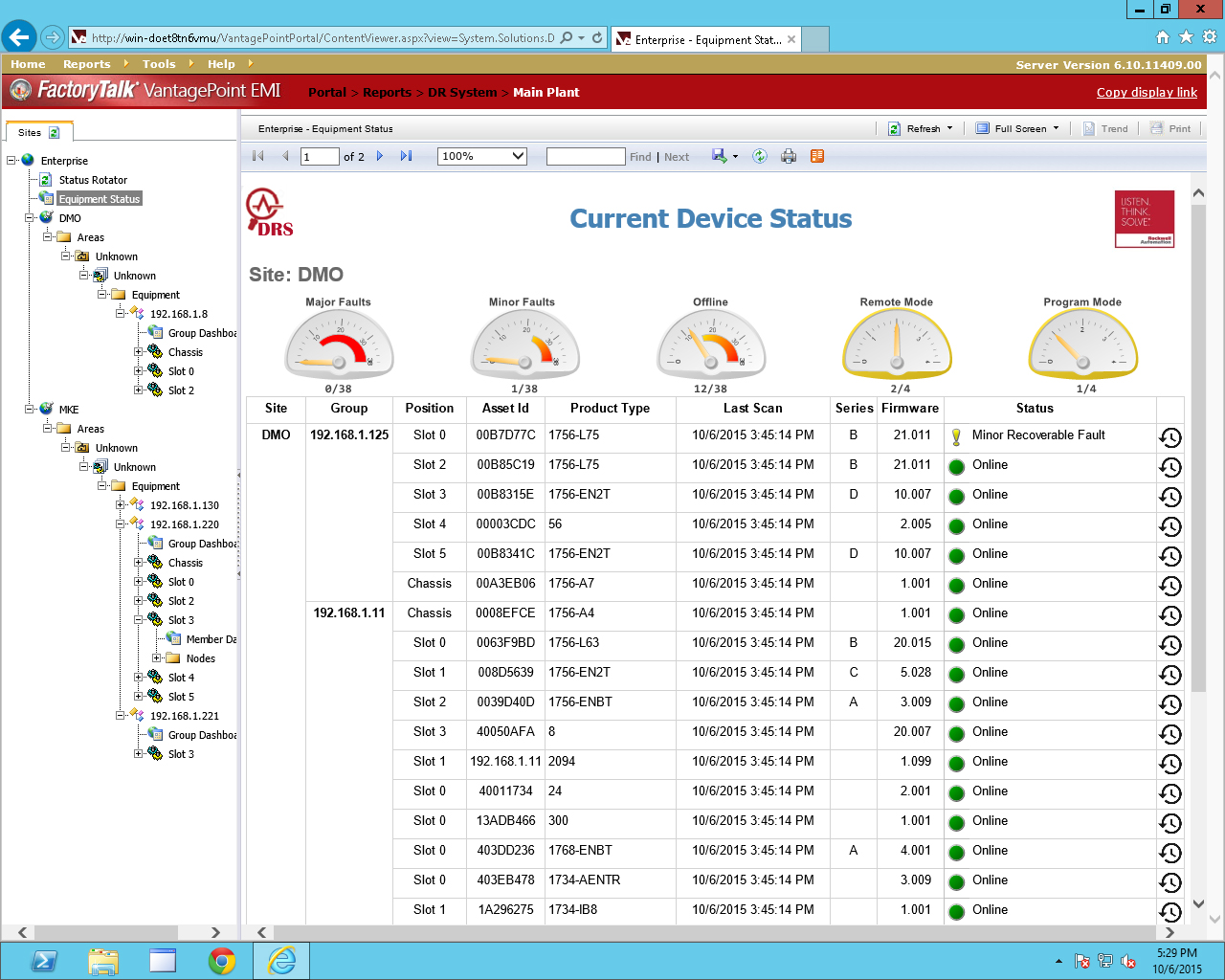

Remote monitoring and diagnostics is a key driver for the Internet of Things strategy adoption in manufacturing and production. Advances in both the technology and services involved in this area appears to be the area of best economic return these days.

Remote monitoring and diagnostics is a key driver for the Internet of Things strategy adoption in manufacturing and production. Advances in both the technology and services involved in this area appears to be the area of best economic return these days.

Rockwell Automation recently released news about its take on a diagnostic reliability service. Rockwell doesn’t tie it to the Internet of Things, much to its credit. But this solution fits within the broad trend I’ve seen developing.

The solution deploys a layer of technology across plant devices and equipment to monitor and perform analysis, and create a continuous improvement approach to reliability maintenance, reducing operational risk. As part of the service, a Rockwell Automation domain service expert also closely tracks equipment performance to advise on reliability improvements to the production facility.

“Our customers have access to a huge amount of data within their assets, but they often struggle to turn data into useful operational intelligence,” said Ryan Williams, product manager, Rockwell Automation. “In the past, companies relied on maintenance personnel on-site to check the status of equipment in the field and then develop corrective action plans. Now, with the diagnostic reliability service, they can transform maintenance data into asset intelligence. This helps build a more Connected Enterprise, leveraging interconnected data systems and producing actionable information. Companies can better prioritize choices on maintenance and production, and do more with less.”

The solution automatically collects identity and health data from all networked devices on the production control network. The data is then modeled with asset management information to trigger events and send alerts to necessary personnel for proactive maintenance. With the service, Rockwell Automation asset reliability professionals assist users in applying the intelligence on their critical equipment to inform data-driven maintenance decisions and increase productivity.

Case in diagnostics

Case in point: A major oil and gas company used the diagnostic reliability solution to help centralize information gathering and monitor hundreds of critical control assets across a California rural valley. The company also needed inventory of all the field devices in its process control network for a companywide cybersecurity policy. The automated identification and monitoring solution helped the company’s California business unit comply with the new corporate policy, reduce costs associated with field service manpower through proactive maintenance, and increase its daily oil production.

Through integrated, automated device identification and tracking, other customers using the diagnostic reliability service can realize approximately 70 percent reduction in manual data-collection time.

The diagnostic reliability offering is applicable to all manufacturers, with an industry emphasis including oil and gas, mining metals and cement, auto tire and rubber, and consumer packaged goods.

by Gary Mintchell | Oct 16, 2015 | Asset Performance Management, Automation, News, Operations Management, Process Control, Security, Technology, Wireless

This is another long post—and it is a summary—running through many of the new products introduced to the press and analysts durning Emerson Exchange 2015. If any of these whet your appetite, visit the Emerson Process Website for more information.

Another place to catch up on happenings at the conference is Jim Cahill’s Emerson Process Experts blog. He also has been introducing readers to highlighted sessions.

Machinery protection

CSI 6500 ATG protection system, a stand-alone machinery protection solution that allows users to cost-effectively introduce prediction monitoring of critical assets from the same system. Predictive intelligence is a key component to increasing availability and improving the reliability of plant assets.

These multi-functional cards can be easily reconfigured for a wide range of measurements, including the impacting or peak-to-peak data used in Emerson’s unique PeakVue technology. In addition to monitoring the start-up and coastdown of critical turbo machinery for safe operation, users will be able to utilize PeakVue technology to identify the earliest indications of developing faults in gearboxes and bearings.

With the CSI 6500 ATG, it is no longer necessary to return to the control room or open cabinets in the field to view or analyze data. The CSI 6500 ATG can be networked over wired or wireless Ethernet to deliver asset health information to authorized users through a PC or phone application.

To facilitate easy system integration with third party systems, CSI 6500 ATG is the first protection system to include a secure embedded OPC UA server.

Gas ultrasonic flow meter

A new Daniel gas ultrasonic flow meter platform elevates its well-proven British Gas design by providing two meters and transmitters in a single body to help natural gas operators and pipelines improve reliability and efficiency. Designed to maximize capital budgets by permitting two completely independent measurements with the installation of just a single flowmeter, the new 3415 (four-path + one-path) and 3416 (four-path + two-path) gas ultrasonic flow meters combine a four-path fiscal meter with an additional check meter, while the new 3417 (four-path + four-path) meter provides two fiscal meters for full redundancy and equal accuracy within one meter body. This two-in-one redundant design delivers continuous on-line verification of custody transfer measurement integrity, device health and process conditions, and improves fiscal metering confidence while ensuring regulatory compliance.

Both Daniel 3415 and 3416 gas ultrasonic meters measure flow using four horizontal chordal paths in addition to a reflective path dedicated to verification of the primary measurement, enabling improved metering insight, more informed decision making and simplified flow meter verification. For enhanced immunity to pipe wall contamination, the 3416 meter is equipped with an additional vertical reflective path to detect liquid or very thin layers of contamination at the bottom of the meter that otherwise remain completely hidden in a direct-path meter design. This allows reliable monitoring of process changes before they affect measurement, thus reducing calibration frequency and enabling maintenance to be condition-based instead of calendar-based.

Electric actuator control

DCMlink Software, a unified electric actuator control, monitoring and diagnostics platform, will allow, for the first time, Emerson customers to diagnose, configure, and monitor all electric actuators from a central location independent of protocol, actuator or host system. The software extends the useful life of field assets by providing actuator data gathering, condition monitoring, events log and prioritization of actuator alarms in a unified and consistent user interface. Actuator configuration includes custom characterization, as well as the ability to import and export historical configuration profiles.

Whether it is viewing value torque profile, live trending data or actionable alarms straight from the actuator, plant operators will be able to access detailed monitoring and diagnostics data, allowing them to take action before a fault occurs. DCMlink offers advanced control and diagnostics, including torque profile curves, initiating partial stroke test or emergency shut down and alarms in NE-107 format. Current communications support included Modbus, TCP-IP, and Bluetooth.

DeltaV v13

Version 13 (v13) of the DeltaV distributed control system (DCS) new features focus on integration, advanced alarm management, and security with an overarching design that improves ease of use and minimizes the need for specialized expertise.

DeltaV v13 delivers technologies to bring sources together for easy operator access and use. These technologies include an Ethernet I/O card (EIOC) for integrating Ethernet-based subsystems and devices, including a direct interface with smart motor control centers and substations. It improves the factory acceptance testing (FAT) experience by providing enhanced safety instrumented system simulation capabilities and easy-to-use virtualization environment.

The new DeltaV Alarm Mosaic has an intuitive alarm display that enables operators to more quickly identify, analyze, and respond correctly to the root cause of an abnormal process condition. The new release also provides trend display optimizations for better visibility of process changes.

SCADA

OpenEnterprise v3.2 release adds a native interface to the AMS Device Manager asset management software, enabling users to remotely manage and maintain HART and WirelessHART devices in wide-area SCADA networks.

OpenEnterprise v3.2 together with AMS Device Manager allows asset owners to extend the reach of their predictive maintenance capability out to their remote assets, providing a powerful and proactive method of diagnosing potential device problems remotely. This results in reduced trips to the field and helps to avoid unplanned process shutdowns, improving safety, reliability, and profitability.

The native interface of OpenEnterprise v3.2 to AMS Device Manager enables the collection of wired and wireless HART digital device data over low bandwidth wide-area SCADA networks from Emerson ROC, FloBoss, and ControlWave RTUs without adding the additional complexity and expense of external HART multiplexers. Support for AMS Device Manager SNAP-ON applications, OpenEnterprise SCADA server redundancy, multiple deployment options, and data collection for up to 10,000 HART devices ensures flexibility and scalability for a wide range of remote oil and gas applications.

Machinery health in PowerGen

Emerson now offers its power generation and water/wastewater industry customers native machinery health monitoring and protection capability within the Ovation distributed control system.

Ovation Machinery Health Monitor leverages the Ovation platform through a high-performance I/O module dedicated to machinery health functions. Simply install by inserting the module into a spare I/O slot.

With the Ovation Machinery Health Monitor, operators receive alerts from a single set of common plant HMIs and no longer need to manually check machinery functions through a separate system.

The Ovation Machinery Health Monitor also reduces the risk of cyber attack by eliminating links to standalone systems and isolating process information – all of which can help facilities meet NERC CIP and other security regulations.

Silica sensing

Costly damage to turbine blades caused by silica deposition can occur due to a poorly monitored steam purity program. The new Rosemount 2056 Silica Analyzer provides continuous accurate measurements of silica in process streams with a range of 0.5 ppb to 5000 ppb. The 2056’s usability features make it one of the easiest -to-use and high performing analyzers.

Harsh duty pressure sensing

Rosemount 3051S Thermal Range Expander with new UltraTherm 805 oil fill fluid enables pressure measurements by direct-mounting a diaphragm seal system to processes that reach up to 410°C (770°F) without requiring the challenging impulse piping or heat tracing used in traditional connection technology. In applications where ambient temperatures drop below ideal operating conditions, system response time becomes slow, resulting in delayed process pressure readings. Traditionally, this problem is solved by using heat tracing which is costly, maintenance intensive, and difficult to install. By using the new thermal range expander dual fill fluid seal, the Rosemount 3051S can reliably measure pressure at extremely high process and low ambient temperatures.

The Rosemount 3051S Electronic Remote Sensors (ERS) System now has safety certification. The ERS System calculates differential pressure through a digital architecture — and is now suitable for SIL 2 and 3 applications.

Rosemount 3051S High Static Differential Pressure Transmitter provides reliable flow measurement in high pressure applications with capabilities up to 15,000 psi (1034 bar). The transmitter’s SuperModule platform and coplanar design reduce potential leak points by 50 percent compared to traditional designs, ensuring the highest differential pressure measurement accuracy, field reliability and safety.

Corrosion monitoring

The Roxar Corrosion Monitoring system, consisting of wireless-based probes, will provide refineries with flexible, responsive, integrated and highly accurate corrosion monitoring.

Combined with the Emerson’s non-intrusive Field Signature Method (FSM) technology, a non-intrusive system for monitoring internal corrosion at the pipewall, refinery operators will be able to access more comprehensive corrosion information and corrosion rates, leading to improved operator insight and control over assets.

The system will also help identify and track opportunity/high TAN crudes and their corrosive elements. Such crudes are less expensive but more corrosive than others with the new system enabling the maximum amount of such crudes to be blended into the mix without increasing corrosion risk.

Wireless pressure gauge

Emerson Process Management has introduced the industry’s first WirelessHART pressure gauge. The Rosemount Wireless Pressure Gauge enables remote collection of field data.

The Wireless Pressure Gauge eliminates mechanical gauge common weak points by removing the components that inhibit the device from reporting/displaying pressure and providing up to a 10-year life, which reduces maintenance cost and time. The large 4.5-inch gauge face provides easy field visibility.

by Gary Mintchell | Oct 15, 2015 | Automation, News, Operations Management, Technology, Wireless

This is a long post, but it brings together several of the more important announcements from this week’s conference. I’ve seen bits of this coming as Emerson has moved its message to incorporate asset management over the past couple of years and is now taking the message to an even higher level in the customer organization. I find it interesting that it takes a holistic look at its product portfolio and then bundles it in such a way as to serve a higher purpose at the customer’s business.

This is a long post, but it brings together several of the more important announcements from this week’s conference. I’ve seen bits of this coming as Emerson has moved its message to incorporate asset management over the past couple of years and is now taking the message to an even higher level in the customer organization. I find it interesting that it takes a holistic look at its product portfolio and then bundles it in such a way as to serve a higher purpose at the customer’s business.

Steve Sonnenberg, Emerson EVP and Emerson Process Management president, said during the opening keynote to Emerson Global Users Exchange 2015, “Managers are looking for dramatic improvements. This is not a time to be satisfied to be as good as everyone else. All are talking top quartile performance. What do you do when all the usual approaches no longer work? Top companies are finding all new approaches. “

The phrase of the day was “Top Quartile Companies.”

Then the concept of improvements in project management and execution was introduced. Jim Nyquist, president of Emerson Systems and Solutions business, added, “Projects are in crisis. 65% of industry’s projects over $1 billion are failing. 33% of projects of $500 million. It seems the larger the project the larger the overrun.”

Global market means more competition leading to increases in the scale of projects.

What’s needed to rein in this runaway stage coach? Nyquist declared that design, engineering, and project management need a reset. Budgets need a resent and predictability and reliability must be improved. Top quartile projects are completed at half the cost and half the schedule of 4th quartile companies. “Industry is at inflection point,” he predicted.

Project Certainty

Then he announced the launch of Project Certainty, an innovative technology- and engineering-based approach for improved capital efficiency and more reliable project schedules.

Emerson’s Project Certainty begins with early engagement during engineering and design studies to define project goals and high impact strategies to meet those goals. Despite traditionally accounting for approximately 4 percent of a project investment, automation is revealing unique and repeatable ways to eliminate cost, reduce complexity and accommodate late-stage project changes, beyond the automation discipline.

For example, Project Certainty relies on the right design engineering strategy to eliminate centralized control system room requirements by 70 to 80 percent, and can eliminate piping in some applications up to 50 to 60 percent. Additionally, tens of millions of dollars in capital spare parts can be eliminated through project-wide equipment reliability analysis.

“Project Certainty also tackles complexity by decoupling the dependencies suppliers have on each other, eliminating bottlenecks and allowing concurrent work streams,” said Nyquist. “Likewise, we are addressing the complexity of data and documentation with innovative technologies that provide features like a single source of project data as well as automated documentation.”

Addressing one of the greatest project vulnerabilities, Project Certainty significantly improves project schedule performance. Technologies like Electronic Marshalling with CHARMs, and pervasive wireless field instrumentation are helping project teams accommodate inevitable last-minute design changes without impacting schedule.

“The path to Top Quartile project performance is right in front of us,” said Nyquist. “The technologies and proven methodologies are here. It will take collaboration and commitment to eliminate outdated project approaches and drive change into the industry.”

Data Link

Part of this new environment is Project Data Link, a project engineering environment that helps reduce complexity and accommodate changes in capital projects. As projects become more complex with multiple contractors and stakeholders, Project Data Link helps keep projects off the critical path by efficiently and consistently translating project information, including tag databases and instrument indices, from multiple sources into project deliverables. It mitigates project risk by normalizing specifications into a single data source with traceability and an integrated change-management system.

Project Data Link gives multiple suppliers, engineering firms, and other stakeholders access to project information including specifications related to field devices and the distributed control system (including control logic and configuration). In addition, data provided in various formats are normalized so that all information is available in a single, consolidated standard view.

The integrity of project information is especially important during late project changes. The data link is always up to date, so when a change is initiated Project Data Link automatically reconciles it against what is in the system, identifies what needs to be changed, automatically sends updates to the DeltaV distributed control system and provides an audit trail of what has changed. This saves time and eliminates errors during the critical late stages of the project.

“Moving forward to improve project certainty, Emerson continues to find methods to reduce the risk of project errors, accommodate change and improve engineering efficiency,” said Randall Fong, project technical manager. “We are confident that Project Data Link will help our customers move towards on-budget and on-time projects.”

Smart Commissioning

Here is yet another part of the portfolio of improving products–Smart Commissioning, a technology-enabled process that reduces automation commissioning time and effort. Smart Commissioning helps automation projects meet strict and shifting deadlines by reducing trips to the field, eliminating tasks, and accommodating late project changes. Smart Automation Commissioning builds on advances made possible by the combination of the DeltaV distributed control system (DCS) Electronic Marshalling with CHARMs and AMS Device Manager Software to remove automation from the critical path of projects.

With the release of version 13 software for the DeltaV DCS and AMS Suite, Smart Commissioning brings ease to automation project implementation. From the initial device connections to final system testing, users save money as they shave weeks off the project schedule by reducing time spent on automation commissioning activities.

Upon arrival at a project site, pre-tagged smart devices can be connected immediately to any channel in a nearby junction box — no need to wait for wiring designs to be complete. Smart Commissioning also eliminates potential errors by automatically finding and identifying all smart devices, then binding them to the configuration. To further accelerate implementation, the device configuration is pushed to all devices based on pre-configured templates. Testing is easily and safely done from the control room by using digital communication, requiring no personnel in the field for confirmation.

“With Smart Commissioning, members of the project team can more easily meet tight project timelines and are not hampered by late design changes,” said Mark Howard, vice president of project execution for Emerson Process Management. “Developed based on industry experience, this solution is another step from Emerson toward attaining project certainty for users.”

Projects in Action

Sasol, an international energy and chemical company, has selected Emerson Process Management to help automate its $8.9 billion petrochemical complex in Lake Charles, La., designed to take advantage of abundant, low cost natural gas. The automation project is one of the largest in history awarded to Emerson.

When completed sometime in 2018, the massive petrochemical complex will more than triple Sasol’s chemical production capacity in the United States. The complex includes an ethane cracker that will produce 1.5 million tons of ethylene annually, as well as six chemical manufacturing plants designed to convert the ethylene into a diverse range of chemicals. Ethylene is a key ingredient in the production of plastics, detergents, anti-freeze, and other petrochemical products.

Emerson Process Management implemented a detailed engineering and project execution plan designed to mitigate project risks, lower costs and reduce time to completion, all part of the company’s strategic Project Certainty initiative.

“For a project of this scale, managing budget and schedule risk is paramount,” said Jim Nyquist, group vice president of Emerson. “This is a great example of our Project Certainty initiative. Early engineering and design work is being used to identify opportunities for automation technology to reduce complexity, create project cost savings, and reduce schedule and cost risks. As the project moves into the execution phase, Emerson is well-positioned to implement the design, accommodate late changes and reduce on-site work – all of which speed execution without compromising quality, safety or reliability.”

I just attended an amazing conference, Industry of Things World USA, in San Diego. Internet of Things was discussed from many angles. The nonstop pace is the reason for no posts for two days. The 400 attendees, about 10% women, gathered from 28 countries and 234 companies. 21 companies sponsored the event, and I was one of the media sponsors. The high profile speakers, ranging from an Undersecretary of the Dept. of Commerce to Harvard Business School professor and author Michael Porter.

I just attended an amazing conference, Industry of Things World USA, in San Diego. Internet of Things was discussed from many angles. The nonstop pace is the reason for no posts for two days. The 400 attendees, about 10% women, gathered from 28 countries and 234 companies. 21 companies sponsored the event, and I was one of the media sponsors. The high profile speakers, ranging from an Undersecretary of the Dept. of Commerce to Harvard Business School professor and author Michael Porter. Jeff Jaffe, president of W3C–the worldwide web consortium, discovered the importance of metadata and interoperability of data among apps. RESTful interfaces lie on the standards roadmap. Everyone seems to want to rename the IoT in their own way. For Jaffe, it is the Web of Things. “The Web is fueling a transition from costly monolithic software to an open market of apps. Check out the diagram showing his idea that Web technologies can enable vertical & horizontal integration. These go vertically field level to business level (low to high levels of abstraction) and horizontally as integration along supply chain to integration along the value chain.

Jeff Jaffe, president of W3C–the worldwide web consortium, discovered the importance of metadata and interoperability of data among apps. RESTful interfaces lie on the standards roadmap. Everyone seems to want to rename the IoT in their own way. For Jaffe, it is the Web of Things. “The Web is fueling a transition from costly monolithic software to an open market of apps. Check out the diagram showing his idea that Web technologies can enable vertical & horizontal integration. These go vertically field level to business level (low to high levels of abstraction) and horizontally as integration along supply chain to integration along the value chain.

Predictive maintenance benefits more from implementation of the Internet of Things than perhaps any other function at this early stage of wide-spread adoption.

Predictive maintenance benefits more from implementation of the Internet of Things than perhaps any other function at this early stage of wide-spread adoption.

Remote monitoring and diagnostics is a key driver for the Internet of Things strategy adoption in manufacturing and production. Advances in both the technology and services involved in this area appears to be the area of best economic return these days.

Remote monitoring and diagnostics is a key driver for the Internet of Things strategy adoption in manufacturing and production. Advances in both the technology and services involved in this area appears to be the area of best economic return these days.