by Gary Mintchell | Nov 10, 2015 | Automation, Industrial Computers, Internet of Things, Networking, News

When we wish to bring new technologies into industrial applications–especially connectivity ones, devices known as gateways bridge the gap from old to new.

For example, when we were moving toward a variety of industrial wireless protocols and some analysts and engineers were concerned about a multiplicity of connectivity points and networks, I told them that gateways would be a solution on the path to complete integration. I guess I learned that in the 80s when my first resource for computing connectivity problems was a great catalog from “Black Box.”

I wrote previously about Dell’s announced Internet of Things Gateway. Two additional ones have hit my Inbox.

First–Mentor Graphics

Mentor Graphics Corporation announced the availability of the embedded industry’s first [note: marketing people are never shy] customizable edge-to-cloud IoT solution that enables companies to get to market quickly while reducing risk, cost, and development cycles. The Mentor IoT solution comprises a customizable IoT gateway System Design Kit (SysDK), a cloud backend, and runtime solutions on which to build a wide array of IoT edge devices. It enables the most demanding IoT requirements with support from 8-bit microcontrollers to the latest 64-bit microprocessors, and deployments of 100,000+ gateways each supporting dozens of edge devices.

Customizable Gateway Reference Design

Mentor Graphics provides a feature-rich hardware and software gateway platform that can be used as-is or customized in both hardware and software to meet specific gateway requirements, including compatibility with legacy and new IoT deployments. The Gateway SysDK reference hardware utilizes the ARM Cortex-A9 based i.MX 6 series applications processor from Freescale Semiconductor.

The base reference software includes a rich Linux BSP with full support for the reference board. To support secure convergence, the Mentor Gateway SysDK can be customized to include secure gateway partitions using ARM TrustZone, which enables secure applications such as certificate management and secure remote firmware upgrades. The integration of cloud middleware supports the functionality provided from the cloud backend. By leveraging the Gateway SysDK, customers can move from concept to production in as little as eight weeks.

Connected and Secure from Edge to Enterprise

The Mentor Graphics end-to-end IoT solution includes support for a comprehensive set of physical connections complemented by a breadth of IoT and cloud protocols for wired and wireless edge device aggregation, and secure communication between the cloud backend, gateway, and edge devices. End-to-end security is provided for data communications, access control, software execution, and intrusion detection. Security integration with enterprise IT infrastructure is provided by Icon Labs’ Floodgate for McAfee ePO.

Second, Advantech

Advantech’s Industrial Automation Group announced the UNO-1252G industrial computer designed to act as a gateway for industrial applications. As small as a micro-sized PLC, the UNO-1252G is only 10cm high and DIN-rail mountable. It comes with a low power Intel Quark processor which only uses 10 watts but powerful enough to perform data transmission and sensing in IoT gateway applications.

Advantech’s Industrial Automation Group announced the UNO-1252G industrial computer designed to act as a gateway for industrial applications. As small as a micro-sized PLC, the UNO-1252G is only 10cm high and DIN-rail mountable. It comes with a low power Intel Quark processor which only uses 10 watts but powerful enough to perform data transmission and sensing in IoT gateway applications.

Gateway computers are useful because they help to connect legacy devices to the IoT without needing to replace the entire infrastructure. This small, economic UNO-1252G is ideal for this purpose since it has an array of integrated I/O ports and the ability to expand even further by using a choice of iDoor modules which is Advantech’s new modular way of adding versatile functionality to choose functions that are needed without purchasing devices that have excess cost or functions that are not needed. iDoor modules can be used to add additional cards such as Wi-Fi and GPS making the UNO-1252G ideal for use in remote locations.

The UNO-1252G includes one GB SD card to run a Yocto Project Linux distribution. The Yocto Project is an open source Linux distribution which allows the development of applications using an SDK. The UNO-1252G supports Advantech software applications such as SUSIAccess for remote control and monitoring. Also, two 10/100 LAN ports, a mPCIe card slot, five LED indicators for power, battery, SD card, COM ports and three programmable indicators to assign your own functions.

by Gary Mintchell | Jul 14, 2015 | Automation, Industrial Computers, News, Security, Technology

Potentially viable start-ups are rare in the industrial automation space. Recently Russ Fadel, Rick Bullotta, and John Richardson did it with ThinkWorx an Internet of Things oriented software they sold to PTC. That was their second effort having previously sold Lighthammer to SAP.

Potentially viable start-ups are rare in the industrial automation space. Recently Russ Fadel, Rick Bullotta, and John Richardson did it with ThinkWorx an Internet of Things oriented software they sold to PTC. That was their second effort having previously sold Lighthammer to SAP.

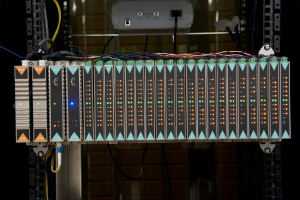

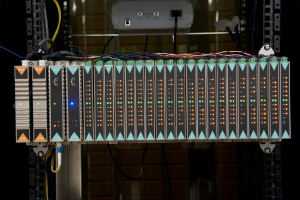

Now we have Albert Rooyakkers, CTO and inventor, and Bob Honor, president and former VP at Rockwell Automation and GE Intelligent Platforms, releasing a new industrial control system and company—Bedrock Automation. This company was introduced to Manufacturing Connection readers last December.

This is a tough area for an entrant. I’ve watched the rise and fall of PC-based control from back in the late 90s. Rockwell Automation and Siemens are so entrenched in the market. The next tier is solid with AutomationDirect, B+R Automation, Beckhoff Automation, Mitsubishi, and Schneider Electric.

When you develop a product for a crowded market, you basically have to execute one of two strategies. Either you think that the products have reached commodity status and that you can make them better, faster, cheaper (at least the last two). Or, you totally disrupt the industry by bringing out something that does what others do better—and adds some significant new features and benefits.

Disruptive?

Bedrock Automation executives believe they have accomplished the latter. The design begins with built-in cyber security. Its patented architecture features a pin-less, electromagnetic backplane. It addresses “virtually all control applications with fewer than a dozen part numbers, reducing cyber attack vectors, cutting lifecycle costs, and simplifying engineering, commissioning and maintenance.”

“Starting from a blank sheet of paper while inventing and deploying advanced semiconductor, mechanical design, cyber computing and communication technologies has resulted in a completely new automation platform. The future is now,” said Bedrock Automation CTO and Engineering VP, Albert Rooyakkers.

Commitment to simple, elegant design is a core tenet of the system. Bedrock delivers I/O, power and communications across the pin-less electromagnetic backplane with a parallel architecture that supports ultra fast scan times regardless of I/O count. The removal of I/O pins improves reliability and increases cyber security while forming a galvanic isolation barrier for every I/O channel. This innovative backplane also allows installation of I/O modules in any orientation and location for “unprecedented” flexibility in I/O and cable management.

Secure I/O modules use layers of advanced technology to deliver software-defined I/O for universal analog, discrete, Ethernet and Fieldbus signal types. A secure power module is functionally and physically coupled to the backplane to deliver single and dual redundant cyber secure power for the control system. A secure universal controller can run virtually every application independent of size or control task: discrete, batch, continuous, or multivariable control from one device that supports as few as ten, to as many as thousands of I/O points. No longer are separate programmable logic controllers (PLC) and distributed control systems (DCS) required.

“As cyber threats to all industries grow, traditional control system vendors respond by adding cost and complexity to their legacy technology. With deep roots in both automation and semiconductors, and unburdened by legacy, Bedrock Automation has created not only the most cyber secure system available today but we have also established new benchmarks for performance, scalability and affordability,” said Bedrock Automation President, Bob Honor.

Layers of protection

Replacing pins with an electromagnetic backplane is one of many layers of cyber security protection that Bedrock Automation has implemented. Additional cyber security layers include:

- A real time operating system with the highest safety (SIL 4) and security (EAL6+) rating of any RTOS available today

- Cyber secure microcontrollers with encrypted keys and TRNG embedded in all system modules including the controller, power supply and I/O

- All modules encased in anti-tamper metal that is impenetrable without metal cutting tools

- Authentication extending throughout the supply chain, including third party software and applications

Adding so many layers of protection to a conventional DCS, SCADA RTU, PAC or PLC would add cost and complexity and degrade performance. With Bedrock, they were built in from the start.

“Brown Engineers is excited to join the Bedrock revolution. Clients in our focus markets of electric, water, and sewer utilities, are increasingly concerned about cyber security and are confident that installing Bedrock will give them peace of mind to tell their ratepayers and their board members that they are taking every precaution to protect their processes. Brown Engineers demonstrates its continued commitment to keeping clients on the forefront of technical innovation,” said Dee Brown of Brown Engineers, an industrial systems integration firm based in Little Rock, Arkansas.

Open, flexible engineering

Bedrock delivers an Integrated Development Environment (IDE) based on an open IEC 61131 software toolset that supports embedded OPC UA. The IDE enables users to develop, operate and authenticate control for a vast array of PLC, SCADA and DCS applications. Fewer components means fewer panel layouts and wiring diagrams to contend with. Software configurable I/O can be changed in the field with the click of a mouse. Ninety percent fewer I/O module types means fewer spare parts to keep and manage. Such innovations contribute to reducing overall engineering design costs by up to 33 percent.

“Bedrock is the first unique platform to enter the control market in the last 15 years. It diverges radically from the typical platforms and is superior in terms of processing power, redundancy, scalability, security and cost efficiency. We plan to use it as a point of differentiation for our business,” said Chris McLaughlin of Vertech, a Phoenix-based industrial systems integrator.

Pricing and availability

The Bedrock control system is available now in baseline configuration starting at $20,000 MSRP. A growing network of world-class system integrators and automation solution providers is available to provide local sales and support.

For more information about the Bedrock revolution, download the first white paper in the series: Revolution – Chapter One: The Backplane.

by Gary Mintchell | Jun 18, 2015 | Automation, Internet of Things, Networking, News, Operations Management, Security

The Cisco and Rockwell Automation partnership continues its step-by-step extension strengthening Rockwell’s “Connected Enterprise” strategy. This strategy builds on the foundation of EtherNet/IP and CIP (common industrial protocol). Now that all the magazines and newspapers and bloggers are writing about the Internet of Things and the Industrial Internet of Things, supplier communications managers cannot keep themselves from applying IoT to everything their companies do.

The two companies have issued two press releases recently. One concerns enhanced training couched in the strategy of bringing IT and OT together (the once and future kingdom). The other relates to extensions and additions to the partners’ reference architecture.

First, let’s see how many buzz words a marketing manager can fit into one sentence:

“The expansion of the Industrial Internet of Things (IoT) and convergence of operations technology (OT) and information technology (IT) systems into The Connected Enterprise raises questions of who within industrial organizations should design and oversee unified network infrastructures. Rockwell Automation, in collaboration with its Strategic Alliance partner Cisco, is helping address this workforce challenge with the new training and certification offerings.”

Last year, the companies jointly rolled out the Managing Industrial Networks with Cisco Networking Technologies (IMINS) training course and Cisco Industrial Networking Specialist certification. This first-of-its-kind course provided foundational skills needed to manage and administer networked, industrial control systems.

This year, Rockwell Automation and Cisco are unveiling the five-day, hands-on Managing Industrial Networks for Manufacturing with Cisco Technologies (IMINS2) course and CCNA Industrial certification exam. The course offers deeper analysis of EtherNet/IP architectures with industrial protocols, wireless and security technologies implementation, and advanced troubleshooting. The CCNA Industrial certification ensures that OT and IT professionals have the skillset needed to design, manage and operate converged industrial networks.

Pathways to Certification

Students who successfully complete the Industrial Networking Specialist and CCNA Industrial certification exams will earn CCNA Industrial certification. Alternatively, IT and OT professionals that already have their CCNA Routing & Switching or Cisco Certified Entry Networking Technician (CCENT) certification can enroll directly in IMINS2 and take the CCNA Industrial certification exam to receive CCNA Industrial certification. Once completed, the certification is valid for three years.

Participants in the IMINS and IMINS2 courses will receive exam vouchers for the Industrial Networking Specialist and CCNA Industrial certification exams, respectively, as part of course tuition. This offer is only available through courses offered and delivered by Rockwell Automation. The CCNA Industrial certification exam can be taken at one of any Pearson VUE testing centers located in more than 165 countries.

IMINS courses are offered on an ongoing basis. The enrollment schedule for IMINS2 will be posted in June, with classes beginning in July. As the leader in OT/IT skills development, Rockwell Automation will continue to invest in The Connected Enterprise and IoT training curriculum to address emerging skills requirements.

Converged Plantwide Ethernet Architectures (CPwE)

As industrial markets evolve to unlock the promise of the Internet of Things (IoT), Rockwell Automation and Cisco are announcing new additions to their Converged Plantwide Ethernet (CPwE) architectures to help operations technology (OT) and information technology (IT) professionals address constantly changing security practices. The latest CPwE security expansions, featuring technology from both companies, include design guidance and validated architectures to help build a more secure network across the plant and enterprise.

The Industrial IoT is elevating the need for highly flexible, secure connectivity between things, machines, work flows, databases and people, enabling new models of policy-based plant-floor access. Through these new connections, machine data on the plant floor can be analyzed and applied to determine optimal operation and supply-chain work flows for improved efficiencies and cost savings. A securely connected environment also enables organizations to mitigate risk with policy compliance, and protects intellectual property with secure sharing between global stakeholders.

Core to the new validated architectures is a focus on enabling OT and IT professionals to utilize security policies and procedures by forming multiple layers of defense. A defense-in-depth approach helps manufacturers by establishing processes and policies that identify and contain evolving threats in industrial automation and control systems. The new CPwE architectures leverage open industry standards, such as IEC 62443, and provide recommendations for more securely sharing data across an industrial demilitarized zone, as well as enforcing policies that control access to the plantwide wired or wireless network.

Rockwell Automation and Cisco have created resources to help manufacturers efficiently deploy security solutions. Each new guide is accompanied by a white paper summarizing the key design principles, as follows:

The Industrial Demilitarized Zone Design and Implementation Guide and white paper provide guidance to users on securely sharing data from the plant floor through the enterprise.

The Identity Services Design and Implementation Guide and white paper introduce an approach to security policy enforcement that tightly controls access by anyone inside the plant, whether they’re trying to connect via wired or wireless access.

This announcement further extends the commitment by Rockwell Automation and Cisco to be one of the most valuable resources in the industry for helping manufacturers improve business performance by bridging the gap between plant-floor industrial automation and higher-level information systems.

by Gary Mintchell | May 4, 2015 | Automation, Data Management, Internet of Things, Manufacturing IT, Networking, News, Operations Management, Technology

For being so quiet for so long, the OPC Foundation is certainly hitting the news often lately. There was news about a couple of open-source initiatives. Then the Foundation itself opened up a little with an “open-shared” program.

For being so quiet for so long, the OPC Foundation is certainly hitting the news often lately. There was news about a couple of open-source initiatives. Then the Foundation itself opened up a little with an “open-shared” program.

Then it was announced as the communication platform of Industry 4.0 in Germany.

Now a couple European automation rivals—Beckhoff Automation (Germany) and B&R Automation (Austria)—have made OPC news.

Taken in sum, these announcements plus the earlier ones reveal the importance of OPC to industrial communication. It became a standard for moving important data from control systems to human-machine interface systems and then on to SCADA and MES systems.

With the introduction of UA built on modern software technologies including built-in security and embeddable format, the technology everyone used but also everyone dissed finds itself on the cutting edge of modern connected industrial Internet strategies.

OPC and Beckhoff

News coming from last month’s Hannover Messe included this joint announcement from OPC and Beckhoff.

OPC UA is about scalable communication with integrated security by design up to MES / ERP systems and into the cloud, EtherCAT is about hard real-time capability in machines and factory control systems. Both technologies complement each other perfectly.

Industrie 4.0 and Internet of Things (IoT) architectures require consistent communication across all levels while using Internet technologies: both in as well as outside of the factory, for example to cloud-based services. That exactly is what the OPC Foundation and the EtherCAT Technology Group (ETG) want to account for by defining a common definition of open interfaces between their respective technologies.

At the Hanover Fair Thomas J. Burke, President and Executive Director of the OPC Foundation and Martin Rostan, Executive Director of the ETG signed a Memorandum of Understanding in which both organizations agree to closely co-operate developing these interfaces.

OPC and B&R

Not to be outdone, B&R Automation issued a press release announcing it will be supporting the OPC Foundation’s new real-time technology working groups, whose goal is to add real-time capability to the OPCUA communication standard. This will involve two key additions to the OPCUA standard. The first is a publisher-subscriber model; the other is utilization of the IEEE 802.1 standard for time-sensitive networking (TSN).

B&R will be contributing its real-time expertise to the working groups. “The updates to the OPC UA standard will benefit from our years of experience in developing real-time solutions,” says Stefan Schönegger, marketing manager at B&R.

OPC UA uses a publish/subscribe network model. B&R is the main proponent of PowerLink. PowerLink uses publish/subscribe technology, too. So, B&R wants to show compatibility.

“This is a fundamental requirement for the M2M communication you find in integrated systems such as packaging lines,” explains Schönegger.

In order to fulfill real-time requirements, the OPC UA standard will make use of the IEEE 802.1 TSN standard. “At the moment, TSN is still a working title for a group of new IEEE standards designed to provide native real-time capability for the IEEE 802 Ethernet standard,” says Schönegger. This would allow for a seamless transition to substantially faster Ethernet standards such as POWERLINK for field-level communication and demanding motion control tasks.

Beyond the automation industry, TSN is currently also being evaluated by the automotive and telecommunications industries. “The first cars based on TSN are expected to hit the market in the very near future,” reports Schönegger. This would help secure the widespread availability of this technology. In addition to B&R, the new OPC working groups will be also supported by other leaders in the field of automation, as was announced by KUKA on April 13, 2015.

OPC UA already plays a central role in the IT-related areas of modern production systems. “The addition of TSN and the publisher-subscriber model will greatly expand the range of potential OPC UA applications,” says Schönegger.

Takeaway

What all this means is that OPC can now become even faster and more usable than before. The little protocol that everyone uses and everyone complains about is getting cred as it becomes more modern. These technological advances should make it more valuable. And that will be significant in this new connected enterprise era.

by Gary Mintchell | Mar 30, 2015 | Automation, Internet of Things, News, Operations Management, Technology

Developing testbeds for testing development of technology extensions seems to be hot right now. The Smart Manufacturing Leadership Coalition has a couple going in conjunction with US government money. There is a bid out from the US government for development of some more, also related to energy efficiency.

The Industrial Internet Consortium announced its first energy-focused testbed: the Communication and Control Testbed for Microgrid Applications. Industrial Internet Consortium member organizations Real-Time Innovations (RTI), National Instruments, and Cisco, are collaborating on the project, working with power utilities CPS Energy and Southern California Edison. Additional industry collaborators include Duke Energy and the power industry organization – Smart Grid Interoperability Panel (SGIP).

I recently saw where an analyst positioned the IIC with the German Industry 4.0 initiative–while ignoring the US Smart Manufacturing group altogether. These advanced manufacturing strategies are showing some growth. Both of these have commercial technology companies solidly behind them. I would think that they will have more impact in the long run than SMLC. But we’ll see.

Here is some background from the IIC press release. “Today’s power grid relies on a central-station architecture not designed to interconnect distributed and renewable power sources such as roof-top solar and wind turbines. The system must over-generate power to compensate for rapid variation in power generation or demands. As a result, much of the benefit of renewable energy sources in neighborhoods or businesses is lost. Efficiently integrating variable and distributed generation requires architectural innovation.”

The goal of the Communication and Control Testbed is to introduce the flexibility of real-time analytics and control to increase efficiencies in this legacy process – ensuring that power is generated more accurately and reliably to match demand. This testbed proposes re-architecting electric power grids to include a series of distributed microgrids which will control smaller areas of demand with distributed generation and storage capacity.

These microgrids will operate independently from the main electric power grid but will still interact and be coordinated with the existing infrastructure.

The testbed participants will work closely with Duke Energy, which recently published a distributed intelligence reference architecture, as well as SGIP to help ensure a coordinated, accepted architecture based on modern, cross-industry industrial internet technologies.

The Communications and Control framework will be developed in three phases that will culminate in a field deployment that will take place at CPS Energy’s “Grid-of-the-Future” microgrid test area in San Antonio, Texas.

The initial phases will be tested in Southern California Edison’s Controls Lab in Westminster, CA.

Advantech’s Industrial Automation Group announced the UNO-1252G industrial computer designed to act as a gateway for industrial applications. As small as a micro-sized PLC, the UNO-1252G is only 10cm high and DIN-rail mountable. It comes with a low power Intel Quark processor which only uses 10 watts but powerful enough to perform data transmission and sensing in IoT gateway applications.

Advantech’s Industrial Automation Group announced the UNO-1252G industrial computer designed to act as a gateway for industrial applications. As small as a micro-sized PLC, the UNO-1252G is only 10cm high and DIN-rail mountable. It comes with a low power Intel Quark processor which only uses 10 watts but powerful enough to perform data transmission and sensing in IoT gateway applications.