by Gary Mintchell | Oct 16, 2013 | Automation, Events, News, Operations Management, Process Control, Software, Technology

This is day two of the Invensys industrial software user conference in Dallas. The atmosphere is on of energy and enthusiasm. It’s an impressive event.

This is day two of the Invensys industrial software user conference in Dallas. The atmosphere is on of energy and enthusiasm. It’s an impressive event.

Invensys people here, just as at the Foxboro/Triconex conference last month, are optimistic about the pending acquisition by Schneider Electric. By the way, the shareholders have approved the acquisition. Now the decision rests with all the various governmental regulatory agencies. Mike Caliel will be the Invensys lead on the integration team—which can’t do anything until all the approvals are received and the deal is final.

Mike took some time out of a busy schedule to chat about Schneider and the software business. Norm Thorlakson, global head of Invensys’ HMI and Supervisory software business, joined us for most of the conversation.

To get the Schneider conversation out of the way, I asked several questions about a post-acquisition Schneider and Invensys knowing that Mike couldn’t answer with any detail. He absolutely cannot comment on Citect—its history and place within the structure. Regarding the Invensys Wonderware partner ecosystem, he could only say that Schneider knows about the importance of partners as the way Invensys software goes to market. But although integration teams have been formed on each side, they cannot begin work until all the approvals are obtained.

My biggest takeaway from two Invensys conferences is the confident optimism of all the Invensys people. The company is filled with intelligent, experienced people, and the Schneider CEO is on record saying he respects that.

I’ll write more on the outlook of a post-acquisition Schneider in the market later. But the combined company should have a considerable impact on the market.

Spiral Crude Assay Management

Mike and Norm also discussed the trends in software that Invensys is capitalizing on—and leading in many ways. In the age of “Big Data”, contextualization is the key to information. The ability to synthesize date into actionable information so that customers have a safe and reliable plant continues to be the focus.

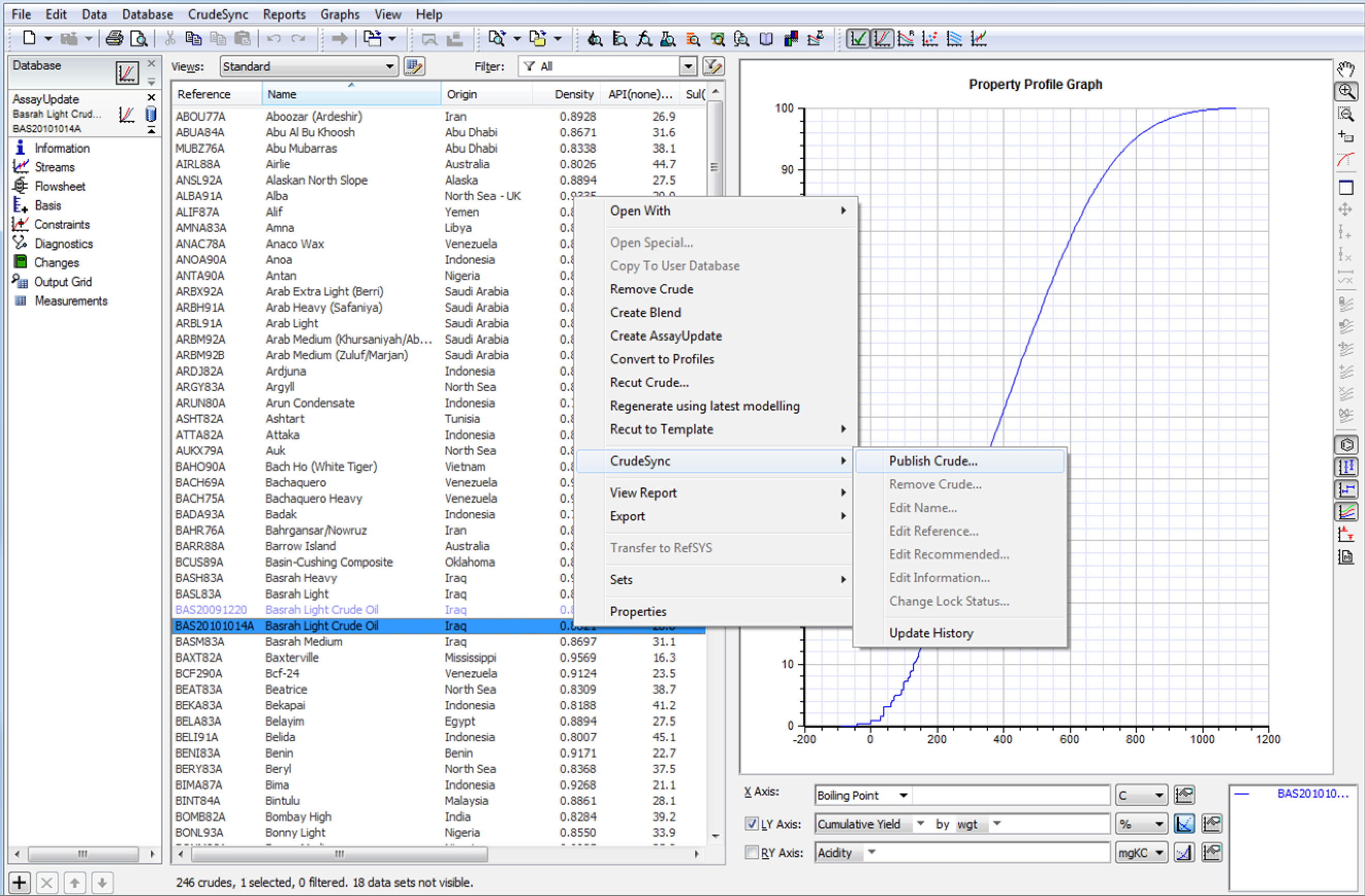

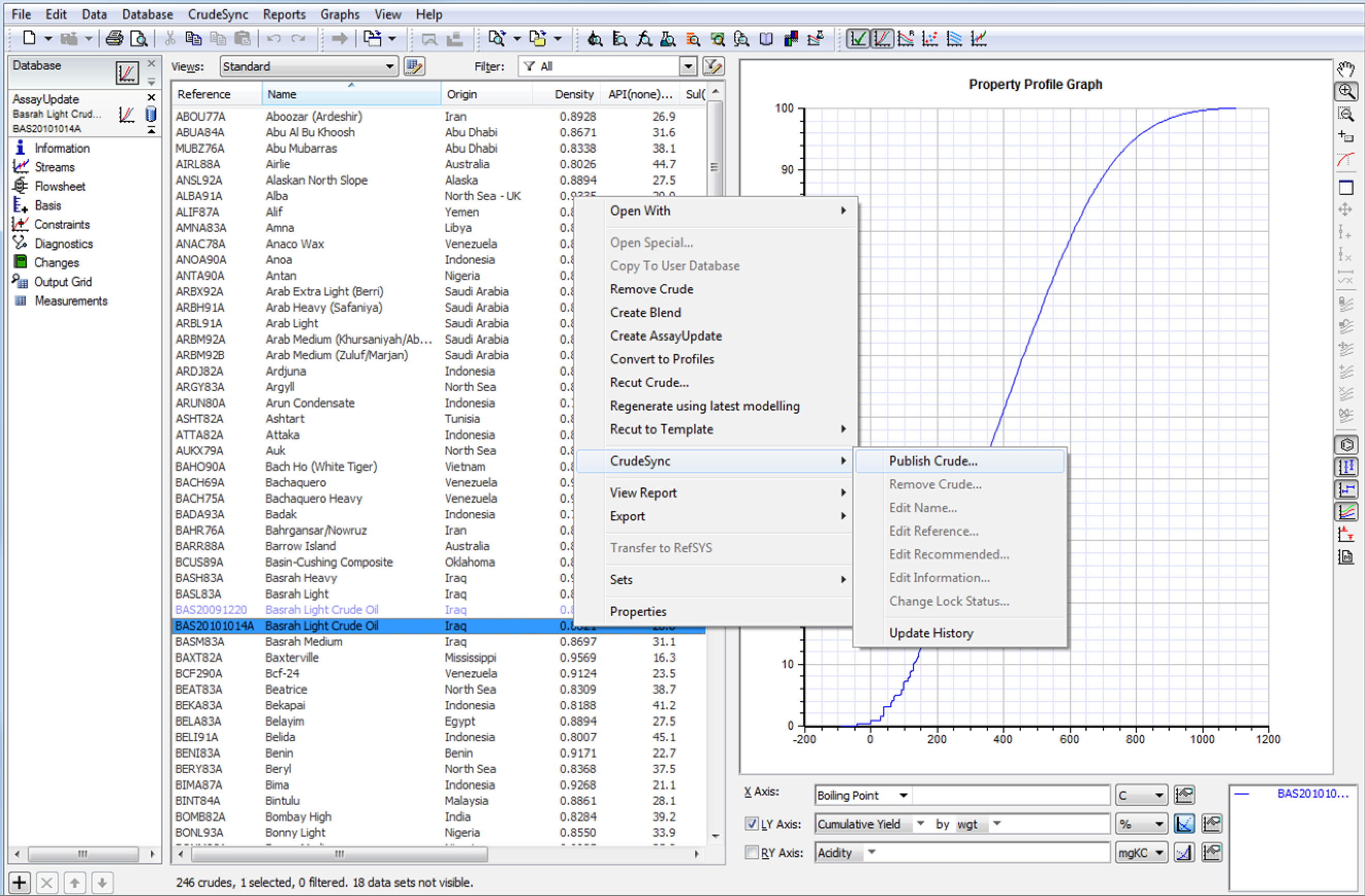

For example, they cited the following product announcement from the SimSci group. This assay management software is even more powerful (especially impactful if you’ve seen the demo) than even the press release says (I know, the reverse is the norm). Combining access to data and powerful modeling tools, an engineer can look at the characteristics of one type of crude on a graph, then perhaps look at other crudes waiting for processing. Perhaps the engineer checks the graphs and finds that two are quite similar. Then with just a click, looks at the characteristics resulting from blending the two. All this is done quickly and easily alleviating a tremendous amount of work, calculations, checking and re-checking that is necessary now.

The product release of the day comes from SimSci–Spiral CrudeSuite crude oil knowledge-management software with its SimSci PRO/II design and ROMeo optimization software. The new integrated offering gives the hydrocarbon processing industry a single-source software solution that enables seamless access of latest crude assay information for refinery design, analysis and optimization. The integrated Spiral CrudeSuite offering will provide accurate and complete crude assay information throughout plant lifecycle modeling from design through operations and performance optimization.

“Integrating our crude assay management, design and refinery optimization software fulfills the potential of the Spiral Software acquisition we announced last year,” said Harpreet Gulati, Ph.D., vice president, design software for Invensys. “We are now able to offer the only full-span refinery optimization solution on the market today, one that will help our customers reduce operating costs, increase throughput and maximize profit. Having complete and accurate crude information for improved design and optimization can help drive cost savings and margin improvements that could total millions of dollars each year.”

Spiral CrudeSuite is an enterprise toolset for sharing, managing and modeling crude oil information. It supplies rich, validated crude assay data so engineers can easily design accurate refinery processes using the company’s SimSci PRO/II software, and its comprehensive crude assay data helps engineers optimize the refinery for maximum profitability using the company’s SimSci ROMeo software.

“Combining our Spiral Crude Assay management, PRO/II design and ROMeo refinery optimization software capabilities allows us to provide a unique, end-to-end solution across the full hydrocarbon processing value chain,” Gulati said. “CrudeSuite software will help refiners understand their exposure to changes in feedstock costs, product demand and refinery operations, and it greatly increases the accuracy of their models and speeds up new designs and revamps. It is going to help our customers make the best possible business decisions using real-time market and operations data. We are excited about the business value and competitive differentiation this will provide to our clients.”

by Gary Mintchell | Oct 15, 2013 | Automation, Data Management, Operations Management, Technology

Rocking out to the Beatles “Revolution”, Invensys software announced “The Industrial Software Revolution Begins Now.” About 1,000 people gathered at the Hilton Anatole in Dallas for the second Invensys conference in a little over a month. Last month it was the process solutions side of the company. This conference focuses on Wonderware, SimSci-Esscor and Avantis.

Rocking out to the Beatles “Revolution”, Invensys software announced “The Industrial Software Revolution Begins Now.” About 1,000 people gathered at the Hilton Anatole in Dallas for the second Invensys conference in a little over a month. Last month it was the process solutions side of the company. This conference focuses on Wonderware, SimSci-Esscor and Avantis.

Expect a stream of new product announcements this week.

This morning I had breakfast with Saadi Kermani and Maryanne Steidinger to discuss mobile, cloud and related technologies. Hint—you can find an app on iOS, Android and Windows 8, just search SmartGlance in your app store. Invensys Wonderware has been on the leading edge of mobility for several years.

System Platform 2014

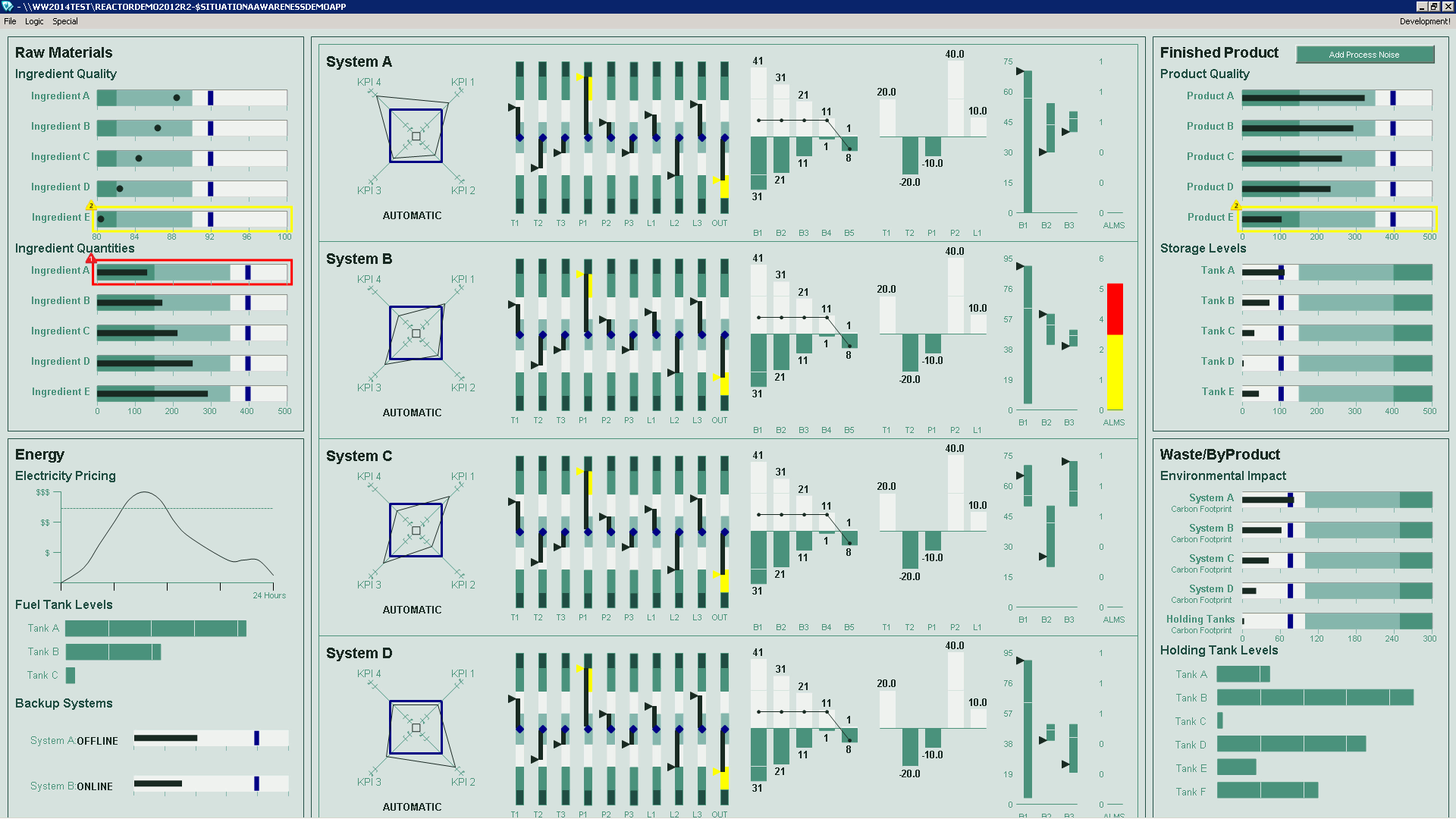

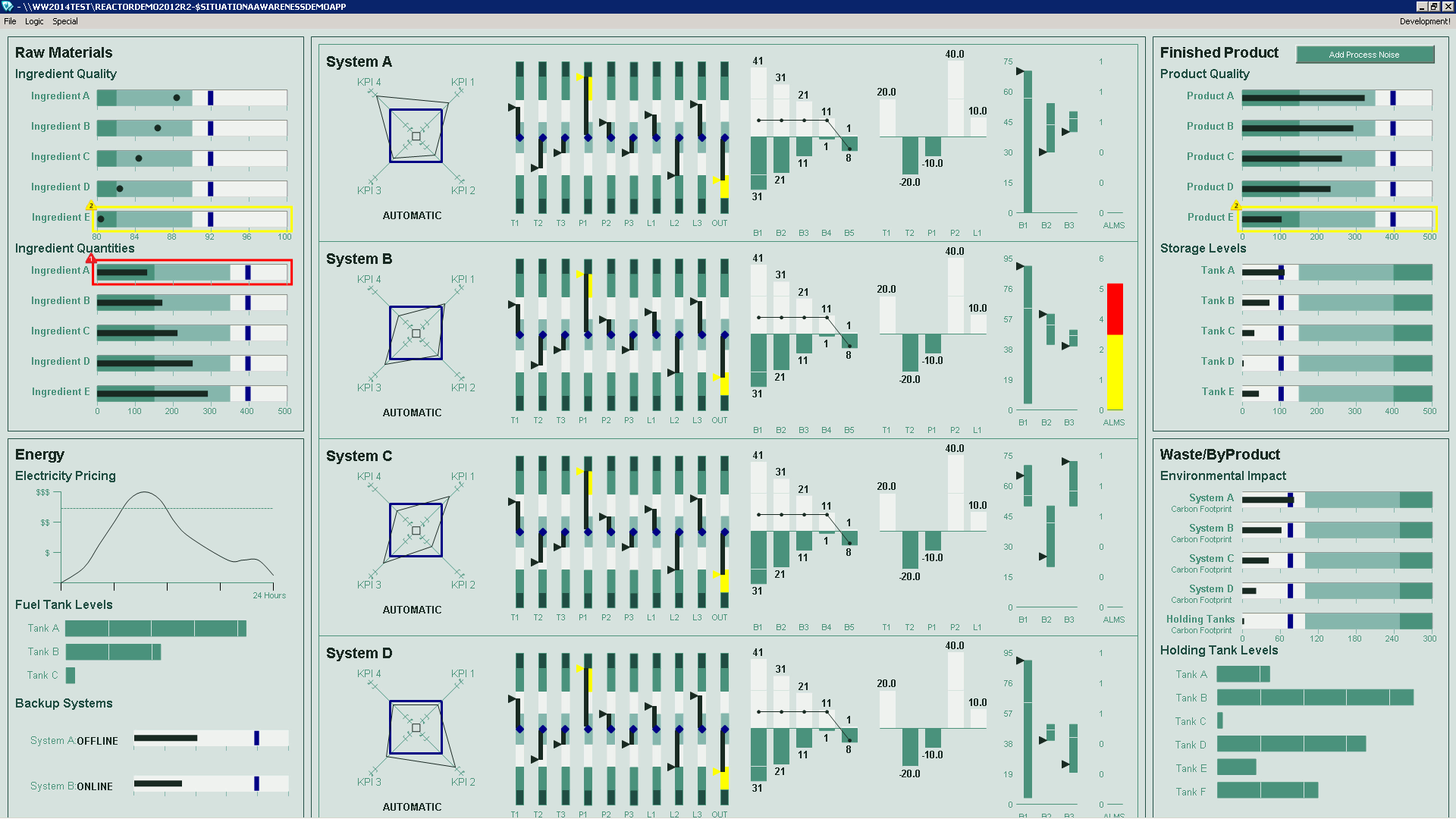

Invensys kicked off the event with the release of its Wonderware InTouch 2014 and Wonderware System Platform 2014 software. Delivering powerful, additional capabilities to its flagship HMI and supervisory offerings, the new software promises to improve operator awareness, optimize performance and minimize disruptions during startup, operation and shutdown.

“While other HMI providers have been focusing solely on graphics to improve the operator experience, Invensys has been collaborating closely with some of the world’s most recognized industrial companies—large and small—to understand their most pressing challenges and issues, and then devise the most innovative ways to solve them,” said John Krajewski, director of HMI and supervisory product management for Invensys.

One major operating challenge is the ability to more quickly identify and address abnormal situations before they impact operations. The company’s Wonderware InTouch 2014 and Wonderware System Platform 2014 software take what the company labels “a revolutionary new approach to HMI design” and supervisory systems by providing new capabilities in alarm management, color representation, information presentation and window navigation, all intended to maximize user performance.

The updates include new object templates; styles for consistent and standardized colors and fonts in HMI applications; and consistency in the way alarms are represented throughout systems, all simply managed from a central repository.

“Utilizing 15 years of human interface studies, we have delivered a toolkit that transforms the way industrial users design and interface with their HMI,” Krajewski said. “We’ve moved from simply presenting data to displaying information in context. Instead of developing a library of ‘graphics,’ these new capabilities enable application builders to focus on creating content, easily assembling the most effective HMI applications and user interfaces for abnormal situation management.

“Initial testing indicates that these new styles and standardized colors can help users reduce situation interpretation time by 40 percent and can lead to a five-fold improvement in detecting abnormal situations before they occur. After the initial detection, our enhanced navigation can improve the success rate for handling abnormal situations by as much as 37 percent, and we’ve seen a 41 percent reduction in the time required to complete tasks.”

These new capabilities implement and encourage best-practices to bring clarity, consistency and meaning to integrated data, allowing senior, experienced and entry-level operators to identify, understand, react to and resolve abnormal situations, thus optimizing their operations. The new capabilities can also empower and train new operators, helping companies address another major issue: the retiring workforce.

by Gary Mintchell | Sep 24, 2013 | News, Operations Management, Organizations, Software

Not a blockbuster, but a very interesting acquisition that consolidates another part of the HMI/SCADA product category. Invensys has acquired InduSoft, a provider of HMI and embedded intelligent device software for the automation market. Headquartered in Austin, Texas, and founded in 1997, InduSoft has delivered more than 250,000 HMI software licenses to more than 700 customers worldwide, primarily industrial computer manufacturers and machine and system builders, who embed InduSoft’s software into their products.

Not a blockbuster, but a very interesting acquisition that consolidates another part of the HMI/SCADA product category. Invensys has acquired InduSoft, a provider of HMI and embedded intelligent device software for the automation market. Headquartered in Austin, Texas, and founded in 1997, InduSoft has delivered more than 250,000 HMI software licenses to more than 700 customers worldwide, primarily industrial computer manufacturers and machine and system builders, who embed InduSoft’s software into their products.

“The acquisition of InduSoft represents the continuing execution of our strategy to strengthen our portfolio through inorganic means, enabling us to target additional segments across our portfolio,” said Ravi Gopinath, president of Invensys’ software business. “InduSoft strengthens and broadens our leading software solutions portfolio, particularly in the embedded HMI segment, and provides a continuing driver for growth. They have a proven and experienced team who we are very happy to welcome to Invensys.”

“Combined with Invensys’ existing software offerings, our capabilities and expertise in the OEM and machine-building segments allow us to provide a broader, end-to-end HMI, SCADA and MES solution to our customers,” said Marcia Gadbois, president of InduSoft. “Together, our software tools will make it easier for them to integrate their information and automation systems. They will continue to work with the same strong InduSoft team, and we will ensure they continue to receive the exceptional products and service they have come to expect from us. But now they will be backed by a company with global capabilities and an excellent worldwide reputation for providing industry-leading HMI, SCADA, historian and advanced applications such as MES software and solutions.”

“With InduSoft we can now offer everything from basic embedded HMI devices to manufacturing operations, asset management and ERP integration,” said Norm Thorlakson, vice president, HMI and supervisory software and solutions, Invensys. “InduSoft technology quickly makes us more competitive and gives us immediate entry to new customers and a stronger OEM sales channel, with a focus on machine builders and embedded systems. We are confident it will make us much more attractive. Wonderware users will now be able buy industrial devices, machines and computers with InduSoft software, while companies that are using InduSoft software will be able to expand their solutions with Wonderware supervisory, historian and manufacturing operations management software.”

InduSoft will continue to be managed by its existing executive team, adding employees to Invensys operations in the United States, Brazil and Germany.

by Gary Mintchell | Sep 12, 2013 | Automation, Events, News, Process Control, Technology

Invensys President and CEO Mike Caliel

A good turnout of customers greeted Invensys (Foxboro and Triconex) executives this week as the company celebrated the 30th anniversary of Triconex and the launch of Foxboro Evo—the new generation of process automation & control operationalizing the InFusion vision.

I might as well begin with what is on most people’s minds—the pending acquisition by Schneider Electric. President and CEO Mike Caliel addressed the situation right away. “At this point there is a formal offer on the table. The Invensys board intends to recommend acceptance to shareholders. After shareholder approval, then will come regulatory reviews. We expect approval of shareholders in October, with the deal probably complete in late 2013 or early 2014. Now we are completely separate companies. There is no impact today. I don’t foresee it changing in the future. If you heard about our plans from anyone but us, they are not our plans. Schneider values the synergies of products and people.”

Caliel will lead the Invensys side of the integration. Schneider CEO Jean-Pascal Tricoire says he wants it to be a growth deal.

I have thought about this acquisition from many angles, then listened to many people discuss it this week. This is probably the best outcome for Invensys, its people and customers. Schneider will most likely let Invensys run the way it has. It has the financial strength and stability to remove all the past uncertainty surrounding the company. There is virtually no overlap, which will eliminate political infighting such as happened with the Modicon acquisition between Modicon people and Square D people. I think in the end, it’s good for Invensys and good for automation customers. When I see the innovation of the Foxboro company and Wonderware, I marvel at the opportunities lost through incredibly bad management. We can only hope that Schneider will provide stability and finance and let them continue to operate somewhat independently.

Evolutionary innovation

Invensys Vice President Peter Martin

Vice President Peter Martin set up the product launch with a history of Foxboro and Triconex innovations. He took the history up to the 2006 launch of InFusion. “InFusion’s goal was to unify the compute space. It represented a different type of innovation, occurred at infrastructure level where people can’t really see it, and built a common industrial system platform. It is a still evolving unified services architecture.”

With characteristic humor, Martin added, “Being an innovator in a very conserviative market like ours has its challenges. We want the latest as long as it has been proven for a decade.” He continued, “We believe evolutionary innovation is essential to your success. The future for industrial companies is challenging and daunting. Speed of business will increase, processes will evolve, regulatory pressures squeeze profitability, higher levels of safety, security, required; new generation of industrial workers will require the operational insight to replace and outperform their predecessors. Each person will have to work at higher levels of performance. Require information and enlightenment. We can meet just as in the past. This week, we’ll show you how.”

Caliel, after addressing the Schneider situation, addressed the future of industrial automation. “We need to turn data into contextual information. The challenge is beyond technology to how to apply to drive business value. You’re under tremendous pressure to not only meet but exceed business needs. But the data is not always helping you, sometimes it’s even hurting you. When people are flooded they may make the wrong decision or act more slowly. Why not take advantage of the advanced software available. We see the value of this enlightenment not just for operators or engineers, but for everyone. What is needed is a process system to meet these challenges, with a new perspective, operational integrity and operational insight.”

Next-Gen Foxboro Evo

Billed as a “Process Automation System,” Foxboro Evo incorporates advanced roles-based tools, extra processing power and safety-system integration improve business continuity and profitability; future-proof automation investments.

Invensys Systems President Gary Freburger

“The three most important ways a process automation vendor can help its customers secure their future is to protect the operational integrity of their plants, enhance the operational insight of its people and enable them to adapt easily and affordably to change,” said Gary Freburger, president of Invensys’ systems business. “Our new Foxboro Evo system does that with unrivaled elegance. With more powerful processing capacity and other new, advanced applications, the system allows our customers to uncover new and hidden value from within their operations. This is another automation breakthrough from a company with a 100-year history of delivering innovative technology advancements. We’re excited about what this means for the industry and for our customers, and we look forward to continuing to help them safely achieve their short- and long-term business and operations goals.”

Foxboro Press Release

The following is from the press release and hits the main themes of the development—especially the role-based thinking.

The Foxboro Evo process automation system has evolved directly from pioneering Foxboro I/A Series and Triconex technology, both entrusted to control and protect some of the world’s largest, most complex process facilities and known for their innovative, layered architecture. The system extends this approach through a component object-based platform, which can undergo major upgrades without halting operations.

“We needed to upgrade the vast majority of our DCS, but like most sites, we didn’t have the luxury of a site-wide shutdown to make a full change possible,” said Michael McKenzie, distributed control systems specialist for BP in Brisbane, Australia. “We were facing a substantial obsolescence issue, which we had ranked as a significant risk to ongoing operations, so we needed a solution that would allow us to upgrade components as we needed them, without sacrificing functionality or usability for operators. The new Invensys system allowed for a much easier upgrade of all components and will ensure that we can keep our system well away from obsolescence, so that we’re not required to perform any additional large-scale upgrades.”

Because users can upgrade at their own pace, the Foxboro Evo system delivers the lowest total cost of automation and highest return on assets. Additionally, its new applications improve the ability of plant personnel to contribute toward the success of the business by streamlining and contextualizing the information they need to make the right business decisions at the right time.

“As the pace of global business accelerates, automation technology becomes increasingly important in helping manufacturers focus on finding more value within their operations and automation assets,” said Chris Lyden, senior vice president for Invensys. “If users in the control room and in the field can better interpret the growing volume and complexity of the information they receive within the proper context of procedures and operational risk, then they will make more valuable contributions to the business. The Foxboro Evo system is loaded with new features that will help them do that, and it is structured to evolve with them as they and their companies change and grow.”

The Foxboro Evo system includes a new high-speed controller, field device management tools, a maintenance response center, an enterprise historian, 1-n redundancy and cyber security hardening. And because the company’s broad portfolio of roles-based engineering tools and productivity applications are integrated within it, the system provides superior visibility into historical, real-time and predictive operating information to help drive production efficiency.

Safety and security personnel will benefit from an innovative coupling of control and safety, which enables sharing of operational information while keeping the safety system functionally isolated, as well as state-of-the-art cyber security.

Engineers will be able to reduce their workloads, protect schedule integrity and reduce risk via more intuitive design and troubleshooting features, virtualization and other flexible technology.

Operators will gain a more complete, real-time view of plant activity via an updated high-performance, mobile accessible HMI.

Maintenance technicians will enjoy lower meantime between repairs via real-time device alerts and analytics, alarm triage, performance monitoring and other benefits.

Current Foxboro I/A Series DCS users can migrate to the Foxboro Evo system with little or no downtime, depending on which version they are running. Users of competing process automation systems, whose wiring terminations are still functional, can migrate to the Foxboro Evo system without ripping and replacing infrastructure, significantly reducing costs and downtime, just as they were able to do with the I/A Series system.

by Gary Mintchell | Aug 28, 2013 | Operations Management, Software

Microsoft became the dominant software platform for automation and operations management by the late 1990s to the early 2000s. Most companies have staked their product development to it. Wonderware took a giant risk when it based its startup product on a Microsoft Windows product that was not generally accepted at the time.

Microsoft became the dominant software platform for automation and operations management by the late 1990s to the early 2000s. Most companies have staked their product development to it. Wonderware took a giant risk when it based its startup product on a Microsoft Windows product that was not generally accepted at the time.

Many companies have people embedded in Redmond. Some visit regularly. These include the likes of Beckhoff Automation, GE-IP, Iconics, Rockwell and Siemens. Even the process control systems suppliers moved to a Microsoft platform. This became evident early in OPC UA development when things were not going as well as some would hope and there was a little kerfluffle about developing OPC UA for a .Net environment. Since patched over.

At the ARC Industry Forum in 1998, there seemed to be a viable Java alternative (the Java people always seemed to think that it was an operating system, not programming software). At the 1999 Forum, many (I forget how many) speakers from the various automation suppliers spoke on developing on Microsoft Windows. Only the guy from Sun (remember it?) got up to speak on Java. The battle was over. Even the OMAC group at the time had a Microsoft Manufacturing User Group.

My, the world has changed. Microsoft still has a massive presence. But much of the world is going mobile. Microsoft missed it entirely. Now Steve Ballmer is out. What is the future of Microsoft? Should it split into “consumer” and “enterprise” as some suggest? But with the consumerization of IT, would that be a mistake?

What about you? What are you using these days? Very much from Microsoft?

I still use Microsoft products. But I’m typing this on a MacBook Pro on a minimalist text editor called Write Room. I’ll cut and paste it into my Web application on Firefox. (I use Chrome sometimes, too.)

What do you think about the future of Microsoft and what products do you think you’ll be using?

Meanwhile, here is Wonderware extending its product portfolio even deeper into mobile. Mobile and cloud-based applications and storage are going to be hugely disruptive to the operations management software space. Wonderware is in front of the trend right now. I hope the new owners let it keep it up.

<h4>Wonderware Extends InTouch To Mobile Devices</h4>

Invensys has released its Wonderware InTouch Access Anywhere software. Users can now access plant-floor data via Wonderware InTouch software. It runs inside a web browser so users can connect to other InTouch applications at anytime from anywhere, using any mobile device. The software also supports Macintosh and Linux-based computer systems, as well as Microsoft Windows PCs and laptops. And because users are not required to install any software on their mobile device, the offering is remarkably easy to deploy, manage and maintain.

This is day two of the Invensys industrial software user conference in Dallas. The atmosphere is on of energy and enthusiasm. It’s an impressive event.

This is day two of the Invensys industrial software user conference in Dallas. The atmosphere is on of energy and enthusiasm. It’s an impressive event.