by Gary Mintchell | May 10, 2018 | Data Management, Internet of Things, News

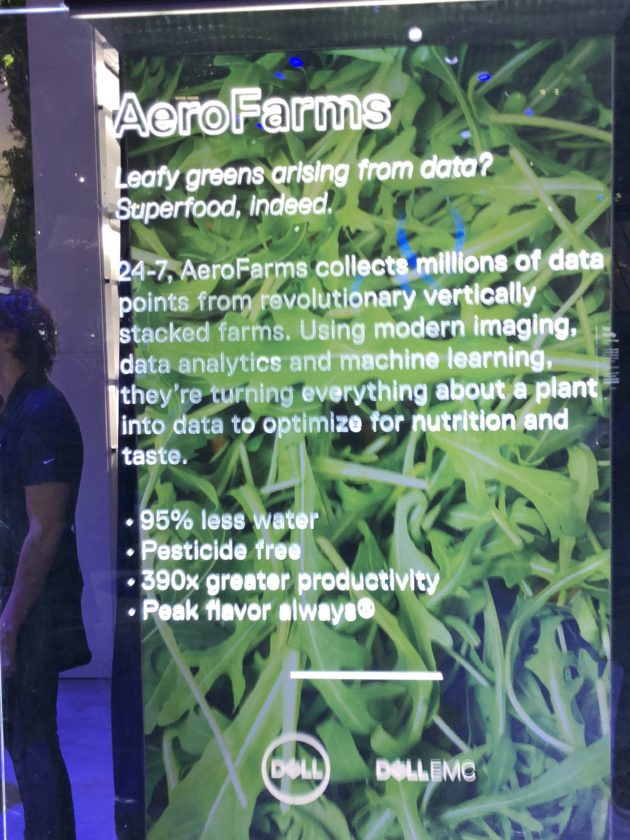

Much time was devoted last week at Dell Technologies World to Dell’s Legacy of Good highlighting people and companies doing some really cool and worthwhile things. I’m especially impressed with the AeroFarms people (see photos below) who are using IoT to find a better way to grow wholesome vegetables. Hey engineers–maybe there’s a thought in here to spark your next creative interest.

Let me take you on a photo journey through the prominent booth at the DT World Expo floor highlighting a number of projects.

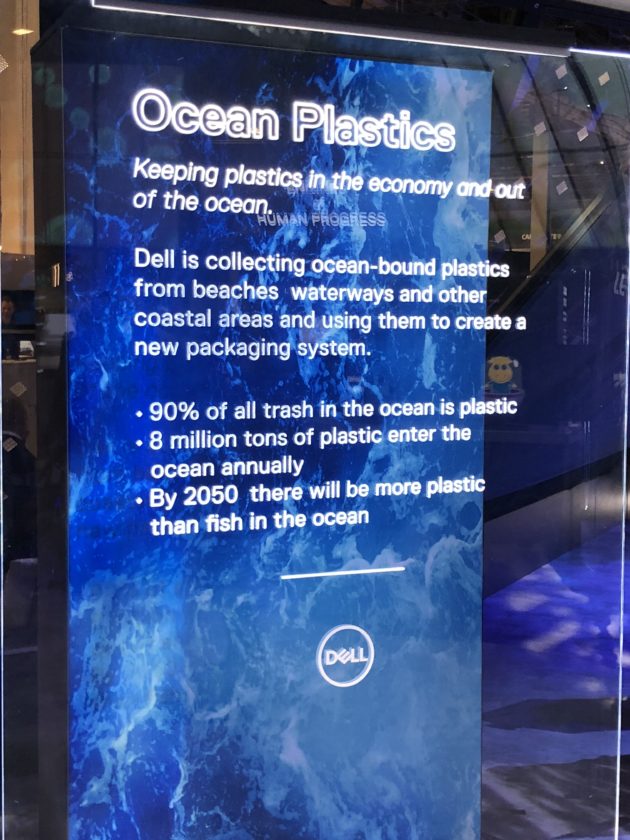

Plastic waste floating in the ocean is fast becoming an environmental catastrophe. Here is someone doing something about it.

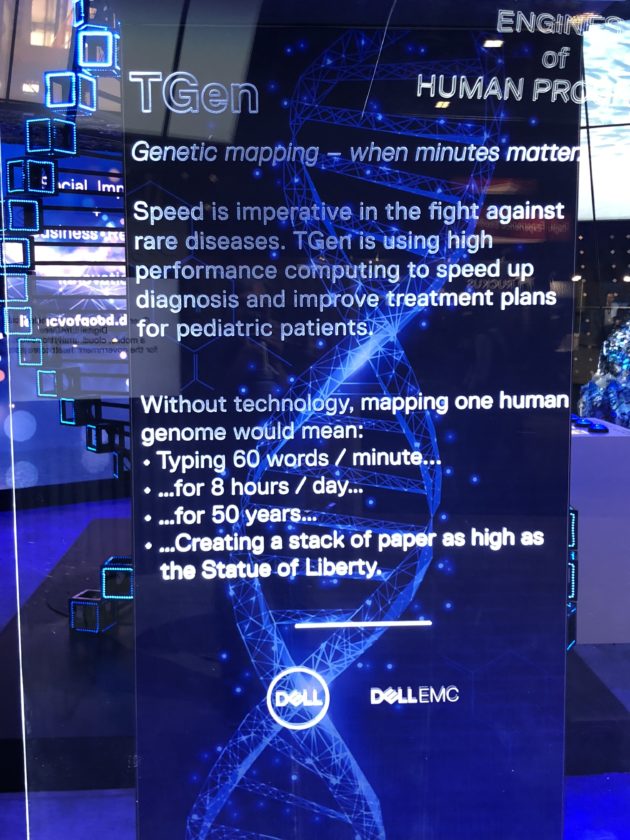

How about genetic mapping improvements for fighting rare diseases?

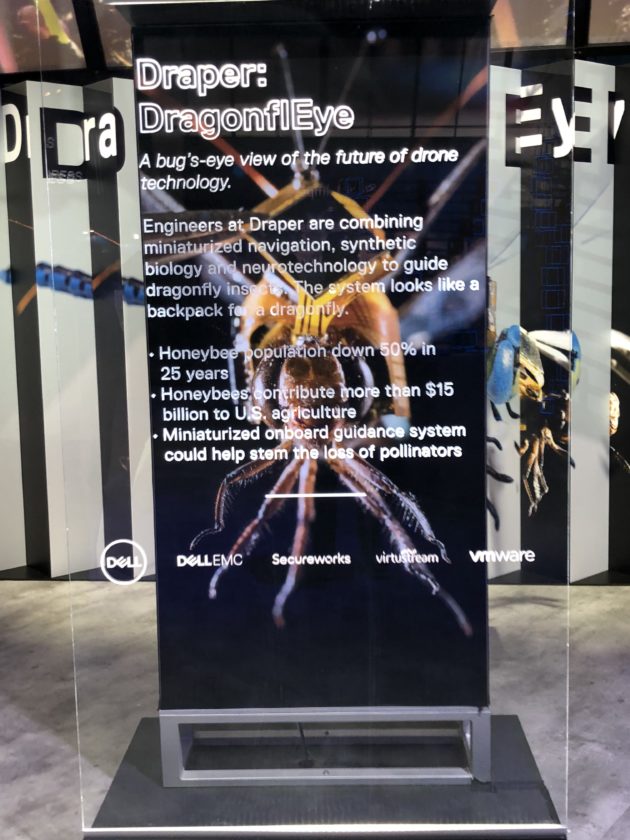

A bug’s eye view with drones to help the honeybee population.

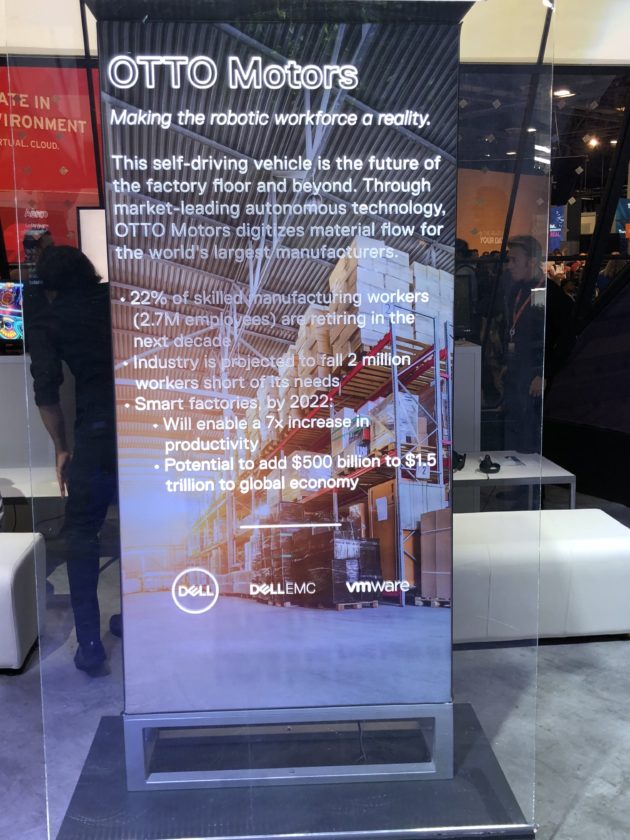

All kinds of wild robot science fiction stories are hitting main-stream media. How about a reality check?

Oh, another main-stream media hype fest–AI. In reality is can be a boost to business not in a scary way.

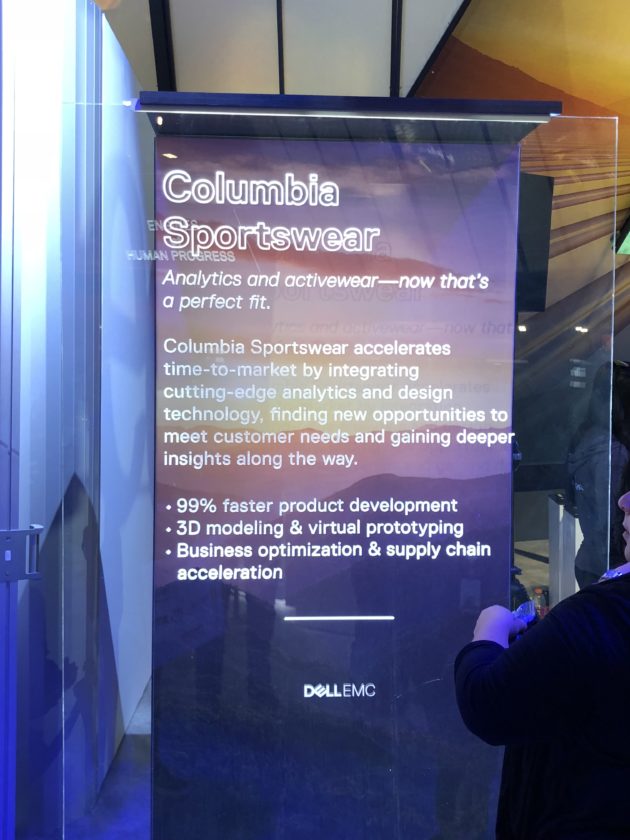

Here is a manufacturing product lifecycle story.

And the AeroFarms story.

by Gary Mintchell | May 2, 2018 | Commentary, Internet of Things, News

Last week it was Hannover Germany in pursuit of the elusive Internet of Things (IoT) where the weather had been in the 70s until I arrived. This week, still in pursuit of the elusive IoT, I’m in a chilly and wet Las Vegas at Dell Technologies World where I’ve talked IoT for some three years.

For two years, Michael Dell featured IoT in his keynote. Last year, he brought VP Andy Rhodes on stage for a highlight. Rhodes has since moved on to another group, the GM of IoT is also the CTO of VMware indirectly reporting to the President of OEM and Global Channel (and IoT). So on the one hand IoT has been elevated in the organization twice in a year. On the other hand, there seems to be less glitter.

Meanwhile this year, Dell brought up IoT in the context of data. Data being in the service of Digital Transformation. In fact, Dell said, “Dell Technologies is in a unique position to integrate innovation for Digital Transformation.” He noted that companies can use data to improve products and services which in turn attracts more customers which generates more data which is analyzed and so the process goes.

However since IoT generates data and date attracts attacks, security is an essential element of the system. Interestingly, I met with Zulfikar Ramzan who is CTO of RSA, the Dell security company who talked in terms of recognizing and managing risk. Making risk visible and using analytics are key strategies.

There were also two briefings with the Unstructured Data Group. So much of our industrial data is in historian databases. But the growth of Websites and IoT has generated unstructured data that must be stored, retrieved, analyzed, and used in order to support business

Trends for IoT within Dell Technologies? After conversations with CTO and GM Ray O’Farrell and my longtime contact Jason Shepherd, I’d say the big thing is that IoT has grown from being a small division—almost a skunk works sort of thing building a product and solution infrastructure to becoming part of the DNA across all Dell Technologies companies. Therefore the fruit of moving the locus of leadership higher in the organization and placed with people that can build alliances and partnerships. And these partnerships now include channel partners as well as solution partners. I’d call this growling maturity.

by Gary Mintchell | May 1, 2018 | Automation, Internet of Things

I went from Germany to Las Vegas and the time change screwed with my posting schedule. So…I am finally finishing up my Hannover Messe reporting before I begin with my recent trip.

My last post detailed the first round of briefings with Hewlett Packard Enterprise. Today I’ll finish up.

But first, a digression.

OPC

Misinformation about what exactly OPC UA is continues to circulate within the industry. I had at least three conversations where people referred to OPC as proprietary. Plus OPC and MQTT are mistakenly considered competitive rather than complementary. OPC Foundation still has some evangelizing to accomplish.

A few years ago it appeared that major automation vendors were ignoring OPC and its interoperability tending toward self-encased solutions. In fact, I got dissed by some dude on YouTube for a report I did on that subject.

Time has passed. More and more people and companies recognize the value of interoperability and OPC UA. No doubt the PubSub helps in some cases. And without a doubt the combination of OPC UA and TSN is enticing to many.

HPE

HPE has devised an application dubbed “Remote Visual Guidance.” It began with an eLearning application HPE MyRoom. Integrated with a hard hat, a camera, and glasses that project an image to the user, the system enables remote support from an expert who may not be able to fly to the site. Imagine working in a remote location such as an offshore oil rig where flying in an expert is both dangerous and expensive, for example. The system comes in three versions—wearable say integrated with a hard hat, smart phone app, or tablet app. Therefore, the three versions are No hands, 1 hand, and 2 hands). Try this for a potential use case for a value add from an OEM. The OEM bundles the app with its machine. This gives the customer direct contact with remote expert for the cost of perhaps a service contract.

I had a good conversation with HPE’s Christian Reichenbach on Blockchain technology. I believe this technology is quickly moving past hype into something we can use. The concepts of trusted transaction and ledger have immediate appeal for industries such as pharma manufacturing. We can think of many more.

Reichenbach identifies three waves of blockchain.

Wave One is personal exemplified by crypto currency—the Bitcoin that garners most of the press

Wave Two came with Enterprise to Enterprise transactions. For example, he pointed to the vision system QA demo at the HPE stand. It uses blockchain to send QA report as a secure, trusted transaction that includes a record.

Wave Three includes Things to Things. This means systems around products leading to systems of systems thinking. Things become autonomous actors. They contract with each other with no middle man. It includes ledger systems. Let’s take the example of an HPE Edge Gateway plus Etherium (an HPE partner). Perhaps it’s the same concept as loyalty card scanning and giving you value for using it. Let’s look at a car. Currently there are lots of sensors but no marketplace to exploit all that data. Say we take Edgeline device connected to CANbus of the car. Then, say, connect to the rain sensor or a sensor in the shock absorber. Previously the end user gave data away for free, but now maybe the car makes a smart contract with weather channel or Waze and sells the data.

One last item I gleaned from the Microsoft booth. HPE has a starter kit to help users easily connect devices to the cloud using HPE Edgeline, Softing (OPC UA kit), and Microsoft Azure.

Overall analysis from HPE visit at Hannover was that IoT has matured in a sense from a department with a product to infusing into the entire manufacturing product and service portfolio.

by Gary Mintchell | Mar 23, 2018 | Process Control, Security

Critical infrastructure control systems have been under cyber attack for years. Need we mention Stuxnet, the attack that brought the issue to the public eye? Pressure has been mounting on controls, automation, and IoT suppliers to protect a nation’s assets.

Siemens and eight partners signed a joint charter for greater cybersecurity at a recent Munich conference.

Highlights include:

- Ten action areas for greater cybersecurity

- Call for dedicated government ministries and chief information security officers

- Independent certification for critical infrastructures and solutions in the Internet of Things

The Charter of Trust calls for binding rules and standards to build trust in cybersecurity and further advance digitalization. In addition to Siemens and the Munich Security Conference (MSC), the companies Airbus, Allianz, Daimler Group, IBM, NXP, SGS and Deutsche Telekom are signing the Charter. The initiative is further welcomed by Canadian foreign minister and G7 representative Chrystia Freeland as well as witnessed by Elżbieta Bieńkowska, the EU Commissioner for Internal Market, Industry, Entrepreneurship and Small and Medium-sized Enterprises.

“Confidence that the security of data and networked systems is guaranteed is a key element of the digital transformation,” said Siemens President and CEO Joe Kaeser. “That’s why we have to make the digital world more secure and more trustworthy. It’s high time we acted – not just individually but jointly with strong partners who are leaders in their markets. We hope more partners will join us to further strengthen our initiative.”

The Charter delineates 10 action areas in cybersecurity where governments and businesses must both become active. It calls for responsibility for cybersecurity to be assumed at the highest levels of government and business, with the introduction of a dedicated ministry in governments and a chief information security officer at companies. It also calls for companies to establish mandatory, independent third-party certification for critical infrastructure and solutions – above all, where dangerous situations can arise, such as with autonomous vehicles or the robots of tomorrow, which will interact directly with humans during production processes. In the future, security and data protection functions are to be preconfigured as a part of technologies, and cybersecurity regulations are to be incorporated into free trade agreements. The Charter’s signatories also call for greater efforts to foster an understanding of cybersecurity through training and continuing education as well as international initiatives.

“Secure digital networks are the critical infrastructure underpinning our interconnected world,” said Canadian foreign minister Chrystia Freeland. “Canada welcomes the efforts of these key industry players to help create a safer cyberspace. Cybersecurity will certainly be a focus of Canada’s G7 presidency year.” The matter is also a top priority for the Munich Security Conference. “Governments must take a leadership role when it comes to the transaction rules in cyberspace,” said Wolfgang Ischinger, Chairman of the Munich Security Conference. “But the companies that are in the forefront of envisioning and designing the future of cyberspace must develop and implement the standards. That’s why the Charter is so important. Together with our partners, we want to advance the topic and help define its content,” he added.

According to the ENISA Threat Landscape Report, cybersecurity attacks caused damage totaling more than €560 billion worldwide in 2016 alone. For some European countries, the damage was equivalent to 1.6 percent of the gross domestic product. And in a digitalized world, the threats to cybersecurity are steadily growing: According to Gartner, 8.4 billion networked devices were in use in 2017 – a 31-percent increase over 2016. By 2020, the figure is expected to reach 20.4 billion.

by Gary Mintchell | Feb 5, 2018 | Automation, Internet of Things, Operations Management

I am still stung by a comment and ensuing discussion made by a maintenance manager during a talk I gave a few years ago. The talk was an early IoT description of networks, data, information, and the like. The guy raised his hand and said, “The engineers in my plant tell me that this stuff doesn’t work. So just forget about it!”

Emerson Automation developed a strategy called Top Quartile Performance and a service plan called Operational Certainty in order to operationalize Industrial IoT to benefit customers. This report comes from Covestro, one of the world’s largest polymer companies, which has selected Emerson to provide Industrial Internet of Things (IoT) technologies to help achieve its goals of minimizing risk and improving uptime at nine high-utilization plants.

As part of the $14 million, five-year contract, Emerson will provide remote monitoring and predictive maintenance to help Covestro optimize these manufacturing facilities for improved production, safety and reliability.

The Emerson program is a tenet of Covestro’s comprehensive digitization program called Digital@Covestro that considers and implements new Industrial IoT strategies and operating procedures to deliver improved performance and meet defined financial targets. Covestro’s reliability program will leverage strategies, solutions and technologies in Emerson’s Operational Certainty program designed to help manufacturers achieve Top Quartile performance. Emerson data shows that Top Quartile companies spend half as much on maintenance compared to average performers and operate with an additional 15 days of available production each year.

Emerson will remotely monitor and maintain 40 of its DeltaV distributed control systems at Covestro plants in China, the United States and Germany. Remote teams at Emerson’s Innovation Center in Austin, Texas, will monitor and provide best practices-based maintenance strategies for local Emerson teams to implement at each Covestro plant. “By collaborating with Emerson to stay proactive about plant availability, we can drive toward always-on production and continue to satisfy customers in our high-demand market,” said Klaus Schaefer, chief technical officer, Covestro.

The Emerson-Covestro agreement reflects an emerging business model in industry, where manufacturers rely on a strategic supplier’s software solutions and deep automation expertise to monitor and execute maintenance, equipment health or energy management programs, allowing customers to focus their attention on critical operating functions that drive plant performance.

“Covestro and Emerson have a shared focus on driving Top Quartile operational performance,” said Jamie Froedge, president of Emerson’s Process Systems and Solutions business. “Connecting Covestro’s global product manufacturing expertise with our remote and local service capabilities allows the right expert to be available, real time, to ensure reliable operations.”