by Gary Mintchell | Dec 9, 2014 | Automation, Industrial Computers, Internet of Things, Networking, Operations Management, Technology

Advantech announced at its Embedded World Partner Conference (WPC) that it would collaborate with Microsoft to build Asia’s first IoT WISE-Cloud (Wireless IoT Solutions Embedded, WISE) platform. Advantech and Microsoft will jointly develop solutions and products intended for the Internet of Things (IoT) with the aim of establishing a cloud application model.

Chaney Ho, Advantech President, said that in recent years, the applications for IoT have been widely established in people’s daily lives and work. Advantech not only established “Enabling an Intelligent Planet” as its corporate vision in 2012, it has been fully engaged in the development of Smart City and IoT technology from the beginning. In the course of its evolution, Advantech found that the embedded board is at the core IoT and so the development of all types of intelligent systems could naturally be realized for a diverse range of fields.”

Chaney further stated that Advantech is deepening its concept of the traditional IoT 3I (Instrumented, Interconnected and Intelligent) concept to develop an IoT cloud platform called WISE-Cloud by using comprehensive wireless networking technology. Moreover, in order to fully perceive the information collected (data) and then convert it into service and effectively apply it to business intelligence, Advantech collaborated with Microsoft at the Platform as a Service (PaaS) layer through the use of Advantech’s SusiAccess and Microsoft Azure.

Miller Chang, vice president of Advantech Embedded Core Computing Group stated, “WISE-Cloud cooperation by Advantech and Microsoft not only enhances enterprise management efficiency but also integrates various cloud service applications. In addition, there will be synergy through the various integrated cloud services, especially when used in business intelligence after data analysis.”

“Big data analytics and machine learning have created more possibilities for business application. Microsoft Azure provides computing and analysis service in the context of the Internet of Things and enables the IoT industry to move toward the intelligent industry via machine learning,” said Roan Kang, General Manager of M&O, Microsoft Taiwan. “The strategic alliance between Advantech and Microsoft Taiwan allows Advantech to use Microsoft Azure cloud platform to process comprehensive data gathered from SUSIAccess solutions. Moreover, by introducing machine learning as a service, Advantech can leverage the IoT to enable smart, value-added business applications, creating more business opportunities. This collaboration not only demonstrates that the combination of the IoT and cloud computing has reached a new milestone but creates a synergistic effect for both parties. Microsoft will provide consulting services to help the establishment of the WISE-Cloud platform while joining hands with Advantech to expand the global reach of the IoT application.”

Steve Teixeira, Director of Microsoft Program Management IoT Operating System Group, said: “Embracing IoT enables business to become truly data-driven in their decision making. Businesses can gain enormous new insights by ingesting device telemetry into the cloud, combining it with other relevant enterprise and industry data sets, and feeding it all into a rich analytics pipeline. As companies mature in their mastery of IoT, we them transition from operational efficiency gains through improved insights to competitive advantage through predictive analytics to business transformation by discovering new revenue opportunities in IoT.”

Enabling Technologies

Networking, especially Ethernet, is a backbone technology platform for the IoT. Advantech also plays in that market recently unveiling its ProView series of SCADA manageable Ethernet switches which are the convergence switches for process control and IT networking management.

The ProView range of switches use Modbus/TCP to communicate with the SCADA software and SNMP that communicates with the NMS (Networking Management System) at the same time, thereby allowing full read control over the devices either from control engineers or for IT administrator.

The ProView series of Ethernet switches come with fast Ethernet or Gigabit Ethernet and a variety of ports. The port-based QoS VIP port for deterministic data transmission allow the priority ports to control the data traffic for process control by tightening delay/jitter times. This is especially useful for process control networking such as I/O scanning data will be sent out ahead of other traffic (even if it has been received after the other traffic) through prioritization applied by VIP port connected to embedded computing.

To further enhance the benefits of the ProView series Ethernet switches, the highest quality components are used to enable an operating temperature range of -40 to 75°C along with EMS Level-3 protection to repel electromagnetic interface for industrial resistance therefore the ProView series of Ethernet switches are able to provide industrial grade reliability in the harshest of environments.

by Gary Mintchell | Dec 9, 2014 | Marketing

How do you get information about manufacturing/production and technology? Are you concerned with the influence of advertisers over editorial? Are you aware if the article you’re reading is from a supplier or “objective” reporter?

I have a friend who left traditional Business-To-Business (B2B) media to go out on his own (no, this isn’t about me in third person!). His mantra is “I don’t take advertising, so I can tell the truth.”

I have another friend in the business (as well as me) who says, “What? You think I don’t tell the ‘truth’ even though there is advertising on my site!?”

I say, “If you want to advertise, call me” 😉 But I’ll say what I want.

Oh, there’s a surprise at the bottom of the post.

Mixing Advertising and Reporting

The New Republic is a magazine with a 100-year heritage. It’s opinionated, but respected. It’s now disintegrating. Maybe.

The problem seems to be the new owner who suddenly wants to see a profit. When the sales department runs a magazine, a continuous tension between editors (who like to think they are independent observers and reporters of events) and sales (who think all articles should promote their clients) is inevitable.

The other issue is writing articles to generate online traffic. Utilize search engine optimization (SEO), the bosses say. Editors traditionally say, who cares. I’m writing the truth.

The New York Times has reported on the New Republic fiasco.

The quintessential social media mogul — Mark Zuckerberg’s Harvard roommate — buys the ultimate symbol of the old media, a progressive opinion journal that dates back to the Woodrow Wilson administration. What could possibly go wrong?

And so what started out as a fairy tale turned into a cautionary one about this fraught moment in the history of the media, when news meetings at even the most respected publications are increasingly taken up with conversations about audience development and search engine optimization.

[One contributor] said that though the values of the magazine, and its focus on long, thoughtful stories, were paramount, “the media environment in which The New Republic operates has changed.”

I don’t believe SEO is necessarily all that bad. My Website designer (Jon DiPietro now of Authentia] and I looked at the keywords that would relate to what I write about, studied their Google strength, and then built in an SEO component in the Website.

The problem occurs especially for The New Republic when sales begins ordering a change in the entire format of the magazine from longer, more thoughtful articles to short snippets designed solely for maximizing page views therefore maximizing ad impressions therefore maximizing the dollar value of the banner ads.

This, by the way, is a short-term strategy. It’s the last gasp of a dying model. But change will require a total restructuring of the model, the role of sales, the role of writers, the problems of suppliers promoting their products and services.

Marketers’ dilemma

Actually, still another issue is that marketers increasingly want to write articles that look just like editorial but are actually advertising. The idea is to trick readers into reading the article as if it were written by an “objective” reporter. Perhaps then, people will read and believe.

I guess that marketers believe that readers will not read articles written by marketing managers—especially engineers—because they are expecting nothing more than a sales pitch. And, we’re all tired of constant sales pitches.

But marketing communications people exist to get their message out in whatever way they can. And why do they think that their message is so lacking in substance that they must resort to trickery?

Solution?

In our industry, technology comes from suppliers. We live on technology among other things. We need to know about the new technologies—what they are and how they are used. This comes from suppliers and early adopters.

I tell marketing professionals when I consult with them (either for free or for a fee) to start a blog. They can get their message out in their own way. But, I always say, ensure that the information is clear, relevant, devoid of “marketing speak”—superlatives and other overboard bragging, and above all technical.

I will read supplier information if it meets those criteria. To be honest, I don’t read supplier articles in trade magazines—haven’t for 30 years. I have higher expectations for the level of content in a magazine. But that’s just me—and old, former editor.

There are a few supplier blogs that I know (if there are others, let me know) and follow for useful information:

Advice for a reader

- In all your reading and television/movie watching, be alert for subtle messages designed to sway you

- Don’t fall for link bait

- Take care passing along information as fact when it hasn’t been verified

- Find your trusted sources and support them

And finally, if you don’t like click bait, don’t click

by Gary Mintchell | Dec 5, 2014 | Data Management, Manufacturing IT, Operations Management, Software

Schneider Electric has released Wonderware SmartGlance 2014 R2 mobile reporting manufacturing software. The updated version includes a host of new features including support for wearable technologies, a modern user interface for any browser, self-serve registration, support for multiple time zones for a global user base and full import and export capabilities for even faster deployment.

Schneider Electric has released Wonderware SmartGlance 2014 R2 mobile reporting manufacturing software. The updated version includes a host of new features including support for wearable technologies, a modern user interface for any browser, self-serve registration, support for multiple time zones for a global user base and full import and export capabilities for even faster deployment.

“Plant personnel are now mobile so they require immediate access to real-time operations information via their smart phone, tablet or whatever mobile device they carry,” said Saadi Kermani, Wonderware SmartGlance product manager, Schneider Electric. “Wonderware SmartGlance 2014 R2 software delivers highly relevant information coming from industrial data sources to targeted plant workers in the form of personalized charts, reports and alerts. It provides them with the flexibility they need to view and instantly collaborate around real-time plant data on any device so they can make rapid, effective decisions.”

With a small install footprint and no additional hardware requirements, the Wonderware SmartGlance implementation process is fast and simple. MyAlerts, the software’s newest mobile app feature, proactively notifies users of process events so they can stay current with real-time information based on configurable thresholds for tag reports. The software can be used with smart watches to alert mobile and remote field workers, plant supervisors and managers of critical production and process information in a real-time, hands-free manner.

By leveraging the combined power of mobility and Schneider Electric’s cloud-hosted managed services, the software empowers mobile and remote users with the right information at the right time, without disruption or distraction, so they can quickly assign resources and resolve issues. It also features an open interface to connect and push data to mobile devices from virtually any data source, including historians, manufacturing execution systems, enterprise manufacturing intelligence systems or any real-time system of record. It also provides connectors for accessing data from any SQL database and any OPC-HDA-compatible system for better access to third-party data sources and systems. This most recent version also extends connectivity to key Schneider Electric software products, including its Viejo Citect SCADA offering, InStep PRiSM predictive asset analytics software and the InStep eDNA historian.

You might also check out my podcast interview with Kermani.

by Gary Mintchell | Dec 3, 2014 | Commentary, News

My friend Jim Pinto has turned from writing on automation to tackling impossible subjects such as politics and economics. His latest ponderings are on poverty and wealth in America.

My friend Jim Pinto has turned from writing on automation to tackling impossible subjects such as politics and economics. His latest ponderings are on poverty and wealth in America.

I must confess that I’m partly to blame. For the 10 years that I was editor of Automation World, he wrote a column for me on automation. We talked monthly about the subject and he always provided insightful views. When I left, the relationship left, too. Now, he’s looking at big subjects.

Take a look at his post and post your own comments.

My own view is that looking for government action to solve society’s problems will never get there. What Jim leaves unsaid is that what is really needed is not politics, but instead a change in people’s hearts.

It is from people acting, helping, giving, that solutions arise. I hear so many stories from around the world listening to TED Talks from people who have done much. There are so many cool engineering problems solved simply and elegantly. So many management issues tackled. Makes me wonder what we are all really doing with our one life.

by Gary Mintchell | Dec 2, 2014 | Automation, Motion Control, News, Operations Management, Process Control, Software, Technology

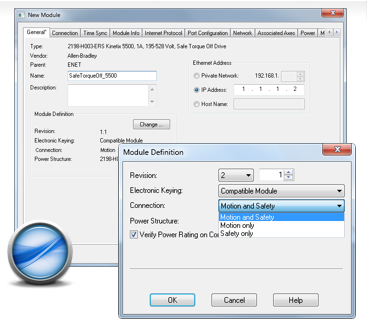

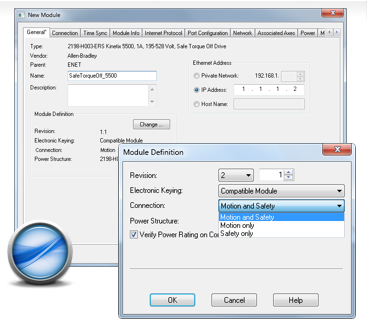

Every Rockwell Automation software executive and product manager who talked with me at Automation Fair almost gushed over the latest and major release of Rockwell Software Studio 5000 Logix Designer v24 (with a name that long, it’d better be good).

Every Rockwell Automation software executive and product manager who talked with me at Automation Fair almost gushed over the latest and major release of Rockwell Software Studio 5000 Logix Designer v24 (with a name that long, it’d better be good).

According to the press release, “Engineers have new design capabilities that can dramatically increase automation productivity, improve start-up time and reduce costs throughout a project’s life cycle. The new additions include an application-centric view of code, enhanced work flows for more efficient re-use of content, and new collaborative tools that make it easier for multiple people to work together.”

“Many machine builders and manufacturers struggle to support production changes due to unstructured code that is not easily understood and organized,” said Mike Brimmer, product manager, Rockwell Automation. “The Studio 5000 Logix Designer v24 software improves the design experience by more intuitively aligning the control system with the manufacturing operation, thus leading to enhanced automation productivity.”

As part of a contemporary automation engineering design environment, the Studio 5000 Logix Designer v24 software is used to configure Allen-Bradley Logix5000 controllers from Rockwell Automation for discrete, process, batch, motion, safety and drive control.

The Studio 5000 Logix Designer v24 software features a new logical organizer that arranges program code based on the users’ applications – rather than how the programmable controller executes. Logical organization of program code can help users identify and troubleshoot code faster for improved downtime recovery.

New library management workflows, meanwhile, ease the ability to store and re-use intellectual property. Users can simply drag and drop modules of code from the Studio 5000 Logix Designer v24 library into a new project. The new workflows enable design engineers to re-use sections of code, which reduces design time and eases the ability to make future operational changes.

Automation system design and maintenance teams are increasingly global and specialized by function. This highlights an increasing need for more powerful collaborations tools. The Studio 5000 Logix Designer v24 software is addressing this need by building on its already strong baseline of multiuser capabilities, which allows many users to work separately and then bring their work back together.

In addition, the Studio 5000 Logix Designer v24 software supports the Allen-Bradley Kinetix 5500 servo drive with integrated safety to help machine builders reduce development and installation time. It also provides support that allows the Allen-Bradley PowerFlex 527 AC drive to be the first variable frequency drive to exclusively use the motion instruction sets within the Studio 5000 Logix Designer v24 software for machine control and motor synchronization.

Additionally, the Allen-Bradley Dynamix 1444 integrated condition-monitoring system allows manufacturers to leverage the Rockwell Automation Integrated Architecture system, rather than an isolated condition-monitoring device. It helps assess current equipment health, predict potential issues, and help avoid damage to critical machinery.