by Gary Mintchell | Feb 25, 2015 | Automation, Technology

An article in today’s Wall Street Journal, Jobs and the Clever Robot, dredges up once again the debate “will automation take away all jobs”.

In typical modern journalism style, the article offers no conclusion. It’s “he said, she said” reporting. Let’s just go out and get a few quotes on each side and fill some space. “People are always interested in whether their jobs will go away,” I’m sure some editor told a reporter.

I, for one, wish we already had driverless cars. My trips to Chicago over the past 16 years would have been so much better if I could have read or worked rather than driving. No train or bus was a feasible alternative. I don’t really want to see truck drivers lose their jobs, but every time I’m on suspect roads (slush, ice, snow, fog) and have a semi rig pass me at a high rate of speed I’d love to see automated drivers.

The problem is, we cannot foresee the types of jobs and the changes in work coming in the future. Maybe we need some science fiction writers to tackle the subject and dream up alternative scenarios. What is manufacturing going to look like in 20 years? Can we automate any more of a refinery than we do now? Should we? That would give us more to think on.

Critical reading

Speaking of “he said, she said” journalism, take this article in The New York Times from this morning, Should Athletes Eat Fat or Carbs?

The writer says that most athletes believe in building up with carbs for a workout, but maybe fats would be just as good or better. Once again the methodology was to go out and interview a bunch of people, string together truncated quotes, reach the desired word limit, hit “send” on the keyboard.

There is too much of this writing. In B2B as well as mainstream media. Let’s take a stand, or at least give a reasoned analysis.

by Gary Mintchell | Feb 23, 2015 | Automation, Internet of Things, News, Operations Management, Technology

The big talk now in the Industrial Internet of Things centers on how to get all the devices to talk the same language.

There is much work going on in the area of interoperability–using a set of a few standards to allow disparate devices and applications to talk.

Here is a company announcing this week at the Embedded Systems Conference in Germany a caveat–since there is no standard, just use our proprietary system.

It “has all the building blocks” to construct a system. Note that this company is not expressly industrial manufacturing. We do have some interoperability standards now, but it is true that getting information from sensor to application can be trying.

At any rate, check out the Connect One system.

Connect One has introduced iChipNet, an Internet of Things (IoT) end-to-end platform that helps customers get their IoT products to market faster.

Connect One’s iChipNet includes all the building blocks – hardware, software, and connectivity – required for IoT product design. Since industry IoT standards are not yet in place, end-to-end solutions from a single vendor can ensure interoperability among IoT functions so that components seamlessly “talk” to each other. Such interoperability enables reliability and maintainability of products once they’re being used in consumers’ homes, building control, or medical devices, and beyond.

Connect One’s iChipNet platform incorporates the following building blocks:

- Embedded technology—Internet Controller chips, Ethernet modules, Wi-Fi modules for embedding inside IoT products

- Gateway/Hub—an optional gateway or hub to connect IoT products to the local network and to the Internet with a zero-configuration feature

- Cloud solution—Server software or service to manage deployed IoT products

- Smartphone app—An app library and example that make it easy for customers to provide a smartphone app with their IoT product

It’s All About Interoperability

The IoT comprises smart devices connected to the network and services that, for example, manage energy usage, provide doctors with real-time medical information, or monitor a baby or child remotely. Such services require a complete IoT platform that can efficiently manage data and ensure fast and reliable delivery to the consumer.

When developing such solutions, customers need an IoT technology vendor that can provide all the building blocks, and confidence that these building blocks work seamlessly together. Over time, by using a single vendor, customers protect themselves from software updates or upgrades that apply to a single part, rather than the whole system, and cause unnecessary system failures.

“In the absence of IoT standards, Connect One is making it easy for anyone to design an IoT device and service and get them to market quickly,” noted Erez Lev, General Manager for Connect One. “By providing all the building blocks needed, we assure customers of ongoing interoperability of our technology as their product evolves in the market. We believe IoT products should be simple and we have designed our technology to provide this.”

Connect One’s IoT Platform: Already Proven in Other Markets

Connect One has provided IoT chips and modules to market segments like home automation, medical, security, point-of-sale, asset management, smart energy, and more since long before the market was called IoT. Building on its M2M expertise, Connect One is tailoring these market-proven chips and modules for the IoT era and consumer space.

Connect One’s new IoT building blocks include everything product designers need to develop, deploy, and manage their IoT products securely and reliably. iChipNet embedded technology, available in many form factors and configurations, recognize the gateway/hub and seamlessly connect to it without end-user intervention.

The cloud solution keeps in touch with the iChipNet-based products, enabling a simple and robust management solution for products in the field. The IoT module connects to the iChipNet cloud solution automatically and its I/O ports can be controlled and managed via the cloud interface. The module has an embedded web server that enables the developer to configure and name the I/O ports according to function in a simple and intuitive manner. Finally, the smartphone app libraries and examples make it easy to build and promote a smartphone app as part of the solution or service provided by the customer.

by Gary Mintchell | Feb 19, 2015 | Asset Performance Management, Commentary, Internet of Things, News, Operations Management, Software

OK, I can take a hint. Maybe. I keep looking at the latest manufacturing strategies—Industry 4.0 and Smart Manufacturing—and asking all of you for your thoughts. The silence screams louder than a pundit trying to stir up “stuff.”

OK, I can take a hint. Maybe. I keep looking at the latest manufacturing strategies—Industry 4.0 and Smart Manufacturing—and asking all of you for your thoughts. The silence screams louder than a pundit trying to stir up “stuff.”

Interesting things are happening at a quieter level under the covers of the grand strategies. I’d call these industrial software mashups. That is now an old term, but I think pretty relevant.

People are building applications on top of existing platforms. Let’s not reinvent the wheel, they say. Let’s leverage an ecosystem of developers and integrators, they say. Let’s get to market faster.

For example, check out this piece I wrote about an ERP vendor, Kenandy, who built atop Salesforce. http://mfgconnection.wpengine.com/2015/01/manufacturing-software-cloud-supports-innovation/

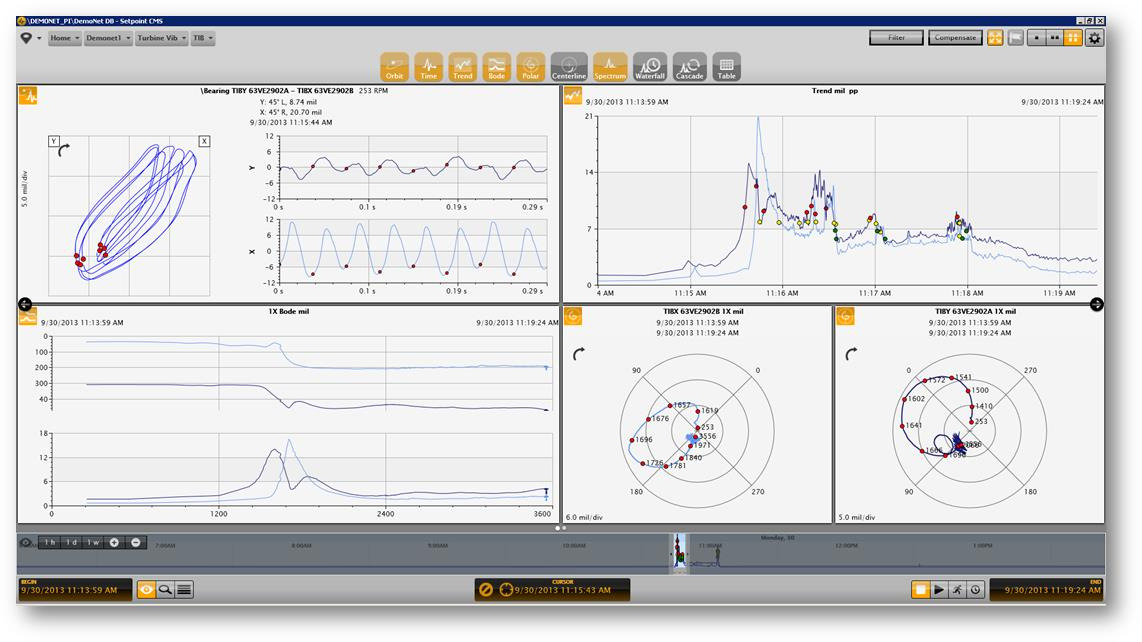

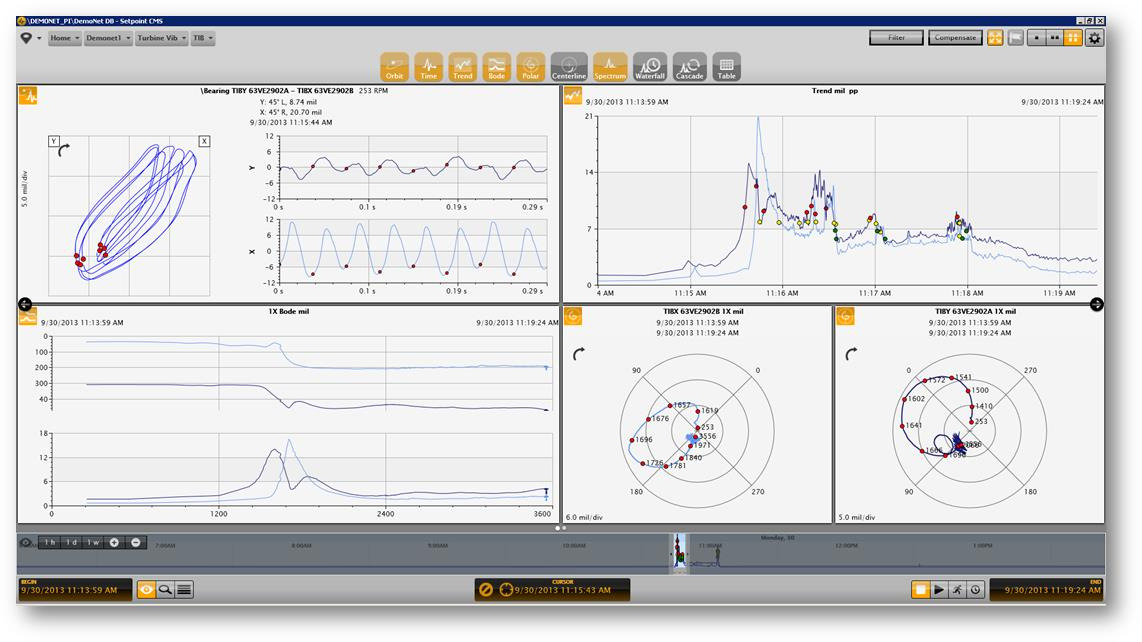

At last week’s ARC Forum, I met another one. Setpoint (by the way, its marketers like it in all caps so that it will shout out on a page, but I’m not reproducing the logo, just the name).

Setpoint is in the condition monitoring market. It began life as an initiative of Metrix Instrument but rapidly grew to a stand-alone company. Metrix wished to grow beyond sensors and transmitters into the systems market. So it build a system with former Bentley Nevada engineers.

Dozens of innovations were embedded in this new system, including a self-contained “universal” monitoring module (UMM) that could be configured do any required measurements in a single module type – making the addition of new measurements no more difficult than loading a new app on your smartphone.

Now that it had the system, to provide more value to its customers, Setpoint needed an industrial software application. Here’s the mashup part. Rather than building a stand-alone software infrastructure the team was entered into a partnership with OSIsoft, – maker of the PI System. Together, they showed that high-bandwidth, sub-millisecond vibration waveform data could be streamed directly into a PI database – something that had been routinely dismissed by the vibration industry as “impractical” or even “impossible.” Time to market was less than 12 months – unheard of in this industry – and during that time the performance capabilities of the PI System continued along its Moore’s Law trajectory, doubling in speed and making high-speed, online vibration data collection completely practical.

OSIsoft PI is an industry standard for historians and analysis. Developers and integrators are plentiful. This was a great way to jump-start a system.

Another benefit is the elimination of redundant computing, network, and software infrastructure. Further is OSIsoft’s ability to envision future market dynamics that could affect the businesses tomorrow. One such trend in the condition-monitoring industry is the drive toward data analytics and predictive maintenance strategies.

A third reason is that making quick and informed decisions on the condition of an asset requires real-time analysis of large volumes of data, also known as Big Data. OSIsoft is a leader in Big Data.

I don’t know what the grand strategies will bring you, but most of you will benefit greatly from this mashup trend.

You could also check out this video that demonstrates the system.

http://www.osisoft.com/Templates/item-abstract.aspx?id=10985

by Gary Mintchell | Feb 16, 2015 | Asset Performance Management, Automation, News, Operations Management, Safety

Asset management, analytics, modeling, safety—some of the significant trends highlighted at last week’s ARC Industry in Transition Forum in Orlando—all popped up at the Bentley Systems press conference session. Highlights were acquisition of C3global and its Amulet Operational Analytics, acquisition of Acute3D and its reality modeling solution, and added process safety and risk management capabilities.

Operational Analytics

Bentley Systems has acquired U.K.-based C3global, provider of web-based Amulet software for operational analytics. Bentley’s AssetWise platform, which serves configuration management, asset health monitoring, inspection, maintenance, and compliance for infrastructure assets, can now deliver additional actionable insights as asset performance management is extended, through AssetWise Amulet, for asset performance modeling. AssetWise Amulet offers unique value in applying predictive and prescriptive analytics that are easily configurable at industrial scale to leverage just-in-time data for improved operational efficiencies.

Gartner recognizes C3global as part of the industrial analytics transformation helping digital businesses (as noted in Gartner’s “Industrial Analytics Revolutionizes Big Data in the Digital Business” report [G00264728], published August 19, 2014). Among the many infrastructure owner-operators benefiting from Amulet operational analytics are water utilities, oil and gas, and power transmission grids. User organizations include Babcock, BP, Chevron, Danfoss, Emerson, MWH, National Grid, South Australian Water, and Total.

AssetWise Amulet can be readily configured to build sophisticated applications tailored to infrastructure operations needs without having to know a programming language. It bridges the gap between information technology (IT) and operational technology (OT), enabling advanced analytics to be an integral part of all aspects of the business process. Through AssetWise Amulet’s interactive and easily configurable operational dashboards, owner-operators are provided with the context they need to be confident in their decisions and are afforded an easy method of measuring and managing the outcomes.

AssetWise Amulet is designed to integrate and analyze “big data” generated by a wide range of external applications and systems – from SQL or Oracle databases to enterprise data warehouses, industrial data historians, and control systems, as well as maintenance and work order management systems. The data can be structured or unstructured and include systems data, photos, video, log books, Microsoft Excel files, event failures, scanned notes, witnessed events, and more.

Once data from the IT and OT systems has been captured and aggregated, the software applies the users’ business rules, models, and knowledge to provide an improved view and understanding of operational performance for decision support. In conjunction with AssetWise-certified integrations to SAP EAM, IBM Maximo, and Oracle eAM, AssetWise Amulet will help drive the right actions at the right time, reducing operational risks and improving operational efficiency.

Reality Modeling

Bentley Systems also announced that it has acquired France-based Acute3D, provider of Smart3DCapture software for reality modeling. Through reality modeling, observations of existing conditions are processed into representations for contextual alignment within design modeling and construction modeling environments. Rapid technology advancements in scanning and photography – and especially the burgeoning application of unmanned aerial vehicles (UAVs) for these purposes – are making the capture of such observations broadly and continuously affordable in sustaining infrastructure.

Acute3D software automates the generation of high-resolution, fully-3D representations from digital photographs taken with any camera, whether highly specialized or embedded in a smartphone. Scalable from site to city, and with precision limited only by the quantity and quality of photography, Acute3D technology can assure that existing conditions are contemporaneously considered throughout the architecture, engineering, construction, and operations of any infrastructure asset. Now that photo sequences from UAVs are likely to become the most feasible source for surveying, construction monitoring, and inspection workflows, Acute3D’s industrial-level accuracy and unlimited scalability are making it a preferred technology for UAV manufacturers and professionals around the world.

Process Safety and Risk Management

AssetWise APM V7.3 the enhanced version of Bentley’s asset performance management (APM) offering – an all-in-one analysis and information management software platform for asset reliability and asset integrity – now also advances process safety.

Alan Kiraly, Bentley senior vice president, server products, said, “Our AssetWise APM V7.3 meets the demanding requirements of reliability, integrity, safety, and maintenance managers and engineers in industries ranging from oil and gas, petrochemical, and mining and metals to power generation and other utilities. The software ensures assets are safe and reliable and that they are inspected and maintained to reduce or eliminate risk. Users further benefit from the elimination of unexpected downtime, increased asset availability and utilization, reduced maintenance costs, and support for regulations and safety standards, including ISA 84, IEC 61511, IEC 61508, and IEC 61882.”

AssetWise APM V7.3’s new process safety features help users manage the integrity of safety systems and hazardous processes, thereby preventing failures and catastrophic incidents and keeping people, assets, and the environment safer. Capabilities include safety instrumented function (SIF) analysis, safety instrumented systems (SIS), safety integrity level (SIL) and safety provisions, overrides, and incidents. AssetWise APM V7.3 also provides version control and approval, the analysis of loss of containment scenarios, and the identification and assessment of risks at the system level, as well as for related assets (risk matrix).

by Gary Mintchell | Feb 13, 2015 | Asset Performance Management, Automation, News, Operations Management

Asset performance management joined the Industrial Internet of Things as a key topic at the 2015 ARC Forum in Orlando. Here is a release from Meridium that reflects many of the trends—data collection, analysis, configurable display, mobility.

Meridium Inc., global supplier of asset performance management (APM) software and services, announced the availability of Asset Answers V2.0. The company claims this as the only cloud-based asset performance diagnostics solution that provides comparative analytics, delivering instant visibility into asset data, and supplying organizations with the insights to drive safer, more informed, and more profitable decisions.

Asset Answers 2.0 delivers next-generation APM insights into industrial assets and their health and overall performance, an improved user interface that includes dashboards and enhanced mobility on a variety of handheld devices that provides true anywhere/anytime availability. Since the introduction of Asset Answers to the market, more than 130 sites in the Petrochemicals, Oil & Gas, Power & Utilities, and Manufacturing industries rely on Asset Answers to support continuous improvement initiatives with the ultimate goal of achieving operational excellence.

For example, Dow Chemical was able to collect and analyze reliability audit report data for 25 production units across 4 plants in less than 1 day, saving 175 man-days of effort and remain focused on cost, availability, and reliability optimization for the company. Another Asset Answers client, Profertil, reduced costs for 30 straight months and was able to readily identify and highlight savings of $900,000 and counting.

According to Roy Whitt, Senior Vice President and General Manager for Asset Answers, “For organizations in asset-intensive industries, Asset Answers 2.0 uncovers the true cost, reliability and availability of asset groups and individual pieces of equipment with the click of a mouse. Subscribers can easily view performance criteria across sites and benchmark themselves anonymously against global industry peers. Combining data mining and preconfigured metrics, reliability engineers can investigate equipment data to identify assets that represent the best opportunities for improving maintenance costs and reliability. With access to the objective truth about asset performance, management can act with confidence to intelligently cut costs while increasing production, especially in times of shrinking margins.”

Asset Answers can identify and evaluate better performing equipment manufacturers and highlight predominant failure modes for specific equipment models. With this analysis, Asset Answers also can create opportunities for equipment improvements and automatically track the savings these improvements have provided.

Whitt also added that, “Asset Answers uses comparative analytics or ‘intelligent benchmarking’ that enables organizations to conduct ‘apples to apples’ comparisons of industrial equipment in production units across multiple plants within an organization. That same information helps organizations compare the relative performance of their assets against industry peers to gain a deeper understanding and a competitive advantage, optimize total cost of ownership (TCO) for critical assets and make better asset purchasing decisions.”

This approach both improves collaboration between Reliability, Engineering & Maintenance and also enables continuous and systematic improvement of operations and production output over time. Benefits of Asset Answers 2.0 include:

- A proven, systematic and secure approach to continuous improvement and Operational Excellence

- Improved plant and operator safety

- Mitigated operational and financial risk

- Improved insight into non-financial performance

- Lower asset total cost of ownership (TCO)