by Gary Mintchell | Mar 9, 2016 | Automation, Internet of Things, Interoperability, Operations Management, Technology

I’ve been thinking deeply about the industrial internet and the greater industrial ecosystem. A friend passed along an article from ZD Net written by Simon Bisson, “There’s A Huge Void At the Heart of the Internet of Things.”

The deck of the article reads, “Closed systems do not an internet make. It’s time to change that before it’s too late.”

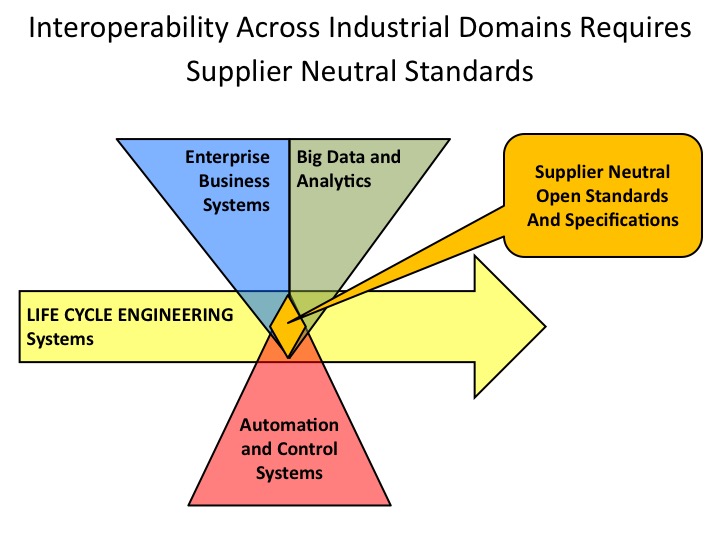

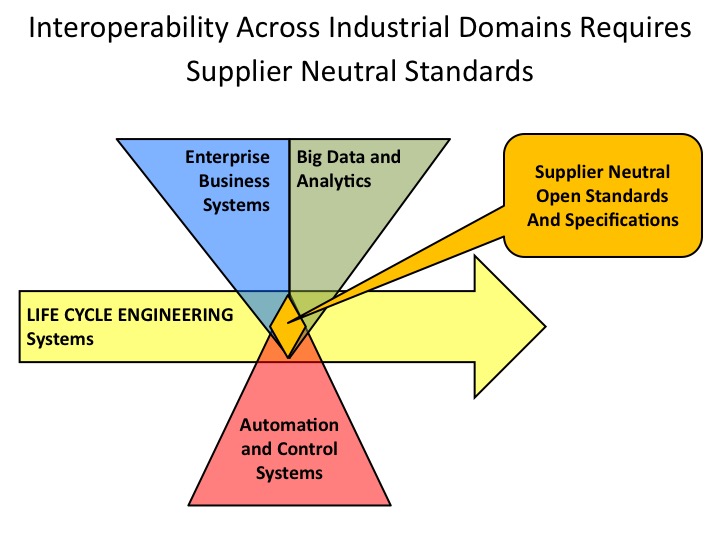

He knew I was working on some white papers for MIMOSA and the OpenO&M Initiative on interoperability of standards in the larger industrial ecosystem. In the case of what I’m writing, there exists a gap in areas covered by Enterprise Business Systems, Big Data and Analytics, Automation and Control Systems, and Life-Cycle Engineering Systems. The gap can be filled with Supplier Neutral Open Standards and Specifications.

Bisson writes, “Sensors are everywhere, but they’re solitary devices, unable to be part of a holistic web of devices that exposes the world around us, giving us the measurements we need to understand and control our environments.”

He notes a few feeble movements toward developing “communication and API standards for these devices, through standards like AllJoyn and Open Connectivity Foundation, the backbone is still missing: a service that will allow us to work with all the devices in our homes.”

Industrial Internet broadly speaking

Typical of a consumer-facing publication, he’s thinking home. I’m thinking industrial in a broad scope.

He continues, “Building that code isn’t hard, either. One of the more interesting IoT development platforms is Node-RED. It’s a semi-visual programming environment that allows you to drag and drop code modules, linking them to a range of inputs and outputs, combining multiple APIs into a node.js-based application that can run on a PC, or in the cloud, or even on devices like the Raspberry Pi.”

Bisson concludes, “The road to an interoperable Internet of Things isn’t hard to find. We just need to remember that our things are now software, and apply the lessons we’ve learnt about building secure and interoperable systems to those software things. And once we’ve got that secure, interoperable set of things, we can start to build the promised world of ubiquitous computing and ambient intelligence.”

I’d take his consumer ideas and apply them to industrial systems. The work I’m doing is to explain an industrial interoperable system-of-systems. I’m about ready to publish the first white paper which is an executive summary. I’m about half done with the longer piece that dives into much greater detail. But he is right. Much has already been invented, developed, and implemented at a certain level. We need to fill the gap now.

by Gary Mintchell | Feb 23, 2016 | Automation, Internet of Things, News, Operations Management, Organizations, Technology

Open Connectivity Foundation Seeks To Unify IoT

Companies are still organizing into groups seeking to influence standards, whether formal or industry, developing the Internet of Things. Here is an announcement from one pushed by Intel–who is seeking to be the chip supplier to the Internet of Things. I’m not sure how industrial this will be since one entity is the Open Interconnect Consortium whose focus was building and home.

The Open Connectivity Foundation (OCF) formed as an entity whose goal will be to help unify IoT standards so that companies and developers can create IoT solutions and devices that work seamlessly together. The goals according to the Foundation state, via cross-industry collaboration, the OCF will work towards unlocking the massive opportunity of the future global IoT segment, accelerate industry innovation, and help all developers and companies create solutions that map to a single, open IoT interoperability specification. Ultimately, with OCF specifications, protocols and open source projects, a wide-range of consumer, enterprise and embedded devices and sensors from a variety of manufacturers, can securely and seamlessly interact with one another.

The OCF unifies the entirety of the former Open Interconnect Consortium with leading companies at all levels – silicon, software, platform, and finished-goods – dedicated to providing this key interoperability element of an IoT solution. [I find this interesting given that I just attended a conference session with the president of the OIC speaking, no mention of “former”.]

The OCF’s vision for IoT is that billions of connected devices (appliances, phones, computers, industrial equipment) will communicate with one another regardless of manufacturer, operating system, chipset or transport. With the OCF fulfilling this promise, anyone – from a large technology company to a maker in their garage – can adopt the open standards of OCF to innovate and compete, helping ensure secure interoperability for consumers, business, and industry.

About Open Connectivity Foundation

Billions of connected devices (devices, phones, computers and sensors) should be able to communicate with one another regardless of manufacturer, operating system, chipset or physical transport. The Open Connectivity Foundation (OCF) is creating a specification and sponsoring an open source project to make this possible. OCF will unlock the massive opportunity in the IoT market, accelerate industry innovation and help developers and companies create solutions that map to a single open specification. OCF will help ensure secure interoperability for consumers, business, and industry.

TSN Test Bed

National Instruments announced a collaboration with the Industrial Internet Consortium (IIC) and industry leaders Bosch Rexroth, Cisco, Intel, KUKA, Schneider Electric, and TTTech to develop the world’s first Time Sensitive Networking (TSN) testbed. These organizations aim to advance the network infrastructure to support the future of the Industrial Internet of Things (IIoT) and Industry 4.0.

To support new digital capabilities, connected manufacturing, designers and users need more reliable and secure access to smart edge devices. Standard network technologies must evolve to meet the demanding requirements of these next-generation industrial systems and improve the way we operate our machines, electrical grids and transportation systems.

The goal of this testbed is to display the value of new Ethernet IEEE 802 standards, referred to as TSN, in an ecosystem of manufacturing applications. TSN powers a standard, open network infrastructure supporting multivendor interoperability and integration with new guaranteed performance and delivery.

The technology can support real-time control and synchronization, for example between motion applications and robots, over a single Ethernet network. TSN can at the same time support other common traffic found in manufacturing applications, driving convergence between IT and operational technologies. Previously, many real-time control applications were deployed using nonstandard network infrastructure or unconnected networks that leave the devices and data much harder to access, if accessible at all. TSN’s value is derived from driving convergence and increased connectivity, unlocking the critical data needed to achieve the IIoT promise of improved operations driven by big data analytics and enabling new business models based on smart connected systems and machines.

“Testbeds are a major focus and activity of the IIC and its members. Our testbeds are where the innovation and opportunities of the industrial Internet – new technologies, new applications, new products, new services and new processes – can be initiated, thought through and rigorously tested to ascertain their usefulness and viability before coming to market,” said Dr. Richard Soley, executive director of the IIC.

The testbed will:

• Combine different critical control traffic (such as OPC UA) and best-effort traffic flows on a single, resilient network based on IEEE 802.1 TSN standards

• Demonstrate TSN’s real-time capability and vendor interoperability using standard, converged Ethernet

• Assess the security value of TSN and provide feedback on the ability to secure initial TSN functions

• Show ability for the IIoT to incorporate high-performance and latency-sensitive applications

• Deliver integration points for smart real-time edge cloud control systems into IIoT infrastructure and application

Quotes:

“We are excited to host the new IIC TSN testbed. TSNs are a critical attribute of a standard Internet model that enables the convergence of real-time control applications and devices onto open, interconnected networks. This technology is necessary for the future of the IIoT and the IIC is providing a community, as well as enabling real-world testbeds, where industry leaders can collaborate to make this a reality,” said Eric Starkloff, executive vice president of global sales and marketing at NI.

“Standardized and open communication is a key feature in our drive and control automation solutions. We at Bosch Rexroth regard the IIC TSN testbed to be a very important contribution for further improvement of vendor interoperability and of exchanging data in an IIoT infrastructure,” said Ralf Koeppe, vice president of engineering and manufacturing electric drives and controls at Bosch Rexroth.

“The new IIC TSN testbed is an opportunity for KUKA to work with other industry leaders to prove standard technology for distributed real-time control systems as needed for edge cloud computing also known as “Fog Computing”. We view TSN, combined with OPC UA Publish/Subscribe, as a core element to implement Industry 4.0 standards,” says Christian Schloegel, chief technology officer of the KUKA group.

“As an innovator in the field of deterministic Ethernet, TTTech is delighted to join forces with industry leaders on the IIC TSN testbed. TTTech brings 20 years’ experience in time-scheduled networks and critical real-time controls to the IIC and looks forward to collaborating with the other testbed members to build an open, standard platform for the IIoT,” said Georg Kopetz, cofounder and member of the executive board for TTTech.