by Gary Mintchell | Jul 28, 2016 | Manufacturing IT, Operations Management, Software

A manufacturing software supplier must go beyond where they are to keep pace with today’s needs. GE Digital just announced such an extension–to offer decision support capabilities. The new GE HMI/SCADA software offers “comprehensive and best-in-class monitoring and visualization capabilities,” as well as work process management, analytics, and mobility. Based on ISA high performance design principles, this solution enables companies to troubleshoot faster, reduce waste and increase productivity.

“Most SCADA systems are still configured as HMIs – simply a display to indicate status,” said Matthew Wells, General Manager Automation Software for GE Digital. “In developing this new generation solution, we have combined industry standards, GE research and Industrial Internet technologies to exceed traditional HMI/SCADA, increasing operational efficiency and delivering on business outcomes.”

Context-driven navigation and situational awareness

The new GE software features a context-rich HMI that changes as the user moves through the system. Navigation is derived from a structured asset model. Using the model, the software always can provide operators with the most relevant information – in context – and minimize time to response. Additionally, the structured asset model mapped to the SCADA database significantly speeds configuration. Modern technologies such as HTML5 and Web HMI allow for centralized development and deployment, as well as accessibility anywhere in multiple form factors.

“With high performance HMI/SCADA, operators are able to quickly determine an abnormal situation and get to the root causes of many issues,” said Sergio Chavez, Automation Engineer with Los Angeles Dept. of Water and Power. “We help operators visualize a process and make alarms very visible. We’re shaving the time it takes for operators to act on a situation.”

To help engineers create the right user experience, GE also provides predefined smart objects and templates designed using efficient HMI concepts. Standard layouts and cards – such as trends, alarms, alarm summaries, and KPIs – are available out of the box, speeding configuration and improving user situational awareness.

Task management and mobility

Additionally, GE’s fourth generation HMI/SCADA portfolio has task management capabilities, triggering the right actions, at the right time, by the right person, in the right place based on alarms or other events. GE’s new Workflow 2.5 and Mobile 2.0 solutions extend the capabilities of Decision Support HMI/SCADA further, helping companies achieve their critical business outcomes with integrated workflows and intelligent alarming, available anytime and anywhere.

“Operator effectiveness allows operators the opportunity to grow professionally,” according to Bill Fritz, Director of Public Works, Waterford Township, Michigan. “They can reinvent themselves and gain new value-added skills. They can take on new roles.”

GE’s Wells explained, “Use technology to improve the operator experience and manage operations for greater efficiency. With just a quick look, operators today should be able to recognize which information requires their attention and what it indicates – which speeds response and drives to business outcomes.”

by Gary Mintchell | Jul 27, 2016 | Operations Management, Software

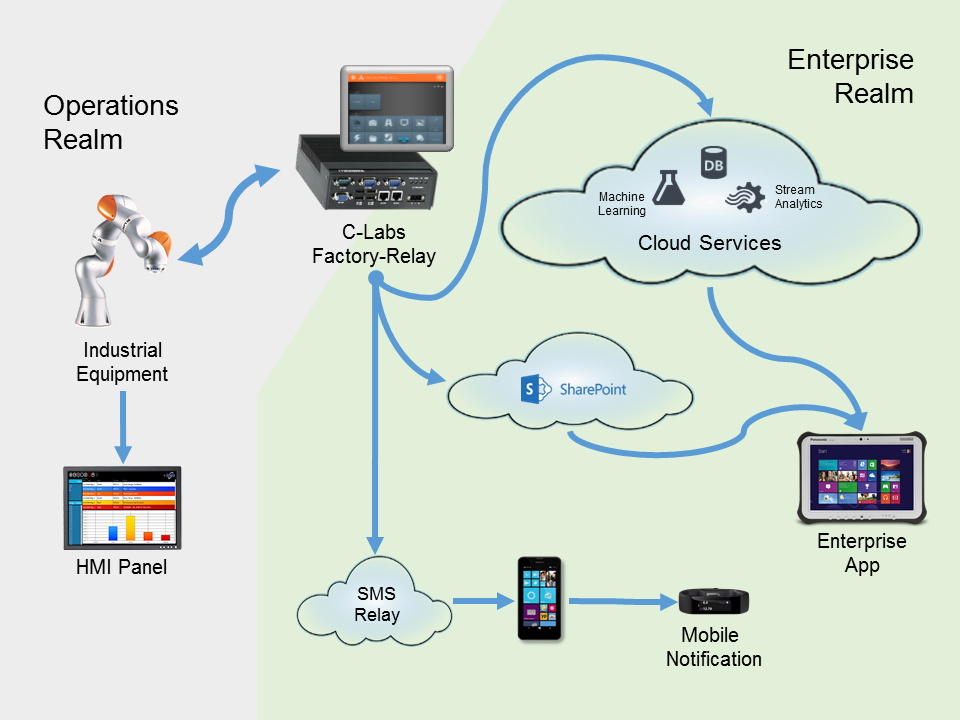

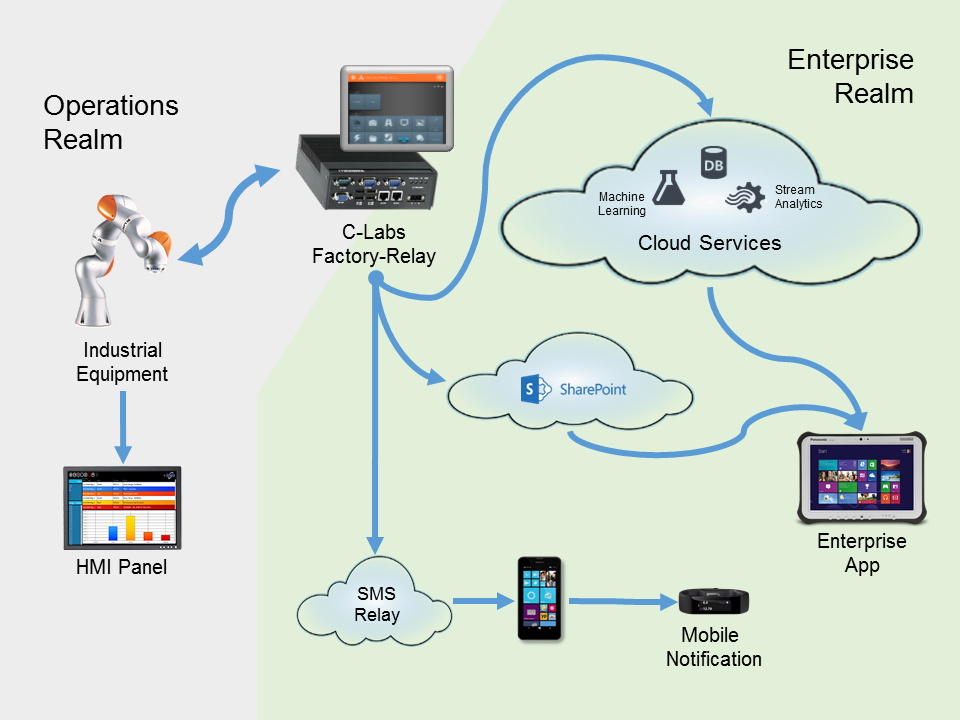

Linking manufacturing software with Microsoft Azure (not so surprising) and Office 365 (huh?) seems to be the new trend.

I wrote previously about GE Predix. People were curious if that was a statement about GE’s cloud. I thought maybe it was about linking to Office. Here is an announcement from Plex with a similar initiative.

[I’ve taken some vacation and am working on at least three intense projects. So my posts have slowed. Hopefully I pick it up soon.]

Here is the news about Plex.

Plex plus Microsoft

Plex Systems has announced an integration with Microsoft Corp. aimed at making it easy for companies to connect Microsoft’s desktop productivity applications to the Plex Manufacturing Cloud. Plex has also leveraged Microsoft’s Azure platform as the foundation for the Plex Developer Portal, the company’s new gateway for customers and partners using Plex’s growing portfolio of REST Application Program Interfaces (APIs).

The integration is part of Plex Connect, the company’s open integration framework that makes it easier for manufacturers to connect people, things and applications to the Plex Manufacturing Cloud.

Plex Connect: Microsoft Office 365

- The new Plex Workcenter Lookup app is now available on the Microsoft store.

- The app enables users to connect, view and analyze manufacturing data from Plex in Office 365, making it easier for business users to leverage that data for getting work done in the desktop applications they use every day.

- Built using Plex Connect REST APIs, the app enables real-time lookups, while maintaining role-based security for customer data.

- Leveraging Plex’s APIs, customers and partners can also create their own connections and applications to interact with the Plex Manufacturing Cloud in ways that support their unique business objectives.

Plex Connect: Developer Portal

- Plex also launched the company’s new developer portal, providing customers and partners with secure access to the company’s expanding portfolio of RESTful APIs.

- Leveraging Microsoft Azure, the Plex Developer Portal takes advantage of the platform’s scalability, tooling and managed services to support Plex customers’ growing requirements for enterprise connectivity.

- The Plex Developer Portal provides sample code, sandbox capabilities, documentation and other resources to help customers and partners build secure, robust connections between the Plex Manufacturing Cloud and third-party applications.

“Microsoft’s desktop productivity applications are fundamental to business, providing people and teams with flexible tools for running their day-to-day operations,” said Karl Ederle, group vice president, products at Plex Systems. “Our goal with Plex Connect is to make it easy for manufacturers to achieve a completely connected enterprise, with rich data always available to support business and customer objectives, whether through desktop applications or connections to other enterprise systems. The Azure platform is an ideal foundation for Plex Connect as we scale to meet the needs of global manufacturers.”

“Microsoft Office 365 and Plex Manufacturing Cloud are more valuable for our joint customers when we bring them together,” said Rob Howard, director, Office 365 Ecosystem, Microsoft. “The power to quickly pull real-time data from Plex’s manufacturing system of record directly into a tool like Excel enables professionals to use and analyze data in ways that support today’s most dynamic work environments.”

by Gary Mintchell | Jul 22, 2016 | Internet of Things, Operations Management

Dell held another Think Tank Industrial Internet of Things roundtable discussion on July 12 at a suburban Chicago conference room. Three Dell people attended as well as a representative of partner company Software AG. Twelve engineers or IT professionals from customer companies also attended. The format echoed that of the one held in Hannover, Germany. And once again I had the pleasure of moderating the discussion.

A few of the customers are actively studying and implementing an Industrial Internet of Things. The rest are deeply interested, but they have not yet started a program. Everyone was looking for ideas to help on their journey.

Everyone sensed that they really needed the help of an experienced guide or consultant to help them get started and organized. Those who were into the study were concerned about lack of clear standards of communication and data.

The principal application they were studying—predictive maintenance.

The most interesting comment pointed out industry’s leading role in the development of IoT technology and application. “Industry can drive this rather than our usual waiting until the commercial world proves it out.”

Industrial Internet of Things Excitement

We asked the group what things you are excited about with IoT.

We asked the group what things you are excited about with IoT.

- Ability to take care of problems remotely.

- There’s a lot of trial and error. It’s real exciting to try new things.

- IoT is the new generation of industrial manufacturing.

- How can IoT help our payment system as complexity increases but uptime needs to stay high. (from one attendee who was from a retail chain rather than industrial)

- We need smart maintenance. We are missing this in a small company. Systems get sick – I’d rather know when it’s going to be sick.

- Don’t want to be on the bleeding edge of technology.

- IoT is both imagination and nightmares. It is constrained only by imagination. But data scares me, security scares me, standards scare me. (Software AG)

- Rip and replace is expensive, but with this we can design for the future.

- It must be scalable.

What IIoT means

Then we asked, ‘What does IoT mean to you?”

Then we asked, ‘What does IoT mean to you?”

- For me, it’s the tablet that the maintenance guy has, with access to data. The engineers would be able to drill down to save time. Both – having that access right with them.

- Customer requests. When they call at 7pm, they want an answer by 7:15. It can take you 8 hours to pull the data together, would be great to pull data up immediately.

- We’ve been dragged into things in the past, would be great to be proactive.

- My industry has gone through transformation. Before, we were siloed, now we are integrated. How is change happening and how does it impact me?

- If you could pull together, say, unstructured social data with repair data. The marketing groups have the social data, the repair teams have the repair data, but the engineer responsible for solving the problem is in the middle, but missing the info from end to end. (Toyota example)

Visual Recorder Sue Keeley

OT/IT convergence

- We are struggling with this – we are silo’d with each small group doing the best they can (quality, engineering, etc) but it’s not coming together. We are a midsized company – do we really need a CIO? You can’t just hire data scientists, because they don’t know your processes.

- You want to future proof, but you want to past proof too. You must bring your legacy solutions along.

- Nomenclature can get in the way. We define opportunities by what we are going to deliver. Key challenge is to segment appropriately to get things done, but to also have everything connect in the future.

Visual Recording of Discussion

Interest in actually implementing Industrial Internet of Things continues to grow. This is going to be interesting.

by Gary Mintchell | Jul 18, 2016 | Automation, Operations Management, Software

SafeMove2

[Industrial] “Software’s Where It’s At.” The blog title was intriguing. It was implied that industrial software was increasingly more important than hardware. Then I began to look at my accumulating queue of news. There is a bunch. Here is a sampling. It appears that more innovation time and investment is going into software than hardware. What do you think? Software is now where it’s at?

Cloud and Analytics

GE and Microsoft announced a partnership that will make GE’s Predix platform for the Industrial Internet available on the Microsoft Azure cloud for industrial businesses. The move marks the first step in a broad strategic collaboration between the two companies. This continues a trend I’ve noticed recently of a newly resurgent Microsoft adding clients to Azure cloud.

“Connecting industrial machines to the internet through the cloud is a huge step toward simplifying business processes and reimagining how work gets done,” said Jeff Immelt, CEO of GE. “GE is helping its customers extract value from the vast quantities of data coming out of those machines and is building an ecosystem of industry-leading partners like Microsoft that will allow the Industrial Internet to thrive on a global scale.”

Bringing Predix to Azure, according to GE, means industrial customers will now have access to additional capabilities such as natural language technology, artificial intelligence, advanced data visualization and enterprise application integration.

Microsoft predicts Azure will support the growth of the entire industrial IoT ecosystem by offering Predix customers access to “the largest cloud footprint available today”, along with data sovereignty, hybrid capabilities, and advanced developer and data services. In addition, GE and Microsoft plan to integrate Predix with Azure IoT Suite and Cortana Intelligence Suite along with Microsoft business applications, such as Office 365, Dynamics 365 and Power BI, in order to connect industrial data with business processes and analytics.

“Every industry and every company around the world is being transformed by digital technology,” said Satya Nadella, CEO, Microsoft. “Working with companies like GE, we can reach a new set of customers to help them accelerate their transformation across every line of business — from the factory floor to smart buildings.”

Software’s Where It’s At

This is the blog that brought my thinking to a focus. ARC analyst Mark Sen Gupta wrote about a recent CEO appointment. Honeywell recently announced that Dave Cote is retiring after 14 years at the helm and will be succeeded by Darius Adamczyk.

In the announcement Mr. Cote states, “Scanning & Mobility and Honeywell Process Solutions are software-based businesses with advanced offerings that blend physical and digital capabilities, and they serve as benchmarks for where the rest of Honeywell is heading. Darius’ deep expertise in software will open new growth paths for all of our businesses, which are blending Honeywell’s advanced software programming capabilities with leading-edge physical products and unparalleled domain expertise in a wide variety of industries.” This is a very interesting statement because it recognizes a crucial shift in automation.

Says Sen Gupta, “When we think of automation we normally think of hardware: DCS, PLC, sensors. However, most of the innovation in the industry is happening in software. This aspect of automation innovation has not escaped the attention of ExxonMobil and has led to culmination of it’s open automation initiative. IIoT, cloud, analytics, edge computing have far more to do with what is provided from a software aspect than from a hardware aspect. This is not to say that hardware has no value. In fact if you were to check the balance sheets, you would find that the large automation companies earn more revenue on what we consider hardware, and something has to host the software.”

Digital Twin

Fellow ARC analyst, Dick Slansky recently wrote on how manufacturing and production systems will undergo significant changes. He foresees the eventual realization of the “lights-out” factory with adoption of all the new digital technologies.

“This is a case of leading PLM solutions providers offering advanced analytics solutions applied to the manufacturing processes and to operational optimization. The common objective is to use predictive and prescriptive analytics to improve the overall performance of production operations.”

He continues, “One of the most sought after but elusive goals of product design engineering is to validate that you have achieved all the design criteria in the as-built product. That is, closing the loop between the as-built to the as-designed, and validating that the physical product will meet all design criteria before the product is manufactured. This is where the concept of the digital twin in now being applied to product design criteria, and the goal of ‘closed-loop PLM’.”

“As IIoT, the digital thread and digital twin evolve within the overall ecosystems of product and process, the methodologies, including analytics, for both product development and production processes will converge. The intent and goal of the digital enterprise is to maintain a continuous and real-time digital thread that connects the lifecycle from concept through design, test, and build, to supply chain and products in field.”

ABB Robotics

There has been little radical innovation within industrial robots for some time. Improvements, yes; Innovation, not so much.

But ABB has been working on the software side. It just announced SafeMove2, the latest generation of its safety certified robot monitoring software.

SafeMove2 includes a host of cutting-edge safety functions, including safe speed limits, safe standstill monitoring, safe axis ranges and position and orientation supervision. The new generation functionality encourages the development of innovative robot applications by integrating safety features directly into the robot controller.

“To be efficient, robots must be able to move at speeds suited to the given application. At high speeds this can present a potential hazard for people working in the immediate vicinity. Historically, fences or cages have been used to separate man from machine in an effort to keep them out of harm’s way,” says Dr. Hui Zhang, Head of Product Management, ABB Robotics. “SafeMove2 allows robots and operators to work more closely together by restricting robot motion to precisely what is needed for a specific application.”

SafeMove2 allows for the creation of more efficient and flexible production scenarios, and provides tools that speed the commissioning workflow for faster setup and validation. It also integrates safety fieldbus connectivity into ABB’s IRC5 robot controller family as well as the IRC5 Single, Compact and Paint controllers.

by Gary Mintchell | Jul 11, 2016 | Internet of Things, News, Operations Management, Organizations, Technology

The Industrial Internet of Things is a phrase encompassing a range of technologies and applications across consumer and industrial worlds. Where there is a technology and/or new application with suppliers poised to provide the technology or application expertise, there is an organization. And the organization exists to provide information.

The Industrial Internet Consortium (IIC), the global, not-for-profit, open membership organization formed to accelerate adoption and enablement of the Industrial Internet of Things (IIoT), announced the second edition of The Journal of Innovation. A biannual publication written by IIC members, the second edition of The Journal of Innovation features articles about the Industrial Internet technologies and services that are disrupting the global economy.

“IIoT technologies and processes are expected to generate remarkable business outcomes that will impact the global economy across all industry sectors. The IIC Journal of Innovation showcases innovations driving this transformation through the integration of people, processes, and data,” said Dr. Richard Soley, Executive Director, Industrial Internet Consortium.

The Journal of Innovation includes the following articles about disruptive IIoT technologies authored by IIC member companies:

- Organizations can expect business-model disruption from IIoT platform innovations – an example in transportation – InterDigital.

- The requirements for a connected, interoperable environment for the Industrial Internet – Thingswise/GE Global Research.

- Developing secure, interconnected medical systems – Real-Time Innovations, Inc./Massachusetts General Hospital/Partners HealthCare.

- Vertical Taxonomy Landscape – the business dynamics and technical considerations of IIoT by industry sector – MITRE.

- How IIoT technologies are transforming retail – Tata Consultancy Services.

Note the keywords that are important to the entire IIoT ecosystem.

- Interconnected (key enabler)

- Interoperable (the data must be in a form to be used by multiple applications)

- Secure (if we are connecting plant assets, security is essential)

- Business-model disruption (bright people in a myriad of industries are figuring out new ways of doing business by utilizing data and advanced data analytics)

I took a few vacation days last week, so only a couple of posts. Remember to check out my podcast on Deep Work. I’ll also be taking a couple of days off this week. Tuesday evening I will be moderating another Dell Think Tank (this one in suburban Chicago) on IIoT. Many people are interested in the concept. They just need to figure out what it means to them and how they can use it.

We asked the group what things you are excited about with IoT.

We asked the group what things you are excited about with IoT. Then we asked, ‘What does IoT mean to you?”

Then we asked, ‘What does IoT mean to you?”