by Gary Mintchell | Jun 28, 2019 | Automation, News, Security

Industrial Automation. I guess sometimes it’s good and sometimes not. Tesla had difficulty ramping up production on its low-end vehicle. Elon Musk blamed automation for his problems. Well maybe it was vaguely automation. But maybe they tried automating too much, or they automated things they shouldn’t have. Maybe Rockwell Automation now has a place he can drive to to learn more about automating production.

While I was traveling, Rockwell Automation released some news. I had to seek clarification on some. Here are two interesting items.

The first piece of news concerned Rockwell Automation opening an 8,000 square-foot Electric Vehicle (EV) Innovation Center at 111 North Market Street in San Jose, California, within its Information Solutions development facility. The center will provide live manufacturing demonstrations, hands-on trials utilizing new technology and events showcasing collaboration with industry experts and Rockwell Automation partners.

Upon first glance I thought maybe it was getting into the EV business. Actually it is bringing its experience and products from “Detroit” building cars to Silicon Valley building cars—just with different power trains.

Utilizing augmented and virtual reality modeling, the EV Innovation Center provides automotive start-ups and established manufacturers an environment to learn new technologies and standards, enabling them to deliver electric vehicles to market faster, with less risk and at lower cost.

The Center features not only traditional Rockwell products, but also features partners such as its FactoryTalk InnovationSuite powered by PTC, Eagle Technologies’ battery pack assembly machine, and FANUC robot technologies.

Other partners featured include Hirata, a turnkey assembly line builder, provides an assembly cell that demonstrates electric drive unit assembly and testing; Emulate 3D, Rockwell Automation’s simulation software, helps to prototype and test machines before they’re built; teamtechnik performs functional testing to confirm performance before building the drive into the electric vehicle.

“With growing global consumer demand, electric vehicle companies are challenged to meet aggressive production timelines,” said John Kacsur, vice president, Automotive and Tire Industries, Rockwell Automation. “We established the Electric Vehicle Innovation Center to expand their possibilities and get their products to consumers quickly and at the lowest possible cost, while operating more efficiently.

The second Rockwell news concerns its partner Claroty and cybersecurity services. To help prevent incidents and combat the unpredictable threats that cause them, industrial companies around the world can now manage cyber risk in their operations using the Rockwell Automation Threat Detection Services powered by the Claroty threat detection platform.

“A scary aspect of security threats is what you don’t know about them – what techniques they’ll use, what attack vector they’ll leverage, what vulnerabilities they’ll exploit,” said Umair Masud, manager security services portfolio, Rockwell Automation. “Our Threat Detection Services combine our innate understanding of industrial automation with Claroty’s trusted OT network visibility. The services can give companies peace of mind by protecting not only one facility but their entire supply chain from unpredictable threats.”

The Threat Detection Services help safeguard connected operations in three key ways:

- Identify and Protect: Identifying all industrial control networked assets, and their vulnerabilities, to help companies know what to protect

- Detect: Monitoring networks for not only known threats but, more importantly, anomalous traffic or behaviors to alert companies of a security incident – possibly before it even happens

- Response and Recovery: Developing plans for containing, eradicating and recovering from attacks to keep operations running or more quickly return to a fully operational state

The Claroty threat detection platform creates an inventory of a user’s industrial network assets, monitors traffic between them and analyzes communications at their deepest level. Detected anomalies are reported to plant and security personnel with actionable insights.

“The Claroty platform, used within the Threat Detection Services, can accelerate a company’s journey to more connected and digitally driven operations,” said Amir Zilberstein, co-founder and CEO, Claroty. “Most critically, the platform can help companies detect and quickly respond to threats that bypass their security controls. But it can also give companies a deeper understanding of their industrial assets and improve their ability to keep operations running.”

by Gary Mintchell | Jun 27, 2019 | Manufacturing IT, Podcast

I’ve been busy behind the microphone lately. Here is news about my latest Gary on Manufacturing podcast (I’m taking suggestions for a new name since I cover a much broader area than manufacturing) plus a conversation I had for an SAP-sponsored podcast with the famous Tamara McCleary for a series called TechUnknown. Finally, I will refer you to an education resource Website.

Gary on Manufacturing 191

Podcast 191–If we are ever going to finally bring IT and OT together, indeed break through all of a company’s silos, it will be through adopting coaching as a key component of the manager’s tool kit. I reference Trillion Dollar Coach by Schmidt, Rosenberg, and Eagle—a book about legendary Bill Campbell and how his coaching made the difference for executives at Google, Apple, and many more Silicon Valley companies. I also take a look at another Bill—Bill Gates—whose 10 top tech trends and 10 top challenges to solve appeared in this spring’s MIT Technology Review.

TechUnknown Podcast

I had an entertaining and informative conversation with Tamara McCleary. How do you manage the human element of automation & #AI adoption? I share my thoughts on real-life applications for #IIoT with @TamaraMcCleary on the @SAP #TechUnknown podcast.

Earn a Masters Degree

Industries of all sorts have a need for data scientists. I heard from a publicist for a Website that consolidates and explains degree programs in that area. If you or someone you know wants career advancement or change, check out this page.

by Gary Mintchell | Jun 26, 2019 | Data Management, Manufacturing IT, Operations Management, Software

Digitalization requires digital data, which in turn requires a place to robustly store that data. OSIsoft PI System must be the most widely used industrial historian database. Last November I wrote about the company bringing its PI System to Amazon Web Services (AWS). The company has released OSIsoft Cloud Services—a cloud-native, real-time data management system for unifying and augmenting critical operations data from across an organization to accelerate industrial analytics, data science projects, data sharing, and other digital transformation initiatives.

Given how deep I’ve been led into IT over the past few years, this advancement from OSIsoft becomes part of a significant trend of blending IT and OT just above the control layer. In fact, if you segregate off the actual “control” part of automation, that system itself has become an important element of Internet of Things (IoT) blending into the overall IT infrastructure. If you are not thinking the big picture in today’s industrial environment, then you will be missing important paths to profitability.

Back to today’s OSIsoft news. The OSIsoft Cloud Services (OCS) in a capsule:

- Data sharing – partner companies can access a shared data stream to remotely monitor technology

- Functionality – seamless crossover between the PI System and OCS to compare facilities, perform root cause analysis and run hypotheticals

- Scalability – tests proved OCS can simultaneously manage over two billion data streams, and safely share information with partners

- Petuum uses OCS to stream historical data and live data on production, temperature and variability to its AI platform to assist Cemex, a global cement manufacturer, improve yield and energy to 7% from 2%.

- DERNetSoft uses OCS to aggregate data in one place, allowing users to access useful analytics for ways to reduce power and save money.

- Pharma companies will use OCS to give a regulator access to anonymized drug testing or production, without risk of unauthorized users in the manufacturing networks.

With OCS, an engineer at a chemical producer, for example, could combine maintenance and energy data from multiple facilities into a live superset of information to boost production in real-time while planning analysts could merge several years’ worth of output and yield data to create a ‘perfect plant’ model for capital forecasts.

OCS can also be leveraged by software developers and system integrators to build new applications and services or to link remote assets.

“OSIsoft Cloud Services is a fundamental part of our mission to help people get the most out of the data that is at the foundation of their business. We want their cost of curiosity to be as close to zero as possible,” said Gregg Le Blanc, Vice President of Product at OSIsoft. “OCS is designed to complement the PI System by giving customers a way to uncover new operational insights and use their data to solve new problems that would have been impractical or impossible before.”

Data scientists spend 50 percent or more of their time curating large data sets instead of conducting analytics. IT teams get bogged down in managing VPNs for third parties or writing code for basic administrative tasks. Data becomes inaccessible and locked in silos. Over 1,000 utilities, 80% of the largest oil and gas companies, and 65% of the Fortune 500 industrial companies already use the PI System to harness critical operations data, turning it into an asset for improving productivity, saving money, and developing new services.

Natively compatible with the PI System, OCS extends the range of possible applications and use cases of OSIsoft’s data infrastructure while eliminating the challenges of capturing, managing, enhancing, and delivering operations data across an organization. Within a few hours, thousands of data streams containing years of historical data can be transferred to OCS, allowing customers to explore, experiment, and share large data sets the same day.

The core of OCS is a highly scalable sequential data store optimized for time series data, depth measurements, temperature readings, and similar data. OSIsoft has also embedded numerous usability features for connecting devices, managing users, searching, transferring data from the PI System to OCS, and other functions. OCS can also accept data from devices outside of traditional control networks or other sources.

“The scale and scope of data that will be generated over the coming decades is unprecedented, but our mission remains the same,” said Dr. J. Patrick Kennedy, CEO and Founder of OSIsoft. “OSIsoft Cloud Services represent the latest step in a nearly 40 year journey and there’s more to come.”

OCS is a subscription service currently available to customers and partners for use in facilities in North America. OCS will be extended to Europe and to other regions in the near future.

by Gary Mintchell | Jun 25, 2019 | Commentary, Manufacturing IT, Operations Management, Technology

Antonio Neri, HPE CEO, announced during his keynote address to HPE Discover Las Vegas 2019, that the company was moving toward “Everything as a Service”—a consumption-based model within the next three years. Wait, isn’t this a company that sells boxes? Lots of power inside the boxes, but still. Most of the conversations for the rest of the week reinforced this strategic direction.

From the press release, “HPE will offer entire portfolio through a range of subscription, pay-per-use and consumption-driven offerings, in next three years transitioning the company into an as a Service company over time.” The concept will work out as a service contract with the customer with built-in verifiability as a default. It will offer a low level of granularity.

In the industrial automation space, the reaction differed among competitors and customers when Inductive Automation (note: one of my sponsors) began with its version of pricing for its original HMI/SCADA software. Some 15-16 years later, it seems to be doing well. Actually well enough that in the past year a couple of competitors have announced their responses.

When we discussed Edgeline IoT during the arranged Influencer Coffee Talk—Tom Bradicich, HPE vice president, for years has been a visionary evangelist regarding data generated from the processes, aka the Edge. I met him during his stay at National Instruments where he received industrial grounding after his IBM days where he promoted the concept of “Big Analog Data.” He told us that now he has moved from being a visionary to being an historian. These ideas are now adopted, not just theory. When asked about owning data from manufacturing, he said unequivocally that IT will own the data.

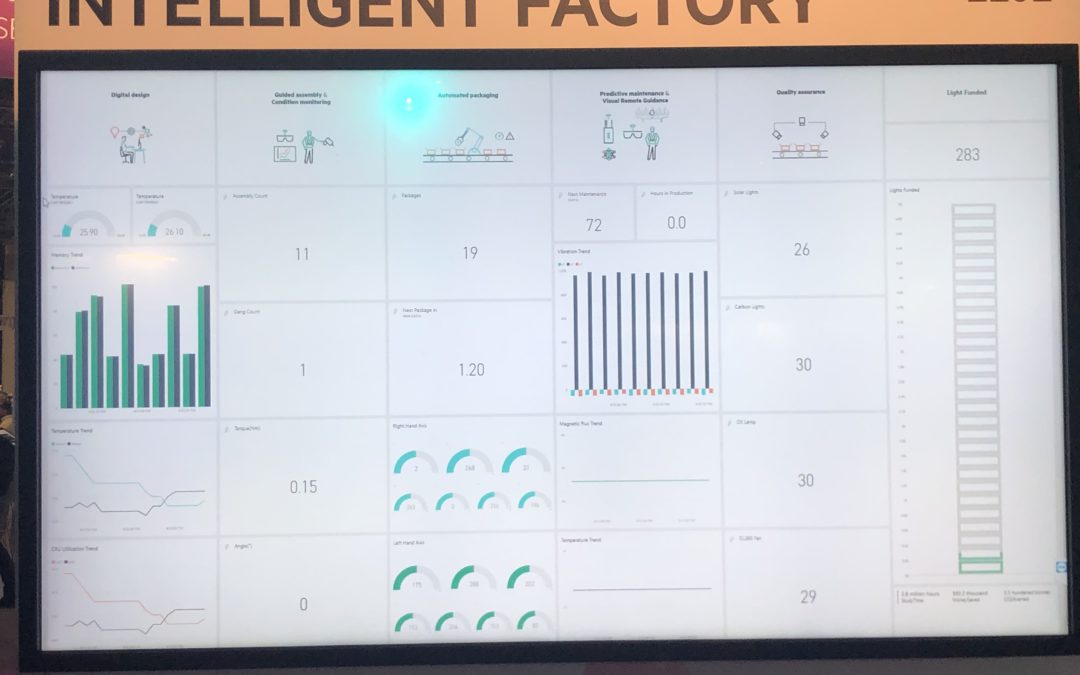

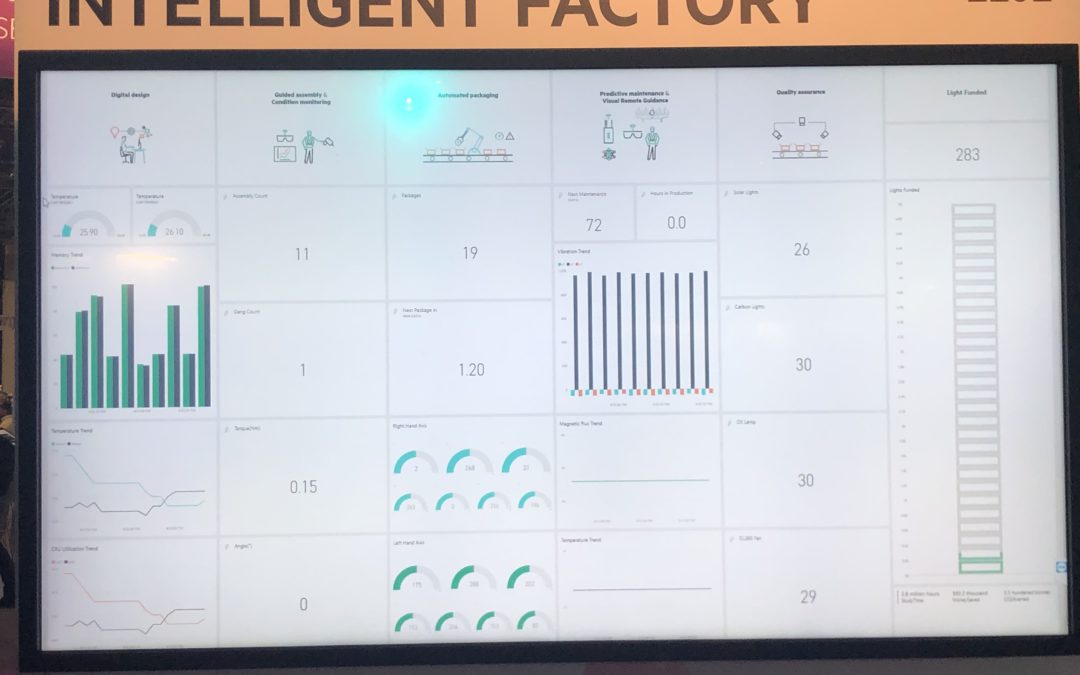

Manufacturing applications are not core to HPE, but we did get a lot of play during Discover. I gave a brief discussion of the manufacturing “demo” in my first post. It was one of the first stands on the exhibition floor. A mock up of a conveyor system with stations formed the layout of the exhibit. The system began with design, continued through assembly, looked at packaging, switched a little into predictive maintenance and troubleshooting of the line, then a quality station.

Two partners sill be immediately recognizable by regular readers—PTC and ABB. The design station featured Creo CAD from PTC along with Windchill PLM. The next station was guided assembly featuring PTC Vuforia augmented reality helping guide assembly along with PTC ThingWorx connecting data from the IP-enabled screwdriver (torque, presence, number of screws per assembly, and the like). An ABB dual-armed robot deftly prepared a box and inserted the product. Later on was another station using PTC’s Vuforia and ThingWorx.

At our 5G Influencer Coffee Talk, executives noted that 5G is still in process, but HPE Aruba is working on it. That is, 5G along with WiFi 6. Before long, there should be some interesting Aruba wireless products. 5G holds great potential for communicating things as well as people. We discussed the difficulties and potentials for handoffs from WiFi to Cellular and back. Could this be a better/faster SCADA? It’s build for today’s cloud not older computing architectures like LTE is.

During our security Influencer Coffee Talk, technologists from HPE discussed silicon-rooted trust. HPE makes its own ASIC that assures only authorized firmware is running on the device.

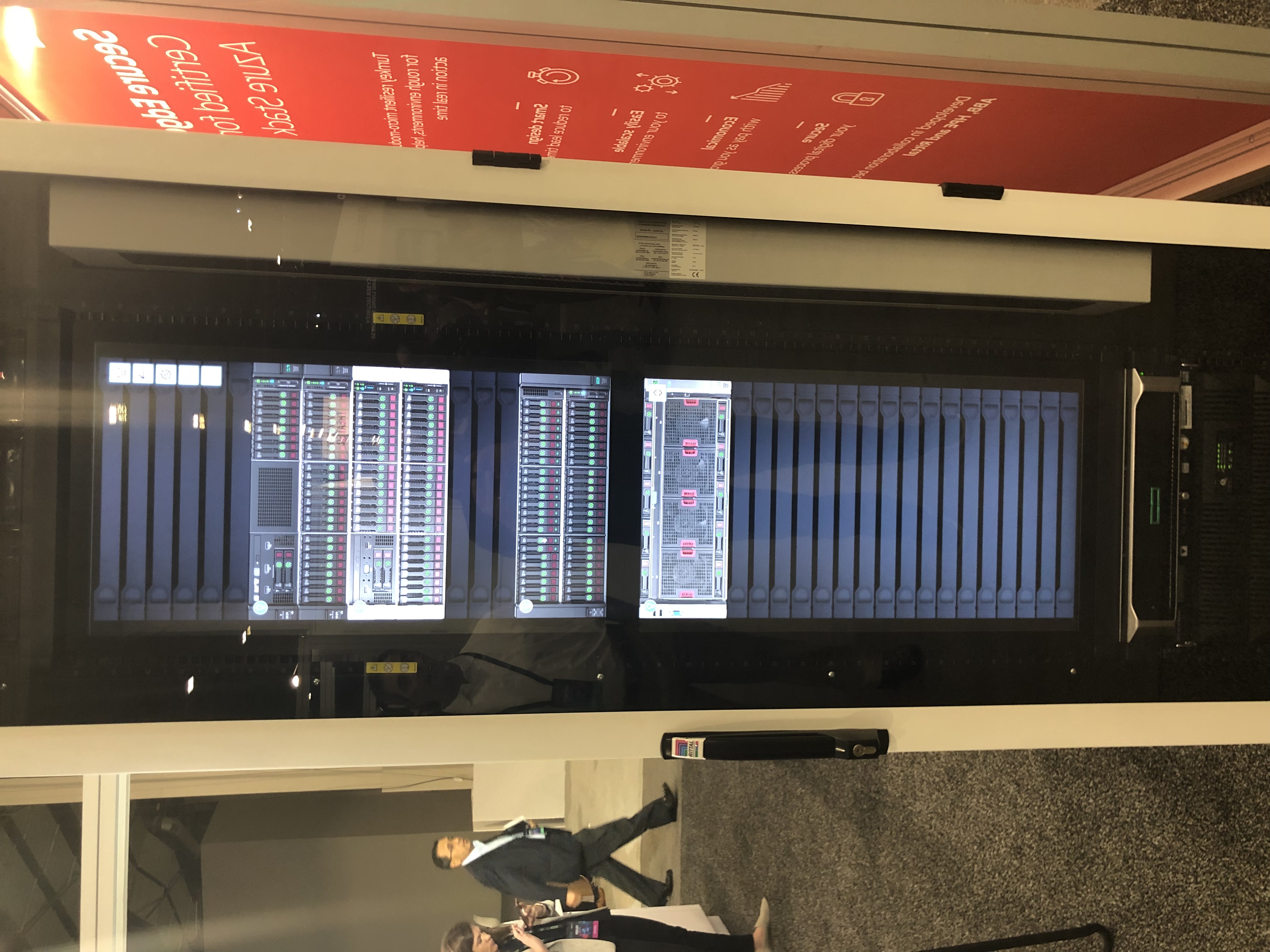

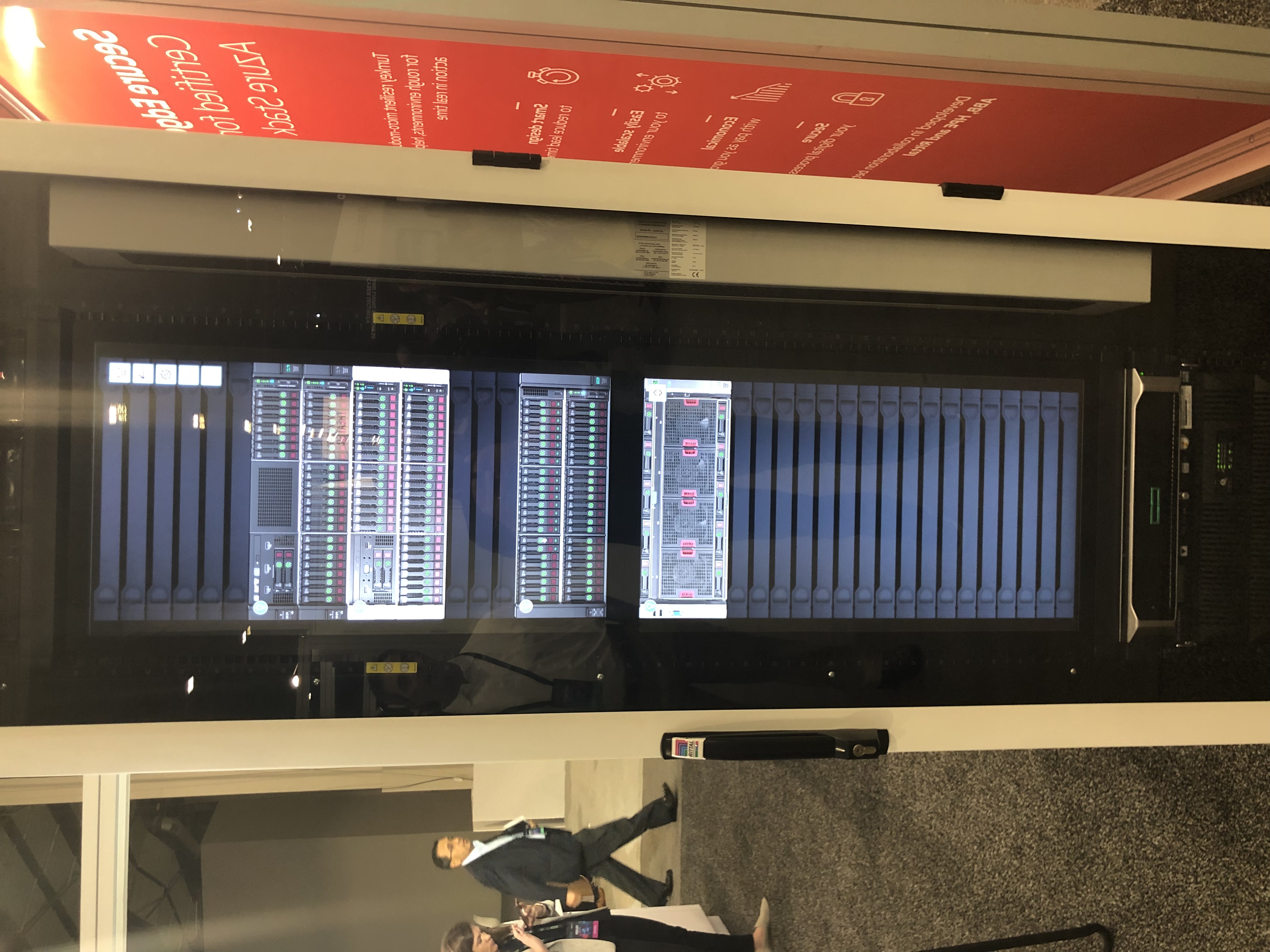

Finally, more thoughts relevant to manufacturing and production in industrial use cases. As “Dr. Tom” Bradicich told us during his session, data is created at the edge, so need the ability get at the data at the edge. Therefore the concept of move data center from cloud to edge. This is actualized by a partnership of HPE, ABB, Rittal, and PTC. There is sort of a “data center in a box”, although the box is actually a rack.

While I was checking the “box” out on the show floor, the representative from Rittal told me that customers at a recent conference in Monaco complained that it was too much work to install equipment at the edge. But this data center in a box concept overcame that objection.

On last tidbit for thought. HPE has a platform called NonStop—a very high availability compute platform. We spotted on in an Edgeline rack. The HPE statement held that it is inventing the market for high availability converged OT, not following. I wonder what applications this could disrupt.

by Gary Mintchell | Jun 19, 2019 | Industrial Computers, Internet of Things, Manufacturing IT, Operations Management, Technology

This week is IT week in my study of how IT and OT are coming together. I am in Las Vegas at the annual Hewlett Packard Enterprise (HPE) customer conference called Discover. This rather long post looks at many of the announcements that show how far HPE has come in its expansion into manufacturing.

An interesting point (and you can see some pictures on my Twitter feed @garymintchell) is that there is a manufacturing demo at the entrance into the show area this week. It demonstrates partnerships with PTC (CAD, augmented reality, and IoT), ABB (robotics in this case, more later), along with video and predictive maintenance analytics.

Following are summaries of a number of announcements at this very busy event that have an impact on manufacturing technology and use cases. HPE calls the Edge—meaning basically not in the servers.

Things announced included new edge solutions, research labs, and programs to simplify and accelerate Intelligent Edge adoption, enabling customers to create unique digital experiences and leverage analytics and machine learning to adapt to changes in real-time.

The new offerings and programs include:

- Major enhancements to Aruba Central, the only cloud-based platform that unifies network management, AI-powered analytics, user-centric service assurance and security for wired, wireless and WAN at the edge.

- Integrations and new turnkey edge-to-cloud solutions, delivered with ABB, Microsoft, Rittal, and PTC, enabling real-time intelligence and control in industrial environments.

- The Intelligent Edge and IoT Center of Excellence (CoE) and Labs, part of Hewlett Packard Labs, to develop and commercialize new capabilities and technologies that accelerate customers’ and partners’ Intelligent Edge journey.

Research suggests that over the next decade, the Internet of Things (IoT) and related data growth has an economic potential of up to $11 trillion per year. To capture this potential, organizations need to implement an Intelligent Edge, an architecture that is fully connected, secured, distributed and autonomous. However, to scale the Intelligent Edge across the value chain, organizations need solutions that secure and simplify deployment and management, converge operational technology (OT) with IT and address the lack of skills and funding.

“The edge has emerged as the new center of the digital universe, opening up opportunities for organizations to create new digital experiences and gain competitive advantage,” said Keerti Melkote, founder and president, Aruba, a Hewlett Packard Enterprise company. “Today, we announce innovations that will enable our customers to capitalize on these experiences and opportunities by dramatically simplifying, securing and accelerating the deployment of the Intelligent Edge.”

Unified cloud-based platform

Siloed network management solutions are creating complexity and increasing time to remediation. To accelerate IT operations and allow IT professionals time to focus on innovation, Aruba is making significant enhancements to Aruba Central. With these enhancements, customers will benefit from AI-powered network analytics, improved security and user-centric assurance for wired, wireless and WAN edge infrastructures from a single point of control. Significant advancements include:

Advanced AI-powered analytics and assurance capabilities based on Aruba NetInsight and User Experience Insight allow IT professionals to resolve infrastructure problems quickly before they impact the organization. Now integrated into the Aruba Central cloud-based platform, Aruba’s Analytics and Assurance capabilities deliver IT professionals a way to quickly remediate intermittent network issues while also proactively identifying how to optimize customers’ infrastructures to ensure optimal experiences.

Software-defined branch (SD-Branch) and SD-WAN, managed on Aruba Central, is now enhanced with improved branch management and orchestration capabilities to centrally define business-intent policies to meet the hybrid cloud connectivity needs for distributed enterprises and reduce operational costs. The new SD-WAN Orchestrator in Aruba Central makes it easier for IT professionals to deploy flexible and secure overlay topologies in a large-scale edge infrastructure, connecting thousands of branch locations with multiple data centers. Aruba Virtual Gateways now available for AWS and Azure, combined with orchestration, cost-effectively extends network and security policies to workloads running in the public cloud. The new SaaS prioritization feature not only enhances the performance of SaaS applications but also provides visibility about the end-user experience for business-critical applications, such as Microsoft Office 365 and Salesforce.

Integrated in Aruba Central, Aruba ClearPass Device Insight provides IoT visibility and security via a single pane of glass, employing automated device discovery, and machine learning-based fingerprinting and identification. Used in conjunction with Aruba ClearPass Policy Manager and Aruba’s dynamic segmentation security capabilities, networking and security teams can automate unique policy enforcement down to each device and user.

New network management workflow enhancements are integrated into Aruba Central to accelerate device provisioning with an automated mobile app to deliver network health views and troubleshooting across all locations allowing IT to focus on delivering the needs of the business.

Flexibility in how to obtain and support edge infrastructure

To provide organizations more flexibility and choice in how they obtain and support their edge infrastructure, Aruba solutions are also available via HPE GreenLake for Aruba a Network-as-a-Service (NaaS) subscription-based offering.

Turnkey edge-to-cloud solutions

In industrial environments, the Intelligent Edge requires an intricate interplay between sensors, actuators, networks, applications and infrastructures from edge to cloud. It also involves unique challenges including harsh environmental conditions, intermittent network connectivity and lack of qualified on-site staff. Consequently, such deployments are often costly, slow and vulnerable to security and reliability problems. To simplify, accelerate and secure deployments, HPE is launching pre-integrated turnkey edge-to-cloud solutions in collaboration with key industry partners:

The integration of ABB Ability Smart Sensor technology with Aruba access points is designed to deliver a scalable, high-performance wireless connectivity solution for operational technology (OT) equipment such as motors, mounted bearings and pumps. This allows industrial companies to capture valuable data and insights from their equipment to proactively monitor their condition and performance, and plan maintenance in advance in order to avoid costly and disruptive downtime.

Jointly developed by ABB, HPE, Microsoft and Rittal, the Secure Edge Data Center for Microsoft Azure Stack is the industry’s first enterprise-grade edge appliance for Microsoft Azure Stack, enabling real-time intelligence and action in harsh industrial environments, while providing seamless integration with Microsoft Azure. The appliance provides IP55-rated environmental protection, cooling, redundant power supply and distribution and automated management – allowing customers to run pre-configured, high-end enterprise applications in locations such as factories or oil rigs.

HPE Edgeline IoT Quick Connect dramatically simplifies the convergence of OT and IT, enabling customers to monitor and control OT equipment such as machines or motors in real time. Jointly delivered with Microsoft, HPE Edgeline IoT Quick Connect is based on the HPE Edgeline OT Link Platform, which connects OT devices, the HPE Edgeline EL300 Converged Edge System and Microsoft Azure IoT, a collection of cloud services to connect, monitor and control IoT assets.

Fast Start Condition Monitoring enables customers set up condition monitoring within 90 days to deliver performance and availability of their OT equipment. An end-to-end solution implemented by HPE Pointnext Services, Fast Start Condition Monitoring is designed for customers who want to get started quickly with condition monitoring, but lack the skills to do so. HPE Pointnext Services help define use cases, OT data sources and workflows, and implement pilots for proof of value, based on HPE Edgeline Converged Edge Systems, the HPE Edgeline OT Link Platform and PTC’s ThingWorx Industrial IoT platform.

The newly established Intelligent Edge and IoT CoE & Lab provides critical capabilities and technologies to HPE’s partners and customers to accelerate Intelligent Edge adoption. It will guide partner activities, M&A and research in the following areas:

- Knowledge transfer to HPE’s channel partners to accelerate market adoption of the Intelligent Edge with the Channel to Edge Institute (CEI), a program which helps HPE’s channel partners gain the required expertise to effectively recommend, sell, implement and manage Intelligent Edge solutions for their customers. The CEI provides training on Intelligent Edge use cases and business cases and will deploy joint go-to-market programs with HPE’s channel and ecosystem partners.

- Research programs to drive rapid commercialization of Intelligent Edge technologies that simplify edge-to-cloud management and OT-IT convergence and enable new use cases – this includes, among others, a unified provisioning, policy and security management across wired networks, Wi-Fi and 5G; the next generation of HPE’s first-of-a-kind HPE Edgeline Converged Edge Systems and HPE Edgeline OT Link Platform; and real-time video analytics for quality, security and customer experience applications.