by Gary Mintchell | Mar 7, 2016 | Operations Management, Software

Tim Sowell always packs many operations management ideas into a brief blog post. Sowell is a VP and Fellow at Schneider Electric Software (Wonderware). I’ve looked at his posts before. He is always thinking out in front of most people.

Tim Sowell always packs many operations management ideas into a brief blog post. Sowell is a VP and Fellow at Schneider Electric Software (Wonderware). I’ve looked at his posts before. He is always thinking out in front of most people.

His Feb. 14 post, Composite Frameworks What Are They, the Shift to Model Driven vs. Custom: How Do They Play?, takes a look at moving the user experience of operations management software into newer territory.

He probably says much more, but this is the take I’m going to analyze. He’s pointing out the difficulties of using traditional approaches to programming and presenting User Interfaces in a way that keeps pace with today’s expectations.

“Traditionally companies have built User Interfaces to an API, with the calls needed to execution actions and transactions; these have worked well especially within a plant. But a key to operational systems being effective and agile is their ability to adapt on a regular basis. This requires a sustainable and evolving system. This is especially important in form/ transaction activities where information is provided and where actions/ data input, and procedures need to be carried out.”

He does not stop there but proceeds to enumerate some challenges:

- Operational Process cross-over functional domains and applications

- Lack of governance

- AgilityResponsive manufacturing business processes

- Increase the performance of their people assets

- Too much Custom Code, making it unmanageable and evolutionary

He wonders why we can’t use techniques gleaned from Business Process Modeling. That’s a good question! He notes that some people will say that BPM is not real-time like manufacturing/industrial applications are. But he rebuts that “this also aligns with what the industrial world is very comfortable world with—that of ‘stable in control loops’.”

Operations management solutions

Here are some proposed solutions:

- Providing a graphical configuration environment for the capture and defining of operational process including the validation of data input, and guiding actions, working inline with the user Interface/ forms etc.

- Providing a framework for building of reusable forms, and reusable procedures that can be managed as templates and standards to enforce consistent operational practices.

- Empowering the operational domain people to develop, evolve and manage their procedures.

“Most of all empowering the different roles in the plant, that operational close loop moving to an “activity” centric system where information, and action is driven from a consistent operational model and practices.”

This is a consistent Sowell message. Let’s see what we can template-ize or project as a model rather than custom code everything.

More and more owner/operators and users I talk to are getting tired of the expense and lead-time for custom coded projects. They need the speed and flexibility of using models and standards for application implementation. I think this is where Sowell was headed (if not, he’ll correct me, I’m sure). This will serve to move industry forward as a more profitable contributor to enterprise health.

by Gary Mintchell | Mar 4, 2016 | News

[This article is updated as of 10/30/19. I received information that noted Google’s Tango has been shelved, but that there is still work being done on the platform. Thank you to Luke Pensworth of Daily Wireless.]

This news is a little outside my usual commentary, but it does reflect a trend. Augmented reality developments have grown steadily for many years. I first wrote about it before it had a name in the late 1990s regarding maintenance applications. Potential applications now are growing faster than the imagination right.

This “first-of-its-kind mobile augmented reality solution” creates a life-size 3D, virtual vehicle to enhance the car buying experience.

Fiat Chrysler Automobiles (FCA) unveiled a prototype of an immersive car sales application at Mobile World Congress designed and built by Accenture Digital using Google’s Project Tango developer kit. The prototype demonstrates how augmented reality can revolutionize the shopping experience for consumers by allowing them to view and interact with a full-scale virtual version of the object – or car – they are considering buying.

The prototype allows car buyers to hold a device and, using the integrated sensor technology and motion tracking, area learning, and depth perception from Project Tango, view, walk around, look inside and configure a life-size virtual car. On the Accenture demo, doors can be opened to reveal a realistic and detailed interior, where changes to upholstery colors or dashboard styles can be made with a tap on the device screen.

Project Tango technology gives mobile devices the ability to navigate the physical world similar to how we do as humans. Project Tango brings a new kind of spatial perception to Android devices by adding advanced computer vision, image processing, and special vision sensors. A Project Tango device maps the 360-degree environment around it, meaning that as it is moved it navigates and views the changing environment in the same way as a person would. As the car is viewed through the device, the virtual car moves in relation to how the user moves.

The first commercial Project Tango device is expected to be available in summer 2016 and this application will be previewed to attendees of this year’s Mobile World Congress. Accenture Interactive, part of Accenture Digital, has worked with FCA to create an application for this new technology that will transform the process of buying and configuring a new car.

Untethered Augmented Reality Experience

Users of the FCA car configuration solution will be able to walk freely around a full-scale vehicle in almost any environment because Project Tango enables an untethered, handheld experience that does not rely on external tracking technology such as markers, beacons or GPS.

“Project Tango is a new, unique technology that is set to become standard functionality in the next generation of mobile devices,” said Matteo Aliberti, Digital Innovation lead for Accenture Interactive EALA. “Accenture has been experimenting with Project Tango and potential business uses for as long as it has been in development, creating a range of potential applications, including this one for the automotive industry.”

Accenture’s design-led development of this solution means that the process of making decisions about cars will be completely transformed with the new generation of mobile devices. FCA is the first automotive brand to use this type of digital car configuration tool. Today’s car configurators are essentially flat, so with this tool FCA customers could have a more interesting and immersive experience.

This work is the latest collaboration between FCA and Accenture that aims to deliver a new and unique digital experience for FCA customers.

“Augmented reality is set to transform the way car-buyers choose and configure vehicles through the provision of immersive technology because it provides an enjoyable, delightful experience for customers,” said Luca Mentuccia, senior managing director and head of Accenture’s Automotive practice. “We believe dealers and car buyers will be quick to embrace this enhanced way of buying a car as the new devices become readily available, taking advantage of the 360-degree mapping environment to create this unique experience.”

by Gary Mintchell | Mar 3, 2016 | News, Organizations, Standards, Technology

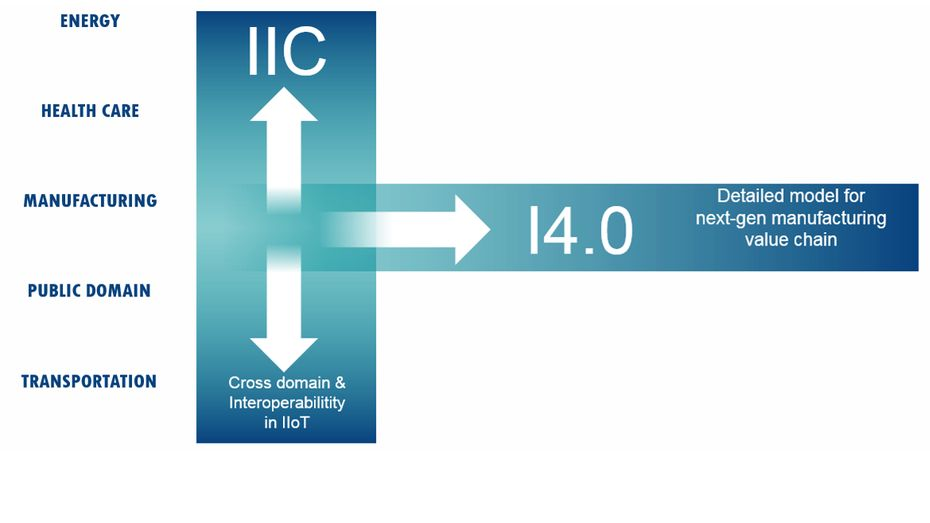

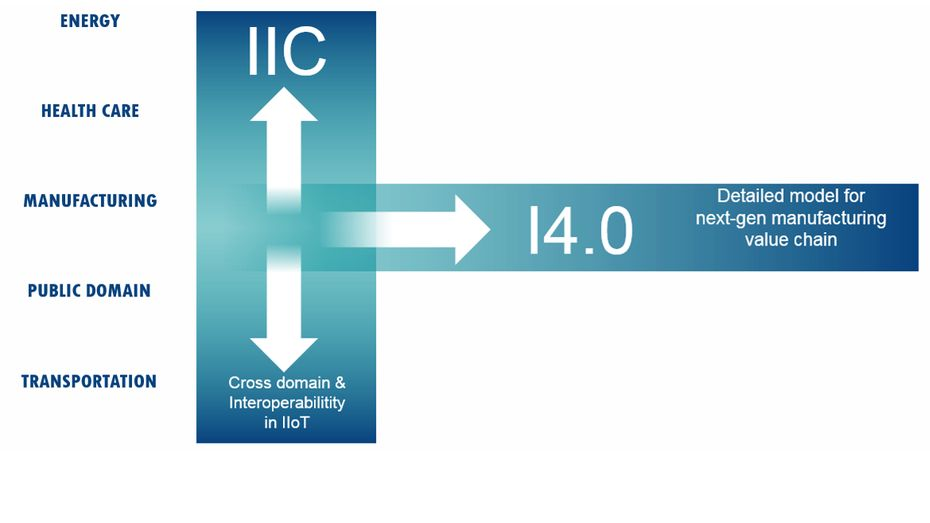

Interoperability among systems spurs economic and technological growth. Two of the leading proponents of new strategies for this next Industrial Revolution that we are beginning recently met.

Interoperability among systems spurs economic and technological growth. Two of the leading proponents of new strategies for this next Industrial Revolution that we are beginning recently met.

Representatives of Plattform Industrie 4.0 and the Industrial Internet Consortium met in Zurich, Switzerland to explore the potential alignment of their two architecture efforts – respectively, the Reference Architecture Model for Industrie 4.0 (RAMI4.0) and the Industrial Internet Reference Architecture (IIRA).

The meeting was a success, with a common recognition of the complementary nature of the two models, an initial draft mapping showing the direct relationships between elements of the models, and a clear roadmap to ensure future interoperability. Additional possible topics included collaboration in the areas of IIC Testbeds and I4.0 Test Facility Infrastructures, as well as standardization, architectures & business outcomes in the Industrial Internet.

The Zurich meeting was originally proposed by Bosch and SAP as members of the steering committees of both organizations. The meeting constituted an informal group which will continue their work on exploring potential alignment between I4.0 and IIC.

The open, informal discovery group included Bosch, Cisco, IIC, Pepperl + Fuchs, SAP, Siemens, Steinbeis Institute and ThingsWise.

Every press release these days, especially when it is an association of many members, includes the requisite quotes. Below are thoughts from some of the leaders.

Industry Reference Architecture Thought Leaders

State Secretary, Matthias Machnig, Ministry for Economic Affairs and Energy: “We welcome the cooperation of both initiatives as an important milestone in the cooperation of companies internationally. The combined strengths of both IIC and Plattform Industrie 4.0 will substantially help to pave the way for a mutually beneficial development of a digitized economy for our international businesses.”

Prof. Dr. Siegfried Russwurm, Technical Director of Plattform Industrie 4.0, CTO and Member of the Managing Board of Siemens AG, said “Collaborating with other initiatives is important, especially for Germany’s export-oriented economy. We are highly interested to cooperate intensively with others in order to pave the way for global standards. Cooperating with IIC – and with other consortia – is an important step in the right direction”

Dr. Richard Mark Soley, Executive Director of the Industrial Internet Consortium, commented, “The effort shows that smart technical people can bridge any gap and find a way to solve problems that might otherwise have created barriers to entry in the adoption of IoT technology for industrial applications. I applaud the participants and thank them for their initial work, and look forward to a successful collaboration moving forward.”

Dr. Werner Struth, member of the Bosch board of management: “This is a huge accomplishment for industry adoption of the Industrial Internet of Things, as it will simplify technology choices immensely and lead to greatly enhanced interoperability.”

Bernd Leukert, Member of the SAP Executive Board emphasizes the importance of alignment between IIC and Plattform Industrie 4.0-initiated testbed initiatives: “This will allow for a much smoother international cooperation between smaller companies and larger enterprise to test out use cases and to initiate standards.”

Greg Petroff, Chief Experience Officer for GE Digital, said: “Breaking down the barriers of technology silos and supporting better integration of these architectures efforts will be key to advancing the Industrial Internet. This collaboration will help build a vibrant, united community around standards that drive integration toward solving the world’s toughest challenges.”

Robert Martin, Senior Principal Engineer in Cyber Security Partnership, The MITRE Corporation and member of the IIC Steering Committee, said “Bringing together the work of the Industrial Internet Consortium and the Plattform Industrie 4.0 Konsortium will dramatically increase the international value of both efforts and help to clarify and resolve the problems and concerns facing the global Industrial IoT marketplace quicker and more effectively than either could do alone.”

“I’m excited to see the two premier Industrial Internet of Things organizations aligning their efforts,” states Stan Schneider, CEO of Real-Time Innovations (RTI) and a member of the IIC Steering Committee. “Industrie 4.0’s strong foundation in industrial manufacturing and process combines well with the IIC’s emphasis on emerging IIoT applications in healthcare, transportation, power, and smart cities. We are working aggressively to align the connectivity infrastructures of the underlying DDS and OPC UA connectivity standards. We look forward to driving the rapid growth of the IIoT across all industries.”

by Gary Mintchell | Mar 2, 2016 | Operations Management, Software

Much time has been invested learning about GE’s new directions, including GE Digital, Digital Twin, Digital Thread, Industrial Software, and Industrial Internet of Things. Then I saw news coming from GE’s annual report–that it has a $5 billion industrial software and analytics company within it that is growing at 20% annually. That is a significant industrial software giant. Letting the GE letter speak for itself:

Digital Industrial

“We are just beginning our transformation as the Digital Industrial Company. The Internet has had a massive impact on consumer productivity and commerce. Its impact on industrial markets is just now being realized. By 2020, 10,000 gas turbines, 68,000 jet engines, more than 100 million lightbulbs and 152 million cars will be connected to the Internet.”

“At GE, we have decided to generate and model this data ourselves—both inside the Company and with our customers. This is what we mean by becoming a Digital Industrial. Our Digital Industrial capabilities will expand our growth rate, improve our margins and bring us closer to our customers.”

As for the Industrial Internet of Things

“There was a time when every sale had a clear endpoint, followed only by routine service and maintenance. Now, sensors on our products send constant streams of data, analyzed and translated into upgrades that drive productivity in industries where even the smallest incremental efficiency can mean very large gains. Capturing it will be a mission in every one of our businesses. Our aspiration is to offer with every GE product a pathway to greater productivity through sensors, software and big-data analytics.”

Benefits

“Our investments are aimed at delivering more productivity for our customers and GE. The performance, so far, of technology companies to generate industrial productivity has been subpar. Industrial productivity, which averaged 4% annually from 1990-2010, is only 1% today. This is because pure connectivity does nothing to create value. Operational productivity requires domain data, physical and digital engineering models, industrial analytics and the ability to modify machines to achieve different outcomes. Ask a hospital CEO how their results have changed once they implemented a new Electronic Medical Record System, and the answer is typically silence. They still lack the data that drives outcomes.”

Industrial Software Killer App

“The ‘killer app’ for the Industrial Internet is GE’s Digital Twin. GE is creating living digital profiles of 500,000+ industrial machines in the field to provide new opportunities for customer growth and productivity. The Digital Twin is a software model of a physical asset or process that will make it possible to manage more precisely than we ever thought possible and deliver better outcomes. The Twin will create new business models and services for GE’s customers and our businesses. On the GE90 engine, we have used Digital Twins to increase fleet availability while saving tens of millions of dollars in unnecessary service overhauls. In rail, we are using Digital Twin models of the Evolution Locomotive to enable our customers to minimize fuel consumption and emissions. The data economy for the industrial world has arrived, and GE is in a unique position to lead it. We enter it bringing decades of deep domain expertise about our industries and volumes of data about our machines and their processes that no one else can match.

Top 10 Software Company

“With this technical leadership, GE can become a top 10 software company by 2020. At the center of this effort is our cloud-based operating system, Predix. Predix offers our customers complete situational awareness to monitor, and continually improve, equipment performance. In practice, it will assure everyone in a given enterprise–whether it’s an airline, a hospital, a railroad, an oilfield, or a wind farm–a real-time stream of relevant information, accessible on mobile assets. Everything we are doing in data and analytics comes together in this operating system.

“We plan to open Predix to our customers and other industrial companies. This gives GE a unique opportunity to create value in the platform ecosystem. We launched Predix in the second half of 2015. By the end of 2016, we expect it to have 200,000 assets under management, 100 GE applications and 20,000 developers creating many more applications.”

Proof of Industrial Internet

“GE applications provide a show site for the Industrial Internet. This year we will generate $500 million of productivity by applying data and analytics inside GE. We will have 75 ‘brilliant factories’ driving yield, cycle and uptime through model-based design. We are using model-based design on our New Product Introductions which allows us to develop and launch new products with reduced cycles, lower cost and higher quality. We can correlate material usage with product performance to change the work scope in a service agreement which drives productivity for GE and the customer.”

by Gary Mintchell | Mar 1, 2016 | Automation, Internet of Things, Networking, Operations Management, Safety, Wireless

Enabling Industrial Internet of Things (IIoT), Reliability, Scalability, and pursuing Real ROI encompass the current mantra of Fluke. Maybe you only know that company for its multimeters or infrared cameras. Well, there is much more behind the curtain.

The company has focused product development on mobile solutions, wireless communications, and data. This quarter’s product releases reflect all of that.

Infrared

The new Fluke Ti450 Infrared Camera takes focus to a new level of clarity with MultiSharp Focus. An out-of-focus thermal image can give you data that may lead to misdiagnosis — potentially costing you thousands — with no way to correct it once it has been captured, short of taking new images. This new infrared camera solves this problem by delivering images automatically focused throughout the field of view.

The new Fluke Ti450 Infrared Camera takes focus to a new level of clarity with MultiSharp Focus. An out-of-focus thermal image can give you data that may lead to misdiagnosis — potentially costing you thousands — with no way to correct it once it has been captured, short of taking new images. This new infrared camera solves this problem by delivering images automatically focused throughout the field of view.

“We are excited to announce this new technology, because it makes a real difference in situations where you have objects at multiple distances that you want in focus. Places like substations, motors driving a long production line, or electrical panels with components at varying depths,” notes Chris Rayburn, thermography business director.

MultiSharp Focus is a new technology that rapidly takes multiple images and combines them to produce one in-focus image. The advanced focusing system enables users to capture an automated, focused image of multiple targets at once, delivering the image clarity needed by professional thermographers and maintenance managers to produce top-quality results and avoid costly rework.

Waveforms

Today’s industrial machinery is more reliable and efficient, but can also be more difficult to troubleshoot because of the complexities of its advanced systems. The new Fluke ScopeMeter 120B Series Industrial Handheld Oscilloscope features Connect-and-View technology that recognizes signal patterns and automatically sets up the scope’s triggering, amplitude, and time base eliminating the typical trial-and-error setup process. Once the waveform is captured, the new IntellaSet intelligent measurement detection automatically selects key measurements based on the acquired waveform type and displays the most relevant measurement values (for example, Vrms and Hz for a line voltage signal, or Vpeak-peak and Hz for a square wave), helping technicians easily identify and characterize potential signal faults.

Today’s industrial machinery is more reliable and efficient, but can also be more difficult to troubleshoot because of the complexities of its advanced systems. The new Fluke ScopeMeter 120B Series Industrial Handheld Oscilloscope features Connect-and-View technology that recognizes signal patterns and automatically sets up the scope’s triggering, amplitude, and time base eliminating the typical trial-and-error setup process. Once the waveform is captured, the new IntellaSet intelligent measurement detection automatically selects key measurements based on the acquired waveform type and displays the most relevant measurement values (for example, Vrms and Hz for a line voltage signal, or Vpeak-peak and Hz for a square wave), helping technicians easily identify and characterize potential signal faults.

The 120B Series also features Event Capture function that captures and identifies elusive intermittent events and lists all those events that exceed a predetermined threshold. This lets technicians identify key events quickly, rather than combing through large data sets, reading by reading.

Fluke Connect

The Industrial Internet of Things is all about connections and data. As part of Fluke Connect— a system of wireless test tools that communicate via the Fluke Connect app, or Fluke Connect Assets software, a cloud-based solution that gathers measurements to provide a comprehensive view of critical equipment status — the 120B Series can automatically record waveform data to the Fluke Connect app on smartphones or tablets ensuring accuracy and eliminating manual recording of data. Those measurements are then wirelessly uploaded to the cloud and can be combined with measurement data from multiple Fluke Connect test tools to create and share reports from the job site via email and collaborate in real time with other colleagues, increasing productivity in the field. Storing then comparing and contrasting waveforms of specific asset test points over time enables maintenance engineers to better identify and troubleshoot conditions that can lead to failures.

Work Orders

Fluke introduces Work Orders, the latest enhancement to the Fluke Connect Assets, an asset management software solution that works with the Fluke Connect system of wireless test tools. Using this new Fluke Connect Assets feature maintenance managers can:

Fluke introduces Work Orders, the latest enhancement to the Fluke Connect Assets, an asset management software solution that works with the Fluke Connect system of wireless test tools. Using this new Fluke Connect Assets feature maintenance managers can:

- View complete work order history coupled with measurement data related to a specific plant asset

- Create work orders from anywhere

- Confidently assign the job to the appropriate technician and balance the task with other work orders in the system.

Technicians are provided with actual measurement data right in the work order allowing them to better understand the problem and work instructions.

The Fluke Connect system allows entire maintenance teams to capture and wirelessly share data via their smartphones. Using the AutoRecord feature measurements are transferred directly from Fluke Connect wireless test tools – eliminating transcription errors – and can be uploaded to FlukeCloud storage. Measurements can be assigned to a specific asset for sharing and analysis. Technicians can collaborate with their colleagues to discuss problems while sharing data and images in real time with ShareLive video calls, which speeds problem solving, decision-making and approvals.

Clamp Meters

Often the most frustrating task for electricians and maintenance technicians is to troubleshoot intermittent faults because they rarely occur at convenient times. The new Fluke Connect-enabled 370 FC Series Clamp Meters log measurements to pinpoint intermittent faults precisely without the need for the technician to be present. Those measurements are then wirelessly transmitted to the Fluke Connect app on smartphones or tablets and automatically uploaded to the cloud, keeping technicians outside the arc flash zone and away from dangerous moving machinery, improving safety.

Often the most frustrating task for electricians and maintenance technicians is to troubleshoot intermittent faults because they rarely occur at convenient times. The new Fluke Connect-enabled 370 FC Series Clamp Meters log measurements to pinpoint intermittent faults precisely without the need for the technician to be present. Those measurements are then wirelessly transmitted to the Fluke Connect app on smartphones or tablets and automatically uploaded to the cloud, keeping technicians outside the arc flash zone and away from dangerous moving machinery, improving safety.

The CAT IV 600 V, CAT III 1000 V safety-rated clamp meters offer advanced troubleshooting performance to capture a wide range of measurements with a single tool, including:

- Proprietary in-rush measurement technology to filter out noise and capture motor starting current exactly as the circuit protection sees it;

- Integrated variable frequency drive low pass filter (376 FC and 375 FC models only) for accurate motor drive measurements;

- True-rms voltage and current for accurate measurements on non-linear signals;

- 500 mV dc measurement range to interface with other accessories (376 FC and 375 FC models only);

- Expanded measurement range to 2500 A ac with the iFlex flexible current probes, which provide access to large conductors in tight spaces.

As part of Fluke Connect— the industry’s largest system of software and more than 30 wireless test tools — technicians can wirelessly transmit measurement data from the 370 FC Series clamp meters and other test tools to their smartphones for secure storage on the Fluke Cloud and team access from the field. With the Fluke Connect smartphone app, technicians can combine measurement data from multiple Fluke Connect test tools to create and share reports from the job site via email and collaborate in real time with other colleagues with ShareLive video calls, increasing productivity in the field.

Tim Sowell always packs many operations management ideas into a brief blog post. Sowell is a VP and Fellow at Schneider Electric Software (Wonderware). I’ve looked at his posts before. He is always thinking out in front of most people.

Tim Sowell always packs many operations management ideas into a brief blog post. Sowell is a VP and Fellow at Schneider Electric Software (Wonderware). I’ve looked at his posts before. He is always thinking out in front of most people.

Interoperability among systems spurs economic and technological growth. Two of the leading proponents of new strategies for this next Industrial Revolution that we are beginning recently met.

Interoperability among systems spurs economic and technological growth. Two of the leading proponents of new strategies for this next Industrial Revolution that we are beginning recently met.

The new

The new  Today’s industrial machinery is more reliable and efficient, but can also be more difficult to troubleshoot because of the complexities of its advanced systems. The new

Today’s industrial machinery is more reliable and efficient, but can also be more difficult to troubleshoot because of the complexities of its advanced systems. The new  Fluke introduces Work Orders, the latest enhancement to the Fluke Connect Assets, an asset management software solution that works with the Fluke Connect system of wireless test tools. Using this new Fluke Connect Assets feature maintenance managers can:

Fluke introduces Work Orders, the latest enhancement to the Fluke Connect Assets, an asset management software solution that works with the Fluke Connect system of wireless test tools. Using this new Fluke Connect Assets feature maintenance managers can: Often the most frustrating task for electricians and maintenance technicians is to troubleshoot intermittent faults because they rarely occur at convenient times. The new Fluke Connect-enabled

Often the most frustrating task for electricians and maintenance technicians is to troubleshoot intermittent faults because they rarely occur at convenient times. The new Fluke Connect-enabled