by Gary Mintchell | Feb 17, 2018 | Automation, Industrial Computers, Internet of Things, Operations Management, Software

I was so busy during the ARC Advisory Group Industry Forum last week, that I just couldn’t find time to write coherently. The keyword was digital supplemented by embedded, edge, IIoT, security, and transformation.

The Forum attracted perhaps not only its largest attendance but also its largest attendance of end users. The things that appeal to me are those that fit into the Industrial Internet of Things the most. Here are two related new product releases. The first one involves embedding HMI/SCADA software and the second involves using that embedded software in addition to many other technologies for an edge device.

First is the announcement from Inductive Automation concerning the creation of its Ignition Onboard program. The program involves device manufacturers embedding Ignition and Ignition Edge software in the devices they manufacture.

The program includes Ignition Onboard and Ignition Edge Onboard. Ignition by Inductive Automation is an industrial application platform with tools for building solutions in human-machine interface (HMI), supervisory control and data acquisition (SCADA), and the Industrial Internet of Things (IIoT). Ignition Edge is a line of lightweight, limited, low-cost Ignition software products which empower solutions designed for edge-of-network use.

“Device manufacturers have joined Ignition Onboard in response to their customers’ demands for an all-in-one solution that contains hardware and software at a reasonable price,” said Don Pearson, chief strategy officer for Inductive Automation. “These are companies that understand the importance of building a strong IIoT, and we’re very happy to be collaborating with them.”

The other announcement came from Opto 22. This is a significant advance in edge devices for industrial and SCADA applications.

The new groov EPIC system from Opto 22 combines I/O, control, data processing, and visualization into one secure, maintainable, edge-of-network industrial system. groov EPIC lets engineers and developers focus on delivering value, not on triaging loosely connected components.

“We are a company of engineers inspired and driven to create products that unleash our customers’ imaginations,” says Mark Engman, Opto 22 CEO. “groov EPIC is a culmination of that mission, a response to industry requests to more wholly integrate IT and OT technologies, simplify development and deployment, and provide a platform for long-term growth now and well into the future.”

Combining reimagined intelligent I/O with an embedded Linux real-time controller, gateway functions, and an integrated display, groov EPIC offers field-proven industrial hardware design with a modern software ensemble, to produce the results that visionary engineers want today.

Connecting legacy systems, controlling processes and automating machines, subscribing to web services and creating mashups, acquiring and publishing data, visualizing that data wherever it is needed, and mobilizing operators—all of these are now within reach. In addition, groov EPIC simplifies commissioning and wiring and helps engineers develop rapidly and deploy quickly.

“The groov EPIC system incorporates in one unit everything needed to connect and control field and operational devices and data, through on-premises IT databases, spreadsheets and other software, to cloud storage and services—and back again,” says Benson Hougland, Opto 22 vice president of Marketing & Product Strategy. “This ability to easily exchange data and use it where needed opens opportunities automation engineers have not had until now. This is a truly new system that builds on the past but looks fundamentally to the future of our industry.”

Of particular interest to original equipment manufacturers (OEMs) will be optional access to the Linux operating system through secure shell (SSH). This access, along with toolchains and interpreters for Java, C/C++, Python, JavaScript/Node.js, and more, allows OEM developers to execute their own custom developed applications on this ruggedized, edge processing control system.

The main point of discussion between Benson and me lately is whether Sparkplug (from the developer of MQTT) is adequate for IoT applications. He favors the lightweight (technical, not pejorative) protocol or I tend to favor OPC UA over MQTT as a better overall solution due to its interoperability. But that’s OK. He and I have had these technical discussions for almost 20 years now. I love pushback, and I think Benson does as well. It raises the energy level.

by Gary Mintchell | Nov 13, 2017 | Industrial Computers, Internet of Things, Standards

IoT Platforms are all the rage. All God’s children need a platform, it seems. Most larger companies have a platform. Oh, and all promise it’s “open” to everyone’s connections. Then there is open source—check out Dell, the Linux Foundation, and others who have developed the EdgeX Foundry.

Now we have an Asian developed one—mostly Japanese along with Taiwan-based Advantech—called the Edgecross Consortium. Edgecross evidently refers to a focus on edge computing and cross vendor.

I received the first notice from Advantech who announced it has partnered with Mitsubishi Electric, Omron, NEC, IBM Japan, and Oracle Japan to establish the “Edgecross Consortium” to overcome boundaries between companies and industries in order to realize collaboration between factory automation and IT. The objective is to create new value centered on edge computing.

The Consortium news release states, “In this way, it will contribute to the promotion of IoT, for which demand is increasing on a global scale, as well as Society 5.0, proposed by the Japanese government, and activities of Connected Industries, which tie in to Society 5.0.”

Initial activities of the Consortium will begin with the development of specifications for the Edgecross open software platform and promoting its dissemination for edge computing from Japan to harmonize with FA and IT. This initial work will include providing avenues for supporting companies to cooperate and collaborate beyond the framework of companies and industries. The Consortium will aim to expand applications for various industries in addition to initiating activities in the global arena in the future.

I should note here that in America and Europe, we generally refer to bringing OT and IT together (rather than FA).

The date of founding is scheduled for November 29, 2017, and an exhibition is planned at the System Control Fair 2017, to be held on the same day.

Overview of Edgecross

An open software platform of edge computing area from Japan built by consortium members beyond the boundaries of companies and industries to realize collaboration with FA and IT.

Features

Real-time diagnosis and feedback

Realizing real-time feedback to the production site by analyzing and diagnosing the data at location close to the production sites

Creating models from production sites

Data can be easily utilized by people or by applications by layering and abstracting the Big data of the production sites

Utilization of various applications in the edge computing area

IT applications can be easily applied to FA application

Applications may be selected from an extensive lineup depending on the situation

System construction completed in the edge computing area are available

Collecting all types of data at the production site

Enable data collection from all equipment and devices regardless of vendor or network

Smooth coordination with FA and IT systems

Realizing supply chain and engineering chain optimization by seamless data coordination with IT systems including the cloud

Operates on industrial PCs

Mountable on various manufacturer’s industrial PCs (IPCs)

Here are a couple of executive quotes about the news.

“Partnering with leading global companies in accelerating our global business in Industry 4.0 is Advantech’s key strategy,” stated Allan Yang, CTO of Advantech. “Advantech joined the Mitsubishi e-F@ctory Alliance this April to foster business opportunities for smart manufacturing in Asia through co-marketing and co-exhibition. Joining the Edgecross Consortium is our next big step to expand global collaboration and business in Industry 4.0. We are very proud to be a part of Edgecross Consortium with these leading global companies; we are looking forward to collaborating with consortium members to develop Industry 4.0 products and solutions to enhance our customer experience.”

Yoshikazu Miyata, Executive Officer and Group President of Factory Automation Systems at Mitsubishi Electric, gave the following statement regarding the new partnership, “The consortium welcomes Advantech as a key member. We are happy to work with Advantech, a worldwide leading innovator for Edge computing and IoT solutions. We are looking forward to co-creating with Advantech to provide innovative IoT solutions to customers.”

by Gary Mintchell | May 15, 2017 | Automation, Industrial Computers

While I am trying to finish a longer post on my Dell EMC experience from last week and all my Hannover experience, I’ll follow up on a conversation I had last week with Dell EMC’s Kevin Terwilliger about the embedded PC market.

He has written a blog post from his visit to Embedded World in Germany. The Embedded Computing market always seemed a little strange to me. In part because huge VME and PCI (and CompactPCI) chassis computers were alongside SOC (what I think of as “embedded”) and other chip and board level computing.

Check out his blog. I posted a comment.

His observation:

After attending Embedded World last month in Germany it was clearer to me than ever before – the embedded PC industry is not dissimilar to the desktop PC industry 30 years ago. When Dell entered the PC market back in 1984 and in the years shortly following, there were 430 PC companies who were each trying to compete based on some level of unique customization they could offer. Dell turned all this upside down with their direct configure to order model.

Good point. I would just add (again, check his blog) that part of the consolidation was technology-driven. CPUs became much more powerful and memory became more plentiful and cheaper. This meant that the PC itself could do much more without add-on cards and peripherals. Customization became firmware and software driven. You could buy one box and make it what you wanted (to a degree).

Dell’s embedded offering could be a foreboding of such a change in the embedded market. What do you think?

by Gary Mintchell | Mar 7, 2017 | Automation, Industrial Computers, Software

One under-the-radar trend in industrial automation and software is the development of a marketplace. Several companies have one type of marketplace or another. I think it’s going to prove to be a powerful concept. Here is a take on it from Advantech.

One under-the-radar trend in industrial automation and software is the development of a marketplace. Several companies have one type of marketplace or another. I think it’s going to prove to be a powerful concept. Here is a take on it from Advantech.

Advantech, a leader of the global industrial computing market, launches the WISE-PaaS Marketplace, an online software shopping website that features exclusive software services provided by Advantech and its partners. The WISE-PaaS Marketplace provides diverse WISE-PaaS IoT application software, including WebAccess/SCADA, WebAccess/HMI, WebAccess/IVS, WebAccess/IMM, WebAccess/NMS, online IoT cloud services, and IoT security services. The WISE-PaaS Marketplace is a sharing platform to integrate with IoT solutions developed by solution partners to provide the building blocks for customers to upgrade existing business systems to Industrial IoT and Industry 4.0 quickly and easily.

Share Success, Grow Business, and Innovate Services

The Wise-PaaS Marketplace is aimed at diverse solution offerings that provide cloud infrastructure services, security services, integrated WISE-PaaS IoT software services, and domain-focused applications for simple and rapid deployment. The WISE-PaaS Marketplace is a value-sharing platform/ecosystem that enables customers to market unique IoT applications and services, increase business opportunities and growth, and maximize returns under the profit-sharing system.

Ongoing Innovation for Future IoT Trends

Customers can subscribe software services via Wise-PaaS Marketplace with WISE-points included in the WISE-PaaS VIP membership packages to access numerous IoT solutions and create IoT innovations for future IoT trends.

by Gary Mintchell | Jan 26, 2017 | Automation, Industrial Computers, Security

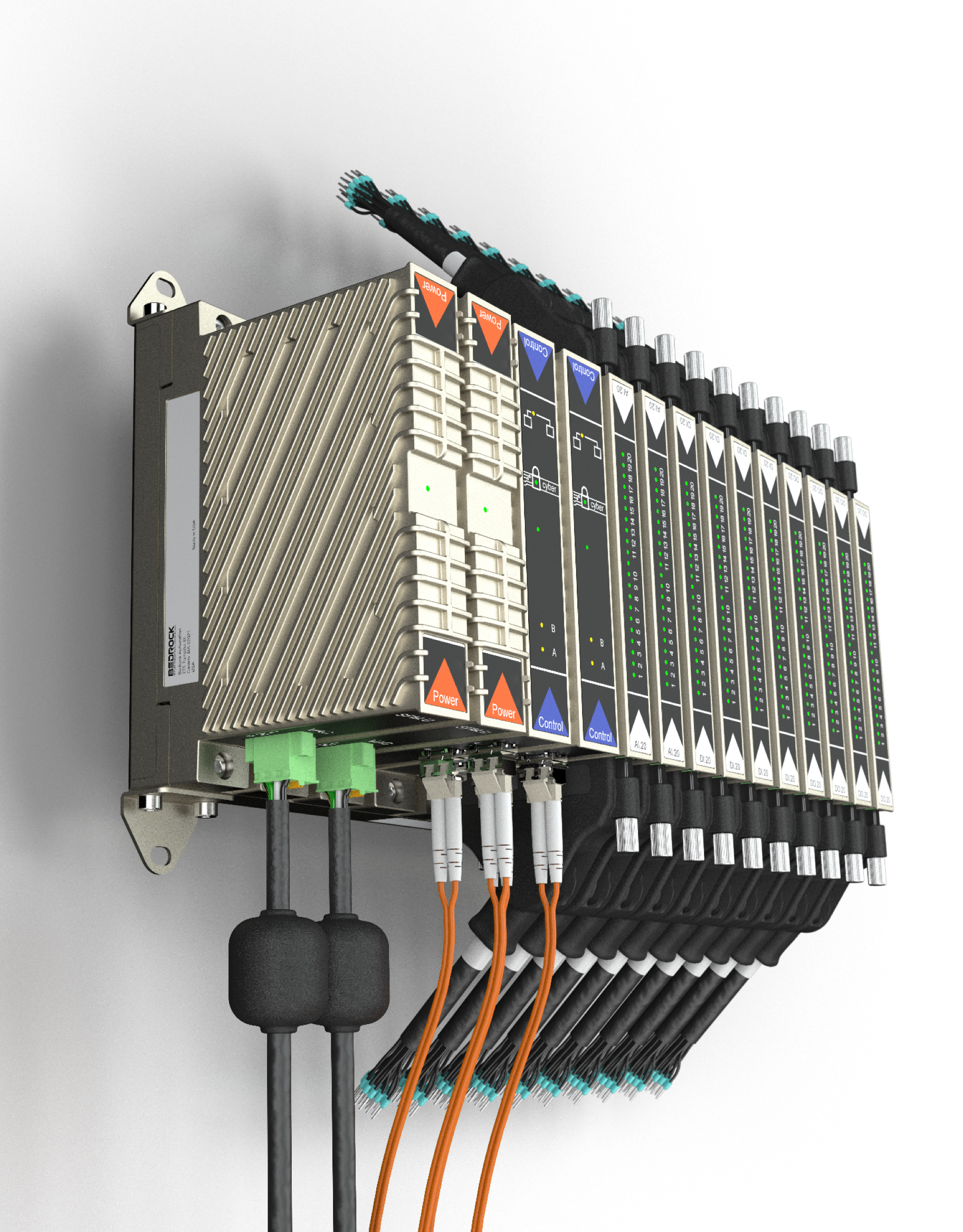

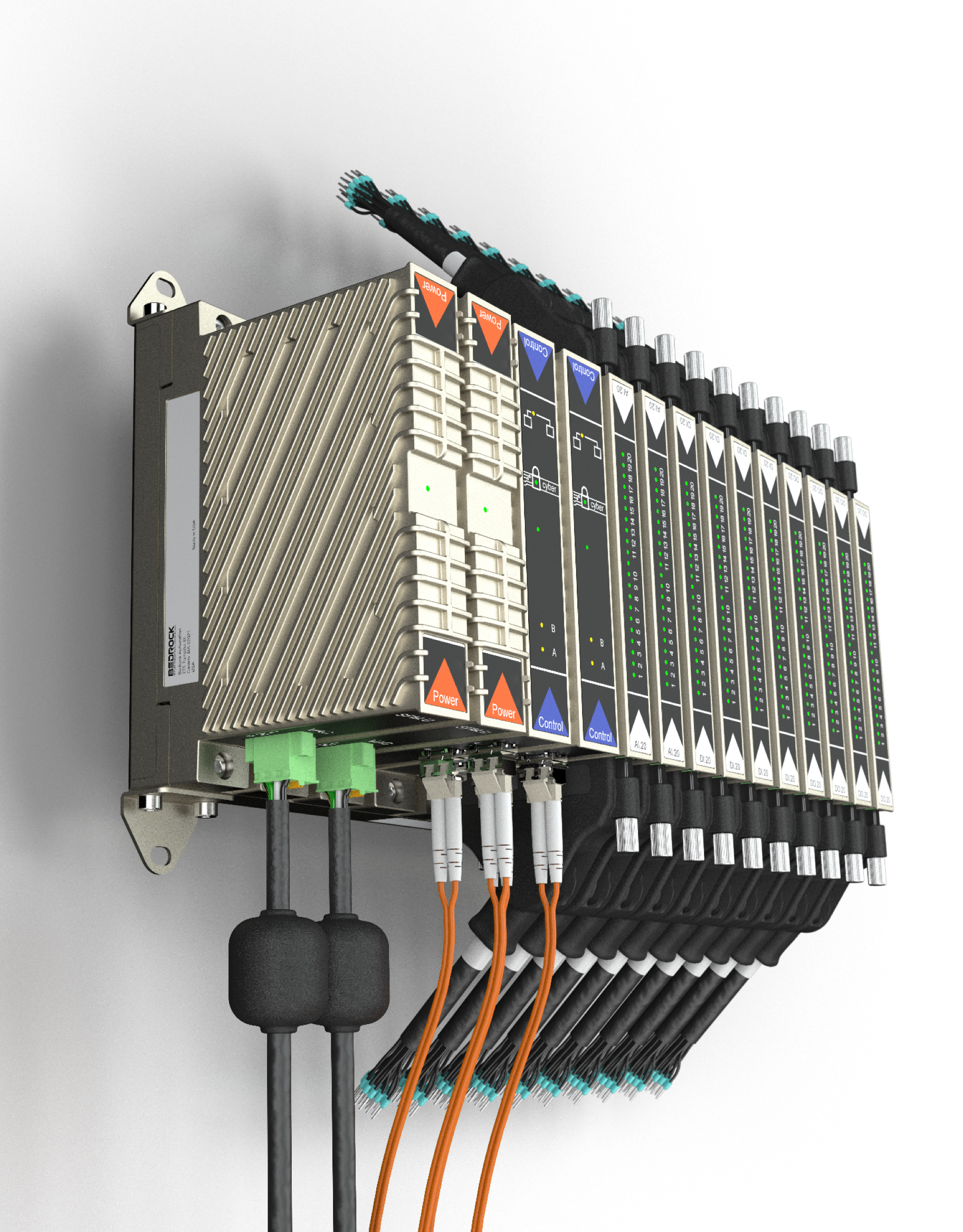

Bedrock Automation has built a good automation platform with built-in security and toughness. I’ve been watching to see just how disruptive it might be in the market. In this announcement, it is showing further growth in its go-to-market strategy of working with integrators. It has signed a memorandum of agreement with Jacobs Engineering Group Inc., one of the world’s largest and most diverse providers of full-spectrum technical, professional and construction services. Under the agreement, the companies will pursue selected projects with automation system requirements for potential implementation of the Bedrock Open Secure Automation (OSA) system.

Bedrock Automation has built a good automation platform with built-in security and toughness. I’ve been watching to see just how disruptive it might be in the market. In this announcement, it is showing further growth in its go-to-market strategy of working with integrators. It has signed a memorandum of agreement with Jacobs Engineering Group Inc., one of the world’s largest and most diverse providers of full-spectrum technical, professional and construction services. Under the agreement, the companies will pursue selected projects with automation system requirements for potential implementation of the Bedrock Open Secure Automation (OSA) system.

“Our clients are increasingly concerned about both cyber security and advanced automation and we have been creating innovative service packages to meet these needs. Bedrock Automation has excellent experience and superior designs in this area. I am impressed with their comprehensive background and knowledge in the industrial DCS and PLC arena,” said Jacobs’ Mission Solutions Chief Technology Officer Dr. Tommy Gardner.

The Bedrock control system is known for its patented Black Fabric Cybershield architecture, which provides an intrinsic cyber secure automation platform to protect user hardware, software and applications. Unlike other conventional industrial control systems, Bedrock was designed from a clean sheet of paper with advanced components and architecture to be simple, scalable and secure.

“Jacobs is taking a leadership role in integrating the next generation of information and automation technologies for its clients,” added Bedrock Automation President Bob Honor. “We see this as a tremendous opportunity to bring our technology and our vision of holistic cyber security to a much larger audience. We look forward to an exciting and mutually beneficial relationship with Jacobs.”

by Gary Mintchell | Apr 21, 2016 | Automation, Industrial Computers

The PC market, especially for consumers but also for business, is slowing. Manufacturers are turning to industrial PC market.The New York Times recently ran an article about Intel cutting jobs due to the continued slowdown in the PC market. Recently I wrote about Dell entering the embedded PC for industrial applications market, most likely due to the same market forces.

From The New York Times article:

Intel, the world’s largest maker of semiconductors, said on Tuesday that it was laying off 12,000 people, about 11 percent of its work force, as it continues to reel from a long downturn in global demand for personal computers.

The company’s chief executive, Brian Krzanich, announced the layoffs as part of a larger corporate restructuring, which will result in a $1.2 billion charge. Intel also reported lower-than-expected first-quarter earnings and reduced its projected revenue for the year.

“Intel has been known as the PC company,” Mr. Krzanich said in an earnings call with Wall Street analysts. “It’s time to make this transition and push the company all the way over” to supplying chips for things like smartphones, cloud computing, sensors and other devices.

Here is my introduction to the Dell embedded PC announcement:

Faced with a declining market for desktop PCs and a burgeoning market for embedded PC, Dell has announced launch of its first purpose-built industrial PC (IPC) products. This release complements its entry into the Internet of Things market announced last fall at Dell World. [Note: I do some work with Dell on IoT issues, but that has no bearing on reporting this.]

Rising Industrial PC Market to Stabilize

While the global market for industrial PCs has experienced ups and downs in recent years, it is forecast to pick up in 2016 and will start to stabilize in 2018. The key reason for the increase in short-term growth is an expected improvement in the outlook for process industry investment and the continued use of industrial PCs in applications outside the established areas of industrial automation.

Global revenue from industrial PCs is forecast to grow at a compound annual growth rate (CAGR) of 6 percent from 2014 to 2019, reaching $4.3 billion, according to IHS Inc.

“While the world market for industrial PCs has enjoyed relatively strong growth since 2013, recovery is projected to be slower through 2016,” said Rita Liu, manufacturing technology analyst, IHS Technology. “This slowed recovery is based on poor performance of downstream process-industry sectors in the current economic environment, with very low oil prices, a global downturn in mining, and the like.”

Europe, Middle-East and Africa (EMEA) was still the largest market for industrial PCs in 2014, at $1.2 billion, or 38 percent of the global total, according to the IHS Industrial PCs Intelligence Service. Asia-Pacific was the second-largest market, with estimated revenues of $ 1.1 billion. “It is worth noting that due to the slowing Chinese economy, the Asia-Pacific market for industrial PCs is projected to grow more slowly,” Liu said. “In fact, the Asia-Pacific market is expected to fall behind the American market this year.”

Of course the performance of the industrial PC market depends largely on the underlying growth in the sectors that use them, including discrete and process manufacturing sectors, as well as building automation, medical, transportation and infrastructure and other non-industrial sectors. Industrial sectors accounted for over half of the world market in 2014 and 2015, and they are expected to grow much more slowly than non-industrial sectors. Generally transportation and infrastructure, medical, and gaming sectors will grow more quickly than the general market through 2019.

Robotics is the fastest growing industrial sector for PCs; followed by materials-handling equipment; food, beverage and tobacco machinery; and packaging machinery. “Tobacco and packaging machinery are closely connected with consumer markets and enjoy relatively stable performance, no matter what the overall economic situation might be,” Liu said.

One under-the-radar trend in industrial automation and software is the development of a marketplace. Several companies have one type of marketplace or another. I think it’s going to prove to be a powerful concept. Here is a take on it from

One under-the-radar trend in industrial automation and software is the development of a marketplace. Several companies have one type of marketplace or another. I think it’s going to prove to be a powerful concept. Here is a take on it from

Bedrock Automation

Bedrock Automation