by Gary Mintchell | Jun 18, 2018 | Internet of Things, Manufacturing IT

The Industrial Internet Consortium (IIC) generates much useful information promoting awareness and technical tips about, well, the Industrial Internet of Things. Last week I had the opportunity to speak to the authors of a new white paper, ”Introduction to Edge Computing in IIoT”, Todd Edmunds, Senior Solution Architect, IoT, Cisco, and Lalit Canaran, VP, SAP.

The paper provides practical guidance on edge computing, architectures and the building blocks necessary for edge computing implementations. The IIC is also planning to release an Edge Computing Technical Report that will contain in-depth technical information in the coming months.

This paper is not a C-level generic paper evangelizing the concept, but rather practical advice designed to open the discussion followed by technical details targeted to those to whom the C-level executives might tell, “I have been reading about the IIoT. This looks like something we should be jumping into.”

We discussed how the edge should be defined by the business objective rather than the technology used. Using computing at the edge improves performance of the system when bandwidth could be the constraining factor for using the cloud.

As the edge gets more powerful, they told me, the role of the cloud will shift to one of orchestration of remote sites plus storage.

“Many companies are wanting to realize the business benefits that edge computing is purported to provide but are unsure where to begin or how to realize those advantages. The IIC has been at the vanguard of the industrial internet since its inception, and edge computing has been an integral part of driving the transformational outcomes that go along with it,” said Edmunds. “With the publication of this white paper, we provide practical guidance on where the ‘edge’ is and the key drivers for implementing edge computing. We also provide detail on edge computing architectures and real-world use cases.”

“Almost every use case and every connected device on the industrial internet requires some sort of compute capability at its source at the edge,” said Dr. Mitch Tseng, Distinguished Consultant, Huawei Technologies, and co-author of the white paper. “Oil rigs in remote locations have sensors gathering data but they need to be mindful of the challenges of data transmission because of bandwidth issues or the cost of transmission. The white paper is a first step in the development of an industrial grade ‘cookbook’ for edge computing.”

“Organizations adopting an IIoT strategy need to understand what data is available, how to use it to drive industrial processes and how to orchestrate, manage and secure data/compute,” said Canaran. “This paper and subsequent technical report will enable enterprises to unlock the full potential of the edge-cloud continuum and drive the business outcomes enabled by next-generation IoT devices, machine learning and AI.”

The full IIC Introduction to Edge Computing in IIoT white paper and a list of IIC members who contributed can be found on the IIC website.

by Gary Mintchell | Jun 4, 2018 | Standards, Technology

Microsoft acquiring GitHub, the repository of many open source projects, on the surface appears almost as an oxymoron. However, as I’ve written previously about big companies and OPC UA standard big companies now find open source and interoperability to be sound business decisions rather than threatening to their proprietary hold on technology.

OPC and Standards

Two years ago in my Podcast Gary on Manufacturing 149 also found on YouTube, I asked the question why major suppliers of automation technology for manufacturing/production hated OPC UA—an industry information model standard. That is by far the most viewed YouTube podcast I’ve ever done. I followed up with Gary on Manufacturing 175 and YouTube to update the situation to current situation.

It is still getting comments, some two years later. Some guy (probably works for a big company?) even dissed me about it.

However, the industry witnessed an almost tectonic shift in the approach of these automation suppliers toward standards. First Siemens went all in on OPC UA. Then last November and following Rockwell Automation has had several deep discussions with me about the adoption of OPC UA.

Why? Users demand more interoperability. And using standards is the easiest way forward for interoperability. Suppliers have discovered that standards allow them to continue to push development of their “black boxes” of technology while allowing themselves and their customers to assemble systems of technology.

Microsoft News

In my favorite news site, Axios, Ina Fried writes:

Microsoft announced this morning it is acquiring GitHub, the social network for coders as well as home to millions of different software projects, for $7.5 billion.

“The era of the intelligent cloud and intelligent edge is upon us. Computing is becoming embedded in the world, with every part of our daily life and work and every aspect of our society and economy being transformed by digital technology. Developers are the builders of this new era, writing the world’s code. And GitHub is their home.”

— Satya Nadellla, CEO, Microsoft

Why it matters: This would further highlight the complete turnaround the company has already made in its stance toward source software.

Behind the scenes: While former Microsoft CEO Steve Ballmer once called Linux a cancer, the company has steadily warmed to open source, with Nadella embracing it with open arms.

GitHub plays into that strategy as it’s used by developers of all stripes to store their code projects. The San Francisco-based company was founded in 2008 and is now home to 80 million software repositories. The company has been searching for a new CEO since last year.

Why it matters: Playing host to the world’s code doesn’t necessarily make Microsoft a more central player, but it could tightly integrate GitHub into its developer tools. Microsoft decided last year to shut down its own CodePlex software repository, bowing to GitHub’s popularity.

What about Windows? Though certainly a fan of its homegrown operating system, Microsoft’s main goal these days is to be in tight with developers and get them writing code that can live in its Azure cloud.

Microsoft even dropped the Windows name from Azure, reflecting the fact you don’t have to use Windows to work with Azure.

History lesson: Microsoft’s shift to embrace Linux is somewhat reminiscent of the earlier move IBM made to do so. Both companies are now seen as the mature veterans of the enterprise market, more interested in meeting corporate computing needs than pushing homegrown architectures.

This information was also posted on the Microsoft Blog.

Other Open Source Information

My other travels and interviews have yielded other companies who have invested heavily in open source.

Within the last two years I have had a few conversations with Microsoft about their open source code donations. While I am a little surprised at acquiring GitHub, perhaps this will lend financial stability to the platform (although we do have to note that large company investments do not always insure financial stability.

Dell Technologies and Hewlett Packard Enterprise, two companies I have more recently studied are both proud to be contributors to open source. A couple of years ago considerable time at one of the keynotes at Dell World to open source projects.

I think that some of these companies are realizing that they don’t have to invent everything themselves. Being good software citizens benefits them as well as the community.

by Gary Mintchell | Jan 30, 2018 | Internet of Things

I’m all about IoT and digitalization anymore. This is the next movement following the automation trend I championed some 15 years ago.

Last month, I started receiving emails about predictions for 2018. Not my favorite topic, but I started saving them. Really only received a couple good ones. Here they are—one from Cisco and one from FogHorn Systems.

Cisco Outlook

From Cisco blog written by Cisco’s SVP of Internet of Things (IoT) and Applications Division, Rowan Trollope, comes several looks at IoT from a variety of angles. There is more at the blog. I encourage you to visit for more details.

Until now, the Internet-of-Things revolution has been, with notable outlier examples, largely theoretical and experimental. In 2018, we expect that many existing projects will show measurable returns, and more projects get launched to capitalize on data produced by billions of new connected things.

With increased adoption there will be challenges: Our networks were not built to support the volumes and types of traffic that IoT generates. Security systems were not originally designed to protect connected infrastructure against IoT attacks. And managing industrial equipment that is connected to traditional IT requires new partnerships.

I asked the leaders of some of the IoT-focused teams at Cisco to describe their predictions for the coming year, to showcase some of these changes. Here they are.

IoT Data Becomes a Bankable Asset

In 2018, winning with IoT will mean taking control of the overwhelming flood of new data coming from the millions of things already connected, and the billions more to come. Simply consolidating that data isn’t the solution, neither is giving data away with the vague hope of achieving business benefits down the line. Data owners need to take control of their IoT data to drive towards business growth. The Economist this year said, “Data is the new oil,” and we agree.

This level of data control will help businesses deliver new services that drive top-line results.

– Jahangir Mohammed, VP & GM of IoT, Cisco

AI Revolutionizes Data Analytics

In 2018, we will see a growing convergence between the Internet of Things and Artificial Intelligence. AI+IoT will lead to a shift away from batch analytics based on static datasets, to dynamic analytics that leverages streaming data.

Typically, AI learns from patterns. It can predict future trends and recommend business-critical actions. AI plus IoT can recommend, say, when to service a part before it fails or how to route transit vehicles based on constantly-changing data.

– Maciej Kranz, VP, Strategic Innovation at Cisco, and author of New York Times bestseller, Building the Internet of Things

Interoperable IoT Becomes the Norm

The growth of devices and the business need for links between them has made for a wild west of communications in IoT. In 2018, a semblance of order will come to the space.

With the release of the Open Connectivity Foundation (OCF) 1.3 specification, consumer goods manufacturers can now choose a secure, standards-based approach to device-to-device interactions and device-to-cloud services in a common format, without having to rely on, or settle for, a proprietary device-to-cloud ecosystem.

Enterprise IoT providers will also begin to leverage OCF for device-to-device communications in workplace and warehouse applications, and Open Mobile Alliance’s Lightweight Machine-to-Machine (LwM2M) standard will take hold as the clear choice for remote management of IoT devices.

In Industrial IoT, Open Process Communication’s Unified Architecture (OPC-UA) has emerged as the clear standard for interoperability, seeing record growth in adoption with over 120 million installs expected as 2017 draws to an end. It will continue to grow into new industrial areas in 2018 driven by support for Time Sensitive Networking.

– Chris Steck, Head of Standardization, IoT & Industries, Cisco

IoT Enables Next-Gen Manufacturing

Manufacturing is buzzing about Industrie 4.0, the term for a collection of new capabilities for smart factories, that is driving what is literally the next industrial revolution. IoT technologies are connecting new devices, sensors, machines, and other assets together, while Lean Six Sigma and continuous improvement methodologies are harvesting value from new IoT data. Early adopters are already seeing big reductions in equipment downtime (from 15 to 95%), process waste and energy consumption in factories.

– Bryan Tantzen, Senior Director, Industry Products, Cisco

Connected Roadways Lay the Groundwork for Connected Cars

Intelligent roadways that sense conditions and traffic will adjust speed limits, synchronize street lights, and issue driver warnings, leading to faster and safer trips for drivers and pedestrians sharing the roadways. As these technologies are deployed, they become a bridge to the connected vehicles of tomorrow. The roadside data infrastructure gives connected cars a head start.

Connected cities will begin using machine learning (ML) to strategically deploy emergency response and proactive maintenance vehicles like tow trucks, snow plows, and more.

– Bryan Tantzen, Senior Director, Industry Products, Cisco

Botnets Make More Trouble

Millions of new connected consumer devices make a nice attack surface for hackers, who will continue to probe the connections between low-power, somewhat dumb devices and critical infrastructure.

The biggest security challenge I see is the creation of Distributed Destruction of Service (DDeOS) attacks that employ swarms of poorly-protected consumer devices to attack public infrastructure through massively coordinated misuse of communication channels.

IoT botnets can direct enormous swarms of connected sensors like thermostats or sprinkler controllers to cause damaging and unpredictable spikes in infrastructure use, leading to things like power surges, destructive water hammer attacks, or reduced availability of critical infrastructure on a city or state-wide level.

– Shaun Cooley, VP and CTO, Cisco

Blockchain Adds Trust

Cities are uniquely complex connected systems that don’t work without one key shared resource: trust.

From governmental infrastructure to private resources, to financial networks, to residents and visitors, all of a city’s constituents have to trust, for example, that the roads are sound and that power systems and communication networks are reliable. Those working on city infrastructure itself can’t live up to this trust without knowing that they are getting accurate data. With the growth of IoT, the data from sensors, devices, people, and processes is getting increasingly decentralized—yet systems are more interdependent than ever.

As more cities adopt IoT technologies to become smart—thus relying more heavily on digital transactions to operate—we see blockchain technology being used more broadly to put trust into data exchanges of all kinds. A decentralized data structure that monitors and verifies digital transactions, blockchain technology can ensure that each transaction—whether a bit of data streaming from distributed air quality sensors, a transaction passing between customs agencies at an international port, or a connection to remote digital voting equipment—be intact and verifiable.

– Anil Menon, SVP & Global President, Smart+Connected Communities, Cisco

FogHorn Systems

Sastry Malladi, CTO of FogHorn Systems, has shared his top five predictions for the IIoT in 2018.

1. Momentum for edge analytics and edge intelligence in the IIoT will accelerate in 2018.

Almost every notable hardware vendor has a ruggedized line of products promoting edge processing. This indicates that the market is prime for Industrial IoT (IIoT) adoption. With technology giants announcing software stacks for the edge, there is little doubt that this momentum will only accelerate during 2018. Furthermore, traditional industries, like manufacturing, that have been struggling to showcase differentiated products, will now embrace edge analytics to drive new revenue streams and/or significant yield improvements for their customers.

2. Additionally, any industry with assets being digitized and making the leap toward connecting or instrumenting brownfield environments is well positioned to leverage the value of edge intelligence.

Usually, the goal of these initiatives is to have deep business impact. This can be delivered by tapping into previously unknown or unrealized efficiencies and optimizations. Often these surprising insights are uncovered only through analytics and machine learning. Industries with often limited access to bandwidth, such as oil and gas, mining, fleet and other verticals, truly benefit from edge intelligence.

3. Business cases and ROI are critical for IIoT pilots and adoption in 2018

The year 2017 was about exploring IIoT and led to the explosion of proof of concepts and pilot implementations. While this trend will continue into 2018, we expect increased awareness about the business value edge technologies bring to the table. Companies that have been burned by the “Big Data Hype” – where data was collected but little was leveraged – will assess IIoT engagements and deployments for definitive ROI. As edge technologies pick up speed in proving business value, the adoption rate will exponentially rise to meet the demands of ever-increasing IoT applications.

IIoT standards will be driven by customer successes and company partnerships

4. IT and OT teams will collaborate for successful IIoT deployments

IIoT deployments will start forcing closer engagement between IT and operations technology (OT) teams. Line of business leaders will get more serious around investing in digitization, and IT will become the cornerstone required for the success of these initiatives. What was considered a wide gap between the two sectors – IT and OT – will bridge thanks to the recognized collaboration needed to successfully deploy IIoT solutions and initiatives.

5. Edge computing will reduce security vulnerabilities for IIoT assets.

While industries do recognize the impact of an IIoT security breach there is surprisingly little implementation of specific solutions. This stems from two emerging trends:

a) Traditional IT security vendors are still repositioning their existing products to address IIoT security concerns.

b) A number of new entrants are developing targeted security solutions that are specific to a layer in the stack, or a particular vertical.

This creates the expectation that, if and when an event occurs, these two classes of security solutions are sufficient enough. Often IoT deployments are considered greenfield and emerging, so these security breaches still seem very futuristic, even though they are happening now. Consequently, there is little acceleration to deploy security solutions, and most leaders seem to employ a wait-and-watch approach. The good news is major security threats, like WannaCry, Petya/Goldeneye and BadRabbit, do resurface IIoT security concerns during the regular news cycle. However, until security solutions are more targeted, and evoke trust, they may not help move the needle.

by Gary Mintchell | Jan 2, 2018 | Asset Performance Management, Operations Management

The product Rockwell Automation executives most wanted to talk to me about at the last Automation Fair event was its new analytics platform.

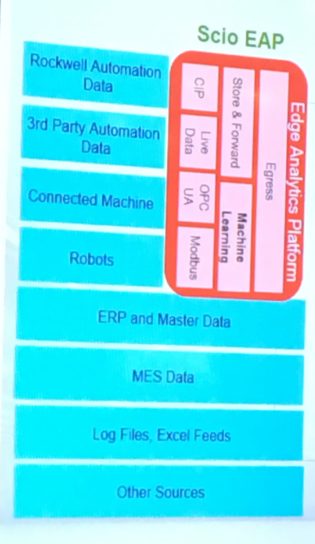

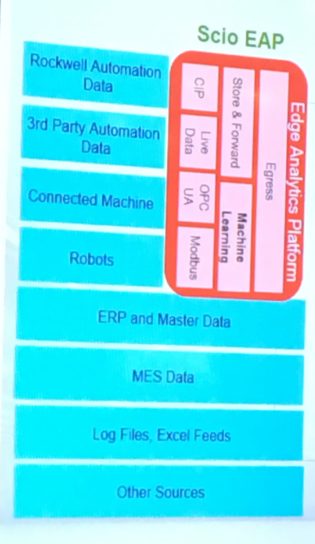

Immediately following the Rockwell event was Thanksgiving, then a trip to Madrid for a Hewlett Packard Enterprise event followed by catching up and Christmas. But I grabbed moments to contemplate the “Project Scio Edge Analytics Platform” (see image) and tried to place it in a context amongst all the platforms I saw this year. Which were many.

Executives including SVP and CTO Sujeet Chand and VP of Information Software John Genovesi were enthused over the new product. I wrote about it here.

I liked much of what I heard. There were many overtures to open connectivity that I have not heard at a Rockwell event—maybe ever. I even got an hour to discuss OPC UA and how Rockwell now intends to implement it. The demo during media days was also powerful.

I drew a mind map and exported an outline. Here is the list of positive things.

Positives

- Developed analytics from acquihire

- Good UX

- Platforms

- Open connectivity including OPC UA

- Should provide customers with insights into control systems and machine performance

However, I’m left with some questions—some of the same ones I often feel about Rockwell Automation. Check out the architecture diagram. It stops with machine level. I always expect to see more, but Rockwell always stops at the machine. Perhaps GE and Siemens have overreached with Predix and Mindsphere (and Schneider Electric with EcoStruxure?), so Rockwell stays closer to its roots on the plant floor? Is it more profitable and manageable that way?

I don’t know the answers. But I’m left thinking that with the rise of platforms [see for example Platform Revolution by Geoffrey G. Parker, Marshall W. Van Alstyne, and Sangeet Paul Choudary] and open ecosystems, Rockwell seems to have a much smaller vision. It talks of “Connected Enterprise”, but in the end I don’t see a lot of “enterprise” in the offerings.

Questions

- Is it platform or a piece of the Rockwell software stack that stops short of plantwide views?

- Is it anything that others (SIs and users?) can add to?

- Is there more coming?

- Is there a way to integrate supply chain and customer chain?

- Seems a natural to integrate with an asset management application–which Rockwell does not have.

I think they’ve done well for what they evidently set out to do. I also think there remains more to do to help customers leverage the Internet of Things and Digital Transformation. Interesting to see what next November brings.

by Gary Mintchell | Dec 7, 2017 | Automation, Internet of Things, Operations Management, Safety, Wireless

An enterprise computing and IT infrastructure company user event seems a weird place for a discussion of the Internet of Things and the Refinery of the Future. But there I was moderating a bloggers’ Coffee Talk with Doug Smith, CEO, and Linda Salinas, plant manager, of Texmark Chemicals, along with an executive of Hewlett Packard Enterprise (HPE) and one from PTC (ThingWorx).

HPE invited me to Madrid, Spain, (and paid my expenses) as an Operations Technology blogger to participate in Influencer sessions, interview a number of technologists, and experience its Discover Madrid user conference. Several times during each of the three days November 28-30 we participated in coffee talks. These were Live Streamed by Geekazine. This is a link to the first day. My session was toward the beginning of the first day, and I appear at the end of day three.

Telling the IoT Story

Texas toll manufacturer Texmark Chemicals teamed with HPE and Aruba to build a Refinery of the Future featuring advanced IIoT capabilities. The results: better process analytics, increased up-time, uninterrupted productivity, satisfied customers, and safer workers.

Every IoT implementation I have seen so far relied on predictive maintenance as the justifying application. Here, the first priority was safety. Then came predictive maintenance, improved operations, and consistent quality.

Texmark produces dicyclopentadiene (DCPD), a polymer precursor for everything from ink to boats. DCPD manufacturing processes involve flammable materials requiring stringent safety measures — and as demand increases, so does the complexity of the supply chains that rely on it.

Its manufacture involves heat and highly reactive chemicals, making safety a top priority. And as demand for DCPD grows, the global supply chain becomes increasingly complex, requiring ever more stringent controls, granular visibility, uninterrupted productivity, and regulatory oversight. Texmark must ensure its workers adhere to Process Safety Management (PSM) procedures at all times, and that its facility is managed in ways that put worker and community safety first.

As a contract manufacturer, Texmark must be prepared to adapt to customer requirements, which can change with little advance warning.

And it must continually drive plant efficiency and productivity. Historically, Texmark has depended on physical inspections of process equipment to ensure all systems remain in working order. However, these plant walk-downs can be time-consuming and labor-intensive. Texmark has 130 pumps in its plant, and spends nearly 1,000 hours a year on walk-downs and vibration analysis.

Depending solely on physical inspections also carries risk, because it relies on employees who — based on years of experience — can tell if a pump is starting to malfunction by recognizing slight variations in its noise and vibrations. But what happens if an employee with that skill is out sick, or reaches retirement age? Texmark needs ways to institutionalize that type of intelligence and insight.

Texmark’s vision for next-generation worker safety, production and asset management hinges on the emerging promise of the Industrial Internet of Things (IIoT): sensored devices combined with advanced analytics software to generate insights, automate its environment, and reduce the risk of human error.

The IIoT architecture must eliminate the need to transmit device data over a WAN, but instead support analytics at the edge to deliver real-time visibility into equipment and processes.

Texmark launched a multi-phase project to implement an end-to-end IIoT solution. Phase 1 and 2 established the digital foundation by enabling edge-to-core connectivity. Aruba deployed a secure wireless mesh network with Class 1 Div 1 access points and ClearPass for secure network access control. Aruba beacons provide location-based services for plant safety and security purposes. The wireless solution cost about half of what it would have cost to deploy a hardwired network.

For its edge analytics, Texmark selected the HPE Edgeline Converged IoT platform, an industrialized solution that supports robust compute capabilities. HPE Pointnext implemented the system as an HPE Micro Datacenter, which integrates its compute and networking technology within a single cabinet. HPE also upgraded Texmark’s plant control room to enable seamless edge-to-core connectivity and high-speed data capture and analytics, and to meet Texmark’s safety and security standards. The Edgeline system runs Texmark’s Distributed Control System software, integrating its operations technology and IT into a single system.

Phase 3 builds on the foundation established by these technology solutions to support Texmark’s use cases: predictive analytics, advanced video analytics, safety and security, connected worker, and full lifecycle asset management.

Texmark’s new IIoT solution will help make its workers even safer. It can monitor fluid levels, for example, reducing the risk of spills. It can alert Texmark immediately if a system starts to malfunction, enabling the company to respond before workers or production are endangered. And in the event of an emergency, it can help protect workers by ensuring Texmark knows their precise location and movements within the facility.

Other benefits will improve the company’s bottom line. Texmark can use data from IIoT sensors to identify which systems require hands-on evaluations, for example, so it can conduct physical inspections in a more focused and efficient manner.

The new IIoT solution makes it easier for the company to plan inspections and maintenance. To work on distillation columns, Texmark must often take systems offline and erect costly scaffolding. Improved maintenance planning will reduce these associated costs by at least 50%.