by Gary Mintchell | Feb 24, 2017 | Automation, Internet of Things, News, Operations Management, Safety, Software, Technology

Connections, services, augmented reality. Three technology directions and three companies that contacted me last month to point out some cool things going on, often beneath the radar. One of them just raised a bunch of VC money, though. I think you’ll be hearing more.

Now that I’m catching my breath from a couple of intense weeks with the ARC Forum and then the Industry of Things Conference, I have time to look at some new directions.

Knowledge Connected

Omnity uses the tagline Knowledge, connected. It accelerates the discovery of otherwise hidden, high-value patterns of interconnection within and between fields of knowledge as diverse as science, medicine, engineering, law and finance.

More than 2,500 scientific papers and 2,200 patent applications are published every day. Just the last five years of most scientific and engineering fields have produced on the scale of 100,000 documents. Reading these one an hour would take 50 years, a professional lifetime. Pair-wise comparison of these documents at three minutes per comparison would take more than 9,000 years, nearly the length of recorded human civilization. It is impossible to stay current in any field, much less the boundaries between two or more different fields, where most innovation occurs.

Omnity enables research and development professionals in all fields to rapidly and efficiently detect otherwise hidden patterns of relevant document interconnections. Whether for basic research or advanced product development, Omnity allows real-time insight into complex document sets, enabling research and development professionals to efficiently and systematically answer a wide range of questions. Read more here.

I heard about it on the podcast/radio show Tech Nation.

Augmenting Field of Vision

Safety Compass overlays information on your smartphone camera view, enhancing your field of vision. Warnings when and where you need it most—it is with you at work whenever and wherever you are, with coverage for the entire team. Simple, clear functionality with interactive hazard information suits any workplace size.

- Sign in and Select Your Site

- Supervisors can add a site or specific area on site within minutes.

- Adding hazard information is easy, simply follow the prompts to identify issues quickly.

- Workers can then sign in with secure login details and select from any number of relevant worksites.

- Scan Your Location for Hazards Using Augmented Reality

- The Safety Compass uses intuitive augmented reality to communicate hazard information to users in the field.

- Using the phone’s GPS and accelerometers the app superimposes real time information onto the camera view that adapts and compensates for worker’s field of vision.

- View Hazards Site-Wide

- By accessing the worker’s physical location, the app presents vital information on present dangers straight to the worker’s phone, avoiding the necessity of bulky safety manuals to locate and manage risk.

- A worker’s position is shown in relation to hazards, and workers can zoom, tilt and pan across a detailed site map.

- Access In-Depth Safety Information

- Workers receive critical site information well before they enter a hazardous area, allowing them time to prepare for safe work practices and overcoming the challenges of reading large volumes of complicated text in dark, shifting, loud or crowded environments.

- Additional safety information including video content can be added for more detail.

Frameworks of Applications

MuleSoft Agility starts with an application network according to MuleSoft. Mobility, Cloud services, the Internet of Things are creating incredible opportunities for business — but they’re raising customers’ expectations. MuleSoft builds application networks: seamless frameworks of applications, data sources, and devices connected by APIs, whether on-premises or in the cloud. They speed up app launch and modification cycles, make it easier to secure and manage access, and ultimately enable companies to do more — and faster — with less.

Leverage the power of API-led connectivity for a complete connectivity solution for digital business. Connect and orchestrate data on IoT devices, across devices, or with back-end applications. Leverage open standards and developer-friendly tools for speed and productivity. Connect to devices using out-of-the-box transport protocols like Zigbee and MQTT. Adapt Anypoint Platform to fit IoT architecture, not the other way around. Achieve full flexibility with a hybrid architecture and extensibility to connect future technologies.

MuleSoft recently received a large investment. Look for more from it.

by Gary Mintchell | Feb 20, 2017 | Automation, News, Operations Management, Process Control, Software, Standards

Open Process Automation and IT/OT Convergence. Thursday, the last day of the ARC Forum, is not always all that well attended. The 2017 edition witnessed two sessions that held the attention of the later departing attendees. These two attracted a reasonably good attendance.

I didn’t do the IT/OT one, but I had great interest in the Open Process Automation Forum (Open DCS?).

This was my 20th ARC Forum. My first Forum featured another open control series of meetings on Thursday morning—The Open Modular Architecture Controller group. That group of engineers and managers sought to specify a PLC based upon the computing standards of the time. The culmination of that effort was a CompactPCI chassis cobbled together by an entrepreneur. It was not picked up. Meanwhile OMAC pivoted when end user companies principally P&G and Nestle moved the focus to packaging machines. The goal became machines that used standard states and HMI in order to reduce training time for operators as they moved from machine to machine.

ExxonMobil appeared at the Forum last year with an idea. It wished to reduce the cost to deploy and eventually upgrade its control systems. It had worked with Lockheed Martin to devise a plan from the avionics industry (FACE).

This session at the Forum updated attendees with progress. It has formed under The Open Group as the Open Process Automation Forum. Although driven by ExxonMobil initially, the goal is to form a broad alliance of owner/operators, end users, systems integrators, and suppliers developing this new automation platform.

Many people at the conference relate this effort to the old OMAC work. They see the end game as a customer trying to drive down the cost of the system. Especially a customer who faces two problems: the immediate problem of upgrading old technology; the long range cost of upgrading technology to newer levels.

Another way to view this initiative is more altruistic in the sense of driving disruptive change in the market for all users using standards.

I am conflicted in trying to understand the dynamics of the situation. As a proponent of standards, I applaud the effort to find ways to implement standards and interoperability. Interoperability has been proven in many industries as a driver for business growth. The idea of decoupling hardware and software holds great promise for future upgrades.

But if, in effect, the customers simply wish to drive automation components and software to commodity level, then I see problems. Such ideas have killed entire industries in the past.

I also look at the old PC technology when there many players developing cards for the PC bus to add on to an “IBM PC.” But over time, technology enabled chip manufacturers to incorporate all those features into the main CPU and the industry returned to basically a single source for a computer.

Predictions? I’m not making any right now. However…

This process is now more than a year old, and yet, the theme of the Forum in Orlando was a plea for participation. There were few other owner/operators. Even though almost all major suppliers have signed on, only two (Schneider Electric and Yokogawa) appear to be active. The leaders have put forth an ambitious timing plan. The group is going to have to build a critical mass of participants quickly.

One more point. There is an age-old tension between an end-user wishing to reduce procurement costs by being able to competitively bid everything. However that means that someone must assemble all the components. On the other hand, end user companies also like partnerships with suppliers for joint development and better service.

By decoupling end user from supplier, something or someone must fill the gap. That would be the system integrator, I guess.

There are many questions.

Without further comment, I’ll leave you with the Open Process Automation Forum’s Vision Statement.

Composed of a broad group of end users, product suppliers, systems integrators, and academics, the Forum will create a technologically appropriate open process automation architecture and specifications along with business guidance for its adoption and use.

- This will result in a standards-based open, secure, and interoperable process automation architecture and instances thereof that have the following characteristics:

Easily integrates best-in-class components to provide timely access to leading edge performance

- Employs an adaptive intrinsic security model

- Enables the procurement and modular interaction of certified conformant components into systems that are fit-for-purpose for the end users’ needs

- Is commercially available and applicable to multiple industry sectors

- Protects suppliers’ Intellectual Property within conformant components

- Enables portability and preservation of end users’ application software

- Significantly reduces the difficulty of future replacements and reduces the lifecycle cost of systems

by Gary Mintchell | Feb 3, 2017 | Internet of Things, News, Organizations

Committee co-chair Mark Crawford of the The Industrial Internet Consortium (IIC) told me yesterday that its Industrial Internet Reference Architecture is a living document. The committee revises frequently in order to stay current with rapidly moving technology and use cases.

Committee co-chair Mark Crawford of the The Industrial Internet Consortium (IIC) told me yesterday that its Industrial Internet Reference Architecture is a living document. The committee revises frequently in order to stay current with rapidly moving technology and use cases.

Therefore, it is no surprise that the organization has published version 1.8 of the Industrial Internet Reference Architecture (IIRA). This new version builds on version 1.7, originally published on June 17, 2015. The document is applicable both for systems architects and business leaders who wish to incorporate the Internet of Things into their corporate strategies.

The IIRA is a standards-based architectural template and methodology designed by a broad spectrum of IIC members, including system and software architects, business experts, and security experts, to assist IIoT system architects to design IIoT solution architectures consistently and to deploy interoperable IIoT systems. It is important to note that the IIRA itself is not a standard.

“The IIC is committed to delivering practical deliverables to the IIoT community that represent the latest thinking about IIoT,” said John Tuccillo, Senior Vice President of Global Industry and Government Affairs, Schneider Electric and IIC Steering Committee Chair. “The IIRA, like all IIC deliverables, is a living document. The IIRA and the now the IIRA v1.8 are the first steps toward an open, innovative and thriving technology development ecosystem across industrial sectors of the IoT.”

“We have already seen customers who are using the IIRA to define and deploy their IIoT systems,” said Dr. Tanja Rueckert, Executive Vice President, IoT and Digital Supply Chain at SAP SE and IIC Steering Committee Vice Chair. “The IIRA and the other IIC deliverables provide significant value to IIC members as well as the broader IIoT and IoT communities.”

IIRA v1.8 Benefits

The IIoT core concepts and technologies addressed in the IIRA v1.8 are applicable to the depth and breadth of every small, medium and large enterprise in manufacturing, mining, transportation, energy, agriculture, healthcare, public infrastructure and virtually every other industry. In addition to IIoT system architects, the plain language of IIRA v1.8 and its emphasis on the value proposition and enablement of converging Operational Technology (OT) and Information Technology (IT) enables business decision-makers, plant managers, and IT managers to better understand how to drive IIoT system development from a business perspective.

“It has been widely recognized that IIoT delivers value and transforms business. A main challenge for many enterprises now is how to get started,” said Shi-Wan Lin, CEO & Co-Founder, Thingswise, LLC and Co-Chair of the IIC Architecture Task Group. “The IIRA provides a framework to drive IIoT projects from a business viewpoint. This is valuable for enterprises to build IIoT systems that can deliver the expected business value.”

Technology vendors can use the IIRA concepts and methodologies to build interoperable system components that address the broadest possible market. System implementers can use the IIRA as a starting point to shorten system development by deploying reusable, commercially available, or open-source system building blocks to reduce project risk, associated costs, and time-to-market. Ultimately, the IIRA will help the IIoT community to realize an open, innovative IIoT ecosystem, thereby reducing the cost of design and operations.

“The value of the IIC is that it brings together a set of diverse, talented people with an extraordinary set of knowledge to develop innovative technology to solve corporate-level industrial challenges,” said Todd Edmunds, Global Manufacturing Solutions Architect – Internet of Things at Cisco Systems and Co-Chair of the IIC Edge Computing Task Group. “The IIRA accelerates the development of solutions to digitize business and realize IIoT’s true potential to transform industry.”

Journal of Innovation

Capping a busy week, the IIC has also published the Third Edition of the Journal of Innovation. A publication written by IIC members, the third edition of the Journal of Innovation is dedicated to the “Smart Factory,” and includes articles on designing, retrofitting, and applying IIoT technologies within the manufacturing industry.

“Manufacturers are challenged to make factories more efficient, safer and greener than ever before,” said Erik Walenza-Slabe, CEO, IoT One and Co-chair, IIC Smart Factory TG. “While no single organization can solve all the problems of the IIoT, the IIC is helping to revolutionize manufacturing through its many activities, including the innovations described in the third edition of the Journal of Innovation dedicated to the ‘Smart Factory.’”

New to this edition are two articles summarizing interviews with two IIC testbed leads, describing insights, outcomes and lessons learned. These articles highlight the innovations taking place in the Time Sensitive Networking (TSN) Testbed and the INFINITE Testbed.

“Testbeds are at the very core of what we do in IIC and we aim to feature testbeds in all of our future editions,” said Edy Liongosari, Chief Research Scientist of Accenture Labs and co-chair of the IIC Thought Leadership Task Group.

The Journal of Innovation includes the following articles authored by IIC member companies:

- “Blurry Box Encryption Scheme and Why it Matters to Industrial IoT”

- “Results, Insights and Best Practices from IIC Testbeds: Time Sensitive Networking (TSN) Testbed”

- “Making Factories Smarter through Machine Learning”

- “Driving Innovation in Product Design and Manufacturing using 3D Printing”

- “Results, Insights and Best Practices from IIC Testbeds: INFINITE Testbed”

- “Smart Factories and the Challenges of the Proximity Network”

Authors and interviewees within the third edition include Cisco, Cork Institute of Technology, Dell EMC Research Europe, Ikergune, IT Research Center, Karlsruhe Institute of Technology, Plethora IIoT, QualiCal, Synapse Wireless, System On Chip Engineering, Xilinx, Wibu-Systems.

by Gary Mintchell | Jan 26, 2017 | Automation, Industrial Computers, Security

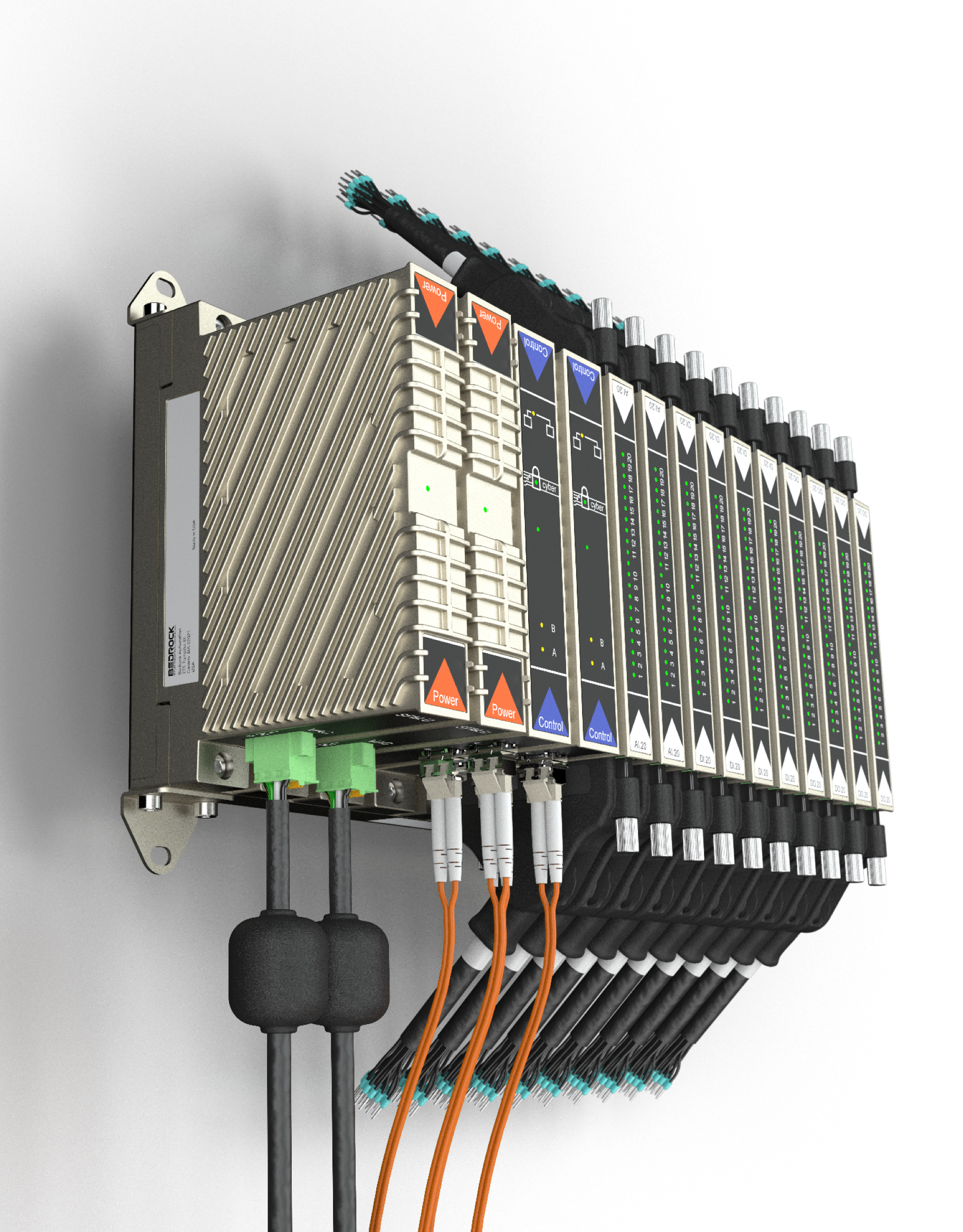

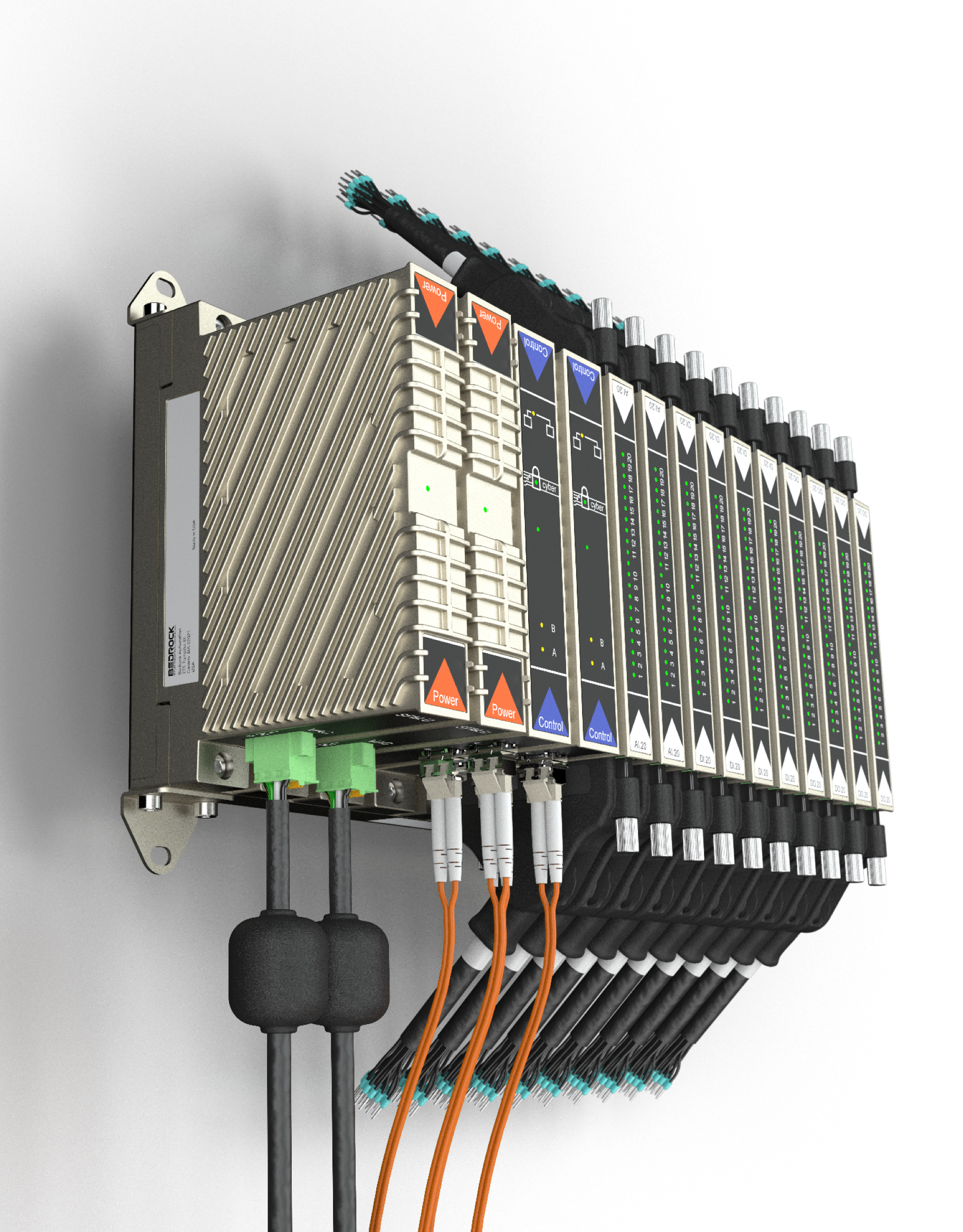

Bedrock Automation has built a good automation platform with built-in security and toughness. I’ve been watching to see just how disruptive it might be in the market. In this announcement, it is showing further growth in its go-to-market strategy of working with integrators. It has signed a memorandum of agreement with Jacobs Engineering Group Inc., one of the world’s largest and most diverse providers of full-spectrum technical, professional and construction services. Under the agreement, the companies will pursue selected projects with automation system requirements for potential implementation of the Bedrock Open Secure Automation (OSA) system.

Bedrock Automation has built a good automation platform with built-in security and toughness. I’ve been watching to see just how disruptive it might be in the market. In this announcement, it is showing further growth in its go-to-market strategy of working with integrators. It has signed a memorandum of agreement with Jacobs Engineering Group Inc., one of the world’s largest and most diverse providers of full-spectrum technical, professional and construction services. Under the agreement, the companies will pursue selected projects with automation system requirements for potential implementation of the Bedrock Open Secure Automation (OSA) system.

“Our clients are increasingly concerned about both cyber security and advanced automation and we have been creating innovative service packages to meet these needs. Bedrock Automation has excellent experience and superior designs in this area. I am impressed with their comprehensive background and knowledge in the industrial DCS and PLC arena,” said Jacobs’ Mission Solutions Chief Technology Officer Dr. Tommy Gardner.

The Bedrock control system is known for its patented Black Fabric Cybershield architecture, which provides an intrinsic cyber secure automation platform to protect user hardware, software and applications. Unlike other conventional industrial control systems, Bedrock was designed from a clean sheet of paper with advanced components and architecture to be simple, scalable and secure.

“Jacobs is taking a leadership role in integrating the next generation of information and automation technologies for its clients,” added Bedrock Automation President Bob Honor. “We see this as a tremendous opportunity to bring our technology and our vision of holistic cyber security to a much larger audience. We look forward to an exciting and mutually beneficial relationship with Jacobs.”

by Gary Mintchell | Jan 11, 2017 | Automation, Manufacturing IT, Operations Management

Easy way to use the cloud to connect traceability applications from different suppliers across these increasingly complex industrial companies? I received another of those press releases that seem almost too good to be true. So I called the company.

The application uses open APIs, proprietary connectors, and other such technologies to tap into all the different databases. But the key points are easy to set up and use as well as easily bring relevant data to the person who needs it.

Leading2Lean, a cloud-based lean manufacturing solutions provider, introduced TraceCloud, a CloudDISPATCH engine designed to identify possible manufacturing problems across disparate systems in different plants. TraceCloud eliminates the cost and risk of removing existing traceability systems and replacing them with a standardized system across all plants—an expense of upwards of tens of millions of dollars.

It’s common for companies to use different traceability systems for each of its plants. Discovering issues and tracking them across various systems can take days and tie up precious IT resources ultimately needed in other areas. Some discovery processes may even include shutting down production. With TraceCloud, companies can access aggregated data from multiple systems and find issues in just minutes.

When a problem is detected—because of a faulty product, for example—TraceCloud is able to quickly alert production teams about the problem, and allow for quick access to the data necessary to identify the root cause. Manufacturers can then contain the suspect material, ultimately preventing the quality issue from being perpetuated or shipped. Once the system has contained the material, TraceCloud enables quick decision-making based on facts and data collected from systems at various production plants and even suppliers.

“TraceCloud is drastically cutting the time to identify, solve and contain quality problems, saving companies millions of dollars,” said Keith Barr, CEO of Leading2Lean.

TraceCloud offers seven key components:

- Traceability and genealogy: Manufacturers can trace all the way through source material to make decisions based on facts. TraceCloud brings simplicity to creating a complete birth certificate of your products, both serialized or lot based.

- Unites existing systems: TraceCloud combines data from multiple systems and sites, enabling easy standardization and eliminating the need for costly replacement of current systems in existing or newly acquired plants.

- Ease of use: No need to make requests to IT. Simply go into TraceCloud’s easy, point-and-click, intuitive system and get the answer back in minutes from the convenience of your office. TraceCloud enables quality engineers to easily identify opportunities for improvement much more quickly.

- Alerting and containment: With TraceCloud, you can notify all relevant parties upon discovering a lot-based or serialized issue. The system will identify the location of all corresponding product issues, and contain the faulty product.

- Dynamic data collection: Leading2Lean’s dynamic-schema architecture lets manufacturers collect variable data length and type, as well as counting to extend product trace detail to any degree desired. Collect machines used, participating operators, settings or readings in the process, and combine bill-of-materials (BOM) from both serialized or lot to create the complete genealogy tree.

- Eleven9s: Leading2Lean performs above industry benchmarks, with Eleven9s durability of historical data. Traceability data is kept above safety standards with little to no risk of data loss.

- Year-Long-Term data storage: Maintain your data for 20-plus years. TraceCloud maintains your data for as long as needed, and the system allows anyone to retrieve data instantly when required.

Committee co-chair Mark Crawford of the

Committee co-chair Mark Crawford of the

Bedrock Automation

Bedrock Automation