by Gary Mintchell | Aug 18, 2018 | Asset Performance Management, Operations Management, Software

Who buys enterprise software applications, how and why? I ran across this article by a contact of mine, Gabriel Gheorghiu, Founder and principal analyst at Questions Consulting, with a background in business management and 15 years experience in enterprise software. I thought it would be most useful. I’m not an ERP analyst, but I have some background and training on the financial side of things. I think this analysis fits with other large-scale software acquisition projects, though, including MES/MOM, analytics, asset performance, and the like.

This will summarize some interesting points. I highly recommend reading the whole thing.

Before we begin, my brief take on enterprise software applications. How many of you have been involved with an SAP acquisition and roll out? How many happy people were there? Same with Oracle or any other ERP, CRM, MES, APM, etc. application. Why did using Microsoft Excel seem to go better?

Well, the big applications all force you to change all your business processes to fit their template. You build Excel to fit what you’re doing. It’s just not powerful enough to do everything, right?

Gheorghiu conducted interviews with 225 companies who were all looking for enterprise resource planning (ERP). The goal of this survey was simple – listen and learn from what these companies had to say about their individual decision-making strategies. We all agree that this is not a simple task. But we also agree that selecting the best ERP software is a critical factor for business success.

Here is why the research phase of this process is considered to be so vital:

- It has the greatest impact on all the subsequent phases and consequently, your final decision.

- Research begins at home – in other words, the first step is to determine your company’s specific and unique needs.

- Once your company has thought through and determined its software requirement, then and only then does the process to evaluate vendors and their offerings begin. This can be a very challenging step because many companies are not equipped with the time, knowledge, or tools to perform this step.

Buyer Profiles: Who’s Looking for ERP and Why?

One problem for analysis is that many are not doing business in just one industry. The breakdown of companies in our business sample, by industry, was as follows: manufacturing (47%), distribution (18%), services (12%), construction (4%), retail (3%), utilities (3%), government (3%), healthcare (3%), and other (10%). However, to complicate matters a little, 20% of manufacturers also manage distribution and some distributors include light manufacturing in their operations, like assembly.

“Companies looking to invest in business software may very well be addressing this additional challenge – looking for a comprehensive package that integrates all aspects of a business. ERP software systems are powerful and comprehensive but are not necessarily known for their agility and ability to accommodate many disparate functions.”

Gheorghiu identifies as a strong influencer consumerization, which changes focus from organization-oriented offerings to end-user focused products. “This was a highly significant turning point in the IT marketplace. By developing new technologies and models that originate in the consumer space rather than in the enterprise sector, software producers opened up the market to a flood of small and medium-sized businesses looking for more cost effective, and less complicated solutions to run their businesses.”

The consumerization of software (as noted above) has precipitated the move by many companies away from enterprise IT towards more streamlined and user friendly consumer-oriented technology. This change is equally relevant for ERP software and manufacturing companies have participated in this very significant development, albeit more cautiously and slowly than SMBs.

Most industries follow a “purposeful implementation” strategy, managing software adoption as a series of “sprints in a well-planned program” rather than insisting on the “all or nothing” approach.

For example, a small company looking to invest in software might decide to begin with an accounting system which can be used alongside point solutions and spreadsheets. As companies grow and their transactions become more complex, they may find that they have also outgrown their initial software selections.

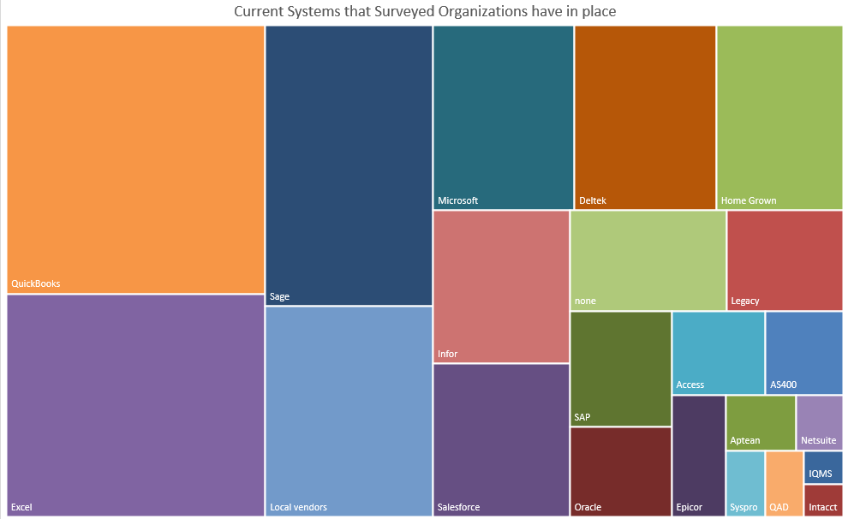

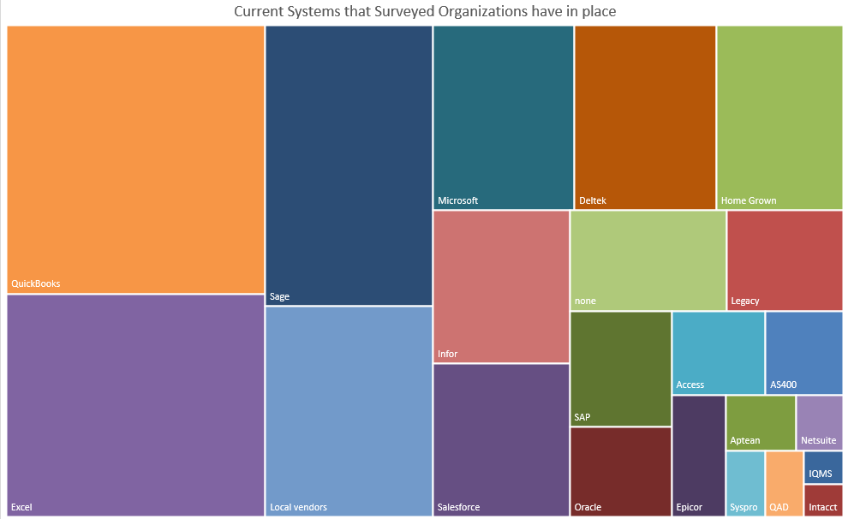

The chart below provides a visual analysis of the mix of software that is currently utilized by our business sample:

Some relevant comments we extracted from our survey included:

- The CEO of a small services company mentioned that he was “tired of the hodgepodge of systems”

- A manufacturer considered their current arrangement to be “very siloed.” Reconciling the inventory balance is a “constant battle.”

Buyer Behavior: How are Companies Approaching ERP Selection?

The selection process is most successful when companies adhere to some basic selection rules: involve as many direct stakeholders as possible and keep business priorities and strategies firmly in mind when making the final decision.

Feature Functions

A software change can trigger a vast administrative upheaval within the company. It is important to carefully analyze the business case for the change and whether it supports the level of disruption as well as the implementation time and spending that will be required. Even if the change may be entirely justified, a well thought out analysis is well worth the time and effort.

The Vendors in the Spotlight

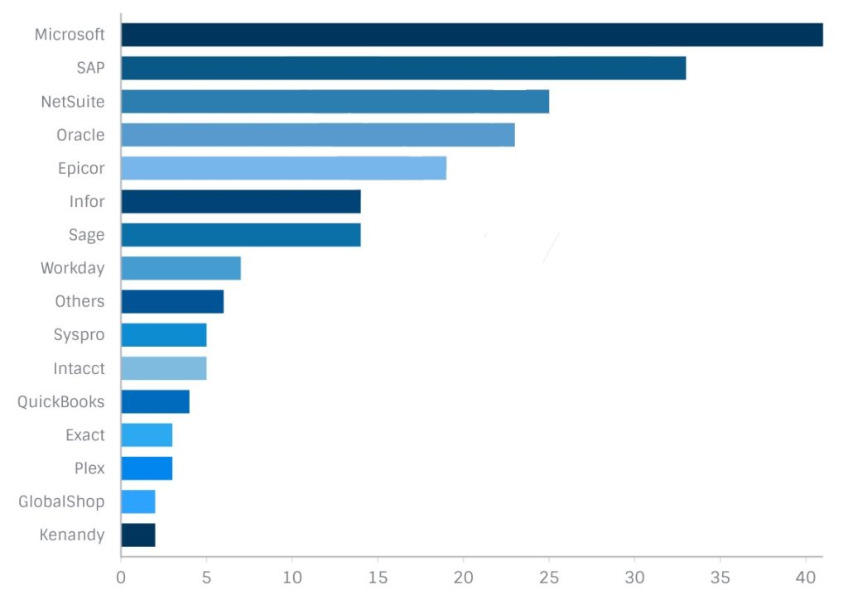

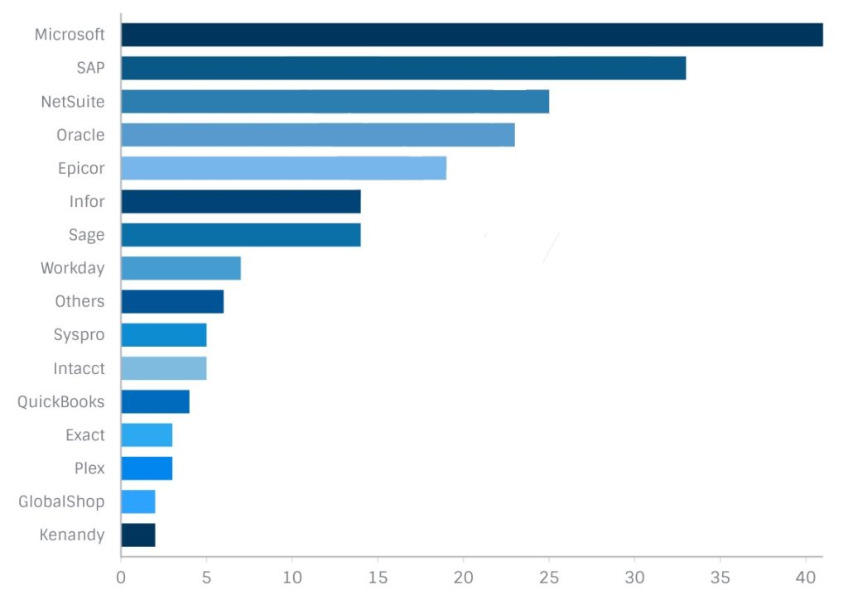

According to our survey results, the chart below identifies the vendors under consideration by the companies surveyed. A majority of companies (53%) were not, for the moment, looking at specific vendors. However 47% of respondents had narrowed their search to specific vendors.

Who’s Involved in this Decision Selection Process?

Our sample results indicate that the people in charge of the selection process are distributed as follows: employees in the finance and accounting departments (23%), IT department employees (23%). The other important categories were independent consultants helping companies with the selection process (17%), operations managers (17%) and presidents or CEOs (12%). It is worthwhile mentioning that project managers and business analysts only made up 5% of the total.

By far, the most effective method of choosing a software is to employ a collaborative system whereby the actual stakeholders of that system (the end-users) have a direct voice in the decision outcome. As the front-line users of the system, their insight and knowledge is very valuable. Their input along with all the other stakeholders input will produce the best possible outcome of this process.

An ERP system is a major business investment and is best handled with the appropriate amount of time and diligence given to the process.

The advent of cloud computing has indeed radically changed the landscape for deployment of business software. According to a recent press release by Gartner, “by 2020, a Corporate “No-Cloud” policy will be as rare as a “No-Internet” policy is today”. In other words, cloud deployment will become the default by 2020.

Our survey results, in fact, support Gartner’s analysis. Ninety-five percent of companies responded that they were open to a cloud deployment model, while just over 50% were willing to also consider on premises ERP. Of this latter group of respondents, 65% of them were manufacturers and distributors. This makes sense of course, given that these industries made significant investments in hardware and IT personnel and may not be as ready or as willing to move to the cloud model.

As for the preference for cloud computing (as demonstrated by our responses), we argue that it reflects the very strong tendency in the market to opt for simpler, more streamlined and less expensive computing solutions. As more information and assurances of security and stability by cloud providers enter the marketplace, more and more businesses will be convinced that the many benefits of the cloud outweigh some of their remaining concerns. Gartner’s prediction that cloud will increasingly be the default option for software deployment looks to be right on course.

Conclusion

An important consideration for companies embarking on an ERP software selection process – the average lifespan of an ERP system is approximately 5 to 10 years. If we consider important factors like the investment of capital, time, and loss of productivity that the selection and replacement of an ERP system requires, perhaps all companies would be more willing to invest the necessary effort in this process.

by Gary Mintchell | May 21, 2018 | Internet of Things, Manufacturing IT, Software

Hannover Messe was the place to learn the latest about all things digital—digital twin, Industry 4.0, Industrial Internet of Things (IIoT). SAP was one of the many stops in my itinerary advancing the trend.

My contact at the SAP booth at Hannover wasn’t around when I arrived for my appointment, so I left—only to get a text a half-hour later that he had arrived. But I was off to another appointment by then. However I did glean this information from the company at and following the show.

SAP enters the digital twin era

SAP SE has introduced SAP S/4HANA Cloud for intelligent product design, a new solution for collaborative research and development.

The solution, which is built on SAP Cloud Platform using SAP’s latest digital twin technology, is one of the building blocks for a network of digital twins to enable new business models.

Powered by SAP Leonardo and integrated with business processes in the digital core, SAP S/4HANA Cloud for intelligent product design enables customers to accelerate product design and development with requirement-driven systems engineering and instant collaboration across an extended network of suppliers and partners.

“The solution provides shared views of digital twin information for customers to gain live insights on new products and to store, share and review engineering documents with internal and external participants,” said Bernd Leukert, Member of the Executive Board of SAP SE, Products & Innovation.

SAP’s network of digital twins synchronizes the virtual, physical, conditional, and commercial definitions of assets and products in real time to accelerate innovation, optimize operating performance, predict service requirements, improve diagnostics and enhance decision-making. It enables new levels of collaboration among manufacturers of products, operators of assets, suppliers and service companies. The approach combines digital twins with manufacturing solutions from SAP, cloud networks and SAP Leonardo capabilities, including machine learning, blockchain and Internet of Things (IoT), to optimize the product lifecycle with:

• Digital representation: SAP synchronizes digital twin business data, product information, asset master data and IoT-connected data from both on-premise and cloud solutions enabling companies to represent the world digitally. Solutions including SAP Predictive Engineering Insights, SAP Predictive Maintenance and Service and the SAP 3D Visual Enterprise applications provide access to rich data processing capabilities and live configuration, state, condition and control information.

• Business process: Rich enterprise-grade data processing capabilities allow customers to create, access and update digital twins to support business processes. SAP solutions provide an integrated data model from design, production and maintenance to service, including packaged integration to existing systems for computer-aided design, ERP, and product lifecycle management. Offerings providing end-to-end process support for manufacturers and operators include SAP S/4HANA, the SAP Engineering Control Center integration tool, SAP Hybris Service Cloud solutions, and the SAP Manufacturing Integration and Intelligence and SAP Manufacturing Execution applications.

• Business networks: With leading network offerings such as SAP Ariba solutions, SAP Asset Intelligence Network, and the SAP Distributed Manufacturing application, SAP is uniquely positioned to provide a virtual platform for collaboration on products and assets. The network of digital twins enables secure data access, sharing and governance on a global scale.

• Networks of digital representation: SAP enables twin-to-twin connections in systems within a specific asset and on an asset-to-asset level. SAP solutions such as SAP Asset Intelligence Network provide semantic and industry-standards support in an asset core modeling environment to enable live enrichment during the product or asset lifecycle.

Digital Manufacturing Cloud

SAP Digital Manufacturing Cloud helps companies optimize performance, elevate production quality and efficiency, and ensure worker safety.

Drawing on SAP’s expertise in the Industrial Internet of Things (IIoT), predictive analytics and supply networks, the solution enables manufacturers to deploy Industry 4.0 technologies in the cloud.

The new cloud solution extends and complements the digital manufacturing portfolio of on-premise solutions from SAP and is available in different bundles to serve manufacturers of varying sizes in both discrete and process industries and roles within their respective organizations.

SAP customers can choose from the SAP Digital Manufacturing Cloud solution for execution, which provides all solutions in the manufacturing cloud portfolio, or the SAP Digital Manufacturing Cloud solution for insights, which focuses on performance management and predictive quality.

“Manufacturers in the era of Industry 4.0 require solutions that are intelligent, networked and predictive,” said Leukert. “Our manufacturing cloud solutions help customers take advantage of the Industrial Internet of Things by connecting equipment, people and operations across the extended digital supply chain and tightly integrating manufacturing with business operations.”

SAP Digital Manufacturing Cloud includes the following:

• SAP Digital Manufacturing Cloud for execution: Industry0-enabled shop floor solution features “lot size one” and paperless production capabilities. It integrates business systems with the shop floor, allowing for complete component and material-level visibility for single and global installations.

• SAP Digital Manufacturing Cloud for insights: Centralized, data-driven performance management enables key stakeholders to achieve best-in-class manufacturing performance and operations.

• Predictive quality: This helps manufacturers gain valuable insights to conform to specifications across processes and streamline quality management. It also allows manufacturers to apply predictive algorithms that can reduce losses from defects, deficiencies or variations, and recommend corrective actions.

• Manufacturing network: The network provides a cloud-based collaborative platform integrated with SAP Ariba solutions connecting customers with manufacturing service providers, such as suppliers of 3D and computer numerical control (CNC) printing services, material providers, original equipment manufacturers (OEM) and technical certification companies.

Also at Hannover Messe 2018, SAP announced SAP Connected Worker Safety, a solution designed to reduce risks, costs and protect employees. Information from wearables and other sensor-enabled equipment can help companies react immediately to a hazardous situation or incident while proactively managing worker fatigue and other hazard inducers. Real-time information allows monitoring of compliance at all times against regulatory and other parameters.

by Gary Mintchell | Mar 28, 2018 | Internet of Things, Manufacturing IT, Software

HMI SCADA as a technology product continues to grow and adapt in this Industrial Internet of Things (IIoT) world. Once a control room technology, new iterations make it a natural for the Internet of Things. Steve Hechtman, founder of Inductive Automation, approached me some 15 years ago (I can’t believe it’s been that long) at a trade show to explain a new HMI SCADA product built with Java and IT-friendly technologies. The product has evolved substantially over the years, but the IT-friendly aspect is proving valuable in this new IT/OT convergence atmosphere.

So, now we have HMI SCADA and Enterprise linked. Inductive Automation has named Brock Solutions as the first system integrator in the new Inductive Automation Enterprise Integrator Program. Inductive Automation defines Enterprise Integrators as those with a high level of Ignition certification, a global presence, the ability to take on enterprise-wide projects, and 250 or more engineers, among other requirements.

Ignition by Inductive Automation is an industrial application platform with fully integrated tools for building solutions in human-machine interface (HMI), supervisory control and data acquisition (SCADA), and the Industrial Internet of Things (IIoT). Ignition is used in virtually every industry, in more than 100 countries.

“We’re very excited to be the inaugural member of Inductive Automation’s new Enterprise Integrator program,” said Davin McDougall, operations leader at Brock Solutions. “This program focuses on organizations looking for an integration partner like Brock Solutions with global/national reach, technical expertise, and breadth of services to roll out enterprise-wide Ignition solutions that are repeatable, scalable, sustainable, and — most importantly — that drive business value.”

Inductive Automation first made the announcement at its Ignition Community Conference (ICC) in 2017. Also at ICC 2017, Brock’s John Southcott presented a session with R.J. Reynolds Tobacco Company about how Brock aided Reynolds in its highly successful enterprise-wide transformation.

Brock Solutions worked closely with Inductive Automation on the development and launch of the Enterprise Integrator Program. “It’s been a pleasure working with Brock Solutions the past three years, and we’re very happy to designate Brock as our first Enterprise Integrator,” said Don Pearson, chief strategy officer for Inductive Automation. “Brock Solutions’ thorough knowledge of its customers, its committed team members, and its strong business processes have led to some very impressive installations of the Ignition software platform, and we look forward to seeing Brock put together more large-scale projects in the future.”

Brock Solutions is an engineering solutions and professional services company specializing in the design, build and implementation of real-time solutions for broad-based industrial/ manufacturing and transportation/logistics organizations globally. With more than 400 employees, Brock Solutions is a privately held, employee-owned organization with more than 30 years in the real-time solutions space.

Inductive Automation creates industrial software cross-pollinating IT with SCADA technologies.

[Disclaimer: Inductive Automation is an advertiser, but they do not dictate my coverage of either it or the space.]

by Gary Mintchell | Nov 7, 2017 | Commentary, Leadership, News

Turning a giant organization that has the great inertia can be likened to turning a large ship at sea. It takes great force and a lot of space. Such is the task of remaking Microsoft.

Satya Nadella has been CEO of Microsoft replacing the combative Steve Ballmer more than three years ago. I’ve seen him speak at conferences at least three times. I’ve talked to many Microsoft people. He truly has turned that big mass toward the future.

Hit Refresh: The Quest to Rediscover Microsoft’s Soul and Imagine a Better Future for Everyone tells Nadella’s personal story, as well as his business and leadership.

He begins personally. The key takeaway is his discovery of empathy. I imagine that that value was in short supply in Redmond during Ballmer’s tenure. Nadella talks about a mentor, but also the birth of a handicapped child and what the family learned while caring for him introducing him to the emotion and value of empathy.

Like most people with an MBA, he was steeped in strategy theories. As he thought about his task as the new leader of Microsoft, naturally he thought about strategy.

His early three-pronged message was

1. Reinvent productivity and business processes

2. Build an intelligent cloud platform

3. Move people needing Windows to wanting Windows

Remembering Peter Drucker’s dictum, “Culture eats strategy,” he also move quickly to change the corporate culture. He includes a few stories revealing how he went about that gigantic task.

His view of what leaders tasks are:

1. Bring clarity

2. Generate energy

3. Find a way to deliver success

He has given much thought to values. These are similar thoughts to what we hear at National Instruments’ gatherings—engineers solving the world’s biggest problems. He urges policy makers, mayors, and others not to try to replicate Silicon Valley but instead to develop plans to make the best technologies available to local entrepreneurs so that they can organically grow more jobs at home—not just in high tech industries but in every economic sector.

by Gary Mintchell | Oct 16, 2017 | Internet of Things, News, Organizations

The Industrial Internet Consortium (IIC) has been incredibly active over the past month. While I’ve been traveling, news releases and interview opportunities have been pouring in.

In brief:

- IIC and Avnu Alliance Liaison

- IIC and the EdgeX Foundry Announce Liaison

- IIC Develops Smart Factory Machine Learning for Predictive Maintenance Testbed

- IIC Publishes Edge Computing Edition of Journal of Innovation

Related:

See my white paper on OPC UA and TSN. I wrote this following interviews at Hannover for the OPC Foundation and subsequent travels to see people. I think this is a powerful combination for the future.

Why it’s important:

These news items when viewed collectively show momentum for what is happening with the Industrial Internet—or as some say the Industrial Internet of Things. These technologies are soon to be powerful business drivers for a new age of manufacturing.

The News:

Liaison with Avnu Alliance

The Industrial Internet Consortium (IIC) and Avnu Alliance (Avnu) have agreed to a liaison to work together to advance deployment and interoperability of devices with Time Sensitive Networking (TSN) open standards.

Under the agreement, the IIC and Avnu will work together to align efforts to maximize interoperability, portability, security and privacy for the industrial Internet. Joint activities between the IIC and the Avnu will include:

- Identifying and sharing IIoT best practices

- Realizing interoperability by harmonizing architecture and other elements

- Collaborating on standardization

“Both Avnu and the IIC are well aligned to pursue the advancement of the IIoT. An example of this is Avnu’s participation in the IIC TSN testbed where members have an opportunity to try their equipment and software on the testbed infrastructure. This provides the participants with the ability to discover what’s working and what is not and provide feedback that helps speed market adoption,” said Gary Stuebing, IIC liaison to Avnu. “The lessons learned in our TSN testbed fuel the ability of both of our organizations. TSN could open up critical control applications such as robot control, drive control and vision systems.”

“Our liaison agreement and work with the IIC TSN Testbed demonstrates real-world applications and solutions with TSN and helps to accelerate readiness for the market. The testbed stands as a showcase for the value that TSN standards and ecosystem of manufacturing applications and products bring to the market, including the ability for IIoT to incorporate high-performance and latency-sensitive applications,” said Todd Walter, Avnu Alliance Industrial Segment Chair. “Our collaboration with IIC and the work coming out of the TSN Testbed is already having a direct impact on suppliers and manufacturers who see the technology as a value add for their system structure.”

Avnu and IIC are meeting for a TSN Testbed plugfest later this month to evaluate and trial TSN device conformance tests that are being developed as a baseline certification in the industrial market.

Avnu creates comprehensive certification tests and programs to ensure interoperability of networked devices. The foundational technology enables deterministic synchronized networking based on IEEE Audio Video Bridging (AVB) / Time Sensitive Networking (TSN) base standards. The Alliance, in conjunction with other complementary standards bodies and alliances, provides a united network foundation for use in professional AV, automotive, industrial control and consumer segments.

Agreement with EdgeX Foundry

The Industrial Internet Consortium and EdgeX Foundry, an open-source project building a common interoperability framework to facilitate an ecosystem for IoT edge computing, announced they have agreed to a liaison.

Under the agreement, the IIC and the EdgeX Foundry will work together to align efforts to maximize interoperability, portability, security and privacy for the industrial Internet.

Joint activities between the IIC and the EdgeX Foundry will include:

- Identifying and sharing best practices

- Collaborating on test beds and experimental projects

- Working toward interoperability by harmonizing architecture and other elements

- Collaborating on common elements

- Periodically hosting joint seminars

“We are excited about working with EdgeX Foundry,” James Clardy, IIC liaison to EdgeX Foundry. “And we look forward to leveraging the experiences of the IIC to help further accelerate the adoption of the industrial Internet.”

“EdgeX Foundry’s primary goal is to simplify and accelerate Industrial IoT by delivering a unified edge computing platform supported by an ecosystem of solutions providers,” said Philip DesAutels, senior director of IoT for The Linux Foundation. “Formalizing this liaison relationship with the IIC is fundamental to unlocking business value at scale. Together, we will provide better best practices that will drive the unification of the industrial IoT.”

Hosted by The Linux Foundation, EdgeX Foundry has an ecosystem of more than 60 vendors and offers all interested developers or companies the opportunity to collaborate on IoT solutions built using existing connectivity standards combined with their own proprietary innovations. For more information, visit

Smart Factory Machine Learning for Predictive Maintenance Testbed

The Industrial Internet Consortium announced the Smart Factory Machine Learning for Predictive Maintenance Testbed. The testbed is led by two companies, Plethora IIoT, a company, designing and developing cutting-edge answers for Industry 4.0, and Xilinx, the leading provider of All Programmable technology.

This innovative testbed explores machine-learning techniques and evaluates algorithmic approaches for time-critical predictive maintenance. This knowledge leads to actionable insight enabling companies to move away from traditional preventative maintenance to predictive maintenance, which minimizes unplanned downtime and optimizes system operation. This would ultimately help manufacturers increase availability, improve energy efficiency and extend the lifespan of high-volume CNC manufacturing production systems.

“Testbeds are the major focus and activity of the IIC and its members. We provide the opportunity for both small and large companies to collaborate and help solve problems that will drive the adoption of IoT applications in many industries”, said IIC Executive Director Dr. Richard Mark Soley. “The smart factory of the future will require advanced analytics, like those this testbed aims to provide, to identify system degradation before system failure. This type of machine learning and predictive maintenance could extend beyond the manufacturing floor to have a broader impact to other industrial applications.”

“Downtime costs some manufacturers as much as $22k per minute. Therefore, unexpected failures are one of the main players in maintenance costs because of their negative impact due to reactive and unplanned maintenance action. Being able to predict system degradation before failure has a strong positive impact on machine availability: increasing productivity and decreasing downtime, breakdowns and maintenance costs,” said Plethora IIoT Team Leader Javier Diaz. “We’re excited to lead this testbed with Xilinx and work alongside some of the leading players in IIoT technologies. This is a unique opportunity to test together machine learning technologies with those involved in the testbed at different development levels starting from the lab through production environments, where a real deployment solution is utilized. As a result, from these experiences, we can significantly reduce the time-to-market of Plethora IIoT solutions oriented to maximize smart factory competitiveness.”

”Xilinx is committed to providing the Industrial IoT industry with our latest All Programmable SoC and MPSoC platforms – ideal for sensor fusion, real-time, high-performance processing, and machine learning from the edge to the cloud,” stated Dan Isaacs, Director of Corporate Strategic Marketing and Market Development for IIoT and Machine Learning at Xilinx. “The combination of these highly configurable capabilities drives the intelligence of the smart factory.”

Additional IIC member companies participating in this testbed are: Bosch, Microsoft, National Instruments, RTI, System View, GlobalSign, Aicas, Thingswise, Titanium Industrial Security, and iVeia. They provide technologies to enable the Smart Factory Machine Learning testbed, including:

- Factory automation

- OT and IT security

- Edge to cloud machine learning and analytics

- Time-sensitive networking (TSN)

- Data acquisition

- Smart sensor technology

- Design implementation

- Embedded programmable SoC technology

- Secure authentication

Journal of Innovation

The Industrial Internet Consortium (IIC) has published the fifth edition of the Journal of Innovation with a focus on edge computing. The Journal of Innovation highlights the innovative ideas, approaches, products, and services emerging within the Industrial Internet, such as smart cities, artificial intelligence, the smart factory, and edge computing.

Edge computing promises to bring real-time intelligence to industrial machines at the edge of the network, where data can be processed closer to its source. Edge computing provides businesses with a cost-effective means to transmit and analyze large quantities of data in real-time, enabling them to reduce unplanned downtime, improve worker safety and enhance asset performance.

“The Journal of Innovation brings together innovators and thought leaders across the IoT spectrum. In this issue, our experts share their insights on edge computing as a key enabling technology poised to transform the IIoT,” said Mark Crawford, co-chair of the IIC Thought Leadership Task Group and Standards Strategist, SAP Strategic IP Initiatives. “Edge computing is not a new concept, but as IIoT transforms business processes, the need to use data closer to its source, whether that be from a wind turbine, a deep-water well’s blowout preventer, or an autonomous car, is paramount.”

The Edge Computing edition of the Journal of Innovation includes articles contributed by leaders at IIC member companies including:

- Where is the Edge of the Edge of Industrial IoT? · Pieter van Schalkwyk XMPro

- Device Ecosystem at the Edge – Manufacturing Scenario · Sujata Tilak, Ascent Intellimation Pvt. Ltd.

- Edge Intelligence: The Central Cloud is Dead – Long Live the Edge Cloud · Yun Chao Hu, Huawei Technologies Duesseldorf GmbH

- Outcomes, Insights, and Best Practices from IIC Testbeds: Microgrid Testbed · Brett Burger, National Instruments · Joseph Fontaine, Industrial Internet Consortium

- A Knowledge Graph Driven Approach for Edge Analytics · Narendra Anand, Accenture Technology Labs · Colin Puri, Accenture Technology Labs

- Industrial IoT Edge Architecture for Machine and Deep Learning · Chanchal Chatterjee, Teradata Inc. · Salim AbiEzzi, VMWare Inc.

- A Practical and Theoretical Guide to Using the Industrial Internet Connectivity Framework · Stan Schneider, PhD. Real-Time Innovations, Inc. · Rajive Joshi, PhD. Real-Time Innovations, Inc.