by Gary Mintchell | Apr 24, 2016 | Automation, News, Technology

The world of advanced manufacturing and digitization continues its steady advance. GE recently announced opening of its first advanced manufacturing facility—a power products manufacturing plant in Greenville, SC.

Interesting that Rockwell Automation just announced a CEO transition leading analysts to look back on Keith Nosbusch’s tenure. Certainly at a time when rivals such as Siemens, Schneider Electric, and, yes, GE have made strong moves in the digital manufacturing space, Rockwell stuck with the “Connected Enterprise.”

That strategy essentially refers to EtherNet/IP networking. I recall my last conversation with CTO Sujeet Chand. I thought maybe he was going to talk about adopting some new technologies. Instead, he introduced a Cisco executive who talked about switches.

I’m en route to Hannover where I have appointments already with Siemens and GE Digital to talk about their digital strategies. Throw in Dell and SAP, and things get interesting.

I think Blake Moret, the next CEO, has his work cut out for him to keep Rockwell Automation relevant in the new age. I’m not usually too critical of Rockwell. I know its reputation for being conservative. Nosbusch stayed the course firmly. I’m starting to think that if Moret doesn’t provide some new directions, there is a risk.

Meanwhile, Back to GE

- The bullet points from its press release:

New Facility Will Deploy Best-in-Class Technologies to Accelerate Improvements in Every Aspect of the Manufacturing Process Including Design, Engineering, Product Development, Production, Supply Chain, Distribution and Service and Will Unlock New Productivity and Growth across GE’s Power Portfolio

- GE Has Invested $73 Million to Date and Will Invest an Additional $327 Million across the GE Power Greenville, S.C., Campus to Boost Innovation and Accelerate the Commercialization of Development of Best-in-Class Technologies for Customers across the Globe

- Eighty Engineering and Manufacturing Jobs Created with the Facility’s Opening, Expected to Have a Multiplier Effect across the Supply Chain

GE celebrated the grand opening of its new state-of-the-art Advanced Manufacturing Works (AMW) in Greenville as the GE Power business continues to introduce tomorrow’s technologies, today. The announcement comes on the heels of GE’s grand opening of its first additive manufacturing center in Pittsburgh in early April and represents the next step forward in GE’s journey as the world’s premiere digital industrial company.

“The opening of the AMW is a pivotal moment for us. We’re building a skilled workforce and culture that’s devoted to delivering breakthrough innovations that deliver better, faster outcomes for our customers and unlock new productivity and growth.”

GE has invested $73 million in the facility to date and will invest another $327 million across the GE Power Greenville campus over the next several years to drive innovation and the faster development of best-in-class technologies that deliver more value for customers across the globe. At least 80 engineering and manufacturing jobs are being created with the facility’s opening.

GE Power President and CEO Steve Bolze was joined by South Carolina elected leaders for the grand opening of the 125,000-square-foot facility at GE’s Greenville manufacturing campus. The facility broke ground in mid-2014.

“GE is leading the transformation of manufacturing in the power industry, and this facility will ignite the digital industrial revolution for our company and the industry,” said Bolze. “The opening of the AMW is a pivotal moment for us. We’re building a skilled workforce and culture that’s devoted to delivering breakthrough innovations that deliver better, faster outcomes for our customers and unlock new productivity and growth.”

The AMW is GE Power’s first advanced manufacturing facility. The facility will revolutionize the way GE Power designs, creates and improves products by serving as an incubator for the development of advanced manufacturing processes and rapid prototyping of new parts for GE’s energy businesses—Power, Renewable Energy, Oil & Gas and Energy Connections. New techniques and production processes developed at the facility will bring new best-in-class products to global customers quicker than ever.

Advanced manufacturing brings a convergence of the latest technologies together to transform every aspect of the production process to make new, better things, faster. Industrial innovations, from new materials science, 3-D printing (additive manufacturing) and automation to advanced software platforms and robotics are redefining manufacturing for the future.

Advanced manufacturing has a huge and growing significance worldwide. Recent research1 found that nearly 24 million people are already employed in advanced manufacturing industries in the U.S., creating about 19 percent of GDP, and that each job in an advanced manufacturing industry supports another 3.5 jobs through the supply chain.

GE started in Greenville more than 40 years ago with a 340,000-square-foot site. With the latest addition of the AMW, the site has grown close to 1.7 million square feet of factories, offices and laboratories focused on manufacturing advanced products for customers worldwide. GE has more than 3,200 employees in Greenville and has invested more than $500 million in the last five years to bolster critical manufacturing activities housed on the campus. The company has established valuable relationships with local community schools, universities and technical programs to develop new technologies and create a system to support those who are passionate about growing with the industry.

1 The workforce of the future: Advanced manufacturing’s impact on the global economy, April 2016, GE. Authors: John Paul Soltesz, Marni Rutkofsky, Karen Kerr, Marco Annunziata

by Gary Mintchell | Feb 1, 2016 | Automation, Networking, News, Organizations

Time Sensitive Networking (TSN) becomes a critical component of companies’ Internet of Things technology strategy. In the past year, I’ve written about TSN and (mostly) AVnu Alliance, four times.

Engineering Software and Industrial Networking Trends

ODVA Enhances EtherNet/IP Industrial Networking Specifications

OPC Foundation Real-Time And Technology Partners

AVnu Alliance Launches Support for Industrial Ethernet Market

Today brings another AVnu Alliance and Time Sensitive Networking press release. Two new members have joined. And one isn’t really a “joiner” company.

Two New Time Sensitive Networking Members

“Rockwell Automation and Kollmorgen, both leaders in industrial automation, bring valuable expertise to AVnu Alliance activities incorporating new standards such as Time Sensitive Networking (TSN) into a common networking foundation.”

Rockwell Automation isn’t really a “joiner company”. It’s alliances are usually smaller with only a few competitors. This one is interesting.

“We continue to evolve our industrial control and information solutions to help customers drive real-time productivity and innovation as they strive towards building a Connected Enterprise.” said Joe Kann, vice president, Global Business Development, Rockwell Automation. “By participating in the AVnu Alliance, we plan to share our industry knowledge and work together with other members towards further enhancing standard IP-based Ethernet for manufacturing.”

Kollmorgen manufactures high performance motion control solutions.

“Kollmorgen’s business as a provider of innovative high-speed motion solutions is driven by ever-evolving customer needs for high-performance, multi-device fieldbus options,” said Steve Crass, VP North America Industrial Automation and Aerospace & Defense at Kollmorgen. “Joining AVnu Alliance is a logical next step for our business and AVnu provides us with a forum that will support open systems architectures for many years to come.”

According to the Association, “The addition of these companies exemplifies the importance of the continued evolution of standard Ethernet through TSN. The experience with control networking that these companies possess will complement the existing efforts within the AVnu Alliance to define a common foundation for the Industrial Internet. This next step for standard Ethernet will enable complete convergence of standard IT traffic and the control system and will enable IoT for the industrial, automation and manufacturing sectors.”

“Rockwell Automation and Kollmorgen have both shown leadership in their respective fields over the years. The AVnu Alliance looks forward to their contributions and forward-thinking philosophies when it comes to automation and how it can improve a variety of industrial processes,” said Gary Stuebing, AVnu Alliance President. “They both bring a range of products and technologies that will complement and bolster our efforts with TSN in the industrial space.”

by Gary Mintchell | Jan 13, 2016 | Automation, Events, News, Operations Management

We are closing in on February and time to start thinking about the ARC Industry Forum in Orlando. I went to my first one in 1998 and have my airline and hotel reservations for this edition.

We are closing in on February and time to start thinking about the ARC Industry Forum in Orlando. I went to my first one in 1998 and have my airline and hotel reservations for this edition.

Given the demise of general industry trade shows, there are precious few opportunities to see a large cross section of the automation and control industry. This is one.

I have 2 or 3 appointments set. If you are there, ping me. Maybe we can do a “meet up” in the lounge before everyone splits for dinner or something. Or stop me to chat during the week. ARC has once again planned an afternoon of press conferences for its sponsors. I’ll arrive in time to listen if you are presenting.

The 20th Annual ARC Industry Forum has the theme, “Industry in Transition: Navigating the New Age of Innovation”.

The conference is February 8-11, 2016 at the Renaissance Sea World in Orlando, Florida.

ARC says, “New information technologies such as Industrial Internet of Things (IIoT), Smart Manufacturing, Industrie 4.0, Digitization, and Connected Enterprise are ushering in a new age of innovation. These concepts are clearly moving past the hype, where real solutions are emerging backed by strong business cases. Expect to see innovations in smarter products, new service and operating models, new production techniques, and new approaches to design and sourcing. Join us to learn how this industrial transformation will unfold and what other companies are doing today to embrace innovation and improve their business performance.”

Questions they expect to address:

- How will inexpensive, easy-to-install sensors change existing products and plants?

- Will cyber security concerns impede disruptive innovation?

- What kind of intelligence will machines have and what value will this bring?

- What role will Wi-Fi and LTE play?

- How do Big Data and predictive and prescriptive analytics enable operational change?

- What is the opportunity in aftermarket services?

- What software capabilities are needed to achieve transformational change?

- Which industries are already changing?

- What steps can organizations take to foster innovative thinking?

Forum’s Keynote Presentations

Michael Carroll, Vice President, Innovation & Operations Excellence, Georgia-Pacific

Michael joined Georgia-Pacific in 2010 to focus his technological and entrepreneurial talents on innovation and leadership. Prior to that he and a partner formed McTech Group, a company focused on innovative products for the building products and construction industry. In addition to his Executive Vice President responsibilities, Michael formed a Joint Venture designed to sell consumer “DIY” products to big box retailers like Wal-Mart, Home Depot, and Lowe’s. Previous positions include Director of Operations at Riverwood International, CEO of North and South American Operations at Shepherd, and Principal Change Agent at Mead Paper.

Sandy Vasser, Facilities I&E Manager, ExxonMobil Development

Sandy has been with Exxon or ExxonMobil for over 35 years and has been involved in a number of Upstream projects covering offshore facilities, onshore facilities, and cogeneration facilities. He currently manages a team of about 120 electrical and I&C professionals responsible for the design, installation, and commissioning of electrical generation and distribution systems, process control systems, and safety instrumented systems for all major ExxonMobil Upstream capital projects. This team is also responsible for developing, promoting and implementing strategies, practices, processes, and tools for successfully executing project automation and electrical activities.

Rob High, Vice President and Chief Technology Officer, Watson Solutions, IBM Software Group

Rob has overall responsibility to drive Watson Solutions technical strategy and thought leadership. He works collaboratively with the Watson engineering, research, and development teams across IBM. Prior to joining Watson Solutions, Rob was Chief Architect for the SOA Foundation and member of the IBM Academy of Technology. He championed an open industry architectural definition of the principles of business and IT alignment enabled by SOA and business process optimization, as well as ensuring IBM’s software and services portfolio is architecturally grounded to enable for efficient SOA-based solutions. Rob has 37 years of programming experience and has worked with distributed, object-oriented, component-based transaction monitors for the last 26 years.

by Gary Mintchell | Jan 11, 2016 | Asset Performance Management, Automation, Internet of Things, Operations Management, Technology

Remote monitoring and diagnostics is a key driver for the Internet of Things strategy adoption in manufacturing and production. Advances in both the technology and services involved in this area appears to be the area of best economic return these days.

Remote monitoring and diagnostics is a key driver for the Internet of Things strategy adoption in manufacturing and production. Advances in both the technology and services involved in this area appears to be the area of best economic return these days.

Rockwell Automation recently released news about its take on a diagnostic reliability service. Rockwell doesn’t tie it to the Internet of Things, much to its credit. But this solution fits within the broad trend I’ve seen developing.

The solution deploys a layer of technology across plant devices and equipment to monitor and perform analysis, and create a continuous improvement approach to reliability maintenance, reducing operational risk. As part of the service, a Rockwell Automation domain service expert also closely tracks equipment performance to advise on reliability improvements to the production facility.

“Our customers have access to a huge amount of data within their assets, but they often struggle to turn data into useful operational intelligence,” said Ryan Williams, product manager, Rockwell Automation. “In the past, companies relied on maintenance personnel on-site to check the status of equipment in the field and then develop corrective action plans. Now, with the diagnostic reliability service, they can transform maintenance data into asset intelligence. This helps build a more Connected Enterprise, leveraging interconnected data systems and producing actionable information. Companies can better prioritize choices on maintenance and production, and do more with less.”

The solution automatically collects identity and health data from all networked devices on the production control network. The data is then modeled with asset management information to trigger events and send alerts to necessary personnel for proactive maintenance. With the service, Rockwell Automation asset reliability professionals assist users in applying the intelligence on their critical equipment to inform data-driven maintenance decisions and increase productivity.

Case in diagnostics

Case in point: A major oil and gas company used the diagnostic reliability solution to help centralize information gathering and monitor hundreds of critical control assets across a California rural valley. The company also needed inventory of all the field devices in its process control network for a companywide cybersecurity policy. The automated identification and monitoring solution helped the company’s California business unit comply with the new corporate policy, reduce costs associated with field service manpower through proactive maintenance, and increase its daily oil production.

Through integrated, automated device identification and tracking, other customers using the diagnostic reliability service can realize approximately 70 percent reduction in manual data-collection time.

The diagnostic reliability offering is applicable to all manufacturers, with an industry emphasis including oil and gas, mining metals and cement, auto tire and rubber, and consumer packaged goods.

by Gary Mintchell | Nov 23, 2015 | Automation, Manufacturing IT, News, Operations Management

I spent more time and took far more notes at the Operational Intelligence stand on my tour of Rockwell Automation’s annual fete, Automation Fair, than any other–even Integrated Architecture which I reported last week.

One reason was a press release that I received regarding a “co-invention” between Rockwell Automation and Microsoft on a mobility solution. This will become a great enabler of the Connected Enterprise according to the release. Unfortunately, when I studied the release, I couldn’t figure out what “it” was. Probably too many companies and too many marketing managers trying to get their two cents in resulting in too many nice-sounding but vague words 😉

Thanks to Ryan Cahalane, director of software product management, and others, I came away with enough of an understanding to see how potentially valuable this project could be.

Mobility

Let’s start with mobile devices. Workers at all levels are bringing them to work whether IT is ready or not. When you own one, you want to use it. So, why not leverage commercial technologies developed by Microsoft (its Project Thali) with industrial application and robustness from Rockwell (Project Stanton).

Let’s start with mobile devices. Workers at all levels are bringing them to work whether IT is ready or not. When you own one, you want to use it. So, why not leverage commercial technologies developed by Microsoft (its Project Thali) with industrial application and robustness from Rockwell (Project Stanton).

Rockwell is making extensive use of HTML 5. But this toolkit in development includes a technology called JXcore from Nubisa. JXcore is a Node distribution. It is designed for developing applications for mobile and embedded devices using JavaScript and leveraging the Node ecosystem. Use the same codebase for server and mobile applications.

The toolkit enables Rockwell Automation offerings with a consistent web-based user interface for a specific device; tablet, smartphone or desktop and now includes a prototype app, dubbed Project Stanton (@Project_Stanton).

Operational Intelligence From Logix

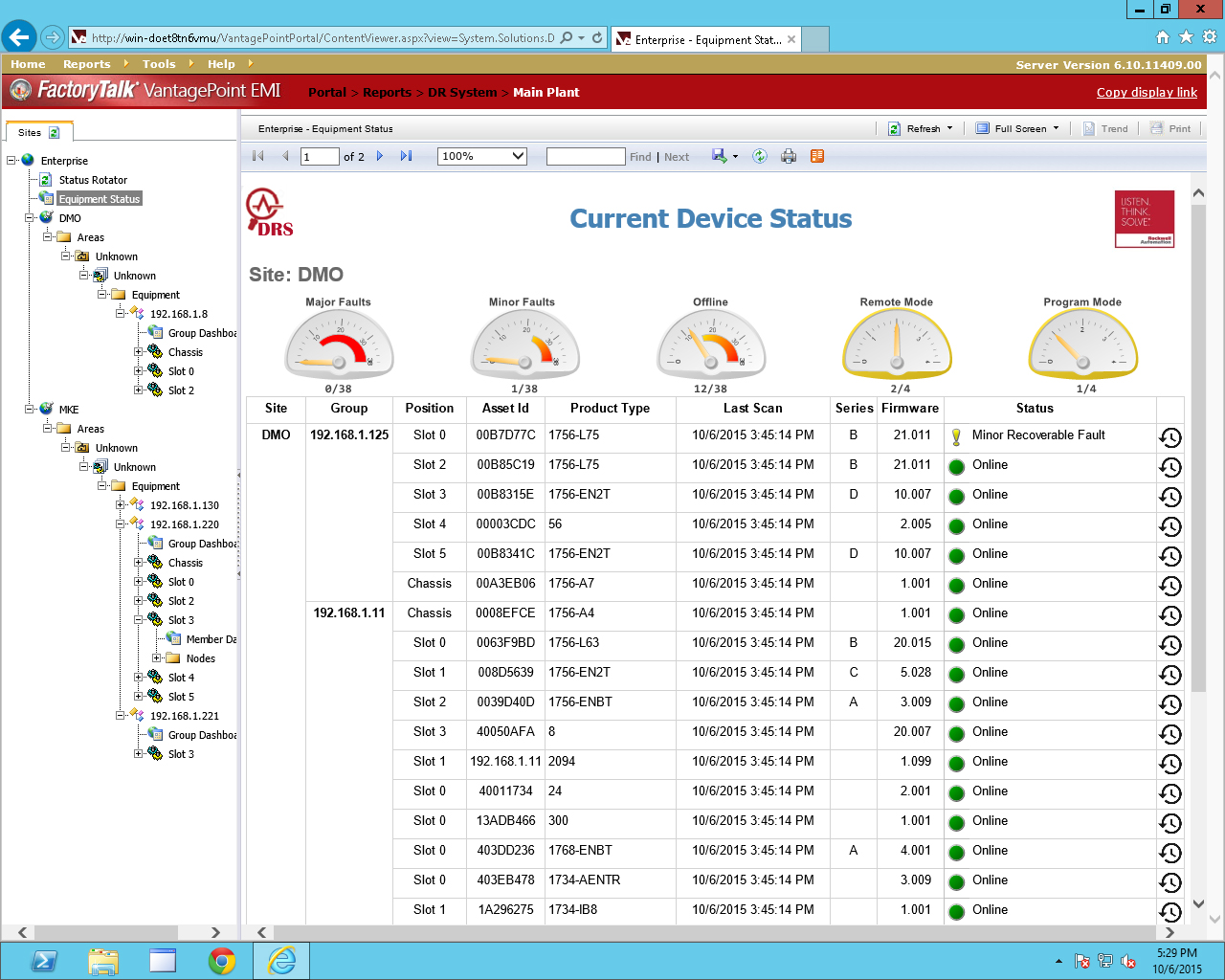

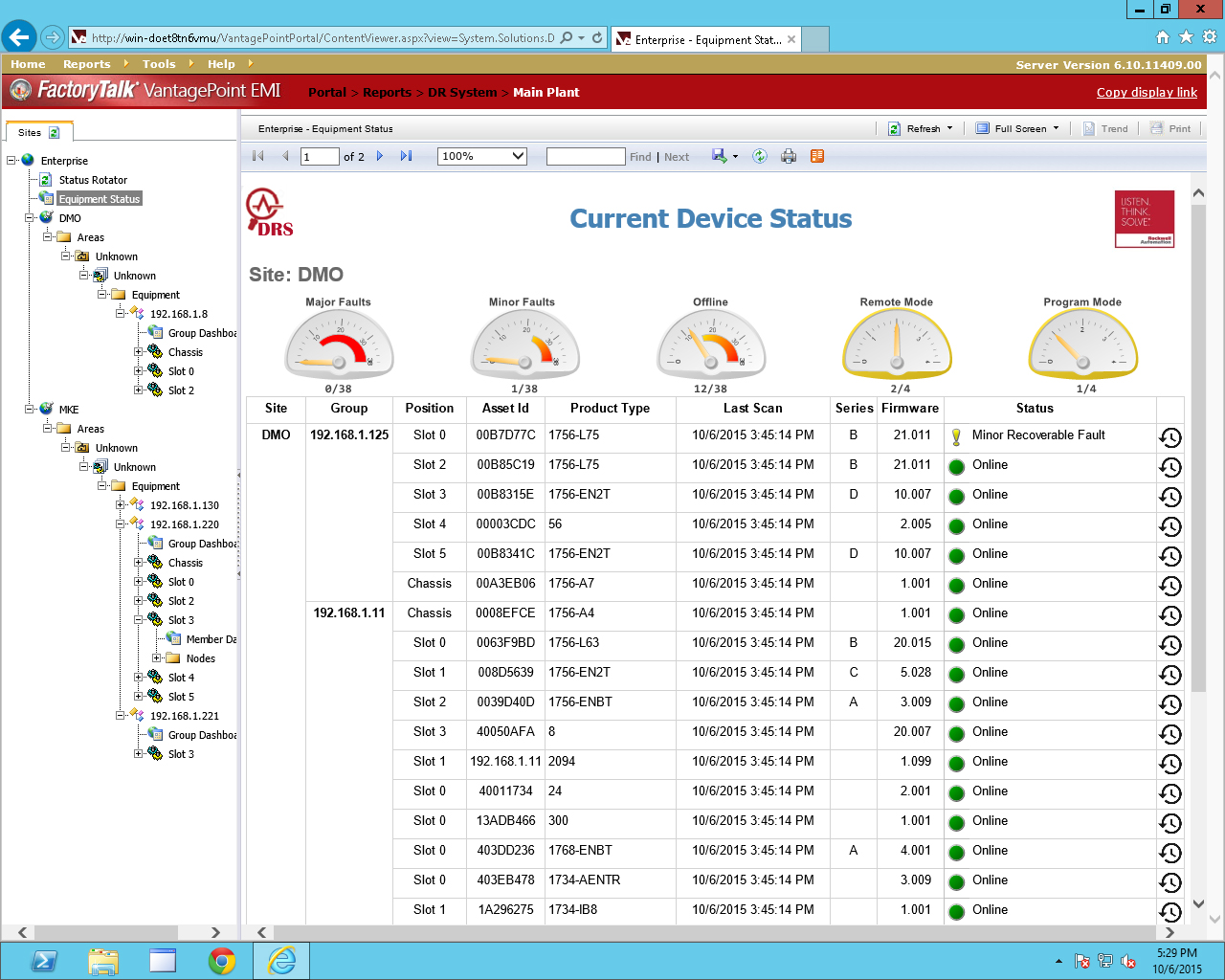

The second technology I wish to discuss is the latest release of FactoryTalk VantagePoint 7.0. Rockwell Automation says, “For manufacturers, making swift use of big data just got easier. The addition of import and configure mobile-based work flows in the FactoryTalk VantagePoint enterprise manufacturing intelligence (EMI) v7.0 software enables the one-time configuration of a manufacturing intelligence solution.”

The second technology I wish to discuss is the latest release of FactoryTalk VantagePoint 7.0. Rockwell Automation says, “For manufacturers, making swift use of big data just got easier. The addition of import and configure mobile-based work flows in the FactoryTalk VantagePoint enterprise manufacturing intelligence (EMI) v7.0 software enables the one-time configuration of a manufacturing intelligence solution.”

This software provides users a seamless way to access their Logix-based data by providing a simple, guided work flow to store and visualize information. Everything from installation, configuration and visualization has been enhanced and consolidated – so users can interact with their Logix-based control data from their device of choice: PC, tablet or smartphone. To promote intelligent decision-making, the new work flows enable authorized users to store and visualize specific data views and trends, and easily share these views with collaborators across the enterprise.

“The FactoryTalk VantagePoint experience now provides access to manufacturing information faster than ever,” said Angela Rapko, product manager, EMI Software Portfolio, Rockwell Automation. “For users, this more cohesive and intuitive experience is a significant step forward. The less time operators spend configuring systems, the more they can focus on how their plants are actually functioning. We have truly reduced the time to trend data with this release.”

Additionally, FactoryTalk VantagePoint software will now silently install with FactoryTalk Historian SE software from Rockwell Automation. Upon completion, the user will be greeted with a VantagePoint mobile Web page, including the new import and configure options.

From any PC or tablet, a user can browse through the FactoryTalk Directory server to an online controller; select the tags from which they aim to collect associated data; and configure scan rates and additional historian parameters. Once this process is complete, the selected tags are stored in the FactoryTalk Historian solution and automatically configured for the FactoryTalk VantagePoint software. By simultaneously configuring tags, a user within the VantagePoint mobile work flow makes a few simple selections in order to begin collecting data, and creating dashboards and trends.

Also new, FactoryTalk VantagePoint v7.0 software offers SQL Server Express with install. This removes complex licensing options from the install process.

We are closing in on February and time to start thinking about the

We are closing in on February and time to start thinking about the

Remote monitoring and diagnostics is a key driver for the Internet of Things strategy adoption in manufacturing and production. Advances in both the technology and services involved in this area appears to be the area of best economic return these days.

Remote monitoring and diagnostics is a key driver for the Internet of Things strategy adoption in manufacturing and production. Advances in both the technology and services involved in this area appears to be the area of best economic return these days.