by Gary Mintchell | Aug 7, 2014 | Automation, Data Management, Internet of Things, News, Operations Management, Technology, Wireless

A large gathering, hinted at around 6,000, crowded the ballrooms to hear the first two days of keynotes. This is always an eclectic gathering of engineers and scientists and academics from a variety of industries, specialties, and interests. Contrary to the emphasis of many trade journal pieces you read about age and gender of engineers, there was an amazing number of females in attendance. They were engineers and scientists, not PR and admins. The age range of attendees was gratifying. And the geographical diversity was apparent–although they were all introduced to Texas food.

The keystone of the first day’s general session is always Dr. T’s talk (James Truchard, president, CEO and co-founder). He didn’t sound as evangelical about virtual instruments and the like this year, but he introduced an interesting idea about timing (in programming). Later I heard a talk on cellular data communications where the speaker noted that the issue was becoming less bandwidth and more about 1 msec response. Timing issue. Interesting.

NI Week (this is my 17th) is always a great conference filled with much energy, passionate (for engineers) hallway conversations about technologies and applications and sessions full of curious attendees. And, Texas BBQ.

IoT, Cyber-physical Systems, Bid Analog Data

The foundation idea of The Manufacturing Connection is the idea of a connected manufacturing enterprise. Note the latest posts about the Internet of Things and its application to manufacturing. So imagine my delight about the conference theme of (Industrial) Internet of Things, Cyber-Physical Systems and Big (Analog) Data.

I have been trying to get my mind around integrating the ideas from Industry 4.0 in Germany, the US Smart Manufacturing Coalition, and now what NI is talking about–especially relating to cyber-physical systems.

Unlike what I’m hearing from Germany, NI’s emphasis this year on cyber-physical systems involved the relationship of physical devices, computation and communication. Wireless as the foundation communication platform was evident everywhere. (I noted that the ballroom where the keynotes were held was ringed by WiFi access points. Thank you very much, NI.) Most of the talk was cellular, especially what will define 5G systems. One major NI interest is improving speed and lowering cost of test for the semiconductor manufacturers in the wireless space.

NI’s emphasis on Big Data, which it calls Big Analog Data, is in the process. Although the process can be geographically dispersed, such as an application by CIH (Case International Harvester to us old farming people) who instrument Case combines (the machines that harvest corn and wheat and soy beans), send the data to the cloud and then analyze that data to help farmers and their own product development.

Another interesting application story was that of Airbus where engineers are researching some far out ways to integrate technology and humans in the building of aircraft. Hopefully I can get a deeper dive on that. They are using video feedback from instrumented tools and looking at virtual reality tools for better control of robots that extend the work of humans into areas difficult for human reach.

My prejudice coming in about Big Data relate to integrating into the MES/MOM Layer 3 and the enterprise layer. Not much talk of that–yet–at NI Week. But I bet in the future we start to see more of this.

I am not going to list all the new products. LabView has been upgraded, there is a CompactRIO with an Intel Atom processor, reconfigurable oscilloscope, faster data acquisition (naturally). You can read the press releases online here.

by Gary Mintchell | Feb 25, 2014 | Automation, Technology

ODVA (originally the Open DeviceNet Vendors Association for historical context) has decidedly discrete manufacturing roots. As it migrated from an emphasis on DeviceNet to Ethernet (and its brand EtherNet/IP), it has also struggled mightily to develop protocols that exploit only commercial off-the-shelf Ethernet chips. It was able to conquer the challenges of Ethernet for real-time and deterministic communication (for example for motion control) without the need to bypass the TCP/UDP part of the stack only recently (CIP Sync and CIP Motion).

Now, as its most stalwart member, Rockwell Automation, has moved strongly into process automation, and as Endress + Hauser has joined, ODVA finds itself needing to work on a protocol for EtherNet/IP for process automation. E+H has already announced implementations of EtherNet/IP for some of its instrumentation.

Within that context, ODVA has announced the availability of a new white paper, Optimization of Process Integration, which outlines a strategic vision for manufacturers wishing to implement an Ethernet solution or, in the words of the marketers of ODVA, “looking to maintain cost-effective, sustainable production capacity in the process industries.” The white paper is designed to help business and technical leaders in these industries define their future network architecture and plan for the efficient integration of their plant’s network infrastructure into existing business applications.

In other words, the white paper is a document around which formation of an industry working group (SIG) can begin to develop the protocols.

From the press release, “ODVA envisions an approach to the optimization of process integration that is convergent, compatible, scalable and open for users and their suppliers. The approach will simplify the exchange of configuration, diagnostic and production data between field devices and higher-level systems, such as supervisory control and data acquisition systems.”

“The approach also will enable plant asset management (PAM) and secure remote access of field installations. This, together with the proven benefits and cost advantages of commercially available, off-the-shelf Ethernet and Internet technologies, will help businesses improve productivity and competitiveness.”

Katherine Voss, president and executive director, ODVA, says that industry will see a continued expansion of Ethernet and IP technologies in automation systems used in process industries. “The Optimization of Process Integration leverages the prevailing trend of convergence in information and communication technologies used in industry and in business applications. As EtherNet/IP is proven in hybrid and discrete industries, it is an ideal technology to provide process industries with a unified communication solution from the field to the enterprise.”

In this white paper, ODVA describes the opportunity for the optimization of process integration (OPI) and an overview of its vision for a comprehensive approach including:

- OPI in the industrial ecosystem;

- ODVA’s vision of OPI in the production domain;

- Industrial use cases for OPI;

- ODVA’s technical approach to OPI; and

- OPI in practice.

Looking at the list of members of ODVA with a process industry emphasis, the only other company that I noticed was Schneider Electric (an ODVA member partly as the godfather of Modbus TCP, which fits nicely). But Schneider Electric had only a small process industry focus until last month. I wonder what the acquisition of Invensys (Foxboro, Triconex) might mean. Something to watch, I suppose.

by Gary Mintchell | Nov 25, 2013 | Automation, Operations Management, Software, Technology

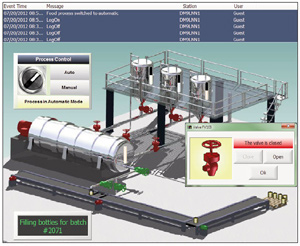

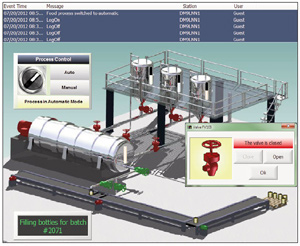

Some people have been telling me that HMI/SCADA software (human-machine interface/supervisory control and data acquisition) has become a commodity item. There is still room for innovation in the category. I traveled to Atlanta last week and came away with this information about AutomationDirect’s new HMI/SCADA platform.

Some people have been telling me that HMI/SCADA software (human-machine interface/supervisory control and data acquisition) has become a commodity item. There is still room for innovation in the category. I traveled to Atlanta last week and came away with this information about AutomationDirect’s new HMI/SCADA platform.

Point of View is software for developing SCADA, HMI, and OEE/Dashboard projects that can be deployed anywhere. Designed for most Microsoft Windows-supported platforms, including Windows XP, 7, 8 and Server editions, Point of View projects can either run locally on a development workstation or be downloaded to a remote workstation to operate using Point of View runtime software.

Developers create a Point of View project using its development tools. A project tag database manages all runtime data, including both internal variables and scanned I/O. Configurable drivers communicate in real time with programmable logic controllers, remote I/O devices, and other data acquisition equipment. Animated HMI screens and OEE dashboards give plant personnel a graphical view of the process. Integrated modules include alarms, events, trends, recipes, reports, scriptable logic, schedulers, a security system, and a complete database interface.

Point of View software supports three types of remote application viewers: a dedicated viewer for plant-floor operations, where navigation must be restricted to specific HMI/SCADA applications; a Microsoft Internet Explorer-based browser that enables full access to any authorized IP address or applications and a Studio Mobile Access viewer that works with any browser. Up to 48 simultaneous viewing clients of each type are supported.

The Point of View SCADA/HMI software contains 19 communications drivers for connection to the most popular industrial controllers, including many models from AutomationDirect, as well as Allen Bradley, Omron, Siemens, GE and Mitsubishi. Also included is a driver for Modbus communication.

The three packages include: Development (starting at $225), Runtime (starting at $345), and a Complete (Development and Runtime) package (starting at $495). Each package is available in 500, 1000, and 5,000 tag count versions. All packages require a USB hardware key priced at $65. Each package includes one thin client, one secure viewer thin client, and one mobile client license; additional licenses are also available.

by Gary Mintchell | Aug 5, 2013 | Automation, Events, News, Technology

I just finished listening to the last of an 8-part series of NI Week Promotional Podcasts. Each of the eight featured 2-3 different technology forums or technology symposia plus descriptions of what attendees will see on the exhibit hall floor.

I just finished listening to the last of an 8-part series of NI Week Promotional Podcasts. Each of the eight featured 2-3 different technology forums or technology symposia plus descriptions of what attendees will see on the exhibit hall floor.

A few of the featured speakers talked about their presentations. Lots of cool technology will be presented. Some of the “extras” surrounding the conference were promoted. Figuring National Instruments brings close to 3,000 people to its fair city, it is proud of its environs–and the many interesting activities and variety of food you will find in Austin, Texas.

One of the features today was fitness/wellness. I began attending NI Week in 1998 and ever since enjoy my early morning runs along the banks of Lady Bird Lake (I think I’m right, used to be Town Lake, right?). If you are out there between 5:30 and 6:30 in the morning–a) you can wave to me as I run the path, and b) you can see some of the famous Austin bats returning home after a night of gorging themselves on the plentiful mosquitoes and other insects.

This has always been a fantastic technical conference with many cool technical people and outstanding keynotes. I look forward to my 16th.

If you see me there, stop me and say hi.