by Gary Mintchell | Oct 6, 2017 | Automation, Workforce

Part of the media / analyst program at Emerson Global User Exchange 2017 was a tour of a manufacturing facility and state-of-the-art (or beyond) training center. The Shakopee, MN facility includes final assembly of pressure sensors, product design (which we didn’t see), and an Interactive Plant Environment training center. The latter itself is a $10 million investment. This is one of two (Charlotte, NC being the other) while a third is planned in Houston.

The Interactive Plant Environment training center includes a classroom and a production facility. The facility includes tanks and pipes, valves, sensors and instrumentation, water and air. No steam or corrosive chemicals, of course. It helps customers and students simulate real life process conditions through hands-on learning in a safe environment. The IPE boasts a breadth of Emerson products where students can increase skills and knowledge through real-life scenario-based labs. Students are taught an aspect of instrumentation and then given a work order. They don hardhat, safety glasses, steel-toed shoes and enter the “plant” to perform the work—whether it be trouble shooting or calibration or whatever.

Students have the opportunity to better understand best practices and troubleshooting techniques from the mentorship of certified Emerson instructors. It is as if they are immersed in a typical plant environment (minus smells and mud) where they can replicate the most common, as well as unexpected, operational scenarios.

This is a great example of forward thinking in the training field. It is also impressive that Emerson continues to make these investments. Emerson alone among its competitors at this time is showing momentum and growth.

The first thing we saw past the lobby was a Collaboration Center. Looking like a high-tech conference room, this Center enables customers to learn to manage remote operations and interact with experts located anywhere in the world. There is one display for video conferencing. Another digital wall includes capability to display a variety of information that people in the room can interact with. The displays may include weather maps with maps of facilities. Or perhaps a “heat map” of wireless installations. This should be a great productivity booster.

Production facility is an excellent example of Lean Manufacturing. We saw an excellent Kanban system as well as many other examples of the visual factory, 5S, and more. I just love seeing the spreading adoption of lean. It’s great for workers, as well as, great for the bottom line.

by Gary Mintchell | Jan 7, 2016 | Automation, Technology

Raspberry PI is an intriguing small, inexpensive computing platform. I’ve seen a number of really cool projects on various tech blogs and video podcasts. I figure there must be a number of engineers figuring out how to implement these devices to reduce cost and complexity.

Raspberry PI is an intriguing small, inexpensive computing platform. I’ve seen a number of really cool projects on various tech blogs and video podcasts. I figure there must be a number of engineers figuring out how to implement these devices to reduce cost and complexity.

Use of Linux in industrial automation has never reached any sort of critical mass. I started following it somewhere around 1999 and even started to write about Linux in automation for a Linux magazine about that time. But Microsoft Windows won (remember the 1999 ARC Forum in Orlando when the Sun guys promoting Java as an OS packed up and headed out?), and Linux has been sort of peripheral.

I keep expecting something to happen. We have moved to the cloud in a big way for many applications including HMI/SCADA. Maybe we’ll see more in the near future.

HMI for IoT and Raspberry PI and Linux

Betting on that is Tatsoft. It has released its FactoryStudio Industrial IoT (IIoT) HMI for Raspberry PI and Linux.

FactoryStudio delivers real-time information with a set of fully-integrated modules in a unified and intuitive engineering user interface. With FactoryStudio, projects can scale from local embedded devices and mobile applications up to very large, distributed, high performance fault-tolerant systems. It provides an Application Development Platform to allow easy creation of solutions for the device level itself, with Graphical real-time displays, communication protocols to PLC’s, data logging, alarm engine, local SQL storage and C#/VB.NET scripting. Those embedded applications can easily communicate with remote FactoryStudio applications on the cloud, or on premises, accessing and consolidating distributed information.

The FactoryStudio platform can also work as the presentation layer and data gateway to historian systems, such as OSIsoft PI, Prediktor APIS, and ERP systems such as SAP, or directly connect with the SQL enterprise databases.

“The development tools are the same whether you are deploying projects to Microsoft Windows computers running .NET Framework, Linux operating system with the Mono Framework and Raspberry PI devices. For Raspberry PI, we also included easy access to onboard I/O in addition to all other HMI features.” explains Marcos (Marc) Taccolini, Tatsoft LLC CTO.

This release complements the FactoryStudio multi-platform solutions that already have runtimes for Windows Compact Framework and iOS devices. According Dave Hellyer, Sr VP Marketing, “Tatsoft believes that we can use the intersection of people, data and intelligent machines to have a far-reaching impact on the productivity, efficiency and operations of industries around the world.”

by Gary Mintchell | Jul 8, 2015 | Automation, Data Management, Events, Internet of Things, News, Operations Management, Process Control, Security

Here is the official wrap of the recent Honeywell Users Group (HUG) Americas symposium. It was the 40th anniversary celebrated with the theme “40 Years of Innovation.” Officially “more than 1,200 people” attended the event.

Here is the official wrap of the recent Honeywell Users Group (HUG) Americas symposium. It was the 40th anniversary celebrated with the theme “40 Years of Innovation.” Officially “more than 1,200 people” attended the event.

I have written a couple of times during the week here and here. This information comes from a press release issued last week. Along with some executive quotes is a note that Honeywell Process Solutions has been developing and implementing technologies for the Industrial Internet of Things (IoT) for many years.

During the event, Honeywell announced a collaboration with Intel Security McAfee which will expand its industrial cyber security capabilities to help defend customers from the increasing threat of cyber attacks.

“The process manufacturing industries are facing a critical time in history due to a convergence of factors such as security threats, a shrinking workforce and lower oil prices, among others,” said Vimal Kapur, president of Honeywell Process Solutions (HPS). “These factors are driving a greater need for our technologies and services because they’re designed to help companies conduct operations more efficiently, and with less risk.”

The conference revolved around three core technology themes directly impacting companies’ abilities to successfully adapt to changing market conditions: digital transformation and smart operations, system evolution and risk reduction, and smart instrumentation with smart integration. Throughout the week, Honeywell executives, technology experts and customers explained how these core areas can turn technology buzzwords like Big Data and Industrial Internet of Things (IoT) into practical applications.

“HPS has been leveraging the concepts and technologies behind the Industrial IoT as part of the vision that we have been evolving towards for several years,” Bruce Calder, HPS chief technology officer told general session attendees. “In order to run a reliable operation that continues to improve performance and business results, you will need to install smarter field devices, achieve more connectivity, collect more data and find ways to use that data to run a smarter operation.”

Calder also gave attendees a first look at HPS’ first native app for mobile devices and tablets that connects to different sources and applications across the company’s portfolio to create a more-intuitive mobile experience for plant workers. Mobility is part of the initiative to introduce a suite of apps that, along with new cloud functionalities, will enhance existing solutions to deliver better business efficiencies.

The conference agenda included a wide range of presentations from Honeywell customers ExxonMobil, Chevron, Reliance, DuPont, Great River Energy, Syngenta, Genentech, Valero and others. These presentations – covering everything from wireless applications and cost-effective control system migrations, to alarm management and energy conservation – highlighted how real-world manufacturers have used Honeywell technology to streamline their businesses by generating and analyzing the most-meaningful data from their operations.

In addition to these presentations, attendees received a first-hand look at some of Honeywell’s newest technologies designed to change the way their enterprises work, generate the right data to inform decisions, and reduce overall risks. Highlighted technologies included:

- UniSim Competency Suite – the newest addition to the UniSim family of training technology, which now includes 3D virtual environment capabilities to provide realistic experiences.

- DynAMo Alarm and Operations Suite – software that leverages more than 20 years of alarm management experience in the process industries to help users reduce overall alarm count by as much as 80 percent, identify maintenance issues and increase visibility of critical alarms that require urgent attention.

- Honeywell Industrial Cyber Security Risk Manager – the first digital dashboard designed to proactively monitor, measure and manage cyber security risk for process control systems.

- SmartLine Level Transmitter – the newest addition to Honeywell’s line of modular, smart field instrumentation designed to integrate with control systems to provide benefits such as extended diagnostics, maintenance status displays, transmitter messaging and more.

- The EC 350 PTZ Gas Volume Corrector – the first member of a new line of high-performance electronic volume correctors (EVCs) that more accurately measure natural gas delivered to industrial customers, helping them meet government and industrial standards.

by Gary Mintchell | Dec 5, 2014 | Automation, Networking

I’m not a Modbus scanner expert, but this new industrial networks product came to me from a friend I trust. Looks interesting.

I’m not a Modbus scanner expert, but this new industrial networks product came to me from a friend I trust. Looks interesting.

Precision Digital Corp., global supplier of digital panel meters and control instrumentation celebrating its 40th year in business, announced the Vantageview PD6730X Modbus Scanner. The PD6730X is a rugged, NEMA 4X/IP65 Modbus master, slave, or snooper (sniffer). The multi-purpose PD6730X is designed for accurate display of and quick access to information, locally or remotely, in wet or dirty environments.

It can accept up to 16 individually programmed process variables (PVs) from multiple devices; four math channels allow for calculations on multiple PVs. The SafeTouch through-window buttons allow operation without removing the cover. The pulse input accepts a wide range of flow transmitter signals, including mV input from a magnetic flowmeter, as well as high frequency signals. The PD6730X includes backlighting, two open collector outputs, and an analog output as standard.

“The versatile Vantageview PD6730X is loaded with features that plant operators can appreciate,” said Jeffrey Peters, President, Precision Digital. “It is simple to program using our free ScanView EX software, displays critical information about the process, and can be seen from wide angles and a distance. The PD6730X is designed for readability and ease of use, from large character and Feet & Inches displays to automatic rate conversions and data logging. Plus, it integrates easily into existing Modbus networks.”

The PD6730X Decimal Display models feature an upper display that is 0.7 inches high and shows five digits of information; the Feet & Inches models feature a level display that reads up to 399 feet, 11 and 15/16 inches and contains a 20-segment tank level indicator. The lower display for both models is 0.4 inches high, with seven alphanumeric characters, for Process Variables, Custom Units, or Tags. The bright LCD display is easily read under varying lighting conditions and from viewing angles of up to +/- 40 degrees (twice that of competitive models); it can also be rotated in 90-fdegree increments for increased readability.

Four sensors in the PD6730X operate as through-window buttons for programming and operation without removing the cover in wet or dirty areas.

These SafeTouch buttons include an energy saving mode to save power, extend battery life, and prevent unintended triggers.

The PD6730X provides flexible power options, including battery, DC with battery backup, DC only, output-loop, or output loop with battery backup. Its element-resistant enclosure provides three threaded conduit holes and integrated pipe or wall mounting holes. Operating temperatures range from -40 to 75 degrees C.

by Gary Mintchell | Dec 5, 2014 | Automation, Data Management, News, Operations Management, Operator Interface, Software, Technology

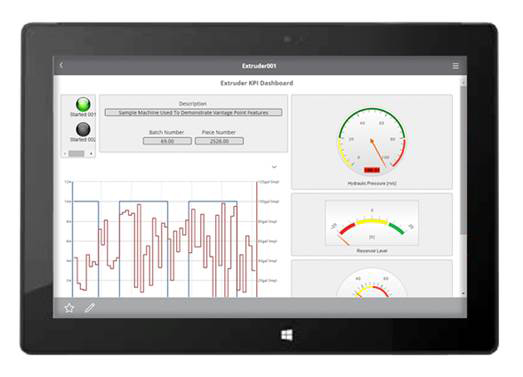

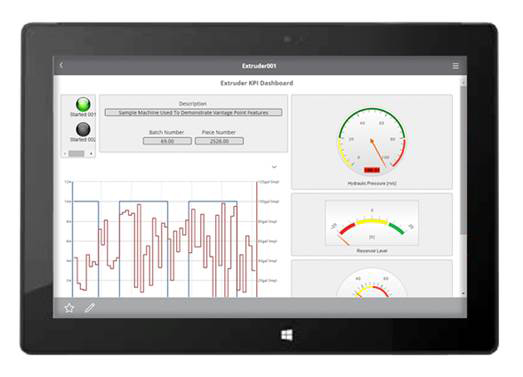

The consumer boom with mobile devices has not been ignored by production automation companies. Rockwell Automation showed FactoryTalk VantagePoint EMI v 6.0 enabling any digital device to access performance metrics and production data analytics from plant floors and machines.

The consumer boom with mobile devices has not been ignored by production automation companies. Rockwell Automation showed FactoryTalk VantagePoint EMI v 6.0 enabling any digital device to access performance metrics and production data analytics from plant floors and machines.

The VantagePoint v6.0 software now includes VantagePoint mobile, a component that enables users to create displays and interact with data across any HTML5-compliant browser and mobile platforms, such as iOS and Android. Users can now easily log in to the VantagePoint system and automatically view Web-based KPI content that is responsive to the device they are using – from smartphones to tablets to PCs. No user-specific configurations created by network administrators or IT staff are required, enabling manufacturers to quickly on-board more users and deliver value to increase productivity.

“The VantagePoint mobile component instantly detects the type of device being used to access information and adjusts the user experience for that screen,” said Angela Rapko, product manager for FactoryTalk VantagePoint software, Rockwell Automation. “This out-of-the-box solution will enable more users to access valuable operational insight while lowering the cost of delivering that data.”

Another new key capability is the “composer” feature, which allows VantagePoint v6.0 users to browse through data and easily customize content based on individual roles, priorities and viewing preferences. Using the software’s drag-and-drop interactive tools, users can create personalized displays to quickly find the information that is most important to them. The “favorites” capability also allows users to configure KPI data in the visual formats they prefer, from bar graphs to gauges to plant maps. They can then save the data or share it with a group using the VantagePoint mobile component.

“Customers have expressed a big need to drive usage of data across their organization for frictionless productivity,” said Kyle Reissner, mobility platform leader, Rockwell Automation. “With portability in mind, we wanted users to be able to move between devices seamlessly, allowing them to be more responsive and reducing time to solution. The VantagePoint mobile component is now at the core of the FactoryTalk VantagePoint software to deliver this ease of use.”

For OEMs, this streamlined connectivity provides the framework for delivering an information-enabled machine. Plus, they gain the ability to visualize data without the need for custom development.

For system administrators and integrators, improved diagnostics built into the VantagePoint v6.0 software on the server side – as well as more application-centric data sources – allow them to view and display the overall health of the system and specific applications. The VantagePoint v6.0 software also includes improved tag-provider templates to allow anyone initially building the model and applications – whether a system administrator or a customer – to accelerate design and deployment time.

All users will benefit from the flexibility of receiving and applying the VantagePoint software updates without having to uninstall, re-install and, in some cases, re-validate their current application.

“With the VantagePoint mobile framework, we intend to release software updates more frequently, including new display widgets and capabilities,” Reissner said. “We’re focused on eliminating friction, realizing productivity value, and ensuring users are able to do more with fewer barriers.”

Raspberry PI is an intriguing small, inexpensive computing platform. I’ve seen a number of really cool projects on various tech blogs and video podcasts. I figure there must be a number of engineers figuring out how to implement these devices to reduce cost and complexity.

Raspberry PI is an intriguing small, inexpensive computing platform. I’ve seen a number of really cool projects on various tech blogs and video podcasts. I figure there must be a number of engineers figuring out how to implement these devices to reduce cost and complexity.