by Gary Mintchell | Apr 12, 2016 | Automation, News, Organizations, Technology

Quite a deluge of press releases coming from the OPC Foundation preparing for the upcoming Hannover Messe. Microsoft was an original OPC supporter, and here a new representative from the company has joined the Board. Key to the announcement is OPC UA communication into the Microsoft Azure cloud.

from the OPC Foundation preparing for the upcoming Hannover Messe. Microsoft was an original OPC supporter, and here a new representative from the company has joined the Board. Key to the announcement is OPC UA communication into the Microsoft Azure cloud.

The OPC Foundation has elected Microsoft to the Board of Directors of the OPC Foundation, which represents many of the world’s most prominent global suppliers. The new board seat, which will be held by Microsoft Director of IoT Business Development Matt Vasey, is an extension of Microsoft’s support for OPC Foundation since the company first became a member in 1995.

Microsoft’s longstanding commitment to interoperability and the OPC Foundation includes the OPC technology portfolio and OPC-UA, active participation in the OPC Foundation technology working groups, and ongoing representation on the OPC Foundation Technical Advisory Council.

“OPC-UA is an essential component of the connected products that manufacturing customers need today, and it is increasingly seen as an important part of enterprise IoT scenarios and business models,” said Matt Vasey, Microsoft Director of IoT Business Development. “I am personally excited to be working with the OPC team to help our customers unlock the value of these high-value IoT scenarios that span from the edge to the cloud. Microsoft is committed to openness and collaboration and fully supports OPC-UA and its evolution.”

“OPC-UA is widely recognized as a key communication technology for the Industry 4.0 initiative,” says Thomas J. Burke, OPC Foundation President & Executive Director. “Microsoft’s support for standards that foster IoT innovation, and specifically for OPC and OPC-UA, result in easy, direct and secure communications from PLC controllers on the shop floor to the top floor world of IT.”

“It’s a great honor to have Microsoft join the OPC Foundation Board of Directors, and we welcome Matt Vasey’s outstanding efforts to facilitate the acceleration of OPC UA as the solution for the Internet of Things,” added Burke.

“As one of the largest IT/Cloud companies, Microsoft joining the OPC Foundation board demonstrates its recognition of the role that OPC UA plays from plant floor to enterprise connectivity and IIoT for industrial automation and beyond”, according to Craig Resnick, Vice President, ARC Advisory Group. “From OPC’s perspective, having Microsoft as part of its board makes sense based on its long history of working with the OPC Foundation as well as its deploying scalable OPC UA connectivity solutions ranging from the sensor to the IT/enterprise and cloud. From Microsoft’s perspective, being part of OPC’s Board shows its commitment to openness for connecting platform independent architectures to its cloud systems, collecting data and providing its Azure cloud services for multiple operating systems beyond just Windows.”

Matt Vasey is currently responsible for IoT business development at Microsoft, working with a cross-functional team to continue to build out the ecosystem of technology partners, standards bodies, and other innovation catalysts that are required for the new generation of IoT applications, services, and systems that serve both individuals and businesses. He also serves as an officer and board member on the OpenFog Consortium, and was instrumental in the formation of this organization working closely with other founders from Intel, ARM, Cisco, Dell and Princeton University.

In addition to Mr. Vasey and Mr. Burke, the OPC Foundation Board includes Russ Agrusa, Founder and Chief Executive Officer of ICONICS; Matthias Damm, President of Ascolab; Stefan Hoppe Senior Engineer of Beckhoff Automation and OPC Vice President, Thomas Hahn, Chief Software Expert at Siemens AG and OPC Vice President, Shinji Oda is General manager, Technology Marketing of Yokogawa Electric Corporation; Veronika Schmid-Lutz, Chief Product Owner for manufacturing products at SAP SE and Ziad Kaakani, Global System Engineering and Architecture, Honeywell Process Solutions.

by Gary Mintchell | Feb 23, 2016 | Automation, Internet of Things, News, Operations Management, Organizations, Technology

Open Connectivity Foundation Seeks To Unify IoT

Companies are still organizing into groups seeking to influence standards, whether formal or industry, developing the Internet of Things. Here is an announcement from one pushed by Intel–who is seeking to be the chip supplier to the Internet of Things. I’m not sure how industrial this will be since one entity is the Open Interconnect Consortium whose focus was building and home.

The Open Connectivity Foundation (OCF) formed as an entity whose goal will be to help unify IoT standards so that companies and developers can create IoT solutions and devices that work seamlessly together. The goals according to the Foundation state, via cross-industry collaboration, the OCF will work towards unlocking the massive opportunity of the future global IoT segment, accelerate industry innovation, and help all developers and companies create solutions that map to a single, open IoT interoperability specification. Ultimately, with OCF specifications, protocols and open source projects, a wide-range of consumer, enterprise and embedded devices and sensors from a variety of manufacturers, can securely and seamlessly interact with one another.

The OCF unifies the entirety of the former Open Interconnect Consortium with leading companies at all levels – silicon, software, platform, and finished-goods – dedicated to providing this key interoperability element of an IoT solution. [I find this interesting given that I just attended a conference session with the president of the OIC speaking, no mention of “former”.]

The OCF’s vision for IoT is that billions of connected devices (appliances, phones, computers, industrial equipment) will communicate with one another regardless of manufacturer, operating system, chipset or transport. With the OCF fulfilling this promise, anyone – from a large technology company to a maker in their garage – can adopt the open standards of OCF to innovate and compete, helping ensure secure interoperability for consumers, business, and industry.

About Open Connectivity Foundation

Billions of connected devices (devices, phones, computers and sensors) should be able to communicate with one another regardless of manufacturer, operating system, chipset or physical transport. The Open Connectivity Foundation (OCF) is creating a specification and sponsoring an open source project to make this possible. OCF will unlock the massive opportunity in the IoT market, accelerate industry innovation and help developers and companies create solutions that map to a single open specification. OCF will help ensure secure interoperability for consumers, business, and industry.

TSN Test Bed

National Instruments announced a collaboration with the Industrial Internet Consortium (IIC) and industry leaders Bosch Rexroth, Cisco, Intel, KUKA, Schneider Electric, and TTTech to develop the world’s first Time Sensitive Networking (TSN) testbed. These organizations aim to advance the network infrastructure to support the future of the Industrial Internet of Things (IIoT) and Industry 4.0.

To support new digital capabilities, connected manufacturing, designers and users need more reliable and secure access to smart edge devices. Standard network technologies must evolve to meet the demanding requirements of these next-generation industrial systems and improve the way we operate our machines, electrical grids and transportation systems.

The goal of this testbed is to display the value of new Ethernet IEEE 802 standards, referred to as TSN, in an ecosystem of manufacturing applications. TSN powers a standard, open network infrastructure supporting multivendor interoperability and integration with new guaranteed performance and delivery.

The technology can support real-time control and synchronization, for example between motion applications and robots, over a single Ethernet network. TSN can at the same time support other common traffic found in manufacturing applications, driving convergence between IT and operational technologies. Previously, many real-time control applications were deployed using nonstandard network infrastructure or unconnected networks that leave the devices and data much harder to access, if accessible at all. TSN’s value is derived from driving convergence and increased connectivity, unlocking the critical data needed to achieve the IIoT promise of improved operations driven by big data analytics and enabling new business models based on smart connected systems and machines.

“Testbeds are a major focus and activity of the IIC and its members. Our testbeds are where the innovation and opportunities of the industrial Internet – new technologies, new applications, new products, new services and new processes – can be initiated, thought through and rigorously tested to ascertain their usefulness and viability before coming to market,” said Dr. Richard Soley, executive director of the IIC.

The testbed will:

• Combine different critical control traffic (such as OPC UA) and best-effort traffic flows on a single, resilient network based on IEEE 802.1 TSN standards

• Demonstrate TSN’s real-time capability and vendor interoperability using standard, converged Ethernet

• Assess the security value of TSN and provide feedback on the ability to secure initial TSN functions

• Show ability for the IIoT to incorporate high-performance and latency-sensitive applications

• Deliver integration points for smart real-time edge cloud control systems into IIoT infrastructure and application

Quotes:

“We are excited to host the new IIC TSN testbed. TSNs are a critical attribute of a standard Internet model that enables the convergence of real-time control applications and devices onto open, interconnected networks. This technology is necessary for the future of the IIoT and the IIC is providing a community, as well as enabling real-world testbeds, where industry leaders can collaborate to make this a reality,” said Eric Starkloff, executive vice president of global sales and marketing at NI.

“Standardized and open communication is a key feature in our drive and control automation solutions. We at Bosch Rexroth regard the IIC TSN testbed to be a very important contribution for further improvement of vendor interoperability and of exchanging data in an IIoT infrastructure,” said Ralf Koeppe, vice president of engineering and manufacturing electric drives and controls at Bosch Rexroth.

“The new IIC TSN testbed is an opportunity for KUKA to work with other industry leaders to prove standard technology for distributed real-time control systems as needed for edge cloud computing also known as “Fog Computing”. We view TSN, combined with OPC UA Publish/Subscribe, as a core element to implement Industry 4.0 standards,” says Christian Schloegel, chief technology officer of the KUKA group.

“As an innovator in the field of deterministic Ethernet, TTTech is delighted to join forces with industry leaders on the IIC TSN testbed. TTTech brings 20 years’ experience in time-scheduled networks and critical real-time controls to the IIC and looks forward to collaborating with the other testbed members to build an open, standard platform for the IIoT,” said Georg Kopetz, cofounder and member of the executive board for TTTech.

by Gary Mintchell | Jan 29, 2016 | Automation, Commentary, Events, Internet of Things, News, Operations Management, Technology

Industry 4.0 and Industrial Internet of Things describe manufacturing strategy as much as technology. But as I occasionally write here and write daily on my spiritual practices blog, there is a people side to all this technology and strategy.

Technologists (most people reading this site) tend to talk technology. Then they get carried away and think that technology will replace all need for people. Hence the science fiction writing and movies on that theme.

Arianna Huffington (the Huffington Post) attended the recent gathering of the world’s elite in Davos, Switzerland at the World Economic Forum. She discovered manufacturing and Industry 4.0. But she wrote a book on the power of getting enough sleep for your essential health. She managed to weave a story from both threads.

Manufacturing strategy

She writes:

The dominant topic of discussion this year — both inside the talks and panels and outside, as well — was transition. Klaus Schwab, the Forum’s founder and executive chairman, captured this sense — the possibilities as well as the challenges — with this year’s theme, the Fourth Industrial Revolution.

Schwab describes this new period as “the fusion of technologies across the physical, digital and biological worlds which is creating entirely new capabilities and dramatic impacts on political, social and economic systems.” It’s an era of automation, constant connectivity, and accelerated change, in which the Internet of Things meets the Smart Factory.

Yes, this new manufacturing strategy, which I must say seems to focus on what we call discrete manufacturing (think autos, airplanes), seeks to go deeper in employing digital technologies. In many ways it is following the lead of process industries (they hate the word manufacturing even though that is a government classification) which always seems to lead in applying math and rigor to its processes.

She continues, quoting Mark Benioff of Salesforce about people and technology:

If the Fourth Industrial Revolution will be defined by speed, connectivity, and change, there’s also a need for a countervailing force. Salesforce CEO Marc Benioff said, “Speed is the new currency of business.” But as he also said, the Fourth Industrial Revolution begins with trust, which has been at the heart of business as long as business has existed — and will only become more important in our more transparent ever-faster-moving world. Benioff’s point exemplified a larger truth of this year’s Forum, that far from being add-ons, a focus on trust, transparency, purpose, and a deeper kind of connection are central to meaningful success in the Fourth Industrial Revolution.

I’ve been writing about trust and transparency on my other blog this week. Sometimes we forget basic human values in our pursuit of either technology or profits.

Oh, yes, and she adds that we all need enough sleep each night to perform at our peak. You can go buy her book–or sleep on it.

from the OPC Foundation preparing for the upcoming Hannover Messe. Microsoft was an original OPC supporter, and here a new representative from the company has joined the Board. Key to the announcement is OPC UA communication into the Microsoft Azure cloud.

from the OPC Foundation preparing for the upcoming Hannover Messe. Microsoft was an original OPC supporter, and here a new representative from the company has joined the Board. Key to the announcement is OPC UA communication into the Microsoft Azure cloud.

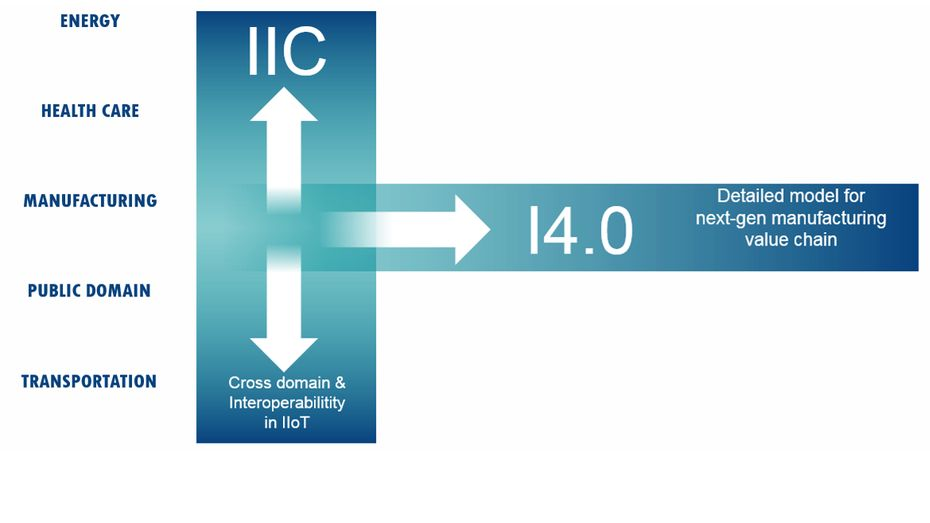

Interoperability among systems spurs economic and technological growth. Two of the leading proponents of new strategies for this next Industrial Revolution that we are beginning recently met.

Interoperability among systems spurs economic and technological growth. Two of the leading proponents of new strategies for this next Industrial Revolution that we are beginning recently met.