by Gary Mintchell | Feb 1, 2017 | Automation, Manufacturing IT, Operations Management, Operator Interface

One of my customers back in the 90s established an OEE office and placed an OEE engineer in each plant. OEE, of course is the popular abbreviation for Overall Equipment Effectiveness—a sum of ratios that places a numerical value on “true” productivity. I’ve always harbored some reservations about OEE, especially as a comparative metric, because of the inherent variability of inputs. Automated data collection and modern data base analytics are a solution.

One of my customers back in the 90s established an OEE office and placed an OEE engineer in each plant. OEE, of course is the popular abbreviation for Overall Equipment Effectiveness—a sum of ratios that places a numerical value on “true” productivity. I’ve always harbored some reservations about OEE, especially as a comparative metric, because of the inherent variability of inputs. Automated data collection and modern data base analytics are a solution.

A press release and email conversation with Parsec came my way this week. It sets the stage by pointing to the pressure to increase quality and quantity, while reducing costs, leading manufacturers to seek a deeper understanding of trends and patterns and new ways to drive efficiency. The very nature of OEE is to identify the percentage of manufacturing time that is truly productive. It is the key metric for measuring the performance of an operation, but many companies measure it incorrectly, or don’t measure it at all.

In the latest example of its efforts to help manufacturers maximize performance while reducing costs and complexity, Parsec launched its real-time Overall Equipment Effectiveness (OEE) Performance Management solution.

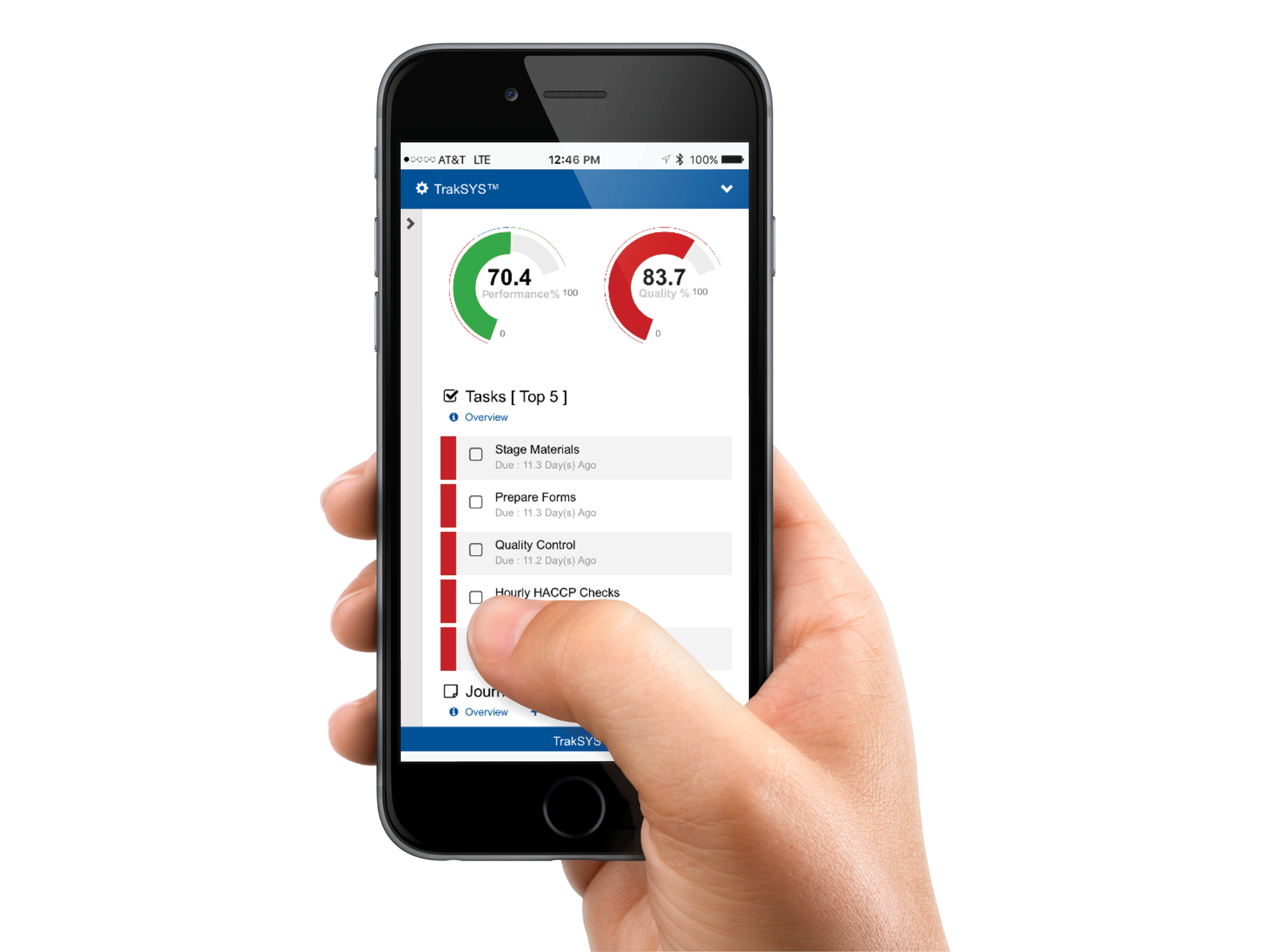

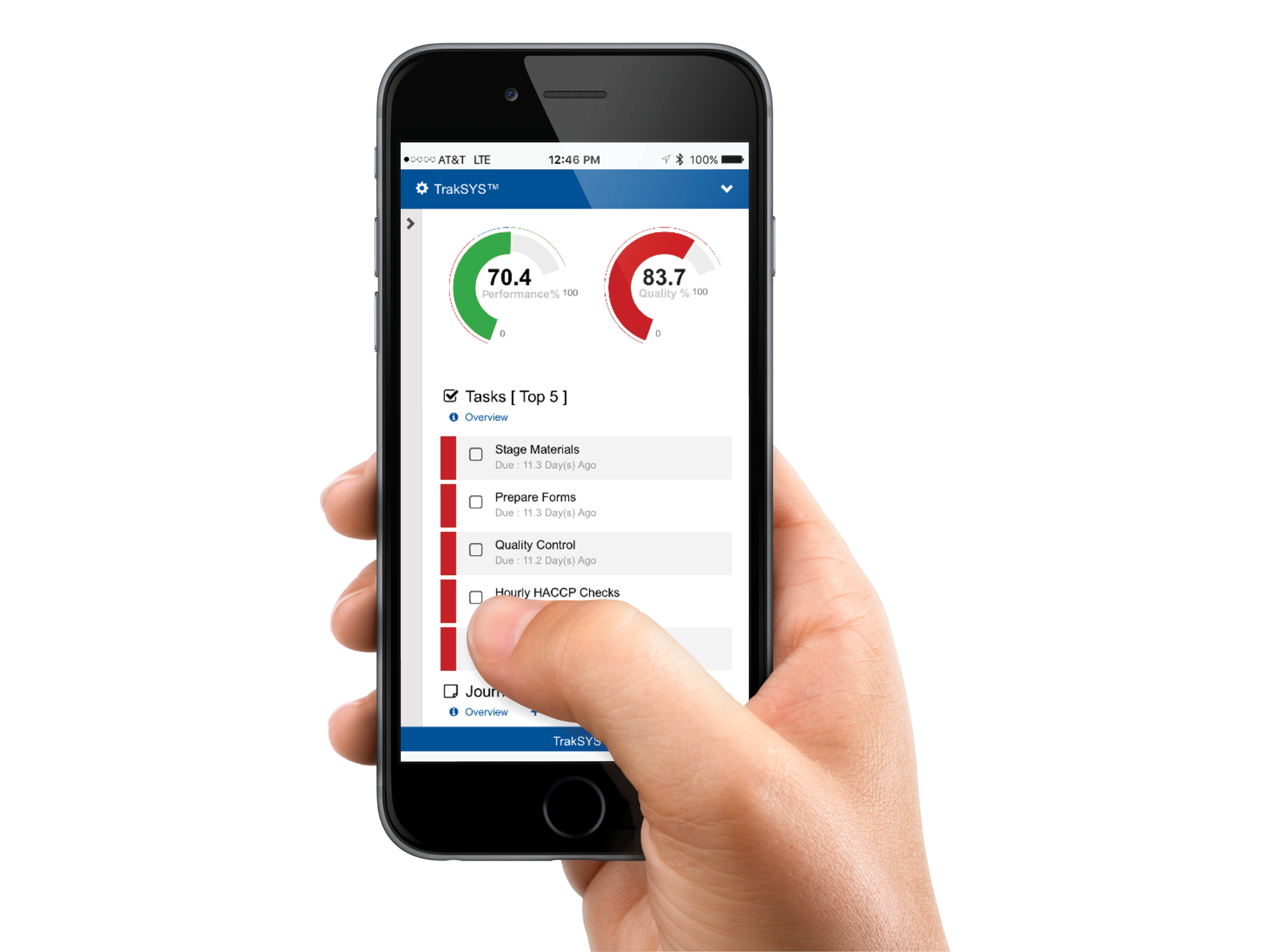

Most OEE measurement systems capture data from a single source and offer reports that may be visually appealing but actually contain very little substance. Other OEE systems capture lots of data but fail to give operators the necessary tools to act on that data. The TrakSYS OEE Performance Management solution collects and aggregates data from multiple sources, leveraging existing assets, resources and infrastructure, and provides insight into areas of the operation that need improvement with the tools to take action.

“We are challenging manufacturers to go beyond OEE measurement and to begin thinking about performance management,” said Gregory Newman, Parsec vice president of marketing. “Our TrakSYS OEE Performance Management solution pinpoints the root causes of poor performance and closes the loop by providing actionable intelligence and the tools necessary to fix the bottlenecks and improve productivity.”

The Power to Perform

When designing the TrakSYS OEE Performance Management solution, Parsec took into account three key criteria for measuring OEE: Availability, Performance and Quality. Availability, or downtime loss, encompasses changeovers, sanitation/cleaning, breakdowns, startup/shutdown, facility problems, etc. Performance, or speed loss, includes running a production system at a speed lower than the theoretical run rate, and short stop failures such as jams and overloads. Quality, or defect loss, is defined as production and startup rejects, process defects, reduction in yield, and products that need to be reworked to conform to quality standards. As part of the solution, Parsec created a variety of standard dashboards and reports as well as the ability to customize reports through powerful web-based configuration tools.

When designing the TrakSYS OEE Performance Management solution, Parsec took into account three key criteria for measuring OEE: Availability, Performance and Quality. Availability, or downtime loss, encompasses changeovers, sanitation/cleaning, breakdowns, startup/shutdown, facility problems, etc. Performance, or speed loss, includes running a production system at a speed lower than the theoretical run rate, and short stop failures such as jams and overloads. Quality, or defect loss, is defined as production and startup rejects, process defects, reduction in yield, and products that need to be reworked to conform to quality standards. As part of the solution, Parsec created a variety of standard dashboards and reports as well as the ability to customize reports through powerful web-based configuration tools.

“Our goal is to empower manufacturers to unlock unseen potential with their existing infrastructure,” added Newman. “Even small tweaks can save a plant millions of dollars each year.”

TrakSYS is an integrated platform that contains all of the functionality of a full manufacturing execution system (MES) in one package. The modular nature of TrakSYS brings flexibility to deploy only the functions that are required, without a major software upgrade. TrakSYS business solutions include OEE, SPC, e-records, maintenance, traceability, workflow, batch processing, sustainability, labor, and more.

www.parsec-corp.com

by Gary Mintchell | Nov 16, 2016 | Manufacturing IT, Operations Management, Software

The major manufacturing management software trend of the year is modular. Let’s make it easier to buy, install, configure, and use. The latest company with a major upgrade is Parsec. The company has announced launch of the latest version of its modular manufacturing management software: TrakSYS. A unified, 100% web-based platform with multiple, fully-integrated modules, TrakSYS can be used as a full manufacturing execution system (MES), or deployed to solve one or more business challenges — from performance and quality to e-records, maintenance, workflow, and more.

TrakSYS gathers critical operations data from machines and people, and delivers insights to help operations run more productively, safely and profitably. Leveraging 30 years of experience in delivering manufacturing solutions, Parsec designed this version of TrakSYS to simplify manufacturing operations in a variety of industries – from pharmaceutical and packaged goods to food and beverage, automotive and more.

“Manufacturing is complex, but your software shouldn’t be,” said Eddy Azad, CEO for Parsec. “The key advantage of TrakSYS lies in its flexibility. TrakSYS has all of the power of traditional MES, without the ‘weight’ and cost. Manufacturers can simply turn on the features they want at any time and customize a solution that specifically addresses their needs.”

Manufacturing Management – Simplified

Under the strain of increased regulations for accurate, accessible electronic recordkeeping, manufacturers need a real-time view of manufacturing operations. The pressure to increase quality and quantity, while reducing costs, also has manufacturers seeking a deeper understanding of trends and patterns and new ways to drive efficiency. Custom software and traditional MES solutions can be used to address these concerns, but they are costly and complicated to manage.

Azad, explains, “It’s all about making software easier to use and more cost-effective to deploy, maintain and scale.”

One Platform, Many Applications

TrakSYS is an integrated platform that contains all of the functionality in one package. The modular nature of TrakSYS brings complete flexibility to deploy only the functions that are required, without a major software upgrade. TrakSYS business solutions include OEE, SPC, e-records, maintenance, traceability, workflow, batch processing, sustainability, labor and more.

“Whether a factory has one line or 100, uses manual or automated production processes, relies on PLCs or an IIoT infrastructure, TrakSYS can help. We designed this powerful version of our proven software with the idea that software should help manufacturers to do their job, not become the job,” added Azad.

The latest version of TrakSYS is now available.

by Gary Mintchell | Oct 31, 2016 | Automation, News, Safety, Software, Technology

I have a little batch of process automation and industry news involving predictive technologies—two acquisitions and a new safety product. Congratulations to Mike Brooks and the team at Mtell for a good exit. Also congratulations to the MaxEAM folks. Finally, an important new take on process automation safety from PAS.

MTell Acquired by Aspen Technology

Aspen Technology Inc., a provider of software and services to the process industries, announced it has acquired Mtelligence Corp. (known as Mtell), a San Diego, California-based pioneer in the field of predictive and prescriptive maintenance for asset performance optimization.

Mtell products enable companies to increase asset utilization and avoid unplanned downtime by accurately predicting when equipment failures will occur, understanding why they will occur, and prescribing what to do to avoid the failure.

The products provide a low-touch, rapidly deployable, end-to-end solution that combines a deep understanding of operations and maintenance processes, real-time and historical equipment data and cutting-edge machine learning technologies. As a result, customers can:

- Monitor the health of equipment, detect early failure symptoms, diagnose their root-cause and recommend the best responses to avoid the failure

- Continually learn and automatically adapt to changing equipment and process behaviors

- Automatically share findings across a network of similar equipment to improve the overall process performance.

Some of the world’s largest process manufacturing companies use Mtell. Customer results have shown significant benefits including improved industrial safety, removal of risk, reduced failures, enhanced productivity and increased profitability.

Mtell products include:

- Previse – Mtell’s flagship end-to-end machine learning solution that monitors equipment health 24/7, detects early indicators of degradation or failures, diagnoses the root cause and prescribes responses that prevent breakdowns and unplanned downtime.

- Basis – A connected condition monitoring application that facilitates collaboration between operations and maintenance organizations to determine the best course of action for equipment alert conditions.

- Reservoir – A high performance, scalable, big data repository that captures, manages and synchronizes large volumes of time series, event and asset data from multiple sources.

- Summit – A remote monitoring center application for monitoring, analyzing and benchmarking asset performance.

The purchase price of the transaction was $37M. Additional terms are disclosed in AspenTech’s Quarterly Report on Form 10-Q for the first quarter of Fiscal 2017 filed with the United States Securities and Exchange Commission.

Schneider Electric Adds to Asset Management Portfolio

Schneider Electric, the global specialist in energy management and automation, announced the acquisition of MaxEAM, a software company with complementary applications that extend Avantis.PRO Enterprise Asset Management. The acquisition further solidifies the portfolio and adds valuable domain expertise to Schneider Electric’s existing team.

Schneider Electric and MaxEAM have a long standing business relationship working together to deliver successful customer projects on a global scale. The acquisition gives customers a single point of contact for support and delivery services, and more closely aligns future product development.

“The strength of our asset management portfolio continues to grow, both organically and through acquisition. MaxEAM enhances the functionality of our Avantis.PRO offering, securing the investment our customers have made in our products,” said Rob McGreevy, Global Vice President, Software at Schneider Electric. “The addition of MaxEAM subject matter expertise and technology will allow us continued expansion of our industry-leading Enterprise APM platform.”

“Our advanced technology linked to mobile work execution streamlines processes, adding tremendous capabilities for mobile workers,” said Eric Stern, President of MaxEAM. “Schneider Electric’s Enterprise APM platform is the broadest in the market today. I’m excited that our people and technology will be an integral component to the overall offering.”

Two years ago Schneider Electric acquired InStep Software, adding advanced predictive analytics. That acquisition furthered its delivery of Enterprise APM solutions leveraging the Industrial IoT, helping to close the gap between IT and OT.

PAS Launches Process Safety Analytics Software

PAS Inc., the solution provider of process safety, cybersecurity, and asset reliability for the energy, power, and process industries announces the general availability of its newest product, PAS IPL Assurance. The software provides real-time predictive analytics on the health and availability of the safety instrumented systems (SIS), Alarm Management Systems, and other Independent Protection Layers (IPL). In addition to managing operational risk, IPL Assurance reduces compliance costs by automatically reporting on the SIS performance during a demand on the safety system.

PAS IPL Assurance delivers actionable information on safety instrumented systems, alarm systems, control loops, and operational boundaries to streamline compliance activities and expose operational risk. As a result, plant personnel can mitigate abnormal situations before they impact plant safety, reliability, and profitability.

IPL Assurance provides the following analytics, alert, and visualization features:

• Safety instrumented function (SIF) performance management,

• Testing and maintenance management,

• Demand on safety system rate tracking,

• Status of safety related alarms,

• Safety system bypass management, and

• Safety and operational risk dashboard.

“IPL Assurance provides up-to-date IPL lifecycle management so that operations can immediately ascertain the overall risk profile of any facility,” said Mark Carrigan, Senior Vice President of Global Operations at PAS. “This visibility from an automated single source of truth is essential to preventing critical safety incidents and supporting IEC and OSHA compliance requirements.”

by Gary Mintchell | Oct 28, 2016 | Automation, Internet of Things, News, Operations Management

Emerson Automation (formerly Emerson Process Management) is the latest automation company to thoroughly exploit the Industrial Internet of Things as it unveiled its digital strategy and reinvigorated Plantweb architecture at Global Users Exchange 2016.

Microsoft continues its deep penetration into industrial and manufacturing automation markets with a renewed commitment from Emerson. The companies announced at Exchange the Plantweb digital ecosystem and Connected Services are powered by Microsoft Azure IoT Suite.

Emerson is also broadly adopting Microsoft’s Windows 10 IoT technology both in its DeltaV and Ovation control systems and in data gateways.

First introduced as the industry’s most advanced process control and safety network, Plantweb now harnesses the power of Industrial IoT to expand digital intelligence to the entire manufacturing enterprise, while also providing an architecture for on-premise applications. Plantweb provides a comprehensive framework to help manufacturers achieve Top Quartile performance in the areas of safety, reliability, production and energy. Top Quartile is defined as achieving operations and capital performance in the top 25 percent of peer companies.

“In 1997, Emerson revolutionized the automation landscape with Plantweb, the first field-based digital plant architecture,” said Peter Zornio, chief strategic officer, Emerson Automation Solutions. “Now, we are doing it again by harnessing the power of Industrial IoT to give customers the technology foundation for Operational Certainty.”

The pieces comprising Plantweb (see diagram) include (from the bottom of the stack): Pervasive Sensing; Secure First Mile; Insight; Advisor; Always Mobile; and, Connected Services. I’ll discuss a little of each of these below. Many are build outs of existing products and technologies, some are new products or services.

Pervasive Sensing

Emerson’s Pervasive Sensing Strategies expand the use of sensor and analytics technology into new operational performance areas through a new generation of low-cost sensors that are easy to install and maintain, take advantage of wireless communications as part of a secure, integrated industrial network and use new analytic algorithms to create insights into the performance of a plant’s assets.

Emerson’s expanding portfolio of pervasive sensing technologies includes capabilities in the areas of hazardous gas sensing, wireless corrosion monitoring, wireless medium voltage equipment monitoring, wireless gas monitoring, wireless non-intrusive surface-sensing temperature measurement, wireless power metering and pressure gauge measurement.

Wireless corrosion monitoring

Emerson’s Permasense Wireless Corrosion Monitoring is a permanently-installed technology that uses unique sensor technology, wireless data delivery and advanced analytics to continuously monitor for metal loss from corrosion or erosion in pipes, pipelines or vessels.

Designed to operate without maintenance for years, this monitoring technology reliably delivers high-integrity data even in the harshest environments, providing ongoing visibility of corrosion and erosion trends in real-time and direct to the engineer.

Wireless medium voltage equipment monitoring

Emerson’s IntelliSAW wireless medium voltage equipment monitoring systems offer real-time, continuous monitoring of electric power switchgear temperatures and smart grid monitoring, providing accurate temperature data for key points in a power transmission network.

Wireless gas monitoring

Emerson’s Rosemount 928 Wireless Gas Monitor is the world’s first integrated WirelessHART toxic gas detection solution. Maintaining remote sites like wellheads and natural gas metering stations is difficult and dangerous because workers approaching these sites may be exposed to unplanned releases of toxic gas. Due to the prohibitive costs to install and operate conventional gas detection systems at these sites, operators have been forced to rely on portable gas detection devices or, even worse, carry on with no gas detection at all. In all these cases, workers may run the risk of exposure when approaching these remote sites to perform maintenance.

Wireless non-intrusive surface-sensing temperature measurement

Emerson’s Rosemount X-well Technology is a surface-sensing temperature measurement solution that eliminates the need for thermowell process penetration when measuring process temperatures in pipe applications and removes leak points to reduce compliance costs and increase safety. X-well technology eliminates the need to drill device connections to get process temperatures, allowing users to avoid the risk of corrosion.

Wireless power metering

The Emerson SensEnable 56WM wireless power meter is designed to monitor voltage, current, power, energy, and other electrical parameters on single and three phase electrical systems with revenue-grade accuracy. The power meter delivers early detection of machine problems through continuous measurement of power consumption and power quality of submeters. Submeters are physical metering devices that monitor electricity, gas, water, steam, and other utilities.

Pressure gauge measurement

Emerson’s Rosemount Wireless Pressure Gauge delivers safer and more reliable readings, enabling remote collection of field data as frequently as once per minute. Accurate, wireless readings keep operators updated on changing field conditions remotely – reducing manual operator rounds and improving safety by keeping personnel out of hazardous areas and safeguarding against catastrophic events.

Secure First Mile

Emerson’s Secure First Mile is a set of architectural approaches and designs, enabled by a family of security services and robust, secure and flexible servers, gateways, and data diodes that ensures that data in existing OT systems can be easily and securely connected to internet based applications.

Using Secure First Mile architectures, a plant can transform its operational technology data into information technology data while ensuring outbound paths of information do not become inbound paths that expose its systems to harm.

As part of its Secure First Mile architectures, Emerson is using OPC Unified Architecture (UA) servers to export data from application databases. OPC UA is an industrial machine-to-machine communication protocol that can be directly consumed by Microsoft Azure, Emerson’s chosen platform for cloud computing. Microsoft Azure enables the building, deployment and management of applications and services through a global network of Microsoft-managed data centers. Its integrated cloud services include analytics, computing, database, mobile, networking, storage and web applications.

To connect its field data aggregation products such as wireless sensor gateways, CHARM I/O cards, Ethernet I/O cards and RTUs, Emerson is using Windows10 IoT edge gateways. These gateways enable data to securely reach the Microsoft Azure cloud by translating operational technology protocols such as FOUNDATION fieldbus (FF) and HART to information technology protocols such as Advanced Message Queuing Protocol (AMQP) & MQ Telemetry Transport (MQTT). These gateways provide a high degree of security through data encryption and key management. In addition, as described, data diodes installed within the system act as physical barriers to incoming information, preventing outside access to a plant’s systems.

Insight

Emerson’s Plantweb Insight applications, which leverage Emerson’s Pervasive Sensing strategies, help users instantly make sense of plant data to drive overall enterprise profitability. It’s a single, lightweight, easy-to-install web-based platform that automatically and strategically interprets plant data through a scalable suite of applications.

Plantweb Insight features a user-friendly, intuitive interface capable of running on any device with access to a web browser (desktop computers, laptops, tablets and mobile phones). Pre-built analytics require minimal configuration, and its flexible software is operating system-independent, easily installing and integrating with existing infrastructures.

The power of Plantweb Insight resides in its collection of easy-to-deploy applications, each containing the embedded domain expertise and analytics that enable existing resources to immediately identify and resolve asset issues that historically were addressed by periodic, manual rounds or unexpected failures. These applications are designed to help users realize the most from Pervasive Sensing strategies at their sites.

More than a dozen total applications are scheduled for release, with each dedicated to a single, specific asset class. The first three applications are available now and future applications will be released at a rate of two per quarter.

Plantweb Insight is currently available with applications for steam trap monitoring, pump monitoring and pressure gauge monitoring.

Advisor

Emerson’s Plantweb Advisor Suite is a scalable set of software products offering two new applications, Health Advisor and Performance Advisor, in addition to the previously released Energy Advisor – all of which leverage the industry-standard OSIsoft Pi System’s highly scalable open data infrastructure that captures and shapes data generated by equipment.

“Together, Emerson and OSIsoft are creating a foundation for digital transformation,” said Martin Otterson, senior vice president of sales, marketing and partners at OSIsoft. “Through the combination of Plantweb Advisor Suite and the PI System, organizations will be able to rapidly achieve deep insights into their operations that in turn will help them boost productivity or develop new services.”These complementary applications are designed to boost operational performance by empowering a plant’s reliability, process and energy experts with critical information about equipment health and efficiency as well as energy consumption and emissions.

Using the Plantweb Advisor Suite, a plant’s essential assets are continuously monitored for potential problems with Health Advisor, operating efficiency of a plant’s equipment is tracked through Performance Advisor, and Energy Advisor maps and manages a plant’s energy consumption in real time.

Always Mobile

Always Mobile solutions deliver secure, instant access to critical information in intuitive views that prepare personnel at all levels to more effectively make business-critical decisions and operate their facilities.

AMS Asset View

AMS Asset View software is a dashboard and messaging application used to present asset health information on desktops, laptops, and mobile devices. An application connecting into the AMS ARES Platform, AMS Asset View’s persona-based views ensure that reliability personnel know the health of their assets in relevant time and always see the alerts they need to see, and only the alerts they need to see, so they can focus on asset conditions critical to production.

AMS Asset View focuses on delivering asset health status and alerts in relevant time, using a push alert mechanism to provide notifications that are pertinent to a user’s responsibilities and the criticality of an individual asset.

DeltaV Mobile

The new DeltaV Mobile application allows process engineers, operators, and plant managers to quickly and easily view personalized watch lists and receive real-time alarm notifications.

Collaborative features enable users to more efficiently diagnose and troubleshoot abnormal process situations—whether they are on site or in a remote location.

Guardian Mobile

Emerson announces Guardian Mobile, a mobile application delivering visibility of critical data for control, asset, machinery, and device monitoring systems. An element of Emerson’s Always Mobile, Guardian Mobile enables users to access their system health score for all associated systems from anywhere.

AMS Trex Device Communicator

The AMS Trex Device Communicator is a handheld communicator for advanced diagnostics, configuration, and troubleshooting in the field, designed to improve the efficiency of the many tasks performed by maintenance technicians.

The Trex communicator supports additional mobile applications, such as ValveLink Mobile, which allows technicians to configure and test valves inline, minimizing the impact on production.

Connected Services

Emerson Connected Services are bridging that gap by harnessing the Industrial IoT to help its customers maximize the health, reliability and performance of plant assets and processes through proactive, predictive analysis that delivers actionable data. A key component of Emerson’s Plantweb digital ecosystem, the service offers remote, continuous assessment of a plant’s equipment and processes by Emerson experts to empower customers with the information needed to improve efficiency and avoid unplanned downtime. Emerson Connected Services utilize Microsoft Azure cloud services and data analytic tools that provide a scalable and secure cloud application environment.

Emerson Connected Services offer support across four main subscription-based service offerings in which experts analyze data from critical equipment to provide actionable insights so customers can align their maintenance and operational responses with their business strategies. These offerings currently include Control Valve Connected Services, Steam Trap Connected Services, DeltaV System Health Connected Services, and Machinery Connected Services.

These new services are an integrated part of Emerson’s Lifecycle Services offerings, enabling Emerson to provide customers with more effective and efficient access to its experts. Rather than physically sending experts to inspect and analyze data from critical equipment on a customer’s site, Emerson is able to bring the data to the experts, wherever they are located, with secure connectivity and cloud services. For the most part, users are leveraging the existing infrastructure in their facility making it easy to start small and focused, and grow the service to deliver more business results.

by Gary Mintchell | Oct 27, 2016 | Asset Performance Management, Automation, News, Safety, Technology

Emerson Automation’s PlantWeb architecture has grown and morphed into a full blown Industrial Internet of Things platform. The redesigned and reinvigorated integrated architecture forms the foundation of Emerson’s new Operational Certainty initiative. This is the first of a few reports on the latest Emerson Automation news.

Steve Sonnenberg, recently elevated into the role of Chairman of Emerson Automation—the company formerly known as Emerson Process Management, introduced new Executive President Mike Train to the assembled customers and press at the 2016 edition of Emerson Global Users Exchange in Austin, Texas on Oct. 24. Train then introduced Operational Certainty.

The previous initiative was Project Certainty where the company strategists arrayed its existing and new products into a package that was designed to remove automation from the critical path of capital projects. These days capital projects are few and far between. Companies are scrambling to wring more profitability from existing assets. Therefore a new approach from Emerson that is obviously driven by its customers’ needs. Train says that this initiative will help wrest more than $1 trillion from operational losses globally.

Initiatives need benchmarks. Emerson introduced peer benchmarking on best practices to achieve Top Quartile performance in safety, reliability, production, and energy management. Top Quartile is defined as achieving operations and capital performance in the top 25 percent of peer companies.

The company is also launching a new Operational Certainty consulting practice plus expanded project execution methodologies and resources. Additionally, on October 24, the company will announce a new Industrial Internet of Things (IoT) digital ecosystem to provide the technology foundation for companies to securely implement Industrial IoT to achieve measurable business performance improvement.

A few examples of Emerson’s findings:

- In terms of safety, Top Quartile performers had one-third the number of safety incidents as compared to their average industry peers.

- In terms of asset reliability, Emerson found that Top Quartile performers spend half as much on maintenance compared with average performers and operate with an incremental 15 days of available production each year.

- In the domain of production, Top Quartile manufacturers spent 20 percent less on production-related expenses as compared to average producers.

- In the area of energy and emissions, the top 25 percent of producers spent one-third as much as the industry average on energy costs and had 30 percent less CO2 emissions.

One of my customers back in the 90s established an OEE office and placed an OEE engineer in each plant. OEE, of course is the popular abbreviation for Overall Equipment Effectiveness—a sum of ratios that places a numerical value on “true” productivity. I’ve always harbored some reservations about OEE, especially as a comparative metric, because of the inherent variability of inputs. Automated data collection and modern data base analytics are a solution.

One of my customers back in the 90s established an OEE office and placed an OEE engineer in each plant. OEE, of course is the popular abbreviation for Overall Equipment Effectiveness—a sum of ratios that places a numerical value on “true” productivity. I’ve always harbored some reservations about OEE, especially as a comparative metric, because of the inherent variability of inputs. Automated data collection and modern data base analytics are a solution.

When designing the TrakSYS OEE Performance Management solution, Parsec took into account three key criteria for measuring OEE: Availability, Performance and Quality. Availability, or downtime loss, encompasses changeovers, sanitation/cleaning, breakdowns, startup/shutdown, facility problems, etc. Performance, or speed loss, includes running a production system at a speed lower than the theoretical run rate, and short stop failures such as jams and overloads. Quality, or defect loss, is defined as production and startup rejects, process defects, reduction in yield, and products that need to be reworked to conform to quality standards. As part of the solution, Parsec created a variety of standard dashboards and reports as well as the ability to customize reports through powerful web-based configuration tools.

When designing the TrakSYS OEE Performance Management solution, Parsec took into account three key criteria for measuring OEE: Availability, Performance and Quality. Availability, or downtime loss, encompasses changeovers, sanitation/cleaning, breakdowns, startup/shutdown, facility problems, etc. Performance, or speed loss, includes running a production system at a speed lower than the theoretical run rate, and short stop failures such as jams and overloads. Quality, or defect loss, is defined as production and startup rejects, process defects, reduction in yield, and products that need to be reworked to conform to quality standards. As part of the solution, Parsec created a variety of standard dashboards and reports as well as the ability to customize reports through powerful web-based configuration tools.