by Gary Mintchell | Aug 28, 2015 | Commentary, Data Management, Interoperability, News, Operations Management

This is a story about data interoperability and integration. This is a much-needed step in the industry. I just wish that it were more standards-driven and therefore more widespread.

But we’ll take every step forward we can get.

Arena Solutions, developer of cloud-based product lifecycle management (PLM) applications, announced that its flagship product, Arena PLM, now offers real-time synchronization with Kenandy Cloud ERP, an enterprise resource planning system for midmarket and large global enterprises built on the Salesforce Platform.

With this integration, the product record can be automatically passed from Arena PLM to Kenandy at the point of change approval. This eliminates errors and accelerates access of product information in Kenandy to create a more cohesive and efficient manufacturing process.

Arena PLM and Kenandy Cloud ERP can now communicate directly with each other, enabling customers to share up-to-date product data with finance, sales and manufacturing departments to ensure accurate financial planning and support operations.

“We are excited to be partnering with Kenandy to deliver a fully cloud-based integrated PLM and ERP solution.” said Steve Chalgren, EVP of product management and chief strategy officer at Arena Solutions. “The integration between our products is simple, clean, and can be implemented quickly. Isn’t that refreshing?”

Using the integration between Arena PLM and Kenandy Cloud ERP, customers can:

- Manage the product development process of product data (items, bill of materials, manufacturer and supplier data) in a centralized Arena PLM system through the entire product lifecycle; and

- Use Kenandy to quickly plan, procure and manufacture products upon handoff of the latest product release from Arena.

Primus Power Benefits from Seamless Integration

Delivering clean-tech energy storage solutions based on advanced battery technology, Hayward, California-based Primus Power was already successfully using Arena PLM for their design and engineering activities. It was essential that their new ERP and existing PLM system integrate seamlessly.

In Primus’ fast moving, design-focused environment, an engineer can now implement a product idea or improvement in the PLM system and within minutes the new part number is generated in Kenandy automatically. Instantly, people throughout the company can find that part; there’s a pricing history for it, a supply history. “People no longer say, ‘Did we order that bracket?’ They can now actually see that it’s on order. They can find the purchase order and the promised delivery date,” said Mark Collins, senior director of operations at Primus. “So much information is now available at people’s fingertips simply because we created a part number that’s now searchable in the system.”

“Cloud solutions deliver business agility in ways that on-premise solutions just cannot,” said Rod Butters, president and chief operating officer at Kenandy. “Together Arena and Kenandy are delivering a solution that can be deployed fast and, more importantly, helps the business run fast. Even though our customers are working with our two products, their entire team sees a single, complete, real-time source of truth from product design to product delivered to bottom-line results.”

I have written about Kenandy a couple of times this year here and here.

by Gary Mintchell | Jul 23, 2015 | Automation, Internet of Things, Operations Management

Tim Sowell, Schneider Electric (Wonderware) vp and fellow, has been writing a weekly blog that I report on for a while now. His Operations Management Systems Evolution blog is always thoughtful and informative.

Tim Sowell, Schneider Electric (Wonderware) vp and fellow, has been writing a weekly blog that I report on for a while now. His Operations Management Systems Evolution blog is always thoughtful and informative.

Recently, I have discovered another Schneider Electric blog, this one by someone whom I do not know (I think)–Gregory Conary.

Each take a look at the Industrial Internet of Things in these posts.

Conary’s recent post discussed the “business opportunities we are seeing emerge from this megatrend.”

He cites information compiled by LNS Research, in its eBook Smart Connected Operations: Capturing the Business Value of the Industrial IoT. 47 per cent of respondents to its Manufacturing Operations Management (MOM) online survey indicated that they did not expect to invest in IoT technologies in the “foreseeable future”. A further 19 per cent indicated that they did not expect to invest in IoT technologies in the next 12 months.

Conary states, “Frankly I’m not surprised. IIoT seems to bring with it the hype of something that will take a long time to adopt. In some cases I think this can be true. And while we are unclear on what time frame is meant by the term ‘foreseeable future’ referenced above, I believe there are business opportunities that can be capitalized on now and in the medium term. IIoT is more prevalent than we imagine. There are examples and business practices that we often don’t even recognize as being enabled by IIoT – things like increasing industrial performance and augmenting operators are two of the opportunities which can make a difference to your business now.”

Increased industrial performance

“Using data to improve industrial performance by connecting things to each other – this is happening now. How is it happening? Through wireless technologies, low cost sensors and using advanced analytics. In practice, this is a decision support system for complex manufacturing operations.”

I agree with Conary. We’ve had the foundation and platform for the Industrial Internet of Things for a long time. It just continues becoming more robust. As better data analytics algorithms are developed and better ways to communicate and display information are devised, then usefulness to manufacturing operators, maintenance technicians, engineers, and managers will increase dramatically.

Tim Sowell riffed off an article in Wired. “As the Internet of Things (IoT) continues its run as one of the most popular technology buzzwords of the year, the discussion has turned from what it is, to how to drive value from it, to the tactical: how to make it work.

We need to improve the speed and accuracy of big data analysis in order for IoT to live up to its promise. If we don’t, the consequences could be disastrous and could range from the annoying – like home appliances that don’t work together as advertised – to the life-threatening – pacemakers malfunctioning or hundred car pileups.”

Sowell adds this analysis, “This follows on from my discussion 2 weeks ago around the need to avoid just gathering data, vs gaining the proportional amount of knowledge and wisdom, which brings in a term you hear a lot ‘machine learning’.”

From Wired, “The realization of IoT depends on being able to gain the insights hidden in the vast and growing seas of data available. Since current approaches don’t scale to IoT volumes, the future realization of IoT’s promise is dependent on machine learning to find the patterns, correlations and anomalies that have the potential of enabling improvements in almost every facet of our daily lives.”

Sowell concludes, “In the industrial world this more applicable than nearly all industries, and in many cases we are already applying “machine levels” at different levels. A key part in the shift from ‘Information’ to ‘knowledge’ is having the tools to drill into historians based on events and to discover learnings and patterns. Once validated and discovered these are turned into ‘self-monitoring’ conditions to understand the current state of the device, and predict / recognize conditions well before they happen. Providing the ‘insight’ to make awareness and decisions where the machines/ devices are telling you where the opportunities are. But a key part of machine learning is that this knowledge in not a once off step, it is a continuous evolution leveraging the gathering history data and developing increased amounts of knowledge.”

Final thought

Both Conary and Sowell point directly to the new reality and to new challenges. We can now gather much more data than we can make sense of. As soon as we have those tools, we will provide better tools to operations and maintenance to improve plant performance.

by Gary Mintchell | Jul 14, 2015 | Automation, Industrial Computers, News, Security, Technology

Potentially viable start-ups are rare in the industrial automation space. Recently Russ Fadel, Rick Bullotta, and John Richardson did it with ThinkWorx an Internet of Things oriented software they sold to PTC. That was their second effort having previously sold Lighthammer to SAP.

Potentially viable start-ups are rare in the industrial automation space. Recently Russ Fadel, Rick Bullotta, and John Richardson did it with ThinkWorx an Internet of Things oriented software they sold to PTC. That was their second effort having previously sold Lighthammer to SAP.

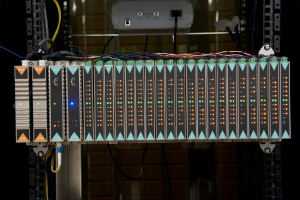

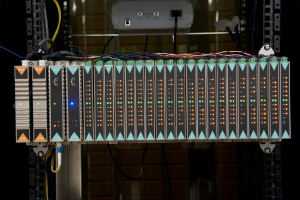

Now we have Albert Rooyakkers, CTO and inventor, and Bob Honor, president and former VP at Rockwell Automation and GE Intelligent Platforms, releasing a new industrial control system and company—Bedrock Automation. This company was introduced to Manufacturing Connection readers last December.

This is a tough area for an entrant. I’ve watched the rise and fall of PC-based control from back in the late 90s. Rockwell Automation and Siemens are so entrenched in the market. The next tier is solid with AutomationDirect, B+R Automation, Beckhoff Automation, Mitsubishi, and Schneider Electric.

When you develop a product for a crowded market, you basically have to execute one of two strategies. Either you think that the products have reached commodity status and that you can make them better, faster, cheaper (at least the last two). Or, you totally disrupt the industry by bringing out something that does what others do better—and adds some significant new features and benefits.

Disruptive?

Bedrock Automation executives believe they have accomplished the latter. The design begins with built-in cyber security. Its patented architecture features a pin-less, electromagnetic backplane. It addresses “virtually all control applications with fewer than a dozen part numbers, reducing cyber attack vectors, cutting lifecycle costs, and simplifying engineering, commissioning and maintenance.”

“Starting from a blank sheet of paper while inventing and deploying advanced semiconductor, mechanical design, cyber computing and communication technologies has resulted in a completely new automation platform. The future is now,” said Bedrock Automation CTO and Engineering VP, Albert Rooyakkers.

Commitment to simple, elegant design is a core tenet of the system. Bedrock delivers I/O, power and communications across the pin-less electromagnetic backplane with a parallel architecture that supports ultra fast scan times regardless of I/O count. The removal of I/O pins improves reliability and increases cyber security while forming a galvanic isolation barrier for every I/O channel. This innovative backplane also allows installation of I/O modules in any orientation and location for “unprecedented” flexibility in I/O and cable management.

Secure I/O modules use layers of advanced technology to deliver software-defined I/O for universal analog, discrete, Ethernet and Fieldbus signal types. A secure power module is functionally and physically coupled to the backplane to deliver single and dual redundant cyber secure power for the control system. A secure universal controller can run virtually every application independent of size or control task: discrete, batch, continuous, or multivariable control from one device that supports as few as ten, to as many as thousands of I/O points. No longer are separate programmable logic controllers (PLC) and distributed control systems (DCS) required.

“As cyber threats to all industries grow, traditional control system vendors respond by adding cost and complexity to their legacy technology. With deep roots in both automation and semiconductors, and unburdened by legacy, Bedrock Automation has created not only the most cyber secure system available today but we have also established new benchmarks for performance, scalability and affordability,” said Bedrock Automation President, Bob Honor.

Layers of protection

Replacing pins with an electromagnetic backplane is one of many layers of cyber security protection that Bedrock Automation has implemented. Additional cyber security layers include:

- A real time operating system with the highest safety (SIL 4) and security (EAL6+) rating of any RTOS available today

- Cyber secure microcontrollers with encrypted keys and TRNG embedded in all system modules including the controller, power supply and I/O

- All modules encased in anti-tamper metal that is impenetrable without metal cutting tools

- Authentication extending throughout the supply chain, including third party software and applications

Adding so many layers of protection to a conventional DCS, SCADA RTU, PAC or PLC would add cost and complexity and degrade performance. With Bedrock, they were built in from the start.

“Brown Engineers is excited to join the Bedrock revolution. Clients in our focus markets of electric, water, and sewer utilities, are increasingly concerned about cyber security and are confident that installing Bedrock will give them peace of mind to tell their ratepayers and their board members that they are taking every precaution to protect their processes. Brown Engineers demonstrates its continued commitment to keeping clients on the forefront of technical innovation,” said Dee Brown of Brown Engineers, an industrial systems integration firm based in Little Rock, Arkansas.

Open, flexible engineering

Bedrock delivers an Integrated Development Environment (IDE) based on an open IEC 61131 software toolset that supports embedded OPC UA. The IDE enables users to develop, operate and authenticate control for a vast array of PLC, SCADA and DCS applications. Fewer components means fewer panel layouts and wiring diagrams to contend with. Software configurable I/O can be changed in the field with the click of a mouse. Ninety percent fewer I/O module types means fewer spare parts to keep and manage. Such innovations contribute to reducing overall engineering design costs by up to 33 percent.

“Bedrock is the first unique platform to enter the control market in the last 15 years. It diverges radically from the typical platforms and is superior in terms of processing power, redundancy, scalability, security and cost efficiency. We plan to use it as a point of differentiation for our business,” said Chris McLaughlin of Vertech, a Phoenix-based industrial systems integrator.

Pricing and availability

The Bedrock control system is available now in baseline configuration starting at $20,000 MSRP. A growing network of world-class system integrators and automation solution providers is available to provide local sales and support.

For more information about the Bedrock revolution, download the first white paper in the series: Revolution – Chapter One: The Backplane.

by Gary Mintchell | Jul 8, 2015 | Automation, Data Management, Events, Internet of Things, News, Operations Management, Process Control, Security

Here is the official wrap of the recent Honeywell Users Group (HUG) Americas symposium. It was the 40th anniversary celebrated with the theme “40 Years of Innovation.” Officially “more than 1,200 people” attended the event.

Here is the official wrap of the recent Honeywell Users Group (HUG) Americas symposium. It was the 40th anniversary celebrated with the theme “40 Years of Innovation.” Officially “more than 1,200 people” attended the event.

I have written a couple of times during the week here and here. This information comes from a press release issued last week. Along with some executive quotes is a note that Honeywell Process Solutions has been developing and implementing technologies for the Industrial Internet of Things (IoT) for many years.

During the event, Honeywell announced a collaboration with Intel Security McAfee which will expand its industrial cyber security capabilities to help defend customers from the increasing threat of cyber attacks.

“The process manufacturing industries are facing a critical time in history due to a convergence of factors such as security threats, a shrinking workforce and lower oil prices, among others,” said Vimal Kapur, president of Honeywell Process Solutions (HPS). “These factors are driving a greater need for our technologies and services because they’re designed to help companies conduct operations more efficiently, and with less risk.”

The conference revolved around three core technology themes directly impacting companies’ abilities to successfully adapt to changing market conditions: digital transformation and smart operations, system evolution and risk reduction, and smart instrumentation with smart integration. Throughout the week, Honeywell executives, technology experts and customers explained how these core areas can turn technology buzzwords like Big Data and Industrial Internet of Things (IoT) into practical applications.

“HPS has been leveraging the concepts and technologies behind the Industrial IoT as part of the vision that we have been evolving towards for several years,” Bruce Calder, HPS chief technology officer told general session attendees. “In order to run a reliable operation that continues to improve performance and business results, you will need to install smarter field devices, achieve more connectivity, collect more data and find ways to use that data to run a smarter operation.”

Calder also gave attendees a first look at HPS’ first native app for mobile devices and tablets that connects to different sources and applications across the company’s portfolio to create a more-intuitive mobile experience for plant workers. Mobility is part of the initiative to introduce a suite of apps that, along with new cloud functionalities, will enhance existing solutions to deliver better business efficiencies.

The conference agenda included a wide range of presentations from Honeywell customers ExxonMobil, Chevron, Reliance, DuPont, Great River Energy, Syngenta, Genentech, Valero and others. These presentations – covering everything from wireless applications and cost-effective control system migrations, to alarm management and energy conservation – highlighted how real-world manufacturers have used Honeywell technology to streamline their businesses by generating and analyzing the most-meaningful data from their operations.

In addition to these presentations, attendees received a first-hand look at some of Honeywell’s newest technologies designed to change the way their enterprises work, generate the right data to inform decisions, and reduce overall risks. Highlighted technologies included:

- UniSim Competency Suite – the newest addition to the UniSim family of training technology, which now includes 3D virtual environment capabilities to provide realistic experiences.

- DynAMo Alarm and Operations Suite – software that leverages more than 20 years of alarm management experience in the process industries to help users reduce overall alarm count by as much as 80 percent, identify maintenance issues and increase visibility of critical alarms that require urgent attention.

- Honeywell Industrial Cyber Security Risk Manager – the first digital dashboard designed to proactively monitor, measure and manage cyber security risk for process control systems.

- SmartLine Level Transmitter – the newest addition to Honeywell’s line of modular, smart field instrumentation designed to integrate with control systems to provide benefits such as extended diagnostics, maintenance status displays, transmitter messaging and more.

- The EC 350 PTZ Gas Volume Corrector – the first member of a new line of high-performance electronic volume correctors (EVCs) that more accurately measure natural gas delivered to industrial customers, helping them meet government and industrial standards.

by Gary Mintchell | Jun 11, 2015 | Automation, Networking, Operations Management, Software

GE set up a conference call for a conversation with Matt Wells, general manager of automation software at GE Intelligent Platforms.

The impetus for the call was to flesh out the press release about the development of the Global Discovery Server (GDS) for OPC UA and the first implementation of it into GE’s Cimplicity HMI/SCADA software.

Wells said that GE is really embracing OPC UA as a core technology. Controllers have it embedded within, and in fact, GE actually evaluated it for inter-controller communication. That latter did not work out, but OPC UA remains core to GE’s connectivity program.

But, Wells continued, OPC UA is not always the easiest to implement. So GE worked with the OPC Foundation to define global discovery server to simplify management of systems.

The first advance concerns namespace. If GDS resides on the network, it will first register clients and servers then GDS provide list of namespace. And not only this, it can say who can talk to whom and it can also restrict who talks.

Secondly, GDS acts as certificate store. It is not a traffic manager, bu it checks for a certificate for all OPC devices and it then handles handshaking among them.

GDS is available as independent software that can be installed in an application. GE did Cimplicity first, partly to show it can be done and how useful it is.

GDS Agent, not part of spec, can act as proxy for existing UA that is not GDS enabled.

Using GDS in an OPC network enhancing usability and ease of implementation. This should increase the adoption of OPC UA.

When my contact set up this conversation, she also mentioned we could discuss something called, “automated operator decision support”. This intrigued me. Turns out this is an alternative phrase for automated or digitized workflow.

I’ve only talked with a few companies that have incorporated workflow. I talked with GE several years ago for the first time. This should be an important advance for manufacturing productivity.

Here are some notes about the workflow conversation.

Overall in HMI/SCADA

1-prevent mistakes so minimize abnormal situations

2-can’t always encode everything, so give advance notification, predictive analytics

3-cant predict everything, so enable operators to quickly ID issue and solve, give corrective action procedures

4-“phone a friend”, utilize mobile techs to call SMEs; We found highest adoption enabling support staff, contact experts, decrease downtime

Digitize SOP policy, workflow; work to encode workflows, as it executes SOP solicit feedback from operator, can coordinate acts of operators and people around them. Make every operator the best operator—baked in—originally sold as risk management mitigation tool. It is popular in pharma and water, especially areas where compliance is crucial.

First step, look at compliances and improving process – process

Take written manual–>encode–>provide checklist–>maybe write directly into system for records–>then after compliance, start looking at optimizing.

It is designed to layer over existing infrastructure (HMI/SCADA, WMS, etc.).

Have seen performance improvements of up to 30%.