by Gary Mintchell | Dec 19, 2016 | Internet of Things, News, Operations Management, Organizations

Collaboration rules the technical world. A professor who influenced me greatly was ex-CIA (ex?). He would proclaim in our international politics classes during the height of the Cold War that politicians might want to close borders, but scientists would never allow it. “Scientists want to publish their findings,” he would say, “so they will publish and leave out a step in the mathematical proof. It would get past censors, but fellow scientists around the world would figure out the missing steps.”

Our world today is rife with politicians trying to close borders. No, it’s not only Trump in America.

Given the political times, I’m encouraged by all the technology collaboration I see. Last week I posted a year end update by Tom Burke of the OPC Foundation highlighting his work in collaborating with other standards bodies. I have been working with MIMOSA (and recently elected Chief Marketing Officer). This organization has also been working with a variety of organizations.

Last week came news of another collaboration. The Industrial Internet Consortium (IIC), the global, member-supported organization that promotes the accelerated growth of the Industrial Internet of Things (IIoT), announced it has signed a memorandum of understanding (MoU) with the China Academy of Information and Communications Technology (CAICT).Under the agreement, the IIC and CAICT will work together to help ensure interoperability for the industrial Internet in China.

Last week came news of another collaboration. The Industrial Internet Consortium (IIC), the global, member-supported organization that promotes the accelerated growth of the Industrial Internet of Things (IIoT), announced it has signed a memorandum of understanding (MoU) with the China Academy of Information and Communications Technology (CAICT).Under the agreement, the IIC and CAICT will work together to help ensure interoperability for the industrial Internet in China.

The agreement is one of a number of agreements made by the IIC’s newly formed Liaison Working Group.

Joint activities between the IIC and CAICT will include:

- Identifying and sharing best practices

- Collaborating on testbeds and research and development projects

- Realizing interoperability by harmonizing architecture and other elements

- Collaborating on standardization

“We look forward to working with the China Academy of Information and Communications Technology to help further the development of the industrial Internet throughout China,” said Wael William Diab, Chair, IIC Liaison Working Group and Senior Director, Huawei. “We’re especially excited about joint activity on testbeds and research and development projects that will help advance the adoption of the industrial internet.”

“We highly value the cooperation between CAICT and the IIC,” said Mr. Xiaohui YU, CTO of CAICT. “The collaboration with the IIC will help establish tight relationships between the IIC and Chinese entities and organizations, such as the AII Alliance, and will develop, facilitate and enhance the industrial Internet.”

The Liaison Working Group is the gateway for formal relationships with standards and open-source organizations, consortia, alliances, certification and testing bodies and government entities/agencies.

China Academy of Information and Communications Technology (CAICT) is a research academy under the Ministry of Industry and Information Technology with over 2,400 employees. A specialized think-tank for the government, and an innovation and development platform for the industry, CAICT holds a service portfolio that covers the areas of information and communication technology, the integration of ICT and industries, such as 5G, Internet IoT and industrial Internet, cloud computing, big data, Intelligent manufacturing etc.

As a leading think-tank and platform in ICT field of China, it contributes to the development and innovation of the country and the ICT industry by providing support and services in terms of national strategies, plans, policies, standards, technology labs, testing and certification etc. CAICT is the national core supporting organization for industrial Internet, intelligent manufacturing and Internet relevant actions to the Chinese government, and is involved in the drafting of the “Internet+ action plan,” “Made in China 2025,”and other national strategies and guidance on IoT, Cloud computing, big data and Broadband China, etc. CAICT is currently the leading organization to promote the development of industrial Internet of China.

The Industrial Internet Consortium is a global, member-supported, organization that promotes the accelerated growth of the Industrial Internet of Things by coordinating ecosystem initiatives to securely connect, control and integrate assets and systems of assets with people, processes and data using common architectures, interoperability and open standards to deliver transformational business and societal outcomes across industries and public infrastructure. The Industrial Internet Consortium is managed by the Object Management Group (OMG).

by Gary Mintchell | Dec 16, 2016 | News, Operations Management, Organizations, Standards

Interoperability, standardization, and collaboration were the key words for OPC Foundation in 2016. Tom Burke, OPC Foundation President, recently recapped a busy 2016 for the Foundation. Adoption of OPC UA has been gaining momentum in the market. Collaboration with other groups is growing. And the technology is finally beginning to show significant use beyond industrial automation.

Burke says, “It has been a very exciting year. We have seen record growth in adoption of the OPC UA technology across multiple domains and vertical markets. The OPC Foundation policy of being truly open has expanded the reach of the OPC technology. The specifications are available to everyone, the technology is open sourced, and now we have opened up our certification labs to non-members.”

The OPC Foundation byline since the beginning has been recognized as the “The Interoperability Standard for Industrial Automation.” With the significant international membership growth and adoption of the OPC UA technology across multiple vertical markets the byline of the OPC Foundation has been ratified as “The Industrial Interoperability Standard.” This byline recognizes the case that OPC is no longer just for automation.

OPC UA specifications and technology are actively being deployed across global boundaries supplying the key infrastructure for everything related to the Internet of Everything (IIoT, Industrie 4.0, China 2025, IIC, M2M…); inclusive of:

- numerous testbeds with the OPC UA technology being standardized in the Industrial Internet Consortium (IIC)

- being recognized as the communication and information modeling standard for Industrie 4.0

- OPC UA being finalized as a Chinese National Standard

In May 2016, BSI (German Federal Office for Information Security) conducted a thorough security analysis of OPC UA and found it exceeded the security requirements for Industrie 4.0.

Collaboration with numerous organizations beyond industrial automation is the strategy and path forward to allow information integration from the embedded world to the cloud.

New members and new products are emerging as end users are looking for information solutions for IIoT, and the OPC UA technology is well-positioned to address the needs of the Internet of Everything.

Numerous organizations continue to partner with the OPC Foundation and/or develop companion specifications for their respective information models to seamlessly plug into OPC UA.

Organizations announcing releases of their companion specifications in 2016 for the OPC UA technology included:

• AutomationML

• PLCopen

• AIM

• VDMA: Injection Molding (status: release candidate)

• VDMA: Vision Cameras (status: in foundation)

• VDMA: Robotics, starting with the help of KUKA (status: in preparation)

VDMA is very active standardizing on OPC UA information models and expects to rollout a multitude of additional information models in 2017, leveraging OPC UA information integration communication as it’s strategy for seamless information integration and interoperability.

Board of Directors

Board members are elected as individuals for a two-year term. Elected to new 2-year terms were: Russ Agrusa, (ICONICS), Veronika Schmid-Lutz (SAP), Stefan Hoppe (Beckhoff) (also VP of OPC Foundation), and Matthias Damm (Ascolab). Also on the OPC Foundation Board of Directors are Thomas Burke (OPC Foundation), Thomas Hahn (Siemens) (also VP of OPC Foundation), Matt Vasey (Microsoft), and Ziad Kaakani (Honeywell) (also Treasurer of OPC Foundation), and Shinji Oda (Yokogawa).

by Gary Mintchell | Nov 28, 2016 | Automation, Networking, Technology

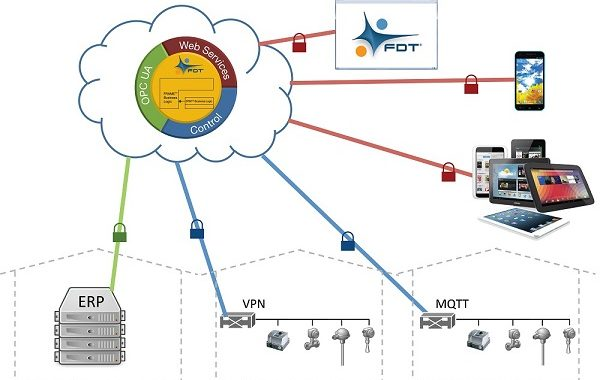

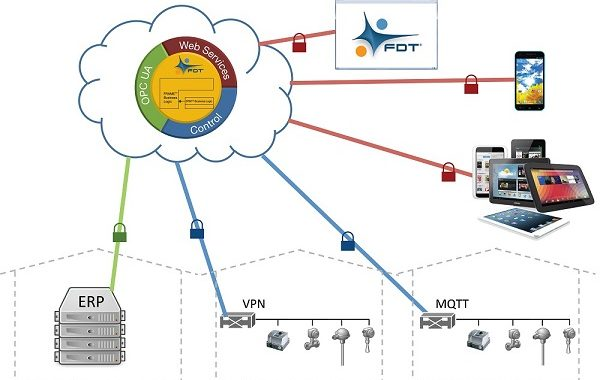

FDT IIoT Server

The FDT Group announced a revised mission statement, an IIoT Server, and agreements with other organizations—OPC Foundation, ODVA for CIP, and AutomationML–at its press conference at SPS 2016 in Nuremberg.

This highlights the role of technology organizations in this connected era—they must cooperate and collaborate or die.

“FDT is the open standard for industrial automation integration of networks and devices, harnessing IIoT and Industrie 4.0 for enterprise-wide connectivity” proclaims the organization on its updated Website.

The FDT Group launched FDT/IIoT Server (FITS) for mobility, cloud, and fog enterprise applications. The FITS solution protects industry investments in FDT through advanced business logic, well-defined interfaces and common components, and enables operating system (OS) agnostic implementation of the technology while supporting today’s integrated automation architecture.

The server features robust layered security leveraging vetted industry standards and utilizing encrypted communications with transport layer security (TLS).

FITS also takes advantage of an OPC Unified Architecture (OPC UA) annex enabling sensor-to-cloud, enterprise-wide connectivity in industrial control systems used in the process, hybrid and factory automation markets. Together, FDT and OPC UA allow sensor, network and topology information to permeate the enterprise, including mobile devices, distributed control systems (DCSs), programmable logic controllers (PLCs), enterprise resource planning (ERP) systems, the cloud, and the IIoT and Industry 4.0.

According to Glenn Schulz, managing director of the FDT Group, the FITS solution represents the key architectural role that FDT plays in an intelligent enterprise. “The FDT Group is working with the various IIoT initiatives around the world to ensure that our new architecture meets their emerging requirements,” Schulz said. “In addition, the FDT platform is being enhanced to include operating system agnostic support for standard browsers, fit-for-purpose apps, and general web services for any potential expansion. These advancements underscore our support for the hundreds of thousands of installed FDT/FRAMES and tens of millions of FDT-enabled products in the global installed base.”

It announced the release of an annex to the FDT standard for the OPC Unified Architecture (OPC UA).

The FDT/OPC UA annex is intended for implementation by automation system manufacturers in FDT Frame Applications (FDT/FRAMEs). System suppliers with an FDT/FRAME embedded in their distributed control system (DCS), asset management system, programmable logic controller (PLC) or other system have the ability to include an OPC UA server in an application accessible from any OPC UA client application.

The combined FDT/OPC standards create a single system infrastructure that standardizes the connection of industrial networks, automation systems and devices. This approach enables unification of system engineering, configuration and diagnosis in Industrie 4.0, and supports Industrie 4.0 devices, but is also able to build a bridge to Industrie 3.0 networks and devices.

Also announced was release of an updated annex to the current FDT standard for ODVA’s media-independent Common Industrial Protocol (CIP). Network adaptations of CIP include EtherNet/IP, DeviceNet, CompoNet and ControlNet. The latest version of the CIP annex to the FDT specification enables the use of proven and widely implemented ODVA networks in FDT/FRAME Applications with the latest enhancements.

And a further announcement was integration of the open AutomationML data exchange standard into open, non-proprietary FDT Technology. Together, the two standards will help advance global adoption of Industrie 4.0 solutions.

First developed in 2006, AutomationML is intended to standardize data exchange in the engineering phase of production systems.

by Gary Mintchell | Nov 2, 2016 | Interoperability, News, Organizations

This is interoperability news day at The Manufacturing Connection with this announcement of an Internet of Things sensor-to-cloud testbed. This announcement also includes SAP (see other news today), along with TE Connectivity, ifm, and the OPC Foundation.

The objective of sensor-to-the-cloud connectivity is to make sensor data available to information technology (IT) systems in near real time, enabling advanced analytics. This is of particular interest to operators of existing manufacturing facilities, as it provides them with opportunities to increase efficiencies, e.g. through reductions in energy consumption.

This type of connectivity and use case has been forming for many years. All the pieces are coming together for a better application.

The Industrial Internet Consortium (IIC) has approved an IIC testbed on sensor-to-the-cloud connectivity called the “Smart Manufacturing Connectivity for Brownfield Sensors Testbed.” The testbed, led by IIC member TE Connectivity (TE), a world leader in connectivity and sensors, is being carried out with fellow IIC member SAP, the world leader in enterprise applications in terms of software and software-related service revenue, ifm, a worldwide leader in sensors, controllers and systems for automation, and the OPC Foundation, the foundation of the industrial interoperability standard OPC Unified Architecture (OPC UA). The idea for the testbed was publicly unveiled at the Hanover Fair in April of this year.

Unlike new deployments, where the appropriate connectivity may be designed in from the beginning, smart solutions are required for these “brownfield” installations in order to enable easy integration at both the operational technology (OT) and the IT level to reduce downtime and save costs.

The Smart Manufacturing Connectivity for Brownfield Sensors Testbed will:

- Introduce a retrofit hardware solution (the “Y-Gateway”) that makes use of existing physical connectivity

- Extract sensor data from the automation system without impacting operations

- Deliver the sensor data to SAP’s IT platform through a secure OT/IT communication based on OPC UA (IEC 62541)

- Define and implement a common device model based on an available open standard to allow for the easy integration of an IO-Link sensor with IT, enabling the remote configuration of the sensor

“Testbeds are a major focus and activity of the IIC and its members,” said IIC Executive Director, Dr. Richard Soley. “Our testbeds are where new technologies, applications, products, services and processes – the innovation and opportunities of the industrial Internet – can be initiated, thought through and rigorously tested to ascertain their usefulness and viability before coming to market.”

by Gary Mintchell | Sep 21, 2016 | Automation, Internet of Things, News

Hannover Messe brought a slice of its automation trade show to this year’s International Manufacturing Technology Show (IMTS)—a venue known for huge machine tools. This was the second time, and it seems to be gaining some traction. Most exhibitors seemed to be central European, but there was a presence from a number of other North American automation companies not to mention many from Asia.

I stopped by a large number of stands. Below are five that had press releases new for the show. Opto 22 was at the show with an opportunity to see its recently released product with a RESTful API in the real plastic, so to speak. That plus a promised MQTT support maintains Opto’s usual spot as an early adopter, if not first adopter in many cases, of IT technologies in its OT products. I also stopped by to talk with Tom Burke and Stefan Hoppe at the OPC Foundation stand. Its news was reported here last week.

(My two-day silence was caused by travel to California and participating in the Inductive Automation Ignition Customer Conference. More on that later.)

Companies addressed below:

- Dell Technologies

- Beckhoff Automation

- Bedrock Automation

- Universal Robots

- Carbon (3D printing)

Dell Technologies

Appearing at IMTS in the automation hall for the first time, Dell Technologies showed its IoT Gateway and Embedded capabilities along with several partners that help it provide a complete Internet of Things solution from data collection through storage, analysis, and uploading to the cloud.

The major solution thrust for Dell thus far in its first year of existence has been predictive analytics especially for predictive maintenance applications. One of the featured partners was IBM Watson, using the famed supercomputer power for predictive analytics and EAP—its predictive maintenance solution.

Eigen showed a real-time quality application with in-process inspection. Some real-time analytics are performed in the gateway before sending data asynchronously to the cloud for further analysis.

Software AG, a partner from the beginning, provides a predictive maintenance software module that provided high speed streaming analytics in an ice cream factory. The module can also create service requests, see anomalies, order spare parts.

Beckhoff Automation

Check me out in these cool Microsoft Hololense Augmented Reality (AR) glasses. In this demo, I could see live data streaming from a robotic application. Beckhoff also showed support for MQTT and AMQP transport technologies (it also has OPC UA embedded), an Internet of Things coupler to Microsoft Azure cloud, and power over Ethernet on EtherCat P.

Check me out in these cool Microsoft Hololense Augmented Reality (AR) glasses. In this demo, I could see live data streaming from a robotic application. Beckhoff also showed support for MQTT and AMQP transport technologies (it also has OPC UA embedded), an Internet of Things coupler to Microsoft Azure cloud, and power over Ethernet on EtherCat P.

Bedrock Automation

Bedrock Automation has built an entirely new automation and control platform from the ground up. Security is designed in, even to the point of designing and manufacturing its own chips. It offers single, double, and triple redundancy, IEC 61131 programming along with a powerful function block editor that brings it into the DCS world. And it features software configurable I/O, software configurable serial module (5 to a card can be RS-232, RS-422, RS-485), and software configurable Ethernet card (think Profinet, EtherNet/IP, etc.).

Bedrock Automation has built an entirely new automation and control platform from the ground up. Security is designed in, even to the point of designing and manufacturing its own chips. It offers single, double, and triple redundancy, IEC 61131 programming along with a powerful function block editor that brings it into the DCS world. And it features software configurable I/O, software configurable serial module (5 to a card can be RS-232, RS-422, RS-485), and software configurable Ethernet card (think Profinet, EtherNet/IP, etc.).

At IMTS it announced its new intelligent, standalone power supply. The SPS.500 Secure Power Supply provides deep trust cyber security authentication and onboard intelligence for diagnostics and secure Ethernet communications. Encased in a NEMA 4X sealed aluminum enclosure, users of any PLC, SCADA RTU, PAC or DCS can retrofit to the new SPS.500 inside or outside enclosures, anywhere in a plant and in harsh environments.

At IMTS it announced its new intelligent, standalone power supply. The SPS.500 Secure Power Supply provides deep trust cyber security authentication and onboard intelligence for diagnostics and secure Ethernet communications. Encased in a NEMA 4X sealed aluminum enclosure, users of any PLC, SCADA RTU, PAC or DCS can retrofit to the new SPS.500 inside or outside enclosures, anywhere in a plant and in harsh environments.

Additional features include:

- Ethernet and OPC/UA communications, enabling local or remote monitoring of power supply health for greater system reliability and plant safety

- A powerful cyber secure microprocessor and onboard memory for diagnostics and software-defined functionality

- A built-in redundancy module, which simplifies installation and increases reliability by eliminating the need for an external redundancy module

- Two built-in, software-configurable Form C contact relays, which provide operating and diagnostic status

Universal Robots

One of the big things in automation this year is collaborative robots, or cobos. A leader in this area is a new entrant—Universal Robots. This Danish company showed its products at IMTS. It also announced two unique new initiatives.

- Universal Robots+: an ecosystem of products and applications, users choosing accessories, end-effectors, and software solutions from Universal Robots+, both distributors and end-users, get high security and predictability that applications will run well from the start.

- +YOU: a unique, free-of-charge developer program, offering a powerful marketing and support platform for the flourishing eco-system of UR-robot application developers.

Alongside the launch of Universal Robots+, a new update for the robot arm’s operating software has been published. The new release (Software Version 3.3) includes updates such as the Profinet IO device functionality. The new compatibility with Profinet protocols opens up numerous additional areas of deployment and activities for robots. “A key feature of the update supporting the Universal Robots+ platform is the ability for providers to now offer solutions that interface seamlessly with the UR software,” says Østergaard.

Carbon 3D

Carbon 3D announced new funding from strategic investors toward the goal of bringing additive technology to more customers transitioning from prototyping-only use cases, to applications requiring final production quality parts with great surface finish, broad and expanding material options and the plans to transition to mainstream manufacturing. A Silicon Valley 3D printing company working at the intersection of hardware, software and molecular science, Carbon also plans to offer its proprietary CLIP technology internationally and is accelerating production to meet worldwide demand for its M1 printer.

The expansion is supported by $81 million from new investors GE Ventures, BMW, Nikon and JSR, as well as existing investors, bringing Carbon’s funding total to $222 million. More details of additional strategic investors involved in this round of financing will be announced in 2017 along with details of their manufacturing projects that utilize Carbon’s technology.

Last week came news of another collaboration. The Industrial Internet Consortium (IIC), the global, member-supported organization that promotes the accelerated growth of the Industrial Internet of Things (IIoT), announced it has signed a memorandum of understanding (MoU) with the China Academy of Information and Communications Technology (CAICT).Under the agreement, the IIC and CAICT will work together to help ensure interoperability for the industrial Internet in China.

Last week came news of another collaboration. The Industrial Internet Consortium (IIC), the global, member-supported organization that promotes the accelerated growth of the Industrial Internet of Things (IIoT), announced it has signed a memorandum of understanding (MoU) with the China Academy of Information and Communications Technology (CAICT).Under the agreement, the IIC and CAICT will work together to help ensure interoperability for the industrial Internet in China.

Check me out in these cool Microsoft Hololense Augmented Reality (AR) glasses. In this demo, I could see live data streaming from a robotic application. Beckhoff also showed support for MQTT and AMQP transport technologies (it also has OPC UA embedded), an Internet of Things coupler to Microsoft Azure cloud, and power over Ethernet on EtherCat P.

Check me out in these cool Microsoft Hololense Augmented Reality (AR) glasses. In this demo, I could see live data streaming from a robotic application. Beckhoff also showed support for MQTT and AMQP transport technologies (it also has OPC UA embedded), an Internet of Things coupler to Microsoft Azure cloud, and power over Ethernet on EtherCat P. Bedrock Automation

Bedrock Automation At IMTS it announced its new intelligent, standalone power supply. The SPS.500 Secure Power Supply provides deep trust cyber security authentication and onboard intelligence for diagnostics and secure Ethernet communications. Encased in a NEMA 4X sealed aluminum enclosure, users of any PLC, SCADA RTU, PAC or DCS can retrofit to the new SPS.500 inside or outside enclosures, anywhere in a plant and in harsh environments.

At IMTS it announced its new intelligent, standalone power supply. The SPS.500 Secure Power Supply provides deep trust cyber security authentication and onboard intelligence for diagnostics and secure Ethernet communications. Encased in a NEMA 4X sealed aluminum enclosure, users of any PLC, SCADA RTU, PAC or DCS can retrofit to the new SPS.500 inside or outside enclosures, anywhere in a plant and in harsh environments.