by Gary Mintchell | Jul 6, 2016 | Podcast, Productivity

My 151st podcast on personal productity dives into “Deep Work: Rules for Focused Success in a Distracted World” by Cal Newport. also viewable on YouTube.

Newport differentiates the work that will lead you to success (deep work–thinking) from that work that just fills time (shallow work–answering email, reading Facebook, etc.).

He provides tips on organizing your day to emphasize setting aside blocks of time for deep work.

This is one of the personal productivity books from my recent binge reading. Previously I discussed The Power of the Other by Dr. Henry Cloud. Podcast or YouTube.

by Gary Mintchell | Jul 1, 2016 | Manufacturing IT, Operations Management, Software

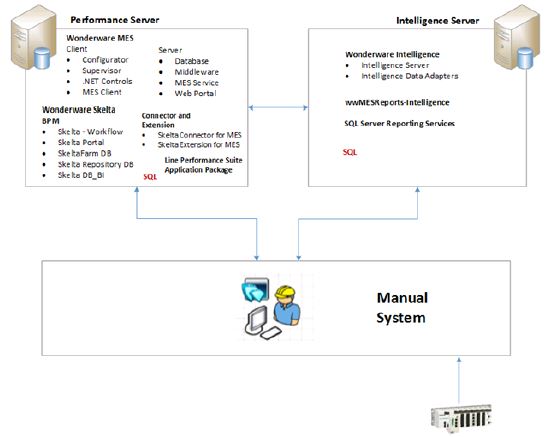

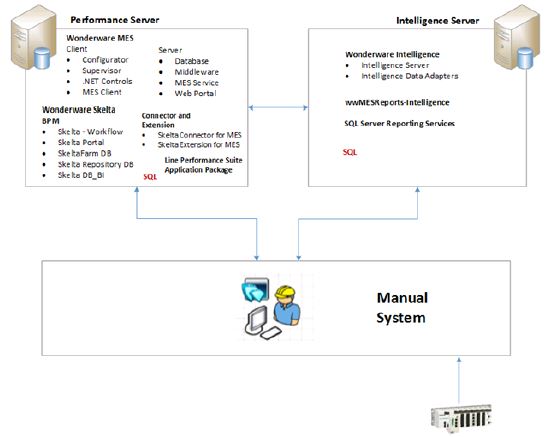

Schneider Electric software aims to boost process line improvement tool for food & beverage and consumer packaged goods (CPG) manufacturers. It announced yesterday availability of Line Performance Suite for Food & Beverage and Consumer Packaged Goods manufacturers.

Schneider Electric software aims to boost process line improvement tool for food & beverage and consumer packaged goods (CPG) manufacturers. It announced yesterday availability of Line Performance Suite for Food & Beverage and Consumer Packaged Goods manufacturers.

This single purpose app is built atop Wonderware MES software. These apps are a growing trend in the industry. Another trend is moving the investment in software from the capital expenditure budget (CapEx) to operations budget (OpEx). Schneider Electric has priced this offering as a subscription service to meet those customer needs.

Turnkey productivity improvement software

Addressing process improvement, Line Performance Suite offers a turnkey line enhancement and productivity improvement solution that can be used across operations.

“Users of the Line Performance Suite can unlock hidden capacity in production lines to help drive improved profitability, higher quality and enhanced Overall Equipment Efficiency (OEE),” said Doug Warren, Vice President, Industry Solutions at Schneider Electric Software. “Integrated reporting and analysis ensures packaging line output is optimized, providing greater understanding to locate process weaknesses and maintain maximum throughput. What results is better intelligence on line performance for more informed decision making.”

“Users of the Line Performance Suite can unlock hidden capacity in production lines to help drive improved profitability, higher quality and enhanced Overall Equipment Efficiency (OEE),” said Doug Warren, Vice President, Industry Solutions at Schneider Electric Software. “Integrated reporting and analysis ensures packaging line output is optimized, providing greater understanding to locate process weaknesses and maintain maximum throughput. What results is better intelligence on line performance for more informed decision making.”

Benefits

Identified benefits of Line Performance Suite include:

- Line Performance – remove bottlenecks, reduce downtime and increase availability to gain process metrics for both automated and manual production lines

- Product Quality – lower scrap rates and improve first pass yields to achieve better quality and right first time metrics

- Visibility to Process Metrics – gain visibility to Key Performance Indicators (KPIs) to achieve real-time access to critical operating parameters

Included in the offering is Schneider Electric’s Customer FIRST Software Maintenance and Support Program. This program enables access to the latest software upgrades, expert technical assistance and self-help tools to improve operational effectiveness.

Economic development

In one of those interesting coincidences, last week I had a breakfast meeting with two people from the Singapore Economic Development agency. They touted an investment by Schneider Electric in a large software development division. That division—it’s the Industry Solutions Business.

by Gary Mintchell | Jun 13, 2016 | Automation, Manufacturing IT, News

I’m in Orlando at the annual summer gathering of Rockwell Automation distributor and customer tech specialists. This is where they go for training in current products and introduction to new ones. And to get a little fired up about the company.

I’m in Orlando at the annual summer gathering of Rockwell Automation distributor and customer tech specialists. This is where they go for training in current products and introduction to new ones. And to get a little fired up about the company.

Rockwell Automation currently bills itself as the largest company solely devoted to industrial automation. True to the billing, current Senior Vice President and incoming President and CEO Blake Moret told the 2,100 gathered attendees, “All we do is industrial productivity.”

Moret’s other significant quote revealed a huge cultural shift that Rockwell Automation has undergone under current CEO Keith Nosbusch—We describe the value of the Connected Enterprise to customers in language specific to each. That means that the company has learned to speak other terminology than discrete manufacturing and machine control. Historically it lost credibility by going into batch and continuous processing companies and describing offerings using the terminology of discrete. Now they can talk pharma, or oil & gas, or whatever.

Sujeet Chand, SVP and CTO, gave the technology keynote. Chand talked about connecting silos of information—something we’ve discussed for years but seems closer to reality than ever before.

Sujeet Chand, SVP and CTO, gave the technology keynote. Chand talked about connecting silos of information—something we’ve discussed for years but seems closer to reality than ever before.

He did not spend much time on trends (collaborative robots, wearables, mobility), but pointed out that many countries are starting advanced manufacturing initiatives. The danger of so many independent initiatives is that this could lead to multiple standards, which would be a mess. He urged us to work for common standards.

Chand reinforced the value propositions for the Connected Enterprise, Rockwell’s focus for several years:

- Faster time to market

- Lower total cost of ownership

- Improve asset utilization

- Enterprise Risk Management

Why do we care about IT/OT convergence—something else we’ve discussed for years. This convergence is a key factor for Connected Enterprise, however, another benefit is it leads to improved workflow.

Since I follow all things IoT, I found Chand’s “IoT Stack” interesting. It’s fairly typical, but he differentiates data abstraction from data accumulation in the mix and does not specifically use the term analytics.

- Collaboration & processes

- Data Abstraction

- Data Accumulation

- Edge Computing

- Connectivity

- Physical devices

Frank Kulaszewicz, SVP Control and Architecture, delved into High Performance Architecture. Fundamental to high performance architecture are devices that are self-aware. A photoelectric, for example, can send a notification that it needs to be aligned or cleaned. Or a motion control servo drive can be self-tuning. Stepping up from self-aware devices are systems that are “system-aware.”

Frank Kulaszewicz, SVP Control and Architecture, delved into High Performance Architecture. Fundamental to high performance architecture are devices that are self-aware. A photoelectric, for example, can send a notification that it needs to be aligned or cleaned. Or a motion control servo drive can be self-tuning. Stepping up from self-aware devices are systems that are “system-aware.”

Dean Kamen, prolific inventor and entrepreneur, was the “star” keynote.

He began with a bit of discouragement, “As society get older, adoption of technology slows.” But then he showed development of some of his notable inventions that have made the world better for many. There is the insulin pump, portable dialysis machine, prosthetic arms with such great control that people can pick up a grape and eat it without crushing the grape designed for people who have lost their entire arms. Lack of clean drinking water is the #1 killer of children globally. He invented “slingshot” a machine that distills and condenses water such that just about anything wet even from manure piles can be converted to safe drinking water. He partnered with Coca-Cola to get them distributed to areas of great need.

His greatest achievement is the invention of the FIRST Robotics competition. Begun in 1989 to inspire high school kids to develop a passion for science and engineering, the movement has spread to 86 countries.

Technology development, especially through the middle ages and even by technologists like Da Vinci, was for development of tools of war for their princely benefactors. Kamen’s vision is to challenge kids (and the rest of us) to develop technology to solve human problems. No Terminators, here.

by Gary Mintchell | Mar 11, 2016 | Automation, Workforce

I just read yet another survey where people think we won’t have any manufacturing jobs in 50 years (or pick your number). Robots and automation will do everything. We will all just sit around, be poor and miserable–except for the few owners.

That begs one essential question. If no one has money to buy things, then what will manufacturing produce? Think about it. Who would be able to buy gasoline, dish washing detergent, Oreo cookies? What we have is a virtuous circle: people have jobs -> people have money -> they buy things -> companies develop new things for them to buy -> people work at those companies to develop and manufacture things -> people have jobs-> etc.

We’ve invested in automation and robots for years. Productivity has not necessarily gone up as a direct result. Read between the lines of yesterday’s post from MAPI.

I’m not arguing from some abstract economic theory. Nor am I sanguine about automation. Nor from a Luddite point of view.

Automation and robots have replaced workers. But if you were in manufacturing plants prior to 1970 and then returned in 2000, you’d have been shocked. Jobs that literally destroyed the bodies of the workers over time had been redesigned such that repetitive lifting of 50 lb. to 75 lb. objects all day, for example, were no longer done manually. Manufacturing jobs that put people in harms’ way were now done with robots. People were moved to safety.

Plants are healthier, cleaner, safer than ever thought possible. Manufacturing jobs that remain are better paying, more satisfying, and safer than before.

Then let’s look at the human spirit. We were made to create.

I have visited the old city dump in Tijuana. A veritable city exists in the dump. People had no where to go. They moved to the dump. They scrounged around and found things with which to build simple houses. The last time I was there I was amazed. People (probably women) had done many things to make those shacks in the dump livable. I saw curtains of a type on the windows. People trying to plant flowers. I wondered how many people were electrocuted climbing up utility poles to tap into the electrical grid so that their house could have some electrical appliances.

It’s a dump. It’s a terrible place to live. The human spirit of the people was amazing. They made the best of what they had.

I didn’t grow up in an upper middle class enclave. I grew up in a small town where all social classes (OK, we didn’t have many of them) mingled. I hung out with “rednecks” as an adolescent. Guys that drank cheap beer and worked on cars. They could do mechanical things that few today can do. Sort of the spirit of the old blacksmiths who build all manner of things for people.

The spirit to build and create is human. We can organize a macro economy any way we want. We’ll still have people figuring out things to do to help people and figuring out ways to do it.

by Gary Mintchell | Mar 10, 2016 | News

A new study by the MAPI Foundation (Manufacturers Alliance for Productivity and Innovation) analyzes productivity growth in manufacturing over the past 25 years and provides “compelling statistical evidence on the importance that capital investment and educated labor have on productivity performance.”

I guess what this study highlights are factors that should have already been well known. Plus the study was financed by Rockwell Automation—a technology developer and supplier—which is an interesting caveat. MAPI is an organization composed of manufacturers and suppliers. I’d really see one of the follow-ups discuss what manner of investment makes the most difference.

The research explores the drivers of productivity performance on subsectors. In particular, the study looks for ways that manufacturers who have already invested in capital equipment can increase productivity and innovation.

Productivity Series

The report is the first in a series on productivity that the MAPI Foundation is producing this year. Cliff Waldman, director of economic studies at the MAPI Foundation, produced the study using well-accepted theory and regression analysis of several decades’ worth of data. The study reveals evidence that innovation and capital investment play a significant role in driving multifactor productivity growth (i.e., output per unit of a combined set of inputs including labor, materials, and capital) in a wide range of manufacturing subsectors. Capital investment is the mechanism by which productivity-enhancing innovation spreads through companies, supply chains, and the broad economy.

“In the manufacturing sector, strong productivity performance is needed to meet the globally driven challenges of cost pressures and competitiveness,” Waldman observes. “For both manufacturing and the economy as a whole, the recent slowdown in productivity causes concern, because it contributes to both slow output and wage growth.”

“Isolating the critical investments required to improve productivity performance is an important foundational element in the MAPI Foundation’s first study,” added Joe Kann, vice president of global business development at Rockwell Automation. “We look forward to the conclusions regarding industry-specific productivity drivers that will be identified in the remaining studies.”

Educated Labor

Waldman’s research finds that another key link to productivity performance is the labor force participation rate of the population holding a B.A. degree or higher, in effect the economy’s supply of educated labor.

The manufacturing sector, a traditional driver of overall productivity, has seen its pace of productivity growth slow over the last 15 years. As Waldman notes, part of this is due to slowing productivity growth in the computer and electronic products industry, which has played an outsized role in driving manufacturing productivity growth in recent decades.

According to the study, industry subsectors that have experienced relative improvements in productivity performance since 1993 include machinery, transportation equipment, and printing. But their growth has not been enough on an absolute basis to replace the decline in computer subsector productivity. Industries with a noticeable drop since 1993 in their relative pace of productivity growth include primary metals and petroleum and coal products.

Sector Correlations

The paper reveals strong cross-subsector correlations for both labor productivity growth and multifactor productivity growth. The apparent interconnectedness of productivity performance across industries, says Waldman, is likely the result of supply chain linkages, innovation spillovers, cluster impacts, and trade channels. Such evidence suggests that, where investments in any one industry lead to faster productivity growth, such expenditures can have impacts that extend to other subsectors as well.

Waldman concludes that a beneficial policy response must consist of a coordinated program that stimulates manufacturing equipment investment as well as innovation investment and increases the supply of educated labor in the broad economy. The MAPI Foundation’s next study on productivity builds on this work and will reveal the findings of a national survey on technology and automation investment that was conducted to determine the drivers and pace of change in various manufacturing industries.

Summary of major findings include:

- While the computer and electronic products subsector has historically played an outsized role in the relatively strong productivity performance of the broader manufacturing sector, productivity growth in the information technology space has slowed dramatically in recent years. This has happened as the high-impact innovation that led to persistent and rapid increases in computer processing speeds, which are necessarily accounted for in the calculation of computer-sector productivity growth, naturally reached physical limits. This is reducing manufacturing’s rate of productivity growth.

- Though the machinery and transportation equipment subsectors have shown notable improvement in their productivity performance over the past 15 years, it has not been enough on an absolute basis to make up for diminishing computer subsector productivity; overall manufacturing productivity growth is therefore languishing at historically weak rates.

- More than two decades’ worth of government statistics and regression analysis demonstrate that innovation and capital investment are directly correlated to and thus play a significant role in driving multifactor productivity growth in a wide range of manufacturing subsectors.

- An increase in the labor force participation rate of those with a B.A. degree and higher correlates to faster labor productivity growth in multiple industries. The supply of educated labor plays a definitive role in driving labor productivity growth across diverse subsectors.

- Statistical analysis shows a strong interconnectedness of productivity performance across subsectors. This evidence supports the hypothesis that because of supply chain linkages, innovation spillovers, cluster impacts, and trade channels, productivity determination is not independent across manufacturing industries. When changes are made in one industry that promote productivity, these can affect productivity performance in other industries as well.

Schneider Electric software aims to boost process line improvement tool for food & beverage and consumer packaged goods (CPG) manufacturers. It announced yesterday availability of Line Performance Suite for Food & Beverage and Consumer Packaged Goods manufacturers.

Schneider Electric software aims to boost process line improvement tool for food & beverage and consumer packaged goods (CPG) manufacturers. It announced yesterday availability of Line Performance Suite for Food & Beverage and Consumer Packaged Goods manufacturers. “Users of the Line Performance Suite can unlock hidden capacity in production lines to help drive improved profitability, higher quality and enhanced Overall Equipment Efficiency (OEE),” said Doug Warren, Vice President, Industry Solutions at Schneider Electric Software. “Integrated reporting and analysis ensures packaging line output is optimized, providing greater understanding to locate process weaknesses and maintain maximum throughput. What results is better intelligence on line performance for more informed decision making.”

“Users of the Line Performance Suite can unlock hidden capacity in production lines to help drive improved profitability, higher quality and enhanced Overall Equipment Efficiency (OEE),” said Doug Warren, Vice President, Industry Solutions at Schneider Electric Software. “Integrated reporting and analysis ensures packaging line output is optimized, providing greater understanding to locate process weaknesses and maintain maximum throughput. What results is better intelligence on line performance for more informed decision making.”

I’m in Orlando at the annual summer gathering of Rockwell Automation distributor and customer tech specialists. This is where they go for training in current products and introduction to new ones. And to get a little fired up about the company.

I’m in Orlando at the annual summer gathering of Rockwell Automation distributor and customer tech specialists. This is where they go for training in current products and introduction to new ones. And to get a little fired up about the company. Sujeet Chand, SVP and CTO, gave the technology keynote. Chand talked about connecting silos of information—something we’ve discussed for years but seems closer to reality than ever before.

Sujeet Chand, SVP and CTO, gave the technology keynote. Chand talked about connecting silos of information—something we’ve discussed for years but seems closer to reality than ever before. Frank Kulaszewicz, SVP Control and Architecture, delved into High Performance Architecture. Fundamental to high performance architecture are devices that are self-aware. A photoelectric, for example, can send a notification that it needs to be aligned or cleaned. Or a motion control servo drive can be self-tuning. Stepping up from self-aware devices are systems that are “system-aware.”

Frank Kulaszewicz, SVP Control and Architecture, delved into High Performance Architecture. Fundamental to high performance architecture are devices that are self-aware. A photoelectric, for example, can send a notification that it needs to be aligned or cleaned. Or a motion control servo drive can be self-tuning. Stepping up from self-aware devices are systems that are “system-aware.”